Top 10 Classic Car Wiring Harness Manufacturers | Full Guide

Finding the right wiring harness manufacturer for your vintage ride can be a real headache. Those beautiful old machines need special wiring that looks period-correct

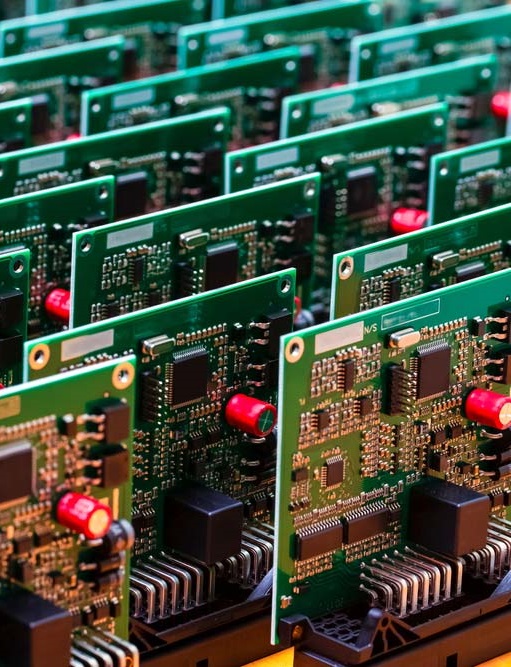

At OurPCB, we’ve successfully assembled over 50 million PCB units for global clients across 10,000+ projects. As an ISO 9001 certified provider, we specialize in high-volume, high-precision assembly with proven reliability. Trusted by thousands, our services are backed by 1,500+ Google reviews and a global reputation for quality and scale.

Need high-volume PCB assembly services? As a leading PCBA manufacturer, we at OurPCB are ready to assist you.

OurPCB is a group of experienced professionals offering state-of-the-art PCB assembly services. With lots of happy customers all around the world, especially in the USA, you can trust OurPCB to deliver exceptional quality and service.

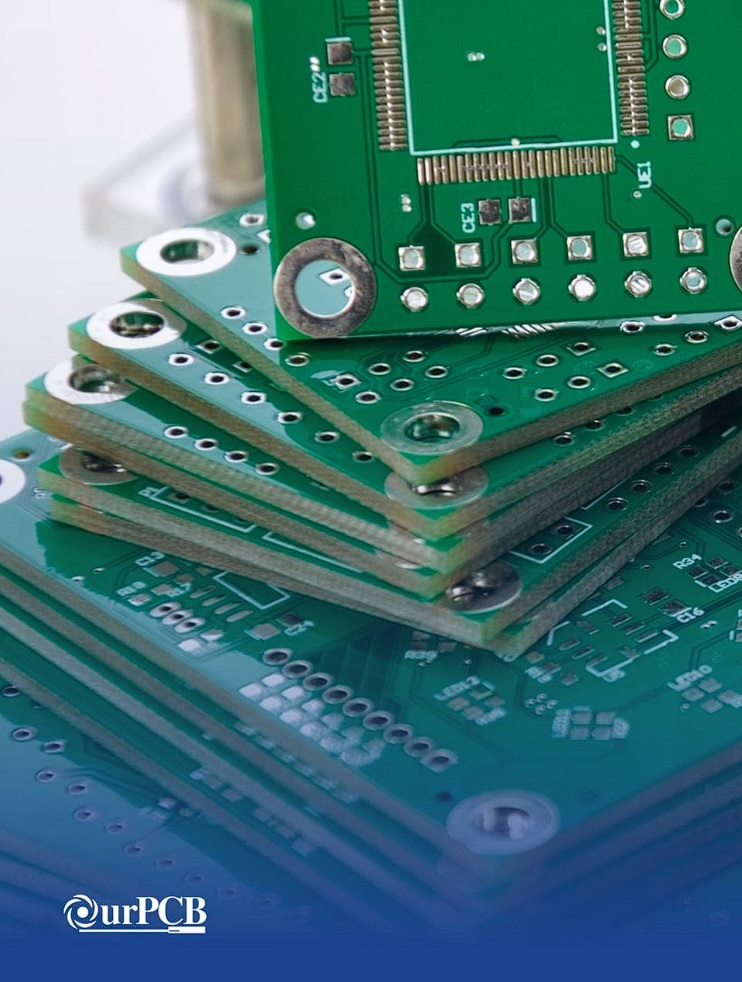

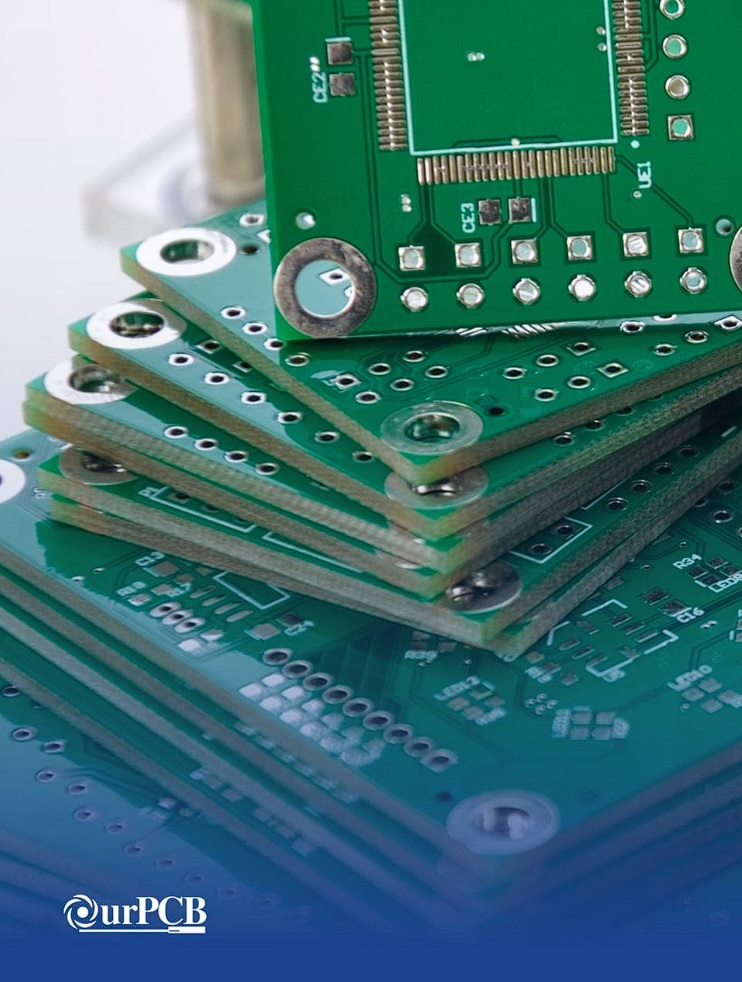

High volume PCB assembly (HVPCBA) involves producing printed circuit boards in batches, starting from a minimum of 1000 to hundreds of thousands per run.

It’s a cost-effective way to capitalize on time that would otherwise be spent on prototyping, which is common with low-volume assembly. It provides bulk PCBs in short turnaround times to meet market demands.

Single or double-side surface mount technology is highly efficient. Our assemblers use precision machines to mount components on the PCB’s surface.

The machines are primed for efficiency and accuracy to ensure they achieve miniaturization and maximum space usage. Automation ensures every PCB in the assembly line maintains the same standard of uniformity.

We use through-hole technology for PCBs in power-intensive applications. In this method, we insert electronic components into pre-drilled holes on the circuit board and solder them securely.

THT is suitable for producing PCBs that can withstand impact or tough conditions.

We use a combination of SMT and THT when we need to include power-intensive components on PCBs that undergo extreme electrical current.

Once we use SMT to place smaller components, we use THT to manually place bigger components that can handle mechanical stress.

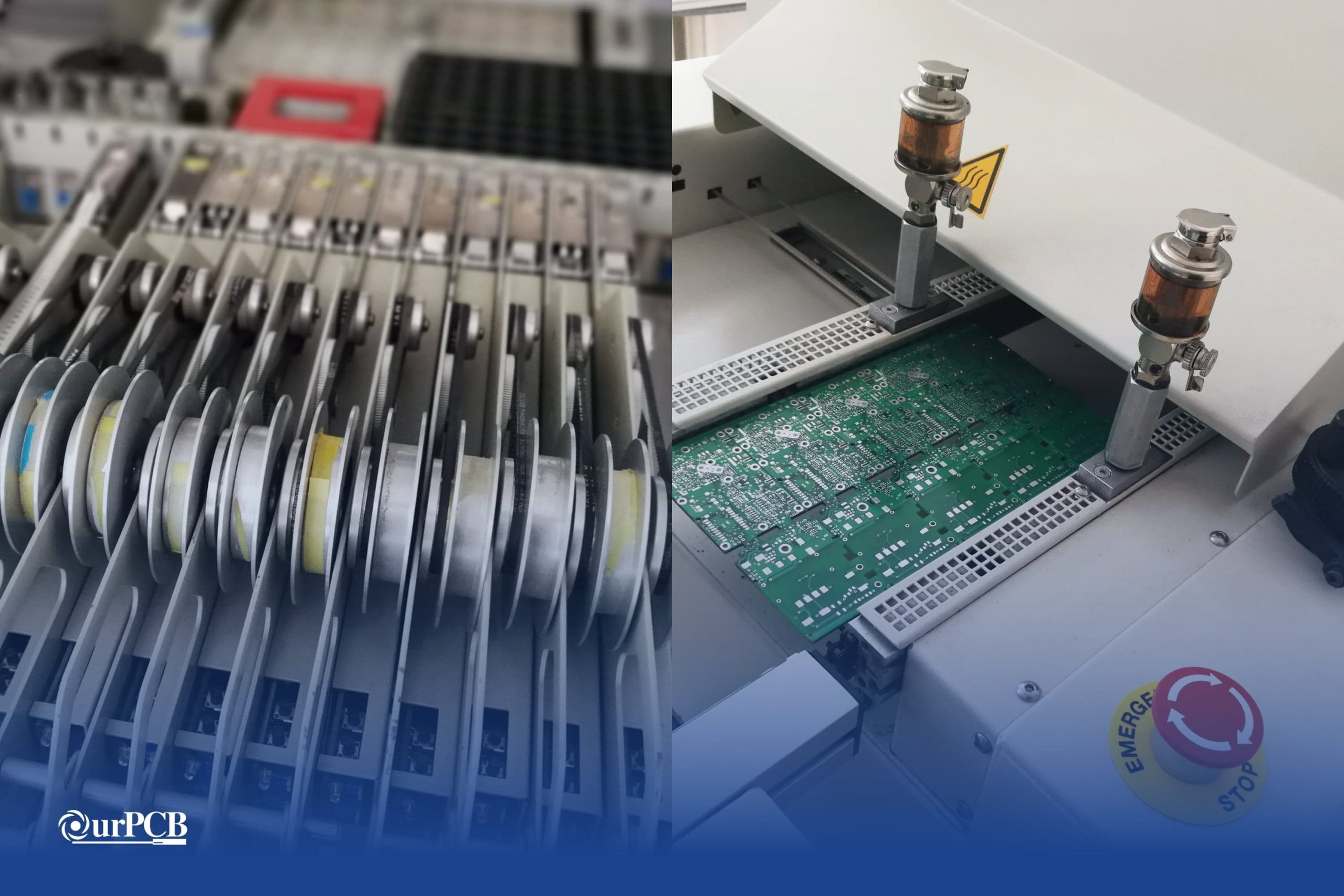

We combine automation and pinpoint component placement when using pick-and-place machines to place surface components on the PCB.

P&P machines use vacuum nozzles to pick components up from trays and place them on PCB pads. These machines can make thousands of successful placements per hour. The end result is efficient boards, finished with accurate component placement.

The key function of reflow ovens is to melt solder paste for soldering surface components to the PCBs. Without reflow ovens, you risk having inconsistent and weak solder joints.

Assemblies use three types of reflow ovens, for specific functions.

We combine automation and pinpoint component placement when using pick-and-place machines to place surface components on the PCB.

P&P machines use vacuum nozzles to pick components up from trays and place them on PCB pads. These machines can make thousands of successful placements per hour. The end result is efficient boards, finished with accurate component placement.

The key function of reflow ovens is to melt solder paste for soldering surface components to the PCBs. Without reflow ovens, you risk having inconsistent and weak solder joints.

Assemblies use three types of reflow ovens, for specific functions.

Unlike small-scale production, high volume PCB assembly cuts down on prototype development, testing, and approval time. Once the initial design is approved, mass production is fast. Also, it’s easier to get favorable costs per unit when purchasing components in bulk.

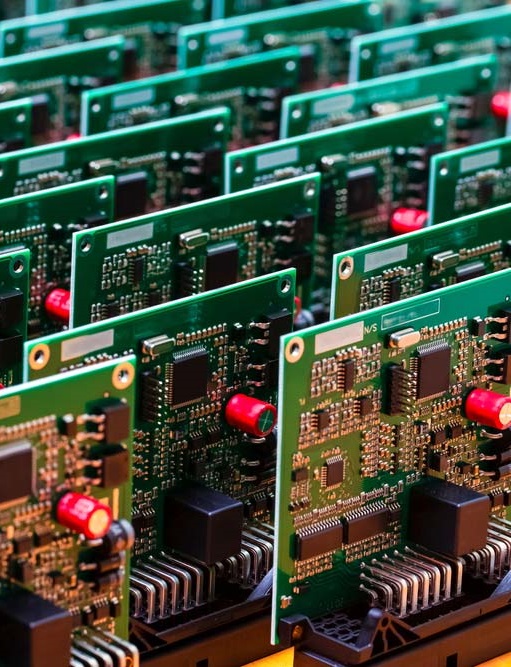

High volume PCB assembly is automated, from stencil printing to functional testing. Since it uses high-speed precision machines, you can get a minimum of 1000 units in a short time.

All the automated machines and processes are inspected for precision and accuracy. This ensures that the final boards come out uniformly and with no errors. The assembled boards also go through multiple testing stages to make sure end users get error-free PCBs.

High volume PCB assembly can boost your production from small scale to global production.

You can easily ramp up production from 1000 units to 100000+ units to meet market demands.

Alternatively, you can reduce production with ease, to accommodate decreased demand. It’s an efficient model for a business looking to grow organically.

High volume PCB assembly is part of virtually every core sector.

We handle everything from parts sourcing to final assembly, providing a hassle-free experience that ensures top-quality boards every time.

Whether you need a few prototypes or large-volume batches, our flexible assembly services adapt to your project’s scope and timeline.

Stay environmentally responsible with our compliant assembly processes, offering RoHS and lead-free options for safe, reliable builds.

No matter the complexity, we can assemble boards of all configurations—single-layer, multi-layer, or a mix—to match your exact specifications.

From one-off prototypes to bulk orders, we accommodate projects of all sizes without compromising on quality or turnaround time.

Join our growing community of satisfied clients who rely on our dependable assembly expertise and dedicated customer support.

Selecting a skilled and experienced HVPCBA provider is critical to your project’s success. Here’s why we’re the obvious choice.

We have a 15-year track record and a good rapport with over 2,000 global customers. Whether rigid PCBs, flex PCBs, or column grid arrays (CGAs), we can cover large-scale production to your design specifications suited for any industry. Our experience allows us to deliver error-free PCBs even when faced with production hitches.

You can trust us to run your PCB production from start to finish. Not only do we use top-of-the-range equipment (8 YAMAHA SMT lines) in our factories, but we also meet ISO 9001-2015 certification.

We rely on a network of trusted partners to source components according to your preference. Furthermore, we have a line-up of industry-standard visual and beyond-surface-level testing machinery to ensure you get error-free PCBs.

We understand your need to grow and expand. Borrowing from the experiences we’ve had with other partners, we can customize assembly plans that suit your production demands.

We grow with you, maintaining tight time schedules and meeting delivery deadlines. As you expand operations, we can increase production accordingly. The best part is you don’t have to worry about diminishing quality as production goes up.

We maintain an active communication line, in case you want to make changes during the assembly process. We’ll assign you a qualified project manager who understands your demands to take your feedback and give you timely updates.

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

The first step to quality assurance in high-volume PCB assembly is choosing a manufacturer that meets ISO certifications. Also, the automated machines must be optimized for maximum precision. That way, there’s less chance of low quality right from the design and prototype phase.

Assembly materials and components must come from trusted suppliers. Once the PCBs pass manufacturing, further quality standards are enforced using various visual testing methods, such as automated optical inspection (AOI), in-circuit testing (ICT), and X-ray testing.

The final test, functional testing, is a rubber stamp on the operational integrity of the manufactured board.

Finding the right wiring harness manufacturer for your vintage ride can be a real headache. Those beautiful old machines need special wiring that looks period-correct

Would your car be able to run without wire harnesses? Not a chance. Wire harnesses connect all the electrical parts together. No harness means no

Making wire harnesses isn’t complicated. At OurPCB, we create custom wire harnesses for an expansive range of industries every day. While it’s a complicated process,

Prototype cable assemblies are the very important place in between PCB design ideas and interconnects. OurPCB brings prototype assemblies with PCB solutions to your tables.

PCB thermal management prevents component overheating through strategic heat transfer techniques. Without proper thermal control, electronics are at risk of electronic failures through weakened solder

ContentsKey TakeawaysWhat is a Multilayer-Printed Circuit Board?How do Multilayer PCB Boards Work?Multilayer PCB ApplicationsMultilayer PCB Manufacturing Process: StepsMultilayer PCB Manufacturing MachinesBenefits of Multilayer Circuit BoardsWhat

We use cookies to improve your browsing experience, which may include personal information. By clicking "Agree," you accept our Privacy Policy and cookie use. You can change your cookie settings in your browser anytime.

Agree