Flexible PCB & Rigid-Flex PCB Manufacturing Service

5 Star Rating on

5 Star Rating on

Specialized In Multilayer And Rigid-Flex Technology.

Flexible Circuit Manufacturing & Assembly as well as multilayer flex and rigid-flex circuits and also provide SMT component assembly on these products.

- High Temperature &High Density Applications

- Quality assured with more Reliability & Durability

- Flexible PCB Lead time:Usually 5-6 days(depends on your special design)

Below is a detailed overview of our Flex & Rigid-Flex PCB capabilities, showcasing the key specifications and performance metrics that highlight our commitment to precision and quality in every project.

Our Flexible PCB Manufacturing Capability

| Project Item | Normal Capability |

|---|---|

| FPC Base Material (Adhesive) | ShengyiSF302:PI=0.5 mil,1 mil,2 mil;Cu=0.5 oz,1 oz ShengyiSF305:PI=0.5 mil,1 mil,2 mil;Cu=0.33 oz,0.5 oz,1 oz |

| FPC Base Material (Adhesiveless) | SongxiaRF-775/777:PI=1 mil,2 mil,3 mil;Cu=0.5 oz, 1 oz (Ultimate:PI=1 mil,2 mil,3 mil;Cu=2 oz) Xinyang:PI=1 mil, 2 mil;Cu=0.33 oz, 0.5 oz, 1 oz Taihong PI=1 mil, 2 mil;Cu=0.33 oz, 0.5 oz, 1 oz Dubang AP:PI=1 mil, 2 mil, 3 mil, 4 mil;Cu=0.5 oz, 1 oz (Ultimate:PI=1 mil,2 mil,3 mil,4 mil;Cu=2 oz) |

| Layer | 1-6 Layers (Ultimate:7-10 Layers) |

| Thickness of Finished Product (Flex part,no stiffener) | 0.05-0.5 mm (Ultimate:0.5-0.8 mm) |

| Size of Finished Products(Min) | 5 mm*10 mm (Bridgeless);10 mm*10 mm (Bridge) Ultimate:4 mm*8 mm (Bridgeless);8 mm*8 mm (Bridge) |

| Size of Finished Products (Max) | 9 inch*14 inch Ultimate:9 inch*23 inch (PI≥1 mil) |

| Impedance Tolerance | Single-Ended:±5Ω(≤50Ω),±10%(>50Ω) Ultimate:Single-Ended:±3Ω(≤50Ω),±8%(>50Ω) |

| Impedance Tolerance | Differencial:±5Ω(≤50Ω),±10%(>50Ω) Ultimate:Differencial:±4Ω(≤50Ω),±8%(>50Ω) |

| Tolerance of Finger Width | ±0.1 mm (Ultimate:±0.05 mm) |

| Min Distance to the Edge of Finger | 8 mil (Ultimate:6 mil) |

| Min Distance between Pads | 4 mil (Ultimate:3 mil) |

| Minimum Laser Hole | 0.1mm |

| Minimum PTH | 0.3mm |

| Min NPTH Tolerance | ±2 mil (Ultimate +0,-2 mil or +2 mil,-0) |

| Solder Bridge Min Width(bottom copper<2OZ) | 4 mil(Green),8 mil |

| Solder Bridge Min Width(bottom copper 2-4OZ) | 6 mil,8 mil |

| Overlay Colour | White、Yellow (printed character:White) |

| Type of Surface Treatment | OSP HASL, Lead free HASL, Immersion gold, Hard gold, Immersion silver, OSP |

| Selective Surface Treatment | ENIG+OSP,ENIG+G/F |

Our Rigid-Flex PCB Manufacturing Capability

| Project Item | Normal Capability |

|---|---|

| FPC Base Material (Adhesive) | Shengyi SF302, Shengyi SF305 |

| FPC Base Material(Adhesiveless) | Songxia RF-775/777, Xinyang, Dubang AP |

| Low flow prepreg | Taiguang EM-37B; Ventec: VT-47N |

| Common rigid board material | Refer to standard rigid board materials |

| Special rigid board material | Arlon: 85N; Rogers: RO4000 series; Nelco: N4000-13 series; Ventec: VT-901 |

| Layer | 2-30 Layers; review required: ≥20 layers |

| Thickness of Finished Product | 0.3-4.0mm; review required: >3.0 mm |

| Size of Finished Products(Min) | 10mm*15mm (no internal positioning designs, panel size <50mm*50mm) |

| Size of Finished Products (Max) | 18inch*22inch; Ultimate:18inch*29inch |

What is the Cost of Flexible PCBs?

On average, flexible PCBs can range from $0.50 to $5.00 per square inch for standard designs and materials. However, this cost is not fixed and can vary based on several factors. The factors that influence the price include necessary assembly labor, prevailing labor rates, and the time required for assembly. Additionally, overhead manufacturing expenses and the design complexity of the board play significant roles in determining the final cost. To get a more accurate cost estimate, please use our free pcb quote form.

Factors Affecting Flex & Rigid-Flex PCB Cost

Many criteria determine the cost of FPCBs, and we have highlighted the major ones below;

- Physical Size; A large FPCB means a higher price, and its calculation is a cost per square inch (FPCB measurement).

- Circuit Construction; It depends on the materials used and the number of layers and pads. An additional layer is costly, and quality materials plus more pads also increase manufacturing costs.

- Volume; a greater volume results in a high cost.

- Layers; Added circuit layers augment assembly costs; thus, if you’re comfortable with a single-sided FPCB, stick with it.

- Finishing; Almost always, a good finishing guarantees a long shelf life for FPCB. Therefore, it’ll be pricey.

- Number and size of holes; Since drilling small holes is tough, FPCB prices are higher. Not only that but more holes equal more cost.

- Flex Board types depend on layers, ultimately determining the price.

- Custom or unique specification; If you require added features on your FPCB, for instance, solder mask clearance, side plating, or contoured edges, you’ll pay extra.

How to Reduce PCB Production Cost?

Every manufacturer should have a flex PCB cost estimator list that helps lower FPCB costs.

- Keep flexible layers to a minimum; Usually, rigid laminates are more cost-effective than flexible laminates. You’ll lower the cost by reducing the number of layers in the flexible circuitry.

- Keep overall layers to a minimum; If you reduce the number of layers, the number of plies of flow prepreg you’ll need will also be low. Thus, the cost decreases.

- Limit controlled impedance requirements; incorporating all achievable impedance values might be tempting. However, if you consider the design’s cost-effectiveness, test and model the values your flex circuit board needs.

- The copper thickness can be flexible and about 1/3 oz.

- Finally, buy FPCBs in large quantities to lower the overall cost.

Flexible & Rigid-Flex PCB Lead Times Overview

| Service Type | Lead Time |

|---|---|

| Standard PCB Manufacturing | 5-6 days |

| Expedited Manufacturing | 24-48 hours |

| PCB Prototyping (Quick Turn) | 1-2 layers: 5 days |

| 4 layers: 6 days | |

| 6 layers: 7 days | |

| 8 layers: 8 days | |

| 10 layers: 9 days | |

| PCB Assembly | 4-25 days, depending on complexity and order volume |

Types of Flex & Rigid-Flex PCBs

Flex and rigid-flex PCBs come in a diverse range of configurations, from simple single-layer flex to complex multilayer rigid-flex designs, each offering unique advantages for different applications.

| PCB Type | Description |

|---|---|

| Single-layer Flex | One conductive layer on a flexible substrate. Simple, cost-effective for basic applications. |

| Double-layer Flex | Two conductive layers with a flexible substrate in between. Allows for more complex circuits while maintaining flexibility. |

| Multilayer Flex | Three or more conductive layers. Offers high circuit density in a flexible format. |

| Rigid-Flex (Basic) | Combination of rigid and flexible board sections. Typically 2-4 layers total. |

| Rigid-Flex (Advanced) | Complex designs with multiple rigid and flex layers. Can have 6+ layers. |

| HDI Flex | High-Density Interconnect flex circuits. Uses microvias for increased circuit density. |

| HDI Rigid-Flex | Combines HDI technology with rigid-flex structure for maximum density and functionality. |

| Sculptured Flex | Varying copper thickness in different areas of the circuit. Allows for both flexibility and robust connections. |

| Dynamic Flex | Designed for repeated flexing or rolling. Used in applications with constant movement. |

| Flex with Stiffeners | Flexible circuits with rigid areas added for component mounting or structural support. |

| Bookbinder Rigid-Flex | Rigid boards connected by flexible sections, allowing the assembly to fold like a book. |

| Rigid-Flex with Cavities | Incorporates hollowed-out areas in rigid sections for 3D component placement. |

| Flex on Board | Flexible circuit attached to a rigid board, often used for interconnections or as a connector. |

| Flex with Embedded Components | Incorporates components within the layers of the flexible circuit. |

| Stretchable Flex | Uses specialized materials to create circuits that can stretch as well as bend. |

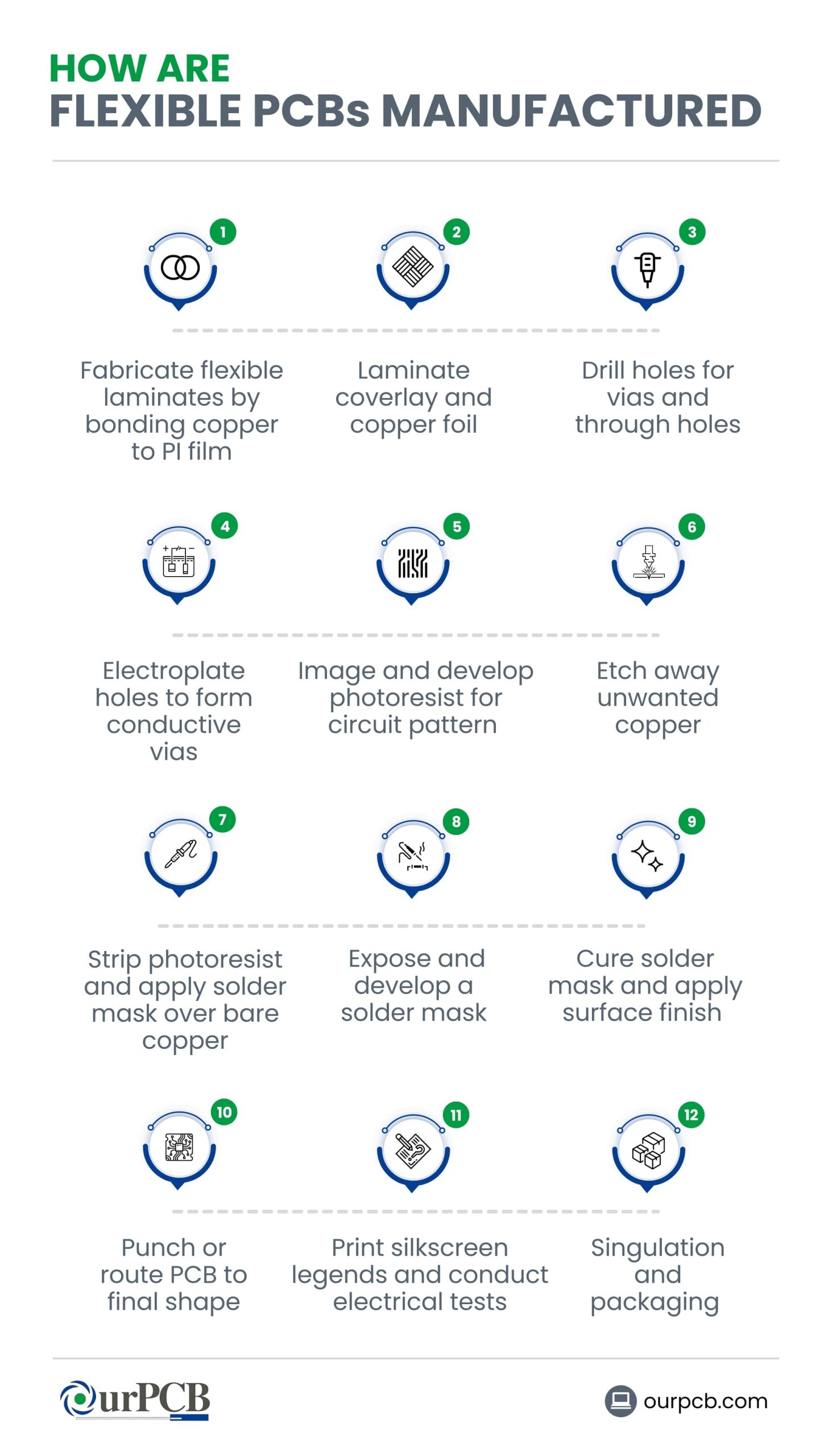

How are Flex & Rigid-Flex PCBs Manufactured?

Flexible PCBs’ manufacturing involves several steps to form thin and flexible boards which are easy to bend, fold and shape. Here are the steps that complete the PCB manufacturing process.

Step 1: Fabricate flexible laminates by bonding copper to PI film

Step 2: Laminate coverlay and copper foil

Step 3: Drill holes for vias and through holes

Step 4: Electroplate holes to form conductive vias

Step 5: Image and develop photoresist for circuit pattern

Step 6: Etch away unwanted copper

Step 7: Strip photoresist and apply solder mask over bare copper

Step 8: Expose and develop a solder mask

Step 9: Cure solder mask and apply surface finish

Step 10: Punch or route PCB to final shape

Step 11: Print silkscreen legends and conduct electrical tests

Step 12: Singulation and packaging

Also read:

Why Choose OurPCB?

OurPCB is a renowned ISO:9001 certified manufacturer of flex and rigid-flex PCBs in China. We have a huge clientele (more than 2000) spread across the world, We are there for you in every step of PCB manufacturing and assembly. Having expertise in wiring harness and cable assemblies, our team always ensures to fulfill our customers’ needs at affordable prices.

Thanks to the flexibility, reliability, space efficiency, and low weight of flex PCBs, the demand for flex PCBs is growing in all industries. If you need any help related to your PCB requirements, contact us. Our team is there to guide you through the process.

Back to Top: Flex & Rigid Flex PCB Manufacturer

Customer Reviews - Flexible PCB

- Author: Percival Bramley

Item: Flexible PCB

Review: The flexible PCBs from OurPCB are of excellent quality. They are durable and can be bent and folded into various shapes without any issues. Highly recommended for compact electronic designs. - Author: Eleri Tamsin

Item: Flexible PCB

Review: Great product with fast delivery. The PCBs were exactly as described and worked perfectly in our project. Customer support was also very responsive. - Author: Thorne Ashby

Item: Flexible PCB

Review: These flexible PCBs are fantastic for tight spaces. The quality is top-notch, and they are very reliable. Will definitely purchase again. - Author: Liora Pemberton

Item: Flexible PCB

Review: Excellent service and product. The flexible PCBs met all our specifications and were delivered on time. Highly satisfied with OurPCB's service.

Services Related to Flexible PCB Assembly

- PCB Assembly Services: Comprehensive solutions for assembling printed circuit boards.

- Quick Turn PCB Assembly: Fast and efficient PCB assembly to meet tight deadlines.

- High Volume PCB Assembly: Scalable solutions for large-scale PCB production.

- Flexible PCB Manufacturing: Specialized in manufacturing flexible PCBs for diverse applications.

- Low Volume PCB Assembly: Cost-effective solutions for small batch PCB assembly.

- Turnkey PCB Assembly: End-to-end services covering all aspects of PCB production.

- PCB Design Services: Expert design services to bring your PCB concepts to life.

- Rigid-Flex PCB Manufacturing: Manufacturing robust and versatile rigid-flex PCBs.

- PCB Prototype: Rapid prototyping services to test and refine your PCB designs.

- Rogers PCB: High-frequency PCBs ideal for RF and microwave applications.

- Aluminum PCB: PCBs with excellent heat dissipation properties, perfect for high-power devices.

- Metal Core PCB: Thermal PCBs with metal bases for effective heat management.

- High Tg PCB: High glass transition temperature PCBs for improved thermal performance.

- High Frequency PCB: Designed for high-speed and high-frequency applications, ensuring superior signal integrity.

- Heavy Copper PCB: Built with thicker copper layers for high current and enhanced thermal management.

- HDI PCB: High Density Interconnect PCBs offering advanced circuitry in a compact design for complex applications.

- Custom Cable Assembly: We offer a wide range of customized cable services, hybrid cables, and wire harnesses.

flexible pcb board CASE STUDY

- 1Order and Procurement

- 2PCB Manufacturing and Preparation

- 3Assembly and Soldering

- 4Inspection and Quality Control

- 5Finalization and Shipping

- Bare PCB in 8 working hours

- PCBA with components in 2 working days

- Bare PCB manufacturing

- Components sourcing

- PCB assembling

- Wire harness manufacturing

- Casing /Housing manufacturing

- Programming/Testing

Adrian Leitch

Andrew Durrant

Andrew Peeler

Andrew Wood

Ben Thomas

Darren Larosa

Debra Beukes

Eastern Europe Archives

frankyc

Fred Van

Greg MacDonald

John Powell

Jonathan Pippard

Jordan Thurgood

Justin Regan

Mark A

Mark Pagura

Maryanne Hassell

Matthew O'Neill

mitch clark

Oli

Peter Lambert

Sasha Marks

Slavko Mali

SPI MX

Steve Visser

Steven Munari

Steven Vatev

Tane Pendragon

Tasmiah Khan

Trevor Gardner

Free Consultation