- PCB Manufacturer

- PCB Assembly Service

- PCB Manufacturer Assembly

PCB Assembly Services

- Prototypes and full PC board assembly

- Over 3,000 happy customers

- RoHS and lead-free assembly services

- Small quantities available

- Single-sided, double-sided, or mixed

Looking for PCB Assembly Services?

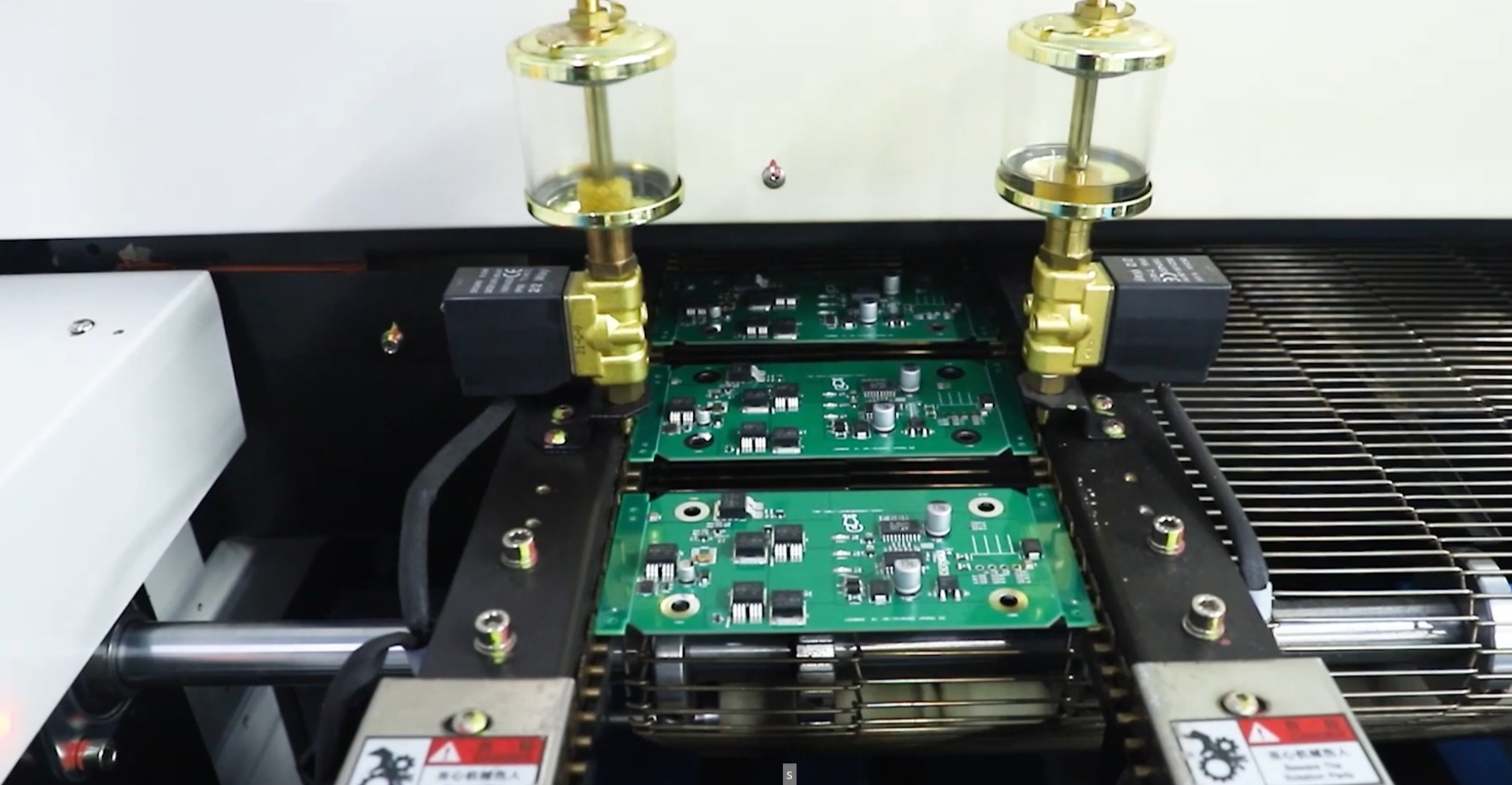

OurPCB provides professional PCB assembly services with high precision and reliability. As a leading printed circuit board manufacturer, we offer end-to-end solutions, including component sourcing, SMT, and through-hole assembly. Get high-quality PCB assembly directly from the manufacturer.

PCB Manufacturing Process

Our PCB Assembly Services

Our state-of-the-art equipment and technology allow us to provide a seamless assembly experience no matter what you need. Below are the expert PCB assembly services we offer:

✔️ SMT, THT, and mixed technology

✔️ Automated process for precision

✔️ Detailed inspection and quality control

✔️ Functional testing

✔️ Fast turnaround times

✔️ From 25 to 5,000 units

✔️ Quick turnaround (1 to 7 days)

✔️ Rigorous checking and testing

✔️ All component sizes

✔️ Leaded or lead-free solder

✔️ 24-hr to 7-day turnaround time

✔️ Fabrication and assembly

✔️ Low- to high-volume

✔️ RoHS-compliant circuit boards

✔️ Rapid prototyping

✔️ Design and assembly

✔️ Quality component sourcing

✔️ Electrical safety testing

✔️ Fortify existing cables

✔️ Off-the-shelf cables available

PCB Assembly Service Cost?

The PCB assembly cost for 50 units, each with 100 square inches, will range from $100.00 to $250.00, based on an assembly rate of $0.02 to $0.05 per square inch.

| PCB Specifications | Quantity | Cost per PCB (USD) | Total Cost (USD) |

|---|---|---|---|

| PCB Manufacturing (Size: 10x10cm, FR4 Material, 2 Layers) | 50 | $1 to $5 | $50.00 to $250.00 |

| PCB Assembly (Square Inch Assembly Cost) | 50 | $0.02/inch² (100 inch²/PCB) to $0.05/inch² (100 inch²/PCB) |

$100.00 to $250.00 |

This is a general estimate, and actual costs may vary based on several factors. For detailed pricing information, please visit our cost page.

PCB Assembly Lead Times Overview

| Service Type | Lead Time |

|---|---|

| Standard PCB Manufacturing | 5-6 days |

| Expedited Manufacturing | 24-48 hours |

| PCB Prototyping (Quick Turn) | 1-2 layers: 5 days |

| 4 layers: 6 days | |

| 6 layers: 7 days | |

| 8 layers: 8 days | |

| 10 layers: 9 days | |

| PCB Assembly | 4-25 days, depending on complexity and order volume |

More PCB Assembly Fabrication Services

Why Choose OurPCB Assembly Services?

Our PCB assembly service is designed to exceed your expectations. Here’s why Our PCB is the ideal PCB assembly and manufacturing partner.

We’ve provided over 3,000 happy customers with cost-effective high volume PCB assembly services. You could be next!

We’ve been a one-stop PCB assembly service for over 17+ years. Our capabilities are built on years of industry expertise.

Our exceptional PCBs and our electronic manufacturing processes meet all safety standards.

OurPCB is committed to validating, fabricating, assembling, and shipping your finished products with rapid turnaround times.

We’re proud to own two ISO 9001:2015 certified PCB assembly factories; one in Shenzhen and one in Shijiazhuang.

We work with only the best suppliers to provide you with durable, high-quality parts that perform.

We’re committed to providing you with the best service possible, even after you’ve received your product. Contact us at any time for help from our experts.

Whether you need a PCB prototype, component sourcing, or full-scale production, we can help. We’re your one-stop solution for all your PCB needs.

Millions of business and innovators use OurPCB

PCB Board Process

Order Received

- Component Procurement

- Preparation

- PCB Manufacture

- Make Process Flow

Soldering

- Solder Printing/Wave Soldering

- SMT/Plugging

- Inspection (repair if necessary)

- AOI (repair if necessary)

- Transfer

Parts Assembly

- Manual Assembly

- Cleaning

- Wire Screw

- Inspection

- Repair If Necessary

Finalization

- Final Confirmation

- Packing

- Shiping

Technical Capabilities

Capabilities & Services

- One-stop PCBA Services (PCB Manufacturing + Components Sourcing + Assembly)

- SMT Assembly + THT Assembly

- BGA Rework

- 60,000 Chips/Hour

- Down to 01005/0210 Size

- Accuracy<±40μm

- Min. QFN Pin Width/Space: 0.15mm/0.25mm

- Min. BGA Diameter/Space: 0.2mm/0.35mm

- Rigid, Flex, HDI, & High-speed Power Boards

- Up to 50 Layers

- 60GHz High Frequencies

- Min. Trace Width/Spacing: 2.5mil/2.5mil

- AOI, X-ray, ICT & FCT Testing

- Controlled Impedance

- ISO 9001, ISO 13485, ISO 14001, IATF 16949, IPC-A-610, UL Certified

- Automotive, Medical, & Military-grade PCBA Manufacturing

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

PCB Assembly Services FAQs

How do I try printed circuit assembly services?

To try our PCB design and assembly services, start by getting your online quote now with $100 off your first order with us! Then, you’d upload your Garber File, pay, and production will start. If you don’t have a Gerber file yet, contact us anyway and we can help you design the perfect PCB. Once production is complete, delivery will take place and your order will be sorted out.

What is the difference between PCB fabrication and PCB assembly?

PCB fabrication and assembly are two separate parts of the manufacturing process. PCB fabrication assembly is when you transcribe a circuit board design onto the physical board.