You have probably worked with several printed circuit boards but maybe didn't check their underlying material. The reality is that several electronic products in the past had halogen elements. However, they are not commonly in use as research bodies banned them. Why did this happen? Also, what is the importance of having Halogen-free printed circuit boards? Our article will explain why halogens are toxic chemicals. Additionally, it'll explore the critical features of halogen-free PCB and how to identify them.

Our article will explain why halogens are toxic chemicals. Additionally, it will explore the critical features of halogen-free PCB fabrication and how to identify them. For more information on fabrication costs, you can always request a PCB quotation online today.

Contents

- What is Halogen-free PCB?

- Why was "Halogen" Banned

- How Do Halogen-free PCBs Be Fire-Resistant?

- How to Determine Halogen-free PCB Materials?

- Halogen-Free PCB Materials

- The Challenge of Designing Halogen Free PCBs

- Advantages of Halogen Free PCBs

- What's Special in Halogen-Free PCB Manufacturing and Assembly?

- Ourpcb: Halogen-Free PCB Manufacturer to the Highest Level

What is Halogen-free PCB?

Printed Circuit Boards in a Laboratory

Halogen-free boards are PCBs that primarily consist of halogen-free copper-clad laminate. This classification is according to the ES-01-2003 - A Japan Circuit Association (JPCA) standard.

Examples include a copper-clad laminate with less than 0.09% Wt of a halogen, such as bromine/ chlorine.

Why was "Halogen" Banned

Halogens are known flame retardants.

Halogens are group 7 elements such as chlorine, fluorine, bromine, and astatine. Usually, chlorine compounds and bromine are beneficial as electronics flame retardants. Thus, this is why you'll find them in use on several circuit boards such as CEM3 PCB and FR4 PCB.

Nevertheless, reputable research indicates that halogen-based retardants emit a toxic smell when burning. Therefore, halogen gases are hazardous substances and are unfit for use in the manufacturing of circuit boards. In addition, they are a deadly carcinogen to humans.

Thus, the European Union and China have banned the use of these hazardous substances in PCBs. Among those excluded include:

- polybrominated diphenyl ethers (PBDE)

- polybrominated biphenyls (PBB)

It is essential in enabling sustainable development.

How Do Halogen-free PCBs Be Fire-Resistant?

Printed Circuit Board with many electrical components

Primarily, halogen-containing flame retardants were favored because of their fire resistance property. Hence, this begs how the alternative halogen-free PCBs are fire-resistant.

Ceramics and metal PCBs are naturally non-toxic and flame resistant. Examples include copper substrate PCBs and aluminum PCBs.

However, it is essential to note that metal substrate halogen-free laminates feature either nitrogen or phosphorus retardant. A substrate containing a phosphorus-based retardant will form meta-polyphosphoric acid after burning.

The acid evolved from the combustion is a solid dehydrating agent. Consequently, it blocks the air supply, which stops further explosion. Thus, it'll form a carbonized film covering the polymer resin containing the phosphorus retardant.

Special Offer: Get $100 off your order!

Email [email protected] to get started!

How to Determine Halogen-free PCB Materials?

Circuit boards soldering and testing.

Halogen-free products don't necessarily mean that there is no halogens present. Instead, it implies that the dangerous chemical is present in trace amounts.

Hence, international bodies have designated the allowed upper limits of the chemical substances to mitigate health risks.

For instance, according to The International Electrotechnical Commission (IEC), halogen-free implies:

- Less than 900 ppm of bromine and chlorine.

- At most, 1500 ppm total concentrations of halogens.

Similarly, the IPC requires electronic components to have less than 500 ppm chloride flux solid content. Thus, to calculate the flux stable for bromide and fluoride, you must adjust their molecular weight difference.

This way, you can calculate their flux content as though they were chlorine-based components.

Halogen-Free PCB Materials

A microprocessor on a circuit board

The following are the halogen-free FR4 materials:

- Ventec's VT-447

- ShengYi's S1165, S6015, S1165M and S1550G

- IT-170GRA1TC by ITEQ

- Panasonic's R1566S, R1566WN, and R1566.

Also, there are halogen-free substrates that include:

- Materials with nitrogen and phosphorus instead of halogens

- Halogen-Free solder mask ink.

The Challenge of Designing Halogen Free PCBs

A red computer circuit board

Earlier, we mentioned that the electronics industry has regulations on halogen levels. You can detect the amount of ionically bonded halogens. However, halogens form covalent bonds.

Thus, the tests available in the electronic industry may not efficiently detect the presence of hazardous materials. The solution is to ensure that you exceed the IEC and IPC standards.

Also, it is essential to ensure that electronic PCB boards lack Tetrabromobisphenol A (TBBPA). It is usually common in laminates. Hence, in the manufacturing process, companies should use alternative raw materials. Reactive phosphorus-based laminate can be a handy alternative.

Advantages of Halogen Free PCBs

Vector set of isometric printed circuit boards.

- They have better electrical insulation than halogen-based electrical products.

- These PCBs feature a relatively more minor thermal expansion coefficient than halogen retardants.

- Additionally, they feature a relatively high glass melting point.

- Also, they have better thermal properties (reliability) than their halogen-based counterparts.

- Moreover, they are safe for human health as they don't pose health risks upon disposal.

- Lastly, they feature slower moisture or water absorption rate.

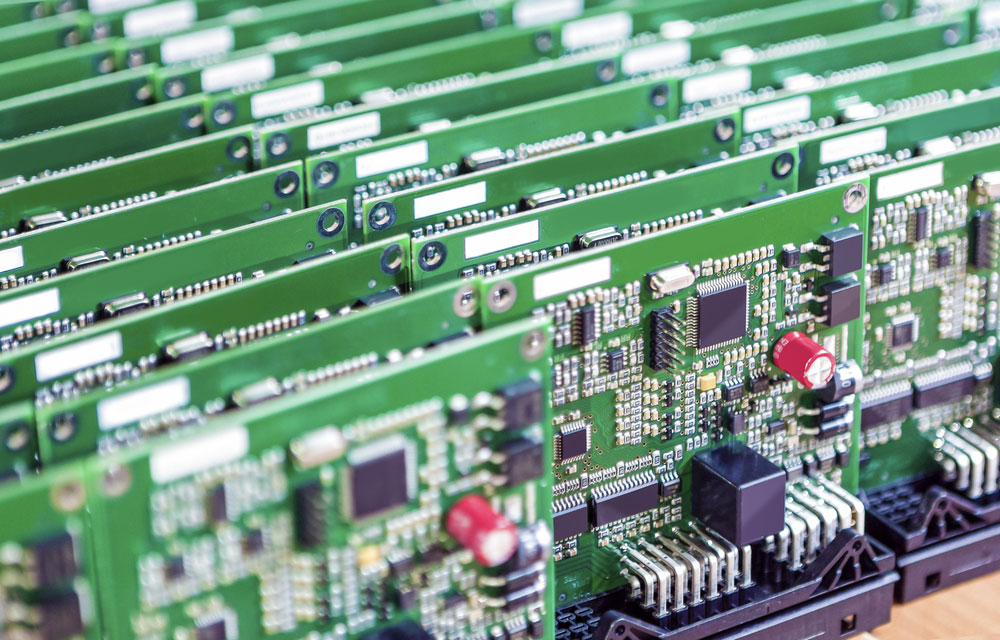

What's Special in Halogen-Free PCB Manufacturing and Assembly?

Different types of circuit boards.

- Halogen-free circuit boards require more substantial power to drill- Unlike the halogen-based PCBs, these have a higher mechanical strength. Thus, due to their mechanical properties, they will need more power supply to drill holes.

- These circuit boards exhibit lower resistance to alkali stripping solution. They have a more down soaking time in the alkali solution. Hence, their wet time should be significantly limited.

- They require a higher temperature for reflow soldering during assembly. Thus, the manufacturer must solder with at least 20 degrees more than conventional PCBs.

Ourpcb: Halogen-Free PCB Manufacturer to the Highest Level

Are you in the electronics industry looking for PCB boards that are safe from bromine exposure? Look no further than OurPCB. We are a market leader in manufacturing PCB products that take environmental protection into account.

We are aware of the significant impact of the absorption of halogen into the body. Thus, we have effective alternatives that also deliver top-notch performance. Reach out to us to order ceramic PCBs and copper substrate PCBs, among other environmentally friendly options.

Also, if you have any queries, talk to us.

Back to top: Halogen-free PCB

Special Offer: Get $100 off your order!

Email [email protected] to get started!