Top 10 Classic Car Wiring Harness Manufacturers | Full Guide

Finding the right wiring harness manufacturer for your vintage ride can be a real headache. Those beautiful old machines need special wiring that looks period-correct

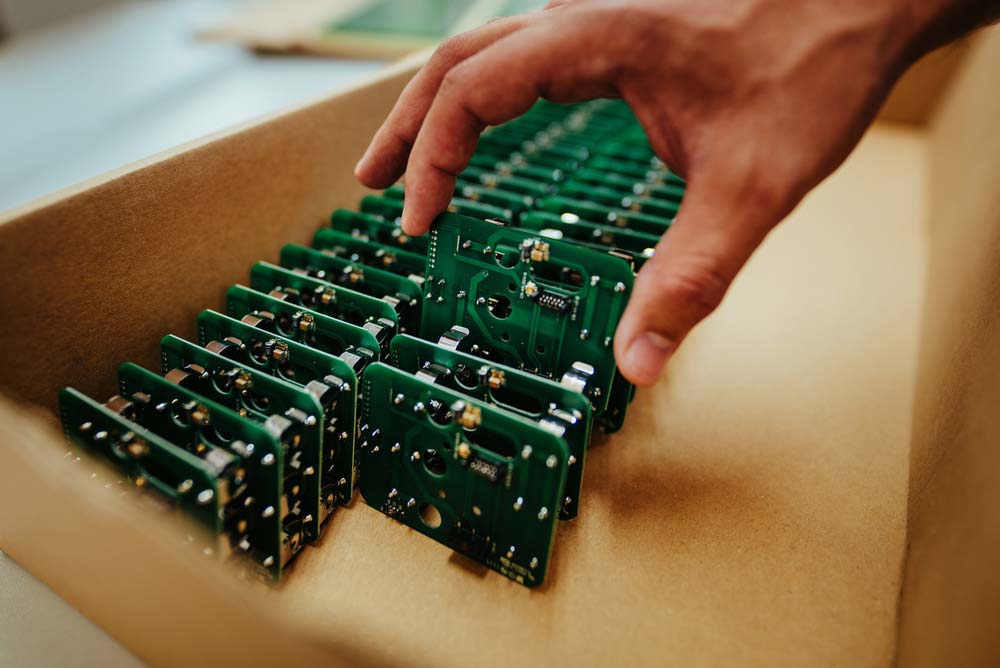

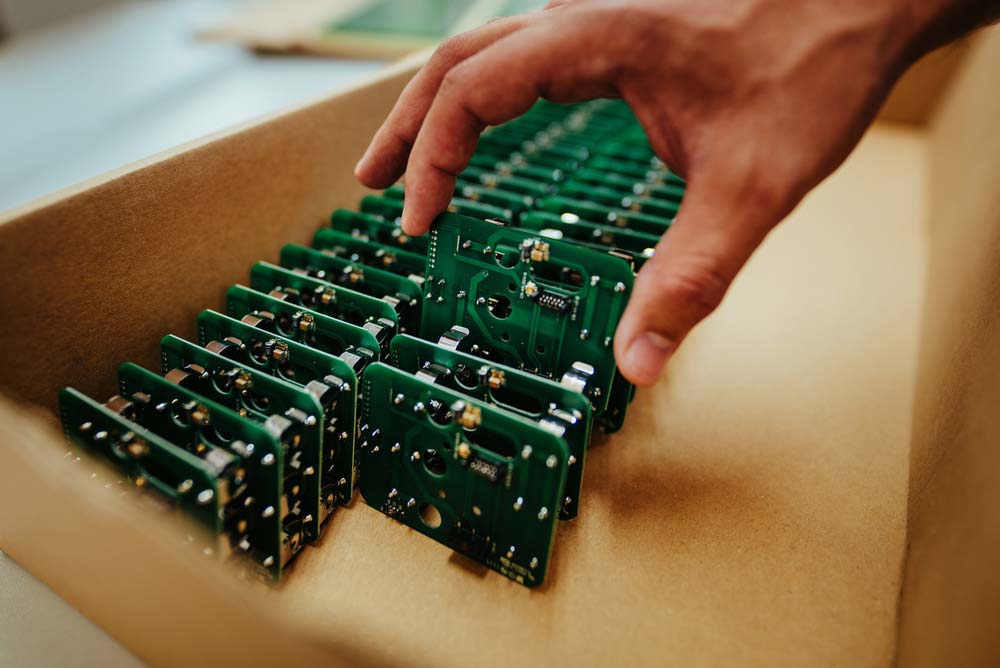

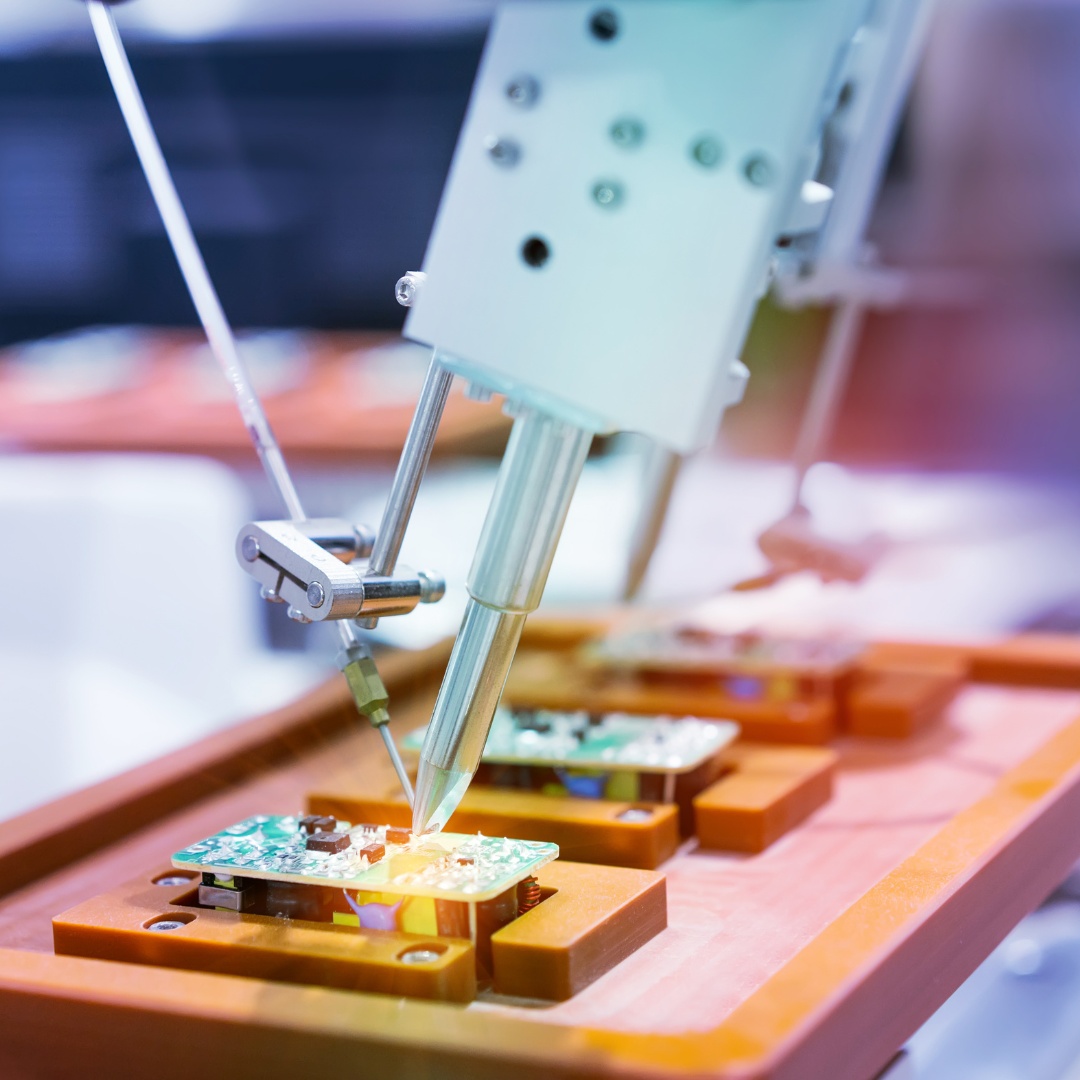

At OurPCB, we specialize in low-volume PCBs and assembly, offering high-quality manufacturing services for small batch production. Whether you need prototypes or limited runs, our experienced team ensures precise assembly and quick turnaround times, meeting your unique specifications. We serve a wide range of industries, from consumer electronics to medical devices, providing cost-effective solutions without compromising performance.

As a leading PCBA manufacturer, we at OurPCB are ready to assist you, with services ranging from only 25 pieces to 5,000 units. OurPCB is a group of experienced professionals offering state-of-the-art PCB assembly services. With many satisfied customers worldwide, particularly in the USA, you can rely on OurPCB to provide exceptional quality and service.

Low-volume PCB assembly introduces several benefits to the electronics business environment, including:

Mass or high-volume production of a new, untested design or circuit upgrade can be buggy. Such products are likely to have negative feedback from the market, resulting in expensive recalls and market share losses that will affect cash flow in the future.

Low-volume PCB production might seem expensive at first, but it’s a cost-effective part of the RnD process that enables prototyping and fine-tuning. This ensures that the product that ends up in the market is the best possible version.

Low-volume production is synonymous with prototyping and falls in the same category as quick-turn PCB manufacturing. Therefore, you’ll get your PCBs in 1 to 7 days, depending on the board’s complexity and the exact number of pieces.

This quick turnaround helps you fine-tune the product quickly and launch the final device in the market within a reasonable timeline.

With the quick turnaround and cost-effectiveness, low-volume production makes it possible to alter the design and change electronic component specifications quickly to improve performance. You can even do tweaks in several prototyping iterations/versions because the cost is manageable. When understanding PCB components, this flexibility is key to refining the circuit design with minimal risk.

Each PCB in the low-volume assembly batch undergoes various checks and rigorous tests to produce the highest-quality product. And since they are few, we’ll be able to commit more resources (time and components) to each piece, which will have a positive impact on quality.

Since we’ll be able to commit more resources to low-volume assembly, the resulting high-quality PCBs will be more reliable. The risk of making mistakes will be lower than when handling large orders in the same time frame.

For low volume PCB manufacturing, assembling a square inch of PCB can cost between $0.02 to $0.05. However, this cost is not fixed and can vary based on several factors. The factors that determine the actual assembly cost per square inch include:

Check out our PCB cost estimator page to learn more.

For low volume PCB manufacturing, assembling a square inch of PCB can cost between $0.02 to $0.05. However, this cost is not fixed and can vary based on several factors. The factors that determine the actual assembly cost per square inch include:

Check out our PCB cost estimator page to learn more.

PCB assembly has its roots in the design process, and our capabilities begin at this point.

OurPCB offers PCB layout design services for low-volume circuit board assembly. Whether you need designs for real-time control, smart devices, or embedded systems, we optimize layouts for manufacturing, ensuring efficiency and functionality in your low-volume PCB production.

Our DFM review ensures your low-volume PCB design is production-ready. We identify potential bottlenecks and suggest improvements like signal and solder mask checks, enhancing manufacturability and minimizing delays or increased costs during low-volume PCB assembly.

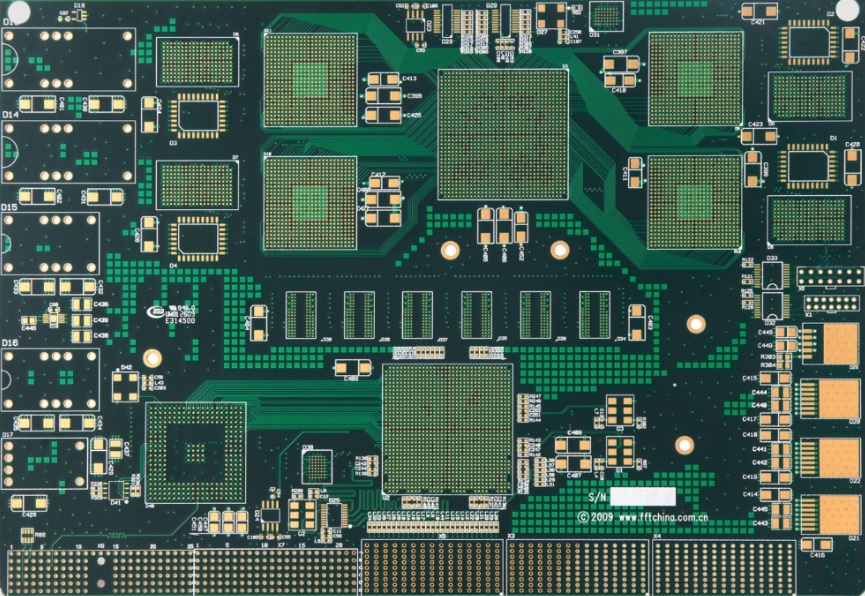

Once approved, OurPCB begins fabricating your design using materials like FR4, ceramic, or aluminum. We offer single-sided, double-sided, and multilayer PCBs (up to 50 layers), perfect for complex, high-density designs, ensuring precision in your low-volume PCB manufacturing.

We source components for quick PCB assembly, stocking common parts and accessing specialized components through trusted global suppliers like Avnet and Mouser. All components are rigorously tested for authenticity, improving reliability in your low-volume PCB production and final assembly.

Conformal coating protects PCBs from moisture, dust, and temperature extremes in environments like aerospace or automotive. OurPCB applies materials such as epoxy, silicone, urethane, and acrylic, offering tailored protection for your low-volume PCB assembly in demanding conditions.

OurPCB provides IC programming services during low-volume PCB assembly, using universal headers or dedicated jigs. We customize the programming process to ensure your ICs are fully functional and meet specific requirements for your low-volume electronics production.

We conduct rigorous testing for all PCBs before assembly, including functional jig and burn-in tests. This ensures that each low-volume PCB assembly meets performance standards, particularly important for high-reliability applications in industries like aerospace and telecommunications.

OurPCB accelerates prototyping with quick-turnaround services such as CNC machining and chemical etching. We specialize in low-volume PCB prototype assembly, ensuring that each test board meets your specific requirements and speeds up product development.

We handle everything from parts sourcing to final assembly, providing a hassle-free experience that ensures top-quality boards every time.

Whether you need a few prototypes or large-volume batches, our flexible assembly services adapt to your project’s scope and timeline.

Stay environmentally responsible with our compliant assembly processes, offering RoHS and lead-free options for safe, reliable builds.

No matter the complexity, we can assemble boards of all configurations—single-layer, multi-layer, or a mix—to match your exact specifications.

From one-off prototypes to bulk orders, we accommodate projects of all sizes without compromising on quality or turnaround time.

Join our growing community of satisfied clients who rely on our dependable assembly expertise and dedicated customer support.

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

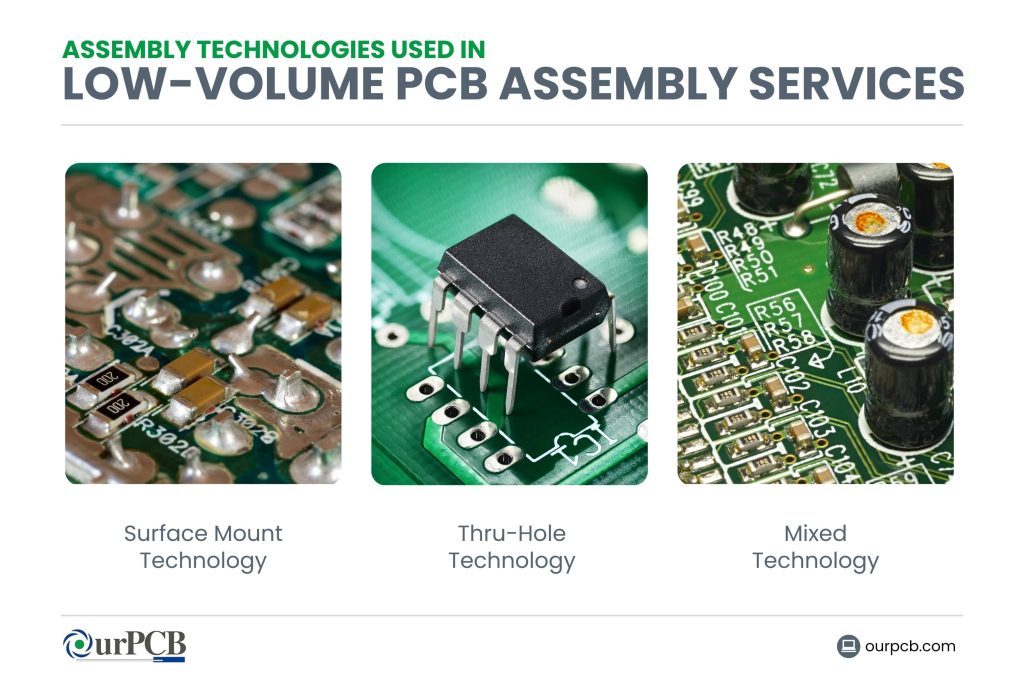

We can handle all component sizes, including the fine-pitch type (as small as 8 mils), passive parts like the 0201 (20×10 mils), BGA, and all chip carriers (leadless and leaded).

We can use leaded or lead-free solder, depending on your requirements. For instance, if you want to make consumer electronics, we use lead-free solder for RoHS compliance. But for applications that require high reliability, such as in military electronic devices, leaded solder might be better.

The process starts with a consultation where you provide your project details, either by submitting design files or a full project description. If you supply design files, we can give you an instant online quote. If you’re just starting with a project description, we’ll work with you to refine the requirements, then provide a quote for the entire project along with expected delivery timelines. After that, the manufacturing process begins, and we’ll keep you updated on the progress, including when prototypes and final boards are ready for shipping. To get started, simply contact us with your project details or design documents (Gerber files and BOM), and we’ll provide you with an instant PCB quotation for your low-volume assembly needs.

Finding the right wiring harness manufacturer for your vintage ride can be a real headache. Those beautiful old machines need special wiring that looks period-correct

Would your car be able to run without wire harnesses? Not a chance. Wire harnesses connect all the electrical parts together. No harness means no

Making wire harnesses isn’t complicated. At OurPCB, we create custom wire harnesses for an expansive range of industries every day. While it’s a complicated process,

Prototype cable assemblies are the very important place in between PCB design ideas and interconnects. OurPCB brings prototype assemblies with PCB solutions to your tables.

PCB thermal management prevents component overheating through strategic heat transfer techniques. Without proper thermal control, electronics are at risk of electronic failures through weakened solder

ContentsKey TakeawaysWhat is a Multilayer-Printed Circuit Board?How do Multilayer PCB Boards Work?Multilayer PCB ApplicationsMultilayer PCB Manufacturing Process: StepsMultilayer PCB Manufacturing MachinesBenefits of Multilayer Circuit BoardsWhat

We use cookies to improve your browsing experience, which may include personal information. By clicking "Agree," you accept our Privacy Policy and cookie use. You can change your cookie settings in your browser anytime.

Agree