One vital aspect of PCB design is to achieve signal integrity and high-speed data transfer rates. It is often a problem in high-frequency PCB designs where a transmitted signal undergoes distortion due to multiple layers. That is where a back drill PCB comes into play.

Here, we cover how to use back drilling to contain the signal noise, quantization noise, and other undesired effects in high-speed PCB.

Contents

- What is Back Drilling in PCB?

- General Characteristics of Back Drill PCBs

- Back Drilling Advantages and Disadvantages

- Advantages

- Disadvantages

- What Kind of PCB Needs Back Drilling?

- Factors That Influence the Effectiveness of Back Drilling

- Board Material and Thickness

- Via Size and Spacing

- Trace and Plane Clearance

- How Much Residual Stub Can Remain After Backdrilling?

- Back Drilling Examples

- Back Drilling PCB Design Guidelines

- Back Drill Table with Design Values

- Steps for a Back Drill

- Difficulties of Back Drilling Process

- Back Drilling Depth Control

- Back Drill Accuracy Control

- Applications of Back Drilling

- Back Drill PCB Cost

- Back Drill vs. Blind Via

- Most Effective Alternatives To Back Drilling

- Back Drill FAQs

- Why is Back drill also called control depth drilling?

- How much should the dielectric thickness design be?

- Name alternate construction techniques that are useful to minimize stub length other than back drilling.

- Conclusion

What is Back Drilling in PCB?

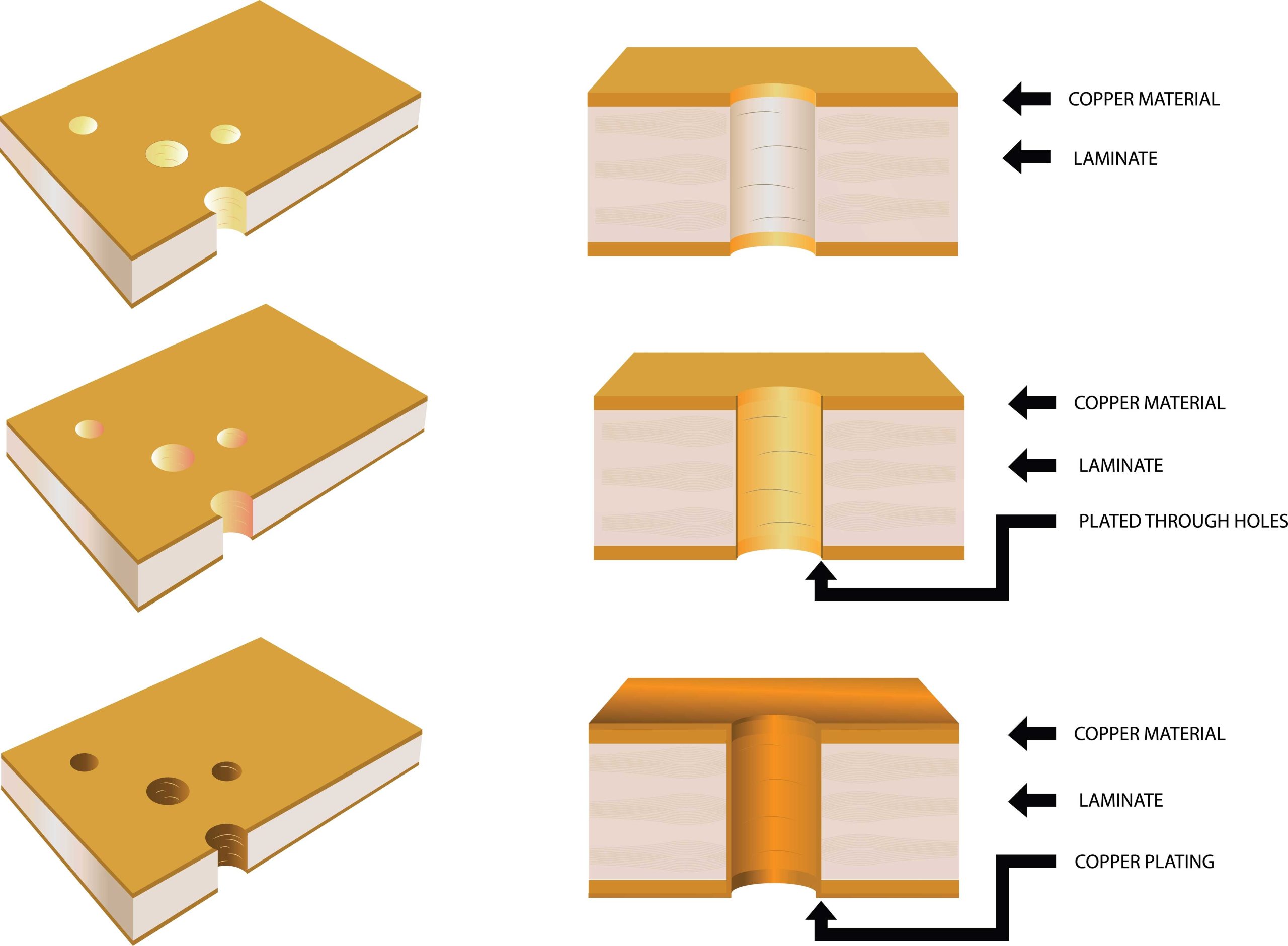

Also known as Controlled Depth Drilling (CDD), Back drilling involves using a drill bit to remove unused portions of copper barrels or stubs from a Plated-Through-Hole or Via in multilayered PCB boards. It is because, in some PCBs, some stubs are a nonworking part of the via and affect signal integrity.

We need an opening slightly larger than the PTH to drill back to remove the conductive region from the through hole. A perfectly done back drilling does not affect the PCB's performance.

(Different drill bit sizes).

General Characteristics of Back Drill PCBs

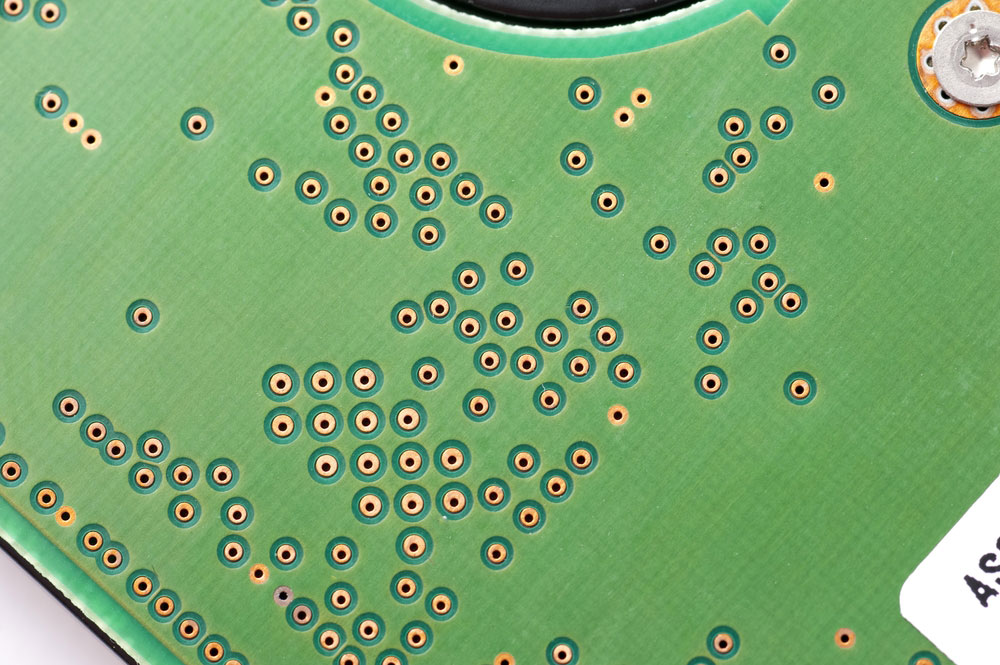

Back drill PCBs are usually rigid on the rear section to enable drilling and remove the unused section. These boards also normally have at least eight layers because such thick stacks are more likely to have plated-through or vias with unused sections.

A PCB with several plated-through holes

Consequently, these boards are 2.5mm thick or more, with the minimum hole size being 0.3mm in diameter and 0.2mm wider than the via or plated-through hole due to the removed materials. Lastly, the tolerance of the backdrill depth must be +/-0.05mm.

Back Drilling Advantages and Disadvantages

Advantages

- This technique reduces the number of bit mistakes per unit of time or Bit Error Rate (BER).

- It increases the channel bandwidth and data rates by removing stubs that cause distortion.

- Also, there is a decrease in signal layer distortion problems called deterministic jitters. These include timing errors caused by EMI, noise-related propagation, and via-to-via crosstalk in the PCB.

- Resonance frequency mode excitation is reduced.

- Better impedance matching and reduces stubs EMI/EMC radiation due to reduced signal attenuation.

- Easy to produce and cost-effective.

Disadvantages

- Back drilling is only suitable for high-frequency boards between 1GHz and 3GHz with no viable blind vias.

- A unique technique must be employed to avoid damaging traces and planes lateral to the backboard hole.

What Kind of PCB Needs Back Drilling?

Generally, PCB boards with circuit tracks carrying signals at rates greater than 1Gbps are viable for back-drill designs. Through-holes are drilled from top to bottom of the PCB board. As a result, it yields high-quality signal transmission. Most times, stub removal occurs via the hole of the PCB interconnection. It happens when the trace connecting the via holes is close to the top PCB layers. Therefore, it results in signal reflections.

There are alternative construction techniques. Examples include laser-drilled vias and blind and buried vias. These alternate arrangements for stacking also reduce signal reflection. However, these options are costly for many high-density PCBs or backplanes/midplanes. For this reason, the only viable option is back drilling to remove the via stub.

Furthermore, some holes on PCB boards are less suitable in their design than blind holes, especially in multilayer printed circuit boards. If the PCB has deterministic jitters, strong BER, or other EMI issues, then PCB back drilling is essential.

Factors That Influence the Effectiveness of Back Drilling

Board Material and Thickness

is the most common material used to build PCBs and it is fairly easy to drill regardless of its thickness. But high-performance circuit boards built using metal (metal cores) and ceramic have some drilling challenges because the materials are relatively tougher than FR4. These materials are more thermally conductive as well, so you’ll need different drilling parameters and bits to get the job done.

Via Size and Spacing

Small vias spaced close to each other require tiny drill bits to conduct more precise drilling, but large vias with more spacing in between give you more leeway. But you’ll need a larger drill bit and possibly do multiple passes to eliminate the unwanted copper and substrate materials.

Trace and Plane Clearance

While backdrilling, it is important to avoid damaging the board by drilling through the copper power/ground planes and transmission lines. Suppose the clearance between these components and the drill bit is too narrow. In that case, it might be better to avoid backdrilling, use an extremely tiny drill bit with utmost precision, or avoid mechanical drilling. Laser and plasma drilling options are more accurate.

How Much Residual Stub Can Remain After Backdrilling?

When you decide to backdrill your multilayer PCB, you must determine how far you’ll dig in or the stub length you want to remain. Determining this value depends on several factors, but the key one is signal integrity.

The longer the stub length that remains, the higher the signal loss, so the shorter it is, the better. Here’s a breakdown of how to determine the residual stub to leave behind based on the signal loss.

| Residual Stub Length | Approximate Signal Loss |

| 1 mil | 0.25% |

| 2 mils | 0.5% |

| 5 mils | 1.25% |

| 10 mils | 2.5% |

| 20 mils | 5% |

| 40 mils | 10% |

| 60 mils | 15% |

| 100 mils | 25% |

| 200 mils | 50% |

Back Drilling Examples

A through-hole via, in a twelve-layer stack-up, goes from internal layers one through twelve. If the visa only has signals from layers one to three, you create the via stub using specific-sized drill bits.

The back drill should be at least eight millimeters in diameter over the primary drill size.

However, ten millimeters is ideal. Hence, it prevents the back drill from accidentally drilling through adjacent layer pairs.

The via stub begins after layer three and continues to layer twelve. It creates resonance and reflections at very high frequencies, attenuating the signals at the resonant frequency.

Back drilling removes unwanted copper plating from layer three to layer twelve, reducing the stub length.

(Plated-through holes on a back drill PCB)

Special Offer: Get $100 off your order!

Email [email protected] to get started!

Back Drilling PCB Design Guidelines

The first step is to use the high-speed routing requirements to identify the back drill locations in the PCB’s inner layers.

Check the controlled impedance routing on high-speed signal lines to avoid signal losses caused by reflections and reduce the number of back-drilled vias on the PCB because the process is expensive and time-consuming.

Consider implementing more buried and blind vias than using back drilling.

Plated-through vs. non-plated-through holes

But if you can’t avoid them, use a back drill chart to determine the depth for each signal layer and the best drill diameter to use, which should prevent errors that cause further signal integrity issues.

Consequently, you should pick the most appropriate back-drilling process. The three most common ones are mechanical drilling, laser ablation, and plasma etching.

When drilling, avoid areas that are too close to the edge to avoid PCB or drill bit damage. Also, do not drill under BGA packages and connectors and separate the back-drilled and non-back-drilled holes using different tool numbers.

Try to make the annular ring width equal to or larger than the anti-pad clearance to maintain structural integrity.

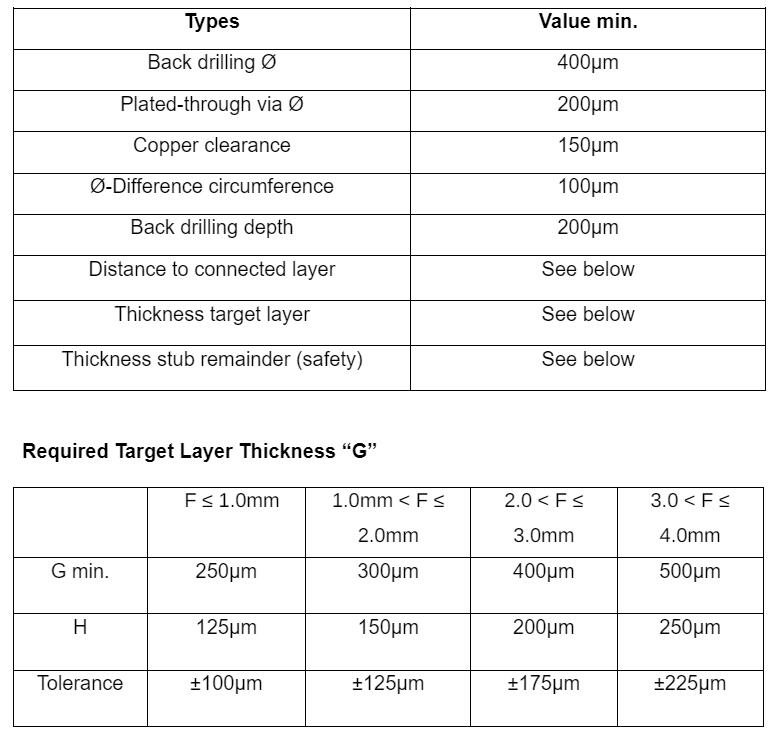

Back Drill Table with Design Values

Key

Gmin. = Thickness Target Layer.

H = Distance To Connected Layer.

Tolerance = Thickness Stub Remainder.

Steps for a Back Drill

Here are the back-drilling steps you need to follow in the manufacturing process of a PCB:

- Locate the first drilling holes using the positioning holes provided on the PCB.

- Place a dry film to seal the positioning holes before electroplating.

- Electroplate the first drilled PCB board layer.

- Transfer outer layer graphics on the electroplated PCB.

- Once there is an outer layer pattern, perform graphic plating on the PCB.

- Ensure dry film sealing treatment on the positioning hole before graphic plating.

- Use the same positioning hole for the first drill for back drilling.

- Back-drill the electroplated holes that need drilling.

- Clean the back drilling holes properly to eradicate residual drill chips in the back drilling.

Difficulties of Back Drilling Process

Back Drilling Depth Control

Utilizing the depth control function of the drill to process the blind vias is essential to back drilling. Usually, the tolerance relies on the accuracy and the tolerance of the medium thickness of the equipment.

Also, accuracy depends on external factors like the drill's resistance, the drill bit's angle, etc. For this reason, selecting suitable drilling materials and methods is vital to achieving accurate control. In turn, you achieve better results.

Back Drill Accuracy Control

Ultimately, back drilling depends on the hole diameter of the primary drill. This feature makes the accuracy of the secondary drilling coincidence vital. Therefore, it affects the quality control of the PCB going forward.

Also, note the essential design rules like board expansion and contraction, drilling equipment accuracy, drilling methods, etc., before commencing the back drill.

Applications of Back Drilling

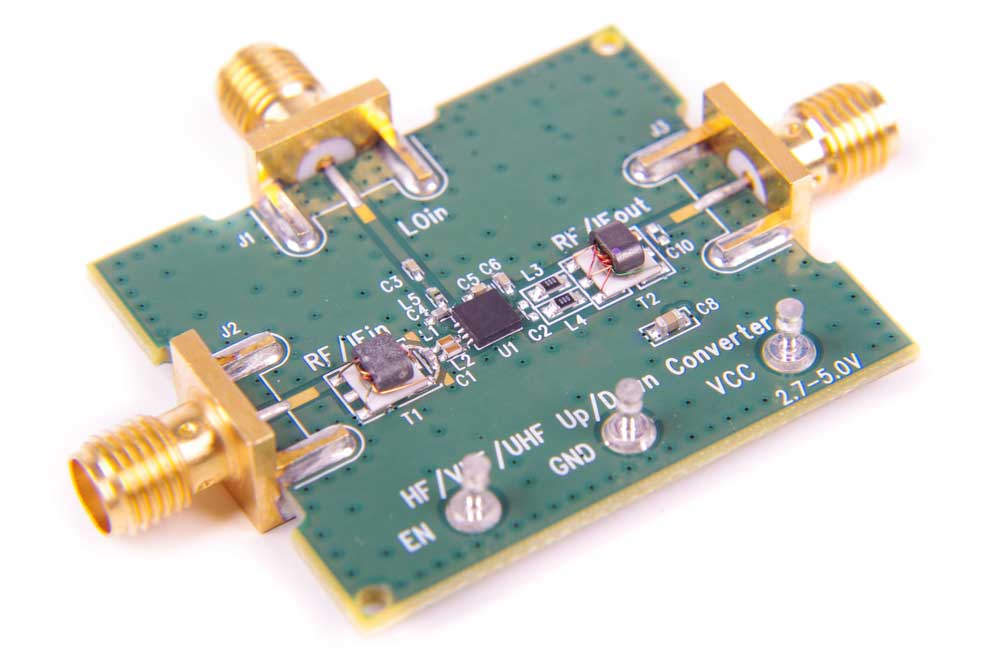

The primary purpose of PCB back drilling is to eliminate signal integrity issues caused by non-functional via stubs, which makes it common in high-frequency, radio-frequency, and microwave PCBs that can experience signal losses due to such issues.

A radio frequency mixer evaluation board

Back drilling is also important in complex multilayer PCBs that have over 20 layers, high-speed digital boards that have multi-gigabit data channels, HDI boards, RAM memory routing (DDR3 and DDR4), network switching equipment, servers, telecommunication equipment, etc.

Basically, all modern devices that handle high-speed, high-frequency transmission and have multiple layers (8+) require backdrilling if they have signal-reflecting plated through holes to prevent EMI and signal losses.

Back Drill PCB Cost

Back drilling introduces a new step in the PCB manufacturing process which can increase the cost of production by as much as 20% if the drilled holes are many.

Generally, the PCB fabrication process starts with inner-layer core fabrication, followed by scrubbing, laser direct imaging/photolithography, oxide conversion, stack-up preparation, hot pressing, depinning/cold pressing, inter-layer drilling, drilled hole inspection, through-hole plating, desmearing, and deburring.

If the PCB requires back drilling, the additional process comes in between through-hole plating and besmearing.

Although expensive, the process might be necessary and can lead to better PCB performance and component density that offsets this additional cost.

Back Drill vs. Blind Via

Unlike back drills, blind vias don’t go all the way through to the other side; they connect the outer layer to the inner layers up to a specific point, meaning they don’t have an unwanted plated copper hole section that goes to the other end.

A PCB with gold-plated through holes

This design eliminates reflections on the extra copper hole that can cause signal losses or introduce EMI, which makes them a better solution than back-drilled through holes.

Additionally, they are cheaper to fabricate because they don’t introduce an extra manufacturing step and eliminate the risk of PCB damage caused by back drilling.

Most Effective Alternatives To Back Drilling

The most effective alternatives are buried and blind vias, where the buried via interconnects the board’s internal layers without being exposed to the outside.

You can also rearrange the PCB layers to avoid back drilling and the challenges it poses.

Back Drill FAQs

Why is Back drill also called control depth drilling?

It is because a back drill requires specific calculations. Hence, it achieves the depth necessary for accurate results during the drill.

How much should the dielectric thickness design be?

The ideal dielectric thickness design is at least 0.2mm.

Name alternate construction techniques that are useful to minimize stub length other than back drilling.

They are laser-drilled vias, Blind and Buried vias, and alternate stack-up arrangements.

Conclusion

A back drill is a useful drilling process for removing problematic stubs from solder masks on a PCB. Problematic stubs often cause deterrent jitters like signal crosstalks. It is essential in improving signal integrity in hole technology boards.

Special Offer: Get $100 off your order!

Email [email protected] to get started!