- PCB Manufacturer

- PCB Assembly Service

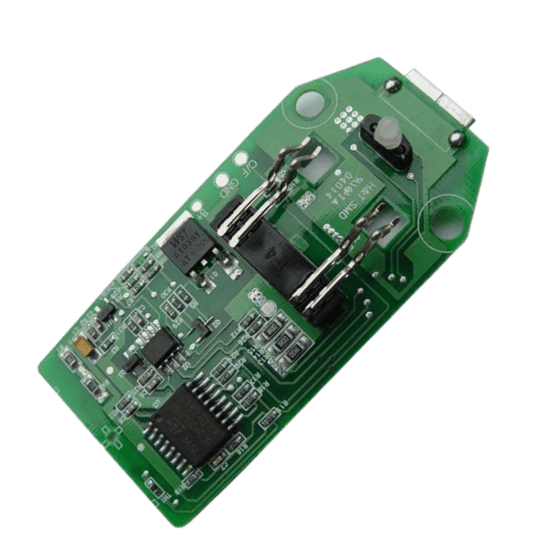

- Medical PCB

Medical PCB Assembly Manufacturer

OurPCB manufactures high-quality medical-grade PCBs for various medical applications. As a trusted printed circuit board manufacturer, we ensure precision, reliability, and compliance with industry standards. We’ve worked with some of the most innovative companies in the world, especially in the USA, delivering custom solutions for diagnostic tools, monitoring systems, and other essential medical devices tailored to your specific needs.

What Are Medical PCBs?

Medical PCBs are circuit boards used to run the circuitry of electrical equipment in the medical industry. As medical equipment becomes more computerized, complex, and compact, they require boards with high-density circuits. Therefore, when you need to source these essential components, obtaining a PCB online quote can help you compare options and ensure you get the best value.

PCB Manufacturing Process

What are the Advantages of Medical PCBs?

Medical-grade PCBs enable compact, reliable, and precise medical devices for diagnostics and treatment. They support real-time monitoring, remote diagnosis, and seamless data collection. Customizable for various applications, they also power AI-driven diagnostics and wearable health tech. If you are looking for a Chinese PCB manufacturer for healthcare applications, OurPCB offers competitive pricing, specialized medical-grade production capabilities, strict adherence to international standards, and expertise in creating high-reliability circuit boards essential for critical medical equipment.

Devices like pulse oximeters and glucose meters enable at-home and remote health monitoring. They are affordable, portable, and easy to use.

PCBs facilitate digital records, improving accessibility, reducing errors, and enhancing treatment accuracy.

Medical devices transmit real-time data for remote monitoring, enabling timely interventions and better patient care.

Smartwatches, fitness trackers, and medical monitors provide continuous health tracking for individuals and healthcare providers.

Accurate patient data helps pharmaceutical companies optimize drug production and supply, ensuring market needs are met efficiently.

Medical PCB Manufacturing Costs

OurPCB offers cost-effective solutions for custom Medical PCB manufacturing. The cost of producing a custom Medical PCB depends on several factors:

| Cost Factor | Details |

|---|---|

| PCB Size and Layers | Larger and more layered boards generally cost more. |

| Material Choice | High-performance materials such as FR4, aluminum, or flex materials can affect pricing. |

| Order Volume | Bulk orders are eligible for significant discounts. |

| Special Requirements | Features like HDI, blind/buried vias, or impedance control may incur additional costs. |

| Assembly Services | Turnkey assembly, component sourcing, and other add-ons contribute to the total cost. |

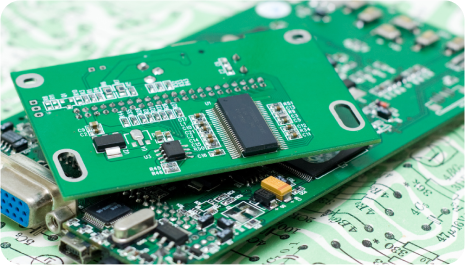

PCB Assembly Services

Our expert engineers craft precise and detailed schematic diagrams, no matter the complexity of your project.

Leveraging advanced tools such as Altium Designer, Cadence, Eagle, and KiCAD, we produce reliable and efficient PCB layouts tailored to your needs.

We provide end-to-end firmware development services to enhance the functionality of embedded systems seamlessly.

Custom software and app solutions according to your specifications.

We specialize in creating innovative algorithm solutions for a wide range of applications, including image processing and data analysis challenges.

Rapid prototyping and optimized designs with 3D printing and enclosure design expertise.

Millions of business and innovators use OurPCB

PCB Board Process

Design (1 day)

- Upload Schematic to Get a Quote

- PCB Review and Quotation

- Customer Makes Payment

- Evaluation & Confirmation of Plan

- Design Start

Layout (1 day)

- Layer Stack-up Design

- Design Rule Setting

- Component Placement Design

- Confirmation & Optimization

- Fanout

Routing (1 day)

- Fanout Optimization

- PCB Routing

- Equal-length Adjustment

- Routing Optimization

- DRC Check

- Routing Confirmation

Optimization (1 day)

- Silkscreen Adjustment

- Data Output

- Customer Final Confirmation

- Production Debugging

- Archiving Projects

- Finish

PCB Board Process

Order Received

- Component Procurement

- Preparation

- PCB Manufacture

- Make Process Flow

Soldering

- Solder Printing/Wave Soldering

- SMT/Plugging

- Inspection (repair if necessary)

- AOI (repair if necessary)

- Transfer

Parts Assembly

- Manual Assembly

- PCBCleaning

- Wire Screw

- Inspection

- Repair If Necessary

Finalization

- Final Confirmation

- Packing

- Shipping

Technical Capabilities

Capabilities & Services

- One-stop PCBA Services (PCB Manufacturing + Components Sourcing + Assembly)

- SMT Assembly + THT Assembly, Single/double-sided Assembly Mixed PCB Assembly

- BGA Rework

- 60,000 Chips/Hour

- Down to 01005/0210 Size

- Accuracy<±40μm

- Min. QFN Pin Width/Space: 0.15mm/0.25mm

- Min. BGA Diameter/Space: 0.2mm/0.35mm

- Rigid, Flex, HDI, & High-speed Power Boards

- Up to 50 Layers

- 60GHz High Frequencies

- Min. Trace Width/Spacing: 2.5mil/2.5mil

- AOI, X-ray, ICT & FCT Testing

- Controlled Impedance

- ISO 9001, ISO 13485, ISO 14001, IATF 16949, IPC-A-610, UL Certified

- Automotive, Medical, & Military-grade PCBA Manufacturing

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

FAQ's

What Types of Medical PCB Assembly Can OurPCB Offer?

At OurPCB, we offer a variety of medical PCB assemblies to suit different device needs. These include single-layer PCBs for simple tasks, double-layer and multilayer PCBs for more complex functions, and rigid PCBs for standard applications. We also provide flexible polyimide PCBs for devices with tight spaces, flexible metal clad PCBs for high-power applications, and rigid-flex PCBs for hybrid designs in wearables. Additionally, ceramic PCBs are ideal for high-temperature environments, and HDI microcircuits deliver high performance in compact devices like wearables and hearing aids.

How Small Can Medical PCBs Get?

Medical devices are becoming increasingly compact, requiring PCBs that fit within tiny, high-precision equipment. Your manufacturer must have advanced machinery to assemble components on ultra-small boards. However, there are limits—currently, the smallest surface-mounted component available measures 0.25 mm × 0.125 mm. Ensuring precision at this scale is critical for reliable performance in medical applications.

What Are the Requirements for Medical PCBs?

Medical PCBs must meet strict electrical, mechanical, and manufacturing requirements. They need low-voltage operation, proper grounding, shielding, and EMI/ESD control. Mechanically, they require strong solder joints, thermal management, and durability. Biocompatible materials are essential, and boards must pass rigorous testing like AOI and X-ray. Compliance with regulations such as UL, IEC, FDA, and ISO is necessary for global use.

What Technologies Are Used in Medical PCBs?

Medical PCBs incorporate several advanced technologies, including IPC Class 3 standards for high reliability, zero annular ring breakouts, and precise plating in thru-holes. High-density interconnection (HDI) reduces board size, while technologies like laser-direct imaging ensure minimal line width reduction. Medical PCBs often use specialized laminates like ceramic, polyimide, and Teflon, and rely on DFM (Design for Manufacturability) to optimize layout for efficient production and assembly.

How Are Medical PCBs Used in Healthcare?

- Cardiovascular medical equipment (defibrillators, pacemakers, heart monitors)

- Medical imaging systems (ultrasonic equipment, MRI, CT scans)

- Blood glucose monitors

- Body temperature monitors

- Electrical muscle stimulation equipment

- Medical instruments for collecting research data and test results