Top 7 Truck Wiring Harness Manufacturers

Truck wiring harnesses are the electrical backbone of commercial vehicles, from long-haul trucks to construction fleets and emergency vehicles. They must withstand continuous vibration, thermal

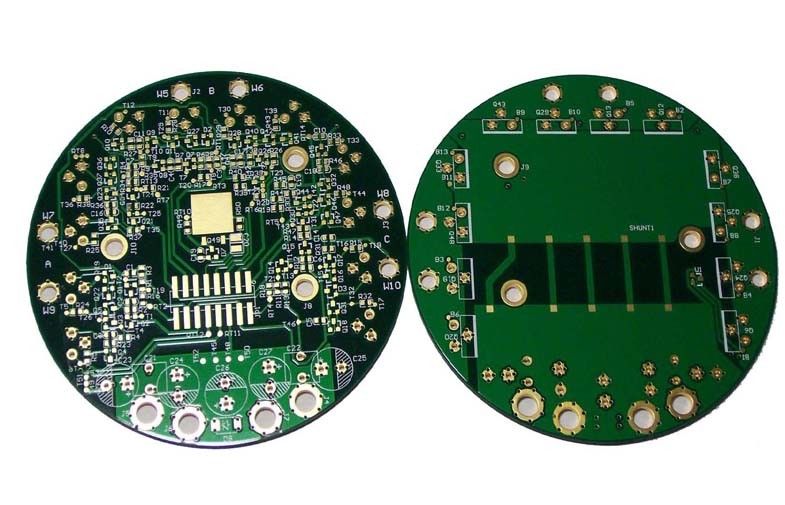

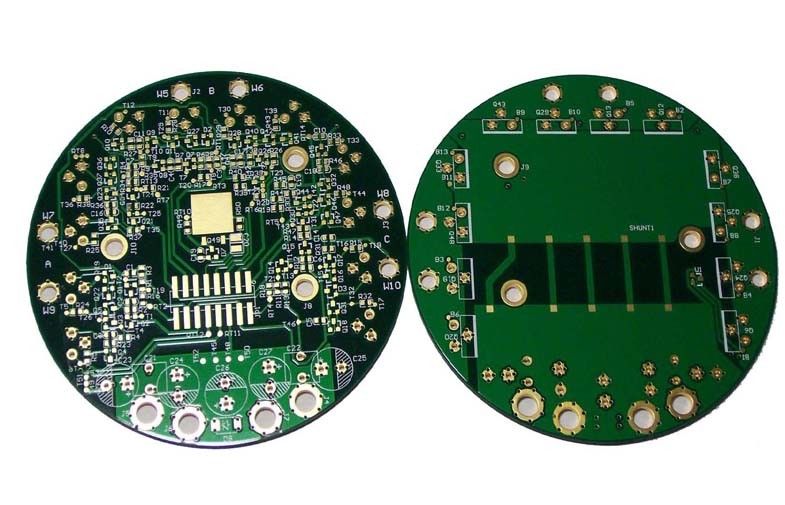

OurPCB specializes in manufacturing high-quality Metal Core PCBs, offering single-sided, double-sided, and multilayer designs. These PCBs efficiently manage heat, improving thermal performance and reliability. Ideal for LED lighting, power supplies, and automotive applications, Metal Core PCBs provide superior heat dissipation compared to traditional FR4 boards. OurPCB ensures precise customization, competitive pricing, and fast turnaround times to meet your specific needs.

Whether you need Injection Molding Services to enhance your designs by creating durable, custom enclosures for your PCBs or require a bare pcb board wholesale factory for large-scale production, we’ve got you covered.

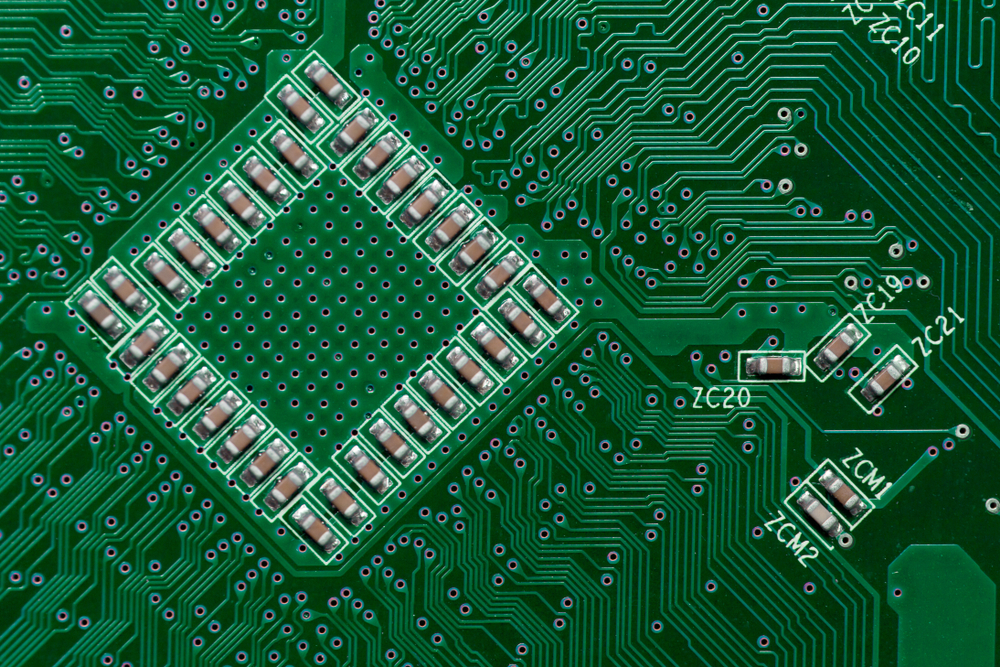

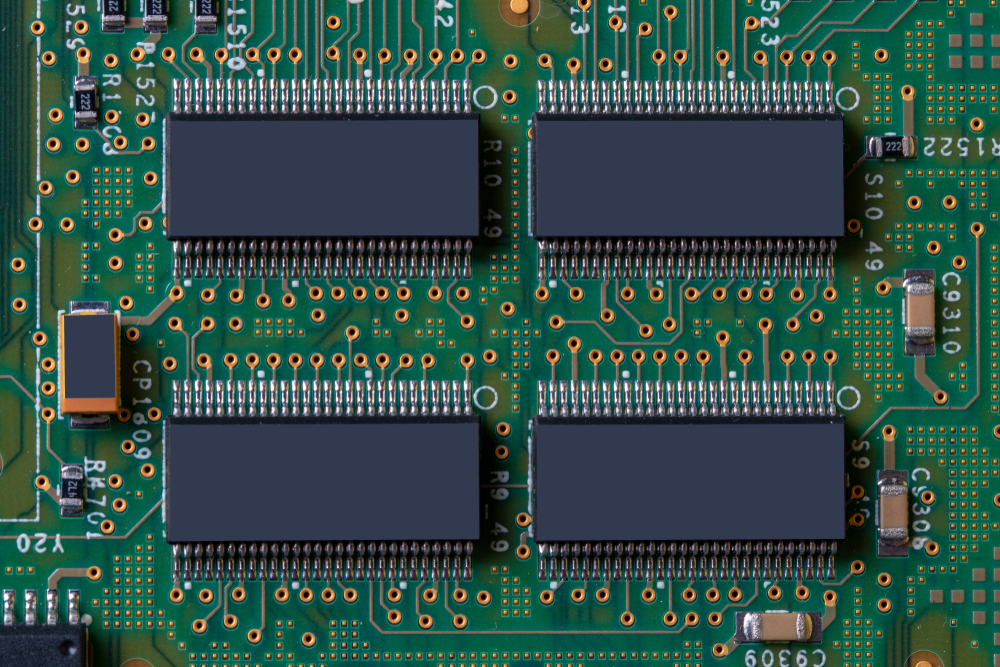

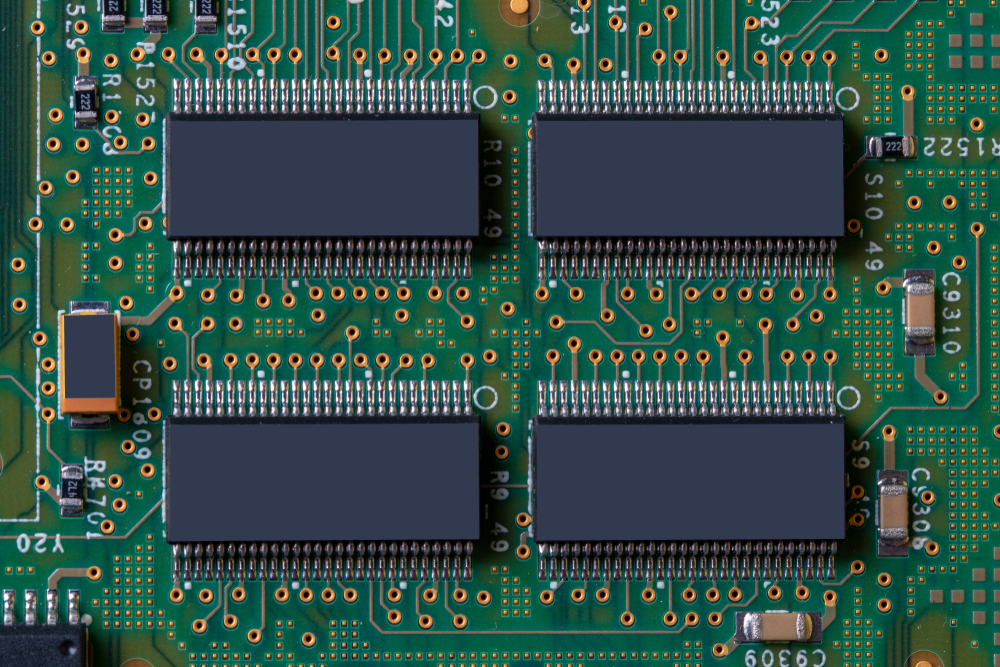

Metal Core PCBs (MCPCBs) are printed circuit boards with a metal base, typically aluminum or copper, for efficient heat dissipation. They improve thermal management, making them ideal for high-power and high-heat applications like LED lighting and power electronics. MCPCBs enhance performance and reliability by reducing heat buildup.

If you’re working on projects that include Passive Infrared (PIR) Sensors, MCPCBs offer excellent thermal performance and are an ideal choice.

| Project Items | OurPCB Capabilities |

|---|---|

| Main Material Suppliers | Shengyi, Quanbao, Xintianyuan, Juding, etc. |

| Metal Types | Copper, Aluminum, Copper-Aluminum Composite, Stainless Steel, Iron |

| Structure | Single-layer, Double-layer/Multilayer, Copper/Aluminum Core, Thermal-Electric Separation |

| Thermal-Electric Separation Flatness | No significant difference(copper core boards) |

| Copper/Aluminum Core Thickness | 0.4–3.2 mm |

| Copper Thickness | (0.33, 0.5, 1, 2, 3, 4, 5, 6) oz, 6–10 oz requires confirmation |

| Insulation Layer Thickness | Thermal conductive insulation: 50, 75, 100, 125, 150 μm Others: FR4 bonding sheets |

| Thermal Conductivity | Standard FR4, 1 W/m·K, 2 W/m·K, 3 W/m·K, up to 15 W/m·K |

| Max Finshed Board Size – excl. Cu Core & Thermal-Electric Separation | 22.5″ × 30″ |

| PTH | Copper Base Thickness <0.8 mm: 0.8–6.0 mm Copper Base Thickness 0.8–1.6 mm: 1.0–8.0 mm Copper Base Thickness 1.7–3.2 mm: 1.2–8.0 mm |

| Countersink Holes | Vertical angle: 90° ± 5° Min drill bit: 0.8 ± 0.15 mm, Can be enlarged if needed Depth tolerance: ±0.20 mm |

| Counterbore Holes | Min angle: 30° ± 5°, Max angle: 180° Min drill bit: 0.8 ± 0.15 mm, Max drill bit: 6.0 ± 0.15 mm Depth tolerance: ±0.20 mm |

✓ Professional Engineer Review for every project

✓ Stringent Quality Control across all manufacturing processes

✓ Advanced Testing Technology including AOI, E-Test, X-RAY, and Impedance Control

✓ Competitive Pricing especially for multilayer Metal Core PCBs

✓ ISO Certified manufacturing facilities

✓ Fast Turnaround times to meet your production schedules

We produce a complete range of Metal Core PCB solutions:

Excellent thermal conductivity at cost-effective pricing

Superior thermal performance for the most demanding applications

Simplified designs for LED applications

Enhanced functionality with optimized thermal management

Complex circuitry with exceptional heat dissipation

Our commitment to excellence as a Metal Core PCB manufacturer is demonstrated through our adherence to stringent quality standards:

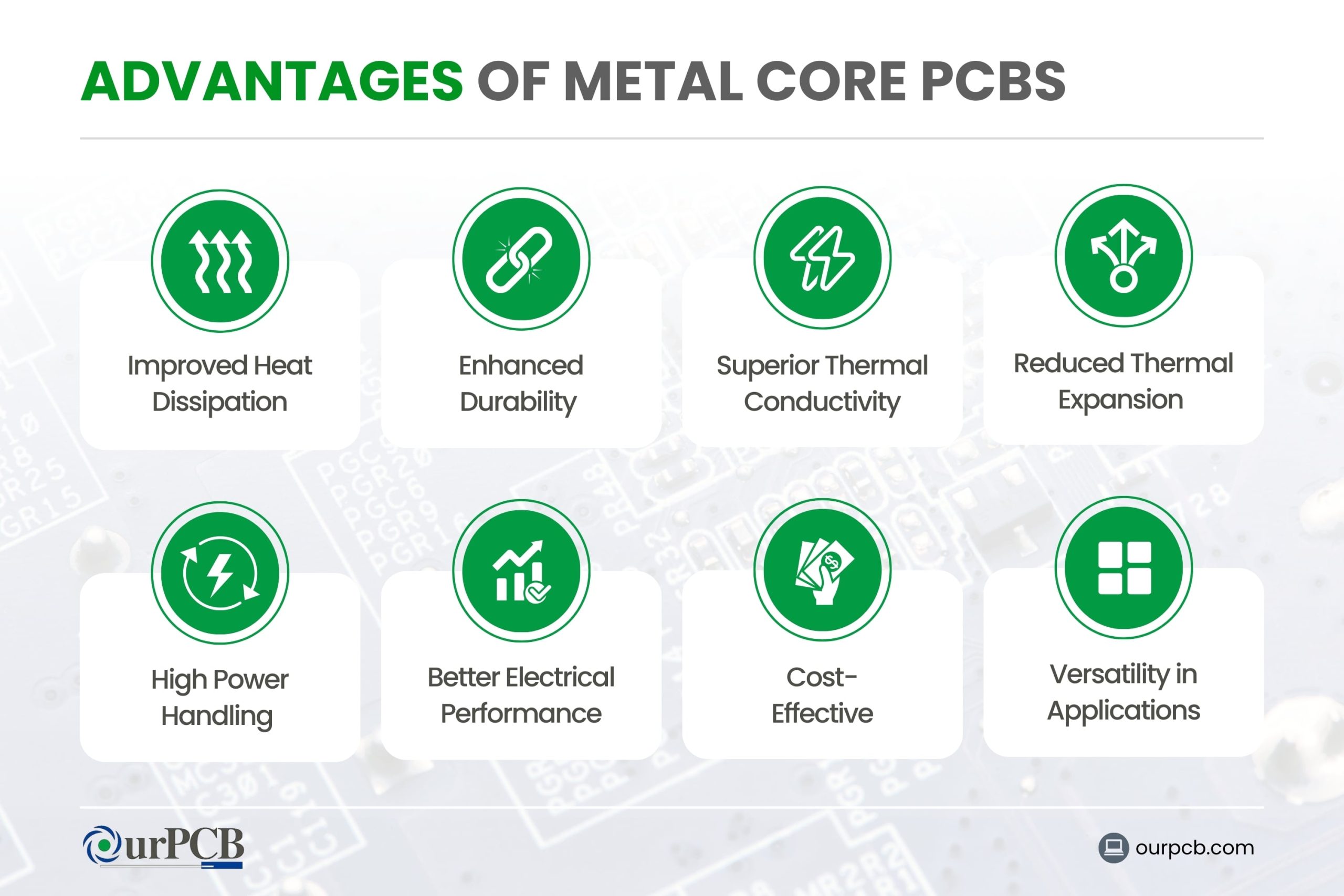

As a Metal Core PCB manufacturer, we focus on providing solutions that not only meet the industry’s needs but also enhance the longevity and performance of your products. MCPCBs are designed to handle high-power applications like LED lighting and automotive systems, offering superior heat dissipation and reduced thermal expansion. The advantages of selective gold plating also play a significant role in ensuring durability and consistent performance in demanding environments.

Our Metal Core PCBs dissipate heat 8-9 times more efficiently than standard FR-4 boards, making them ideal for:

OurPCB’s Metal Core PCBs provide:

As your trusted Metal Core PCB manufacturer, OurPCB provides comprehensive design support to optimize your MCPCB performance:

When designing a Metal Core PCB, it’s crucial to consider not only thermal optimization but also other potential issues like tombstoning. Tombstoning can occur during soldering and affect the reliability of the PCB. At OurPCB, we take extra precautions to ensure that our designs minimize this risk. If you’re unfamiliar with how to prevent it, check out our article on Preventing Tombstoning on PCBs.

Strategic component placement for maximum heat dissipation

Expert guidance on core materials based on your thermal requirements

Optimized dielectric thickness for thermal transfer efficiency

Designs optimized for production efficiency and quality

We handle everything from parts sourcing to final assembly, providing a hassle-free experience that ensures top-quality boards every time.

Whether you need a few prototypes or large-volume batches, our flexible assembly services adapt to your project’s scope and timeline.

Stay environmentally responsible with our compliant assembly processes, offering RoHS and lead-free options for safe, reliable builds.

No matter the complexity, we can assemble boards of all configurations—single-layer, multi-layer, or a mix—to match your exact specifications.

From one-off prototypes to bulk orders, we accommodate projects of all sizes without compromising on quality or turnaround time.

Join our growing community of satisfied clients who rely on our dependable assembly expertise and dedicated customer support.

At OurPCB, we’re not just a Metal Core PCB manufacturer – we’re your thermal management partner. Our team of experienced engineers works closely with you to:

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

At OurPCB, we often receive questions about the differences between Metal Core PCBs (MCPCBs) and Traditional FR-4 PCBs. Here’s a quick comparison to help you decide which type suits your application:

Metal Core PCBs (MCPCBs) offer several benefits over traditional FR-4 PCBs, particularly in heat management and durability. Here’s why they are a preferred choice for high-power applications:

MCPCBs are an excellent choice for applications where efficient heat dissipation and durability are essential. Need help selecting the right PCB? Contact us today!

Truck wiring harnesses are the electrical backbone of commercial vehicles, from long-haul trucks to construction fleets and emergency vehicles. They must withstand continuous vibration, thermal

Medical cable assemblies sit at the intersection of electrical safety, biocompatibility, and sterilization durability. For regulated medical devices, OEMs must work with manufacturers that understand

Robotics cable assemblies are unlike ordinary cables, they must survive continuous motion, tight bend radii, torsion, vibration, electrical noise, and often harsh industrial or outdoor

Waterproof cable assemblies have to do more than just “keep water out.” For outdoor, marine, industrial washdown, and transportation platforms, assemblies are expected to survive

Aerospace cable assembly manufacturers work under standards such as AS9100, ISO 9001, and RTCA/DO-160, and many also maintain ITAR registration to support flight-critical and space-qualified

When considering the best places for manufacturing data cables, China immediately comes to mind. It’s no surprise either — the country has rapidly ascended in

We use cookies to improve your browsing experience, which may include personal information. By clicking "Agree," you accept our Privacy Policy and cookie use. You can change your cookie settings in your browser anytime.

Agree