Knowing the difference between countersink vs. counterbore is important to make sure your PCBs and other projects are of the highest quality. Drilling holes might seem like a minor detail, but getting this right can take your designs to a whole new level.

At OurPCB, we’re committed to designing and manufacturing PCBs for all your needs. Contact us for a free quote ... And learn about countersink vs. counterbore so you can streamline your own PCB designs!

Contents

- What is Countersinking?

- What is Counterboring?

- Key Differences Between Countersinking and Counterboring

- Information Needed for Countersinking

- Information Needed for Counterboring

- PCB Design Considerations

- Countersink Considerations

- Counterbore Considerations

- Advantages of Countersinking

- Advantages of Counterboring

- What Tools are Needed to Create Countersink and Counterbore Holes?

- Countersink Tools

- Counterbore Tools

- Symbols and Specifications

- Countersink

- Counterbore

- What Other Types of Holes are Used in Machining?

- Drilled Holes

- Tapped Holes

- Plated Through-Holes (PTH)

- Blind Vias

- Buried Vias

- Microvias

- Non-Plated Through-Holes (NPTH)

- Via-in-Pad

- Backdrilled Holes

- Get in Touch!

What is Countersinking?

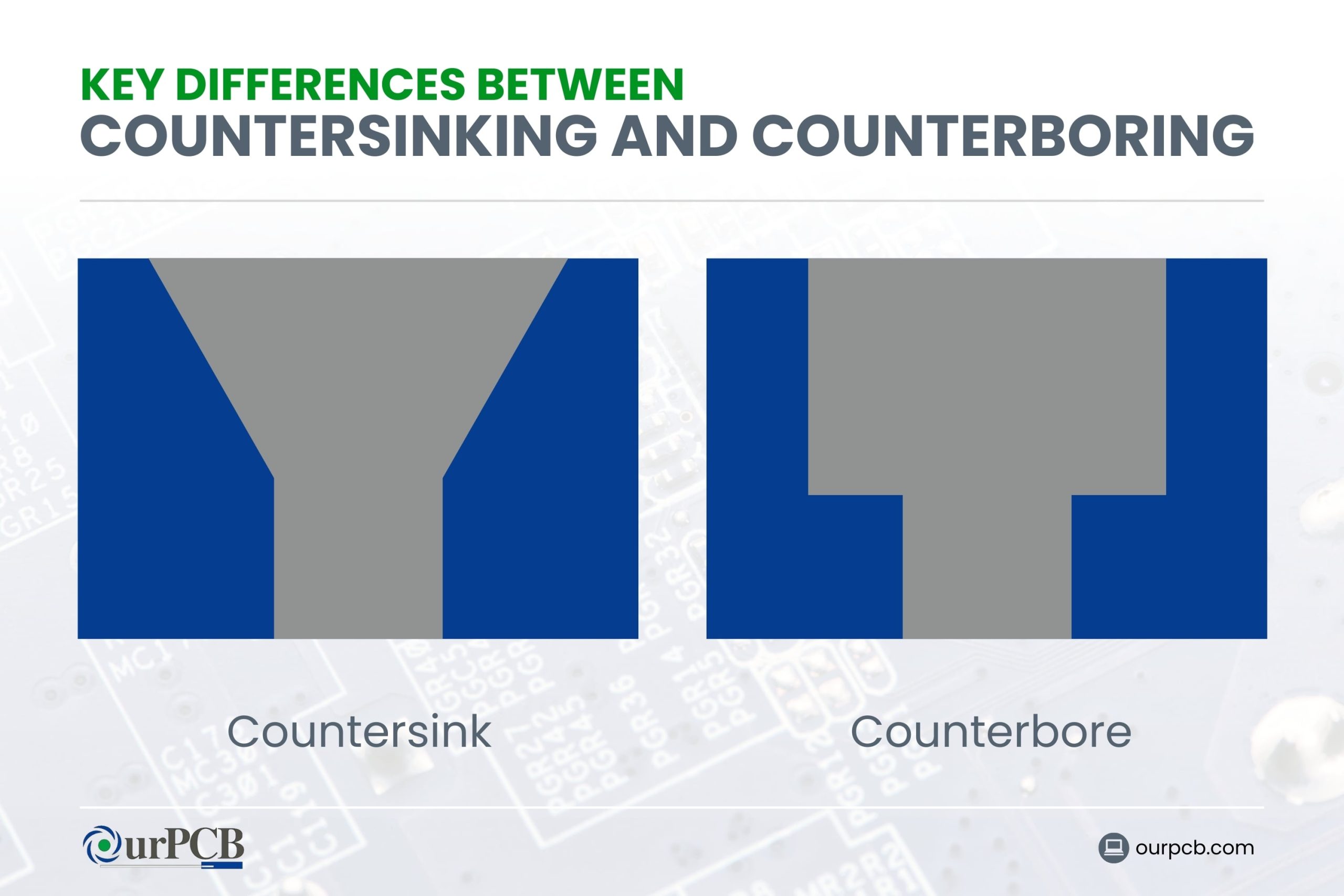

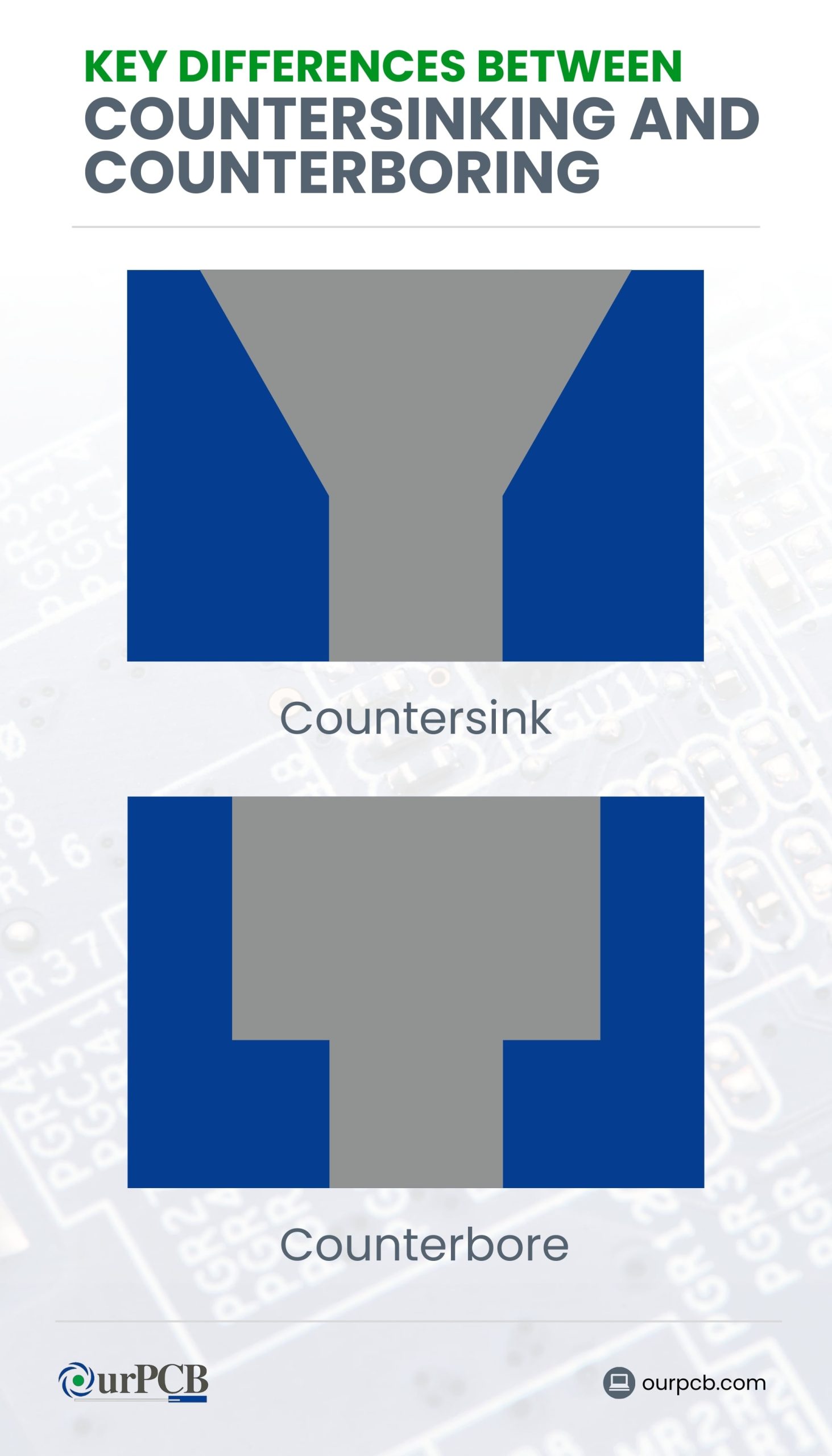

Countersinking is a machining process used to create a small, shallow, conical hole in a material. This hole is designed to allow the head of a countersunk screw or bolt to sit flush with or just below the surface of the material.

The main purpose of countersinking is to provide a smooth, flat surface for fastening, which helps to avoid snagging or interference from protruding screw heads. This process is typically used in woodworking, metalworking, and plastic fabrication.

A specialized tool called a countersink bit is used to create the conical shape at the top of a pre-drilled hole. The angle of the countersink usually matches the angle of the screw head, which is commonly 82 degrees in the United States.

What is Counterboring?

Counterboring is a machining process used to enlarge a portion of an existing hole to create a cylindrical recess. This recess allows the head of a bolt or screw to sit flush with or below the surface of the material. Unlike countersinking, which creates a conical shape, counterboring creates a flat-bottomed hole.

The process involves using a counterbore tool, which has a pilot to guide the cutter into the pre-drilled hole and make sure it’s accurate. The diameter and depth of the counterbore are determined by the size of the screw or bolt head that needs to be recessed.

Key Differences Between Countersinking and Counterboring

When working on projects that involve screws or bolts, understanding the differences between countersinking and counterboring is essential. Both techniques are used to create recesses in materials, but they serve different purposes and are suitable for different applications. We’ve outlined the key differences below:

| Aspect | Countersinking | Counterboring |

|---|---|---|

| Purpose and Application | — Creates a conical hole for the screw head to sit flush with or below the material surface — Used for flat-head screws |

— Creates a cylindrical hole with a flat bottom, allowing the screw head or bolt to sit entirely within the hole — Used for socket-head or cap screws |

| Tools | — Uses a countersink bit, which has a conical shape — Common angles: 82° for standard screws, 90° for other applications — Bit designed to match screw head's angle |

— Uses a counterbore bit (a larger drill bit with a flat cutting edge) — Often includes a pilot bit for accurate centering over pre-drilled hole — Counterbore size should match screw for precise recess |

| Appearance | — Conical, tapered hole — Streamlined finish |

— Cylindrical, flat-bottomed hole — Robust, industrial finish |

| Structural Differences | — Allows for a flush finish — Reduces snagging or catching on the screw head |

— Provides more depth — Allows for a stronger hold or significant recess if necessary |

| Common Uses | — Ideal for projects prioritizing appearance and smooth material surfaces — Typical uses: furniture making, cabinetry, decorative installations |

— Best for strong hold requirements and concealed or protected screw heads — Commonly used in machinery assembly, automotive applications, heavy-duty construction |

Information Needed for Countersinking

- Board side (top or bottom)

- Hole wall plating (plated or non-plated)

- Primary drill diameter (inner shaft)

- Major diameter (surface)

- Angle of tapered drill

- Depth of countersink

Information Needed for Counterboring

- Board side (top or bottom)

- Hole wall plating (plated or non-plated)

- Primary drill diameter (inner shaft)

- Major diameter (surface)

- Depth of counterbore

Special Offer: Get $100 off your order!

Email [email protected] to get started!

PCB Design Considerations

When designing printed circuit boards, choosing the right holes can make a big difference to the effectiveness and aesthetics of your projects.

Countersink Considerations

Countersink holes are conical, allowing flat-head screws to sit flush with the PCB surface. This design is particularly useful in compact electronic devices where space is limited, such as smartphones and smartwatches. In addition, countersinks offer a smooth surface, which reduces potential interference with other components and improves the aesthetic finish of the PCB.

However, countersinks can pose challenges, especially in high-layer-count PCBs. The precision required to drill angled holes can lead to registration issues, causing alignment problems across multiple layers. They can also increase the risk of trace breakage on outer layers due to the material removal process, which can weaken the board’s structure.

Counterbore Considerations

Counterbore holes are cylindrical with flat bottoms, and they provide a stable surface for socket cap screws. This makes counterbores ideal for applications requiring strong and secure mounting. The parallel sides of a counterbore hole eliminate the need for precise angle measurements, simplifying the manufacturing process and reducing the risk of misalignment.

Counterbores are distinctly advantageous for internal PCB layers. They also allow for the inclusion of spacers or washers, which can enhance the board’s overall mechanical strength.

Typically, the diameter of a PCB counterbore is 0.1 to 0.5 mm larger than the screw, and the depth is usually 50 to 75% of the board thickness, ensuring a secure fit without compromising the board’s integrity.

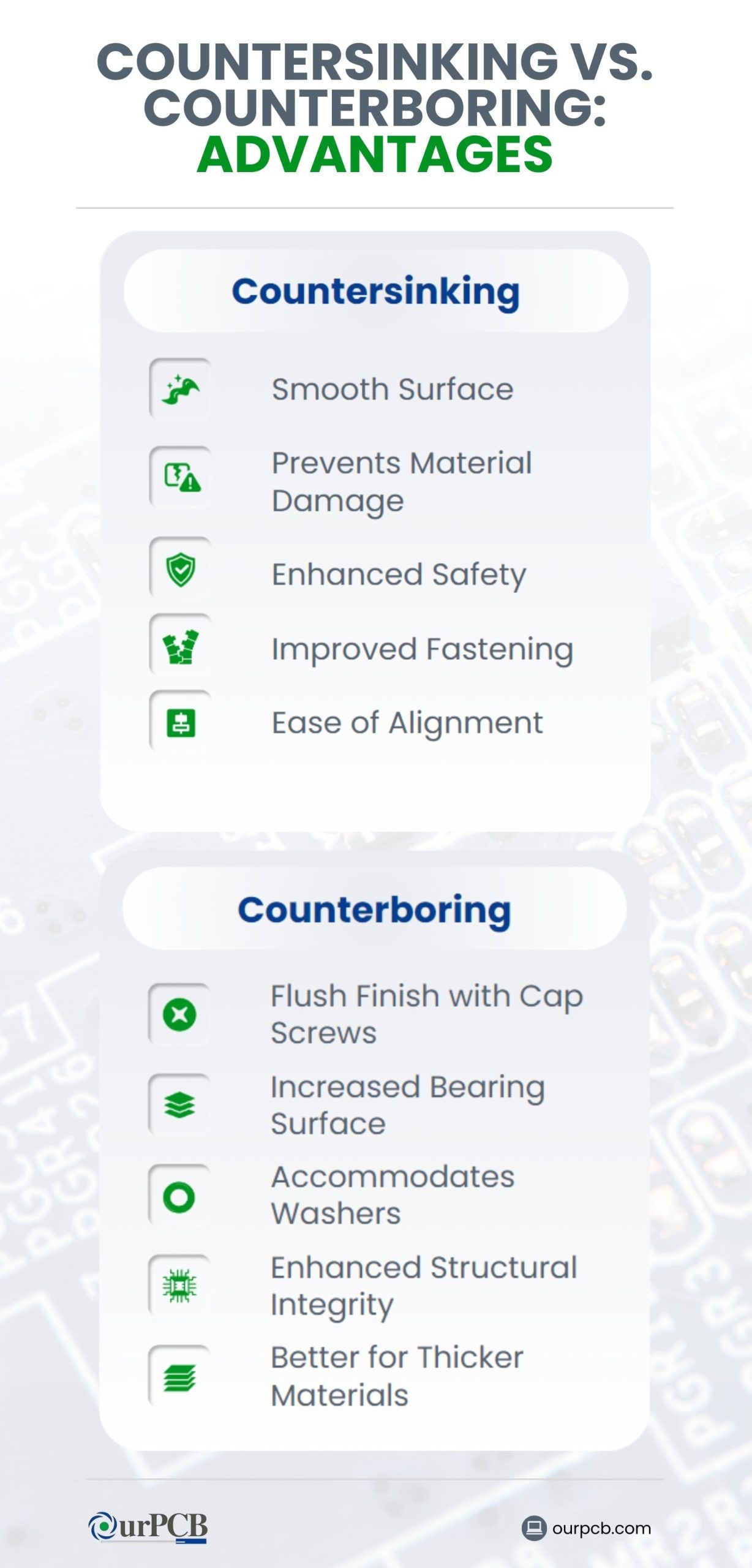

Advantages of Countersinking

- Smooth Surface: Countersinking allows the screw or bolt head to sit flush with or below the surface of the material. This provides a smooth and aesthetically pleasing finish.

- Prevents Material Damage: By creating a tapered hole, countersinking helps prevent material damage such as splitting or cracking, especially in softer materials like wood and plastic.

- Enhanced Safety: A flush or recessed screw head reduces the risk of snagging or catching on the screw, enhancing safety.

- Improved Fastening: Countersinking makes sure that the screw or bolt head fits snugly into the material, which results in better load distribution and a more secure fastening.

- Ease of Alignment: Countersunk holes help in aligning parts accurately during assembly, reducing the chances of misalignment. This can save time and improve the precision of the final product.

Advantages of Counterboring

- Flush Finish with Cap Screws: Counterboring creates a flat-bottomed hole that allows cap screws, bolts, or other fasteners to sit completely flush with the surface. This is essential in applications where protruding fastener heads could cause issues, as in machinery or automotive assemblies.

- Increased Bearing Surface: The larger diameter of the counterbore hole provides a greater bearing surface for the fastener head, which distributes the load more evenly and reduces the risk of fastener failure.

- Accommodates Washers: Counterboring can be designed to accommodate washers under the screw or bolt head. This provides additional load distribution and decreases wear on the material surface.

- Enhanced Structural Integrity: By embedding the fastener head within the material, counterboring helps protect it from external forces and potential damage. This is particularly effective in environments where the fasteners might be exposed to harsh conditions or impacts.

- Better for Thicker Materials: Counterboring is ideal for thicker materials where a deeper, larger hole is needed to house the fastener head. This method is commonly used in heavy-duty construction, metal fabrication, and engineering projects.

What Tools are Needed to Create Countersink and Counterbore Holes?

To create countersink and counterbore holes, you’ll need specific tools designed for each type of hole. Here’s a breakdown of the essential tools required:

Countersink Tools

- Countersink Drill Bit: These drill bits are specifically designed to create a cone-shaped hole. They come in various sizes to match different screw heads.

- Cordless Drill or Drill Press: A power drill or drill press is essential for driving the countersink bit into the material.

- Depth Stop: This tool helps ensure consistent depth for multiple countersinks, which is crucial for a professional finish.

- Chamfer Cutter: Used to create a beveled edge around the hole, improving the aesthetic and functionality of the countersink.

Counterbore Tools

- Counterbore Drill Bit: Counterbore bits are designed to create a flat-bottomed hole, often with a pilot hole in the center. They come in different sizes to fit various bolt heads.

- Cordless Drill or Drill Press: A power drill or drill press is used to drive the counterbore bit into the material.

- Forstner Bit: Forstner bits can also be used for counterboring as they create flat-bottomed holes with clean edges.

- Depth Gauge: This tool helps maintain a consistent depth for counterbore holes, ensuring uniformity across multiple holes.

- Boring Bar: Sometimes used for precise enlarging of existing holes to create counterbores, especially in metalworking.

Symbols and Specifications

Countersink

The symbol for a countersink is usually a “V” shape or an inverted triangle, which indicates the tapering nature of the hole.

Specifications

- Angle: Common countersink angles include 82°, 90°, and 100°. 82° is the most frequently used angle in the United States.

- Diameter: The diameter of the countersink is specified based on the screw size and the desired head flushness or protrusion.

- Material: Countersinks are made from high-speed steel (HSS), carbide, or cobalt, suitable for various materials such as wood, metal, or plastic.

Counterbore

The symbol for a counterbore is a “⊔” shape or a horizontal rectangle with a vertical rectangle underneath, showing the flat-bottomed enlargement of the hole.

Specifications

- Diameter: The counterbore diameter is determined by the bolt or screw size that will fit into the counterbored hole. Standard sizes correspond to common bolt sizes.

- Depth: Counterbore depth is specified to allow the fastener’s head to sit flush or below the surface of the material.

- Material: Like countersinks, counterbores are also made from HSS, carbide, or cobalt, designed to work with a variety of materials.

What Other Types of Holes are Used in Machining?

Drilled Holes

Drilled holes are created using a drill bit to remove material and create a cylindrical cavity. These are some of the most common types of holes used in machining and can vary in diameter and depth depending on the requirements. Drilled holes are used in a wide range of applications, including attaching components, creating pathways for wires, and preparing surfaces for threading.

Tapped Holes

Tapped holes are drilled holes that have internal threads cut into them. These threads allow screws or bolts to be securely fastened. Tapping is typically done using a tap tool that matches the desired thread size and pitch. Tapped holes are essential in many assembly processes where components need to be fastened together tightly.

Plated Through-Holes (PTH)

Plated through-holes are holes that have been coated with a layer of metal, usually copper, to allow electrical connections between different layers of a printed circuit board. This plating provides a reliable electrical connection and helps in the overall functionality of the PCB. PTHs are crucial for connecting components on different sides of the board.

Blind Vias

Blind vias are holes that connect an outer layer of a PCB to one or more inner layers but do not go all the way through the board. They are implemented to save space on the PCB and to connect components on different layers without affecting the opposite side. Blind vias are typically smaller than through-holes and are often used in high-density PCB designs.

Buried Vias

Buried vias are similar to blind vias but are located entirely within the inner layers of a PCB. They don’t reach the outer layers, making them invisible from the surface. Buried vias are used to connect different inner layers without disturbing the outer layers, allowing for more complex and compact PCB designs.

Microvias

Microvias are extremely small vias typically used in high-density interconnect (HDI) PCBs. They have a diameter of less than 150 micrometers and are often used in advanced electronic devices where space is at a premium. Microvias can be blind or buried and are created using laser drilling techniques.

Non-Plated Through-Holes (NPTH)

Non-plated through-holes do not have a conductive coating. These holes are frequently used for mechanical mounting purposes, such as aligning and securing components or the board itself within an assembly. NPTHs don’t serve an electrical function, but are important for the physical structure of the PCB.

Via-in-Pad

Via-in-pad technology involves placing vias directly in the pad where a component lead or ball will be soldered. This technique helps reduce inductance and resistance, improving electrical performance. Via-in-pad is commonly used in high-speed and high-frequency circuit designs to enhance signal integrity.

Backdrilled Holes

Backdrilled holes are used to remove the unused portion of a through-hole that extends beyond the last connected layer in a PCB. This process helps to eliminate stub effects that can cause signal integrity issues, especially in high-speed circuits. Backdrilling is a technique used to optimize the performance of critical signal paths.

Get in Touch!

OurPCB is ready to manufacture PCBs to your exact standards. Get in touch with us and let’s take your PCB projects from design to reality!

Back to Top: Countersink vs Counterbore | Differences, Tools, Drills

Special Offer: Get $100 off your order!

Email [email protected] to get started!