Soldering flux is critical for the soldering process but leaves a corrosive yellow residue that can damage electronic components. So it is imperative to use a PCB flux cleaner to remove the residues after soldering.

We will show you the solder flux remover options for your PCB and the cleaning process to get the job done. Let's get right into it!

Contents

- What Is Flux?

- Types of Flux

- No-Clean Flux

- Rosin Flux

- Water Soluble Flux

- Why You Need To Clean Flux

- Prevent PCB Corrosion

- Prevent Conformal Coating Adhesion Issues

- Enhance the Board's Appearance

- Inhibit Dendritic Growth

- PCB Flux Cleaner: Cleaning of Flux Residue Using Isopropyl Alcohol

- Clean Toothbrush

- Acid Brush

- PCB Flux Cleaner: Flux Residue Cleaning Using Aerosol Flux Cleaners

- PCB Flux Cleaner: Poly Clens

- PCB Flux Cleaner: Ultrasonic Cleaner

- What About Water-Soluble Flux?

- Wrap Up

What Is Flux?

Metals naturally form an oxide coat that prevents further reaction.

This layer causes soldering problems because the melted metal cannot create strong bonds with the oxide coat.

So you will not get the required wetting to form a durable joint.

Solder flux helps the soldering process by corroding the oxide film to expose the metal to better wetting, allowing the molten metal to flow and settle uniformly over the surface.

Flux also aids in the desoldering process.

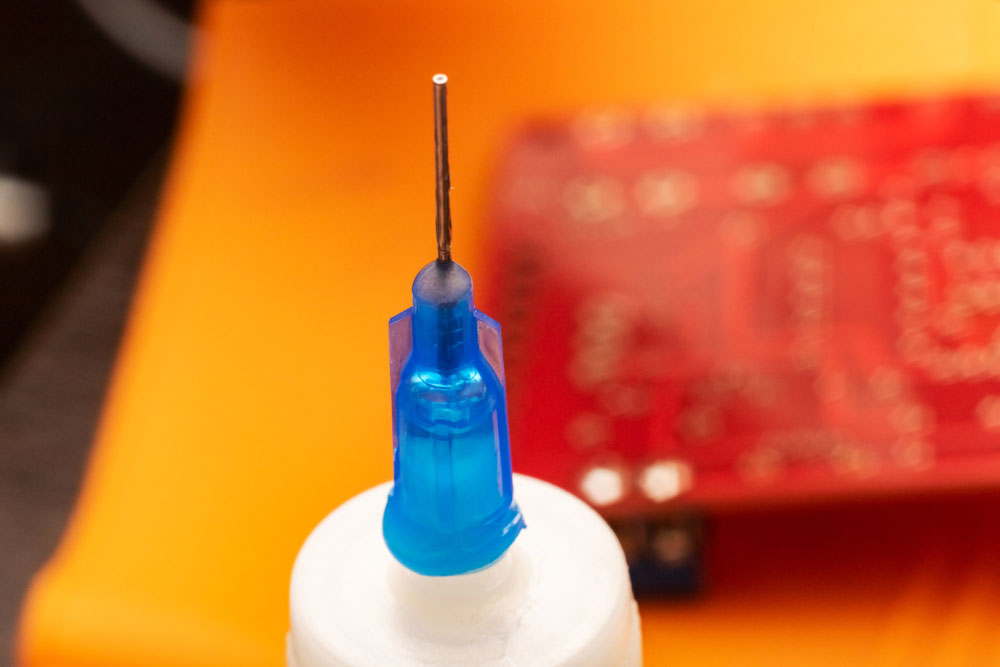

Soldering tools ready for work on a PCB (note the solder flux in the syringe)

Types of Flux

Flux is available in different types that fall into these three categories.

No-Clean Flux

As the name suggests, this flux requires no cleaning after soldering.

Rosin Flux

This flux has a natural resin extracted from pine trees and is available in three sub-categories.

- Rosin (R): Leaves no residue after soldering, but you can only use it on clean surfaces.

- Rosin Mildly Affected (RMA): Has activators for cleaning the solder-coated lands plus component terminations for wetting the adjacent areas.

- Rosin Activated (RA): Leaves more residue after soldering because it is the most active.

A dispenser for Rosin flux

Water Soluble Flux

Also known as organic acid flux, water-soluble flux contains resin mixed with organic materials.

This combination gives good flux activity, resulting in the best soldering and wetting results because it eliminates impurities and oxides.

However, it can contaminate the board if not cleaned properly.

Why You Need To Clean Flux

Flux removal is essential due to the following reasons.

Prevent PCB Corrosion

Flux residue is acidic and can draw moisture from the surrounding air to form an acidic solution.

This acid will corrode the board and sensitive components, leading to failure or unreliability.

A circuit board with flux residue

Prevent Conformal Coating Adhesion Issues

Although conformal coating prevents corrosion, it cannot stick to the board and do its job if there is flux residue on the surface.

Instead, it will lift and peel, allowing moisture from the air to mix with the residue to form a corrosive acid.

Enhance the Board's Appearance

Flux leaves a yellow residue that makes the board look greasy and unclean.

Delivering such a PCB to a customer will make your work look unprofessional.

A technician with flux solder and chip held using tweezers ready for soldering.

Inhibit Dendritic Growth

Flux dust has ions that can join to form a chain after interacting with air. This chain is known as a dendrite, and it is electrically conductive.

So it can cause current leakage or short-circuiting. But dendrites created by no-clean flux are not problematic because the paste has few ionic materials, which get consumed during change activation.

Special Offer: Get $100 off your order!

Email [email protected] to get started!

PCB Flux Cleaner: Cleaning of Flux Residue Using Isopropyl Alcohol

An isopropyl alcohol solution (90% or more) is ideal for cleaning flux residue from circuit boards because it is cheap, has fewer chemicals, and evaporates quickly.

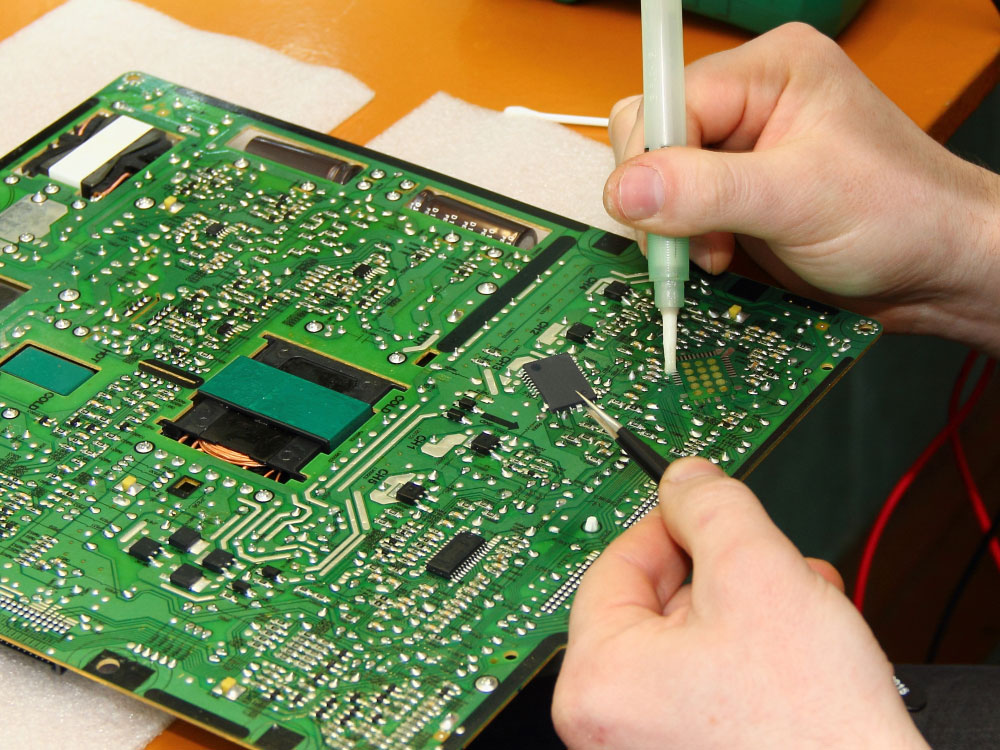

So most people use it with a toothbrush or acid brush, and you can follow these steps to clean flux residue.

Note: It is possible to use acetone in place of ISA.

A 91% isopropyl alcohol solution

Clean Toothbrush

Ensure you have a clean toothbrush, then dip it in ISA. Flip the toothbrush 2-3 times to remove the excess alcohol solution, then gently scrub the residual flux off the board using the brush.

The alcohol should dissolve the residue after repeated scrubbing, but don't apply too much pressure because you might break the joints.

However, the residue does not evaporate like ISA. So use a dry rag to absorb the solution and flux as you clean the area.

Leave the board to dry and clean the toothbrush using distilled water. Once the PCB dries, blow any remaining dust using canned air.

A person cleaning a computer motherboard using an air compressor.

Acid Brush

Before cleaning, cut the brush diagonally to have a long side for removing flux from hard-to-reach places and a short side for scrubbing.

Dip this brush in alcohol, then scrub the board gently to remove the residue.

You can use a liquid dispenser to wet the brush or pour the cleaning solution directly on the board.

Wipe the area using a paper towel or dry rag, then leave the PCB to dry. Finish off by blowing any remaining dust using canned air.

A solution containing 99.9% acetone

PCB Flux Cleaner: Flux Residue Cleaning Using Aerosol Flux Cleaners

ISA evaporates quickly and might not give the solution enough time to remove baked-on flux residue.

So consider using aerosolized solvent blend flux cleaners that dry slowly and are more potent than isopropyl alcohol.

Aerosol packages also have the advantage of being sealed, meaning the pressurized cleaning solution is always contaminant-free.

Plus, the pressure gives extra agitation to remove stubborn flux residue.

We recommend spraying the entire board while holding it at an angle first for general cleaning.

After that, focus on the residue spots using the extension tube included with the can.

This tube increases spray pressure for more intense agitation as you spray with pin-point accuracy.

Rinse the entire area with the spray again for the solution to flow down with the residue.

Some aerosol cleaners come with a brush attachment you can use to scrub stubborn residue.

The solvent flows through the brush, enabling you to spray and scrub concurrently.

PCB Flux Cleaner: Poly Clens

Poly Clens is ideal for immersion cleaning and might provide better cleanup of stubborn flux.

But get a container large enough to submerge the PCB first.

Next, pour Poly Clens inside, then immerse the board. Stir it gently for about 30 seconds to agitate the residue.

Remove the board, rinse it using distilled water, then dry using a heat gun.

The process eliminates brushing, making the cleaning method easier. However, you'll need more solution quantity and a heat gun (or more drying time).

PCB Flux Cleaner: Ultrasonic Cleaner

Ultrasonic cleaners also require board immersion and are ideal for cleaning flux from delicate components because they eliminate brushing (soft bristles can be abrasive to such electrical components).

The process uses high-frequency sound waves to create microscopic bubbles in the cleaning solution.

These bubbles agitate the board surface, which breaks the flux for easy removal when rinsing using deionized water.

The waves and bubbles reach all hidden crevices, making this method ideal for boards with complex or inaccessible geometries.

An ultrasonic cleaner for medical instruments

You can use water, alcohol, or mildly alkaline/acidic solutions, provided they don't have metal cations. And ensure the board dries completely before continuing with assembly or plugging it back.

What About Water-Soluble Flux?

Water-soluble flux is highly corrosive (acidic), so you must eliminate its residue wholly. The only way to do that is to use hot water and a saponifier. Saponifiers are alkaline solutions that react with acids to form soap and glycerin, which are easier to wash off using hot water.

Wrap Up

As you can see, several PCB flux cleaner solutions and methods exist.

However, the one you choose depends on the board's electrical components, the type of flux, and your preference.

But personal preference does not apply with water-soluble flux because you must use a saponifier.

So consider your situation first, then determine which cleaning method to use. And contact us if you need further guidance.

Special Offer: Get $100 off your order!

Email [email protected] to get started!