Are you aware that motor controllers are an integral part of our daily lives? But how, you may ask. Looking around, you'll notice that we use printers, electric cars, airplanes, fuel pumps, motorbikes, and other propulsion systems almost daily. All these devices depend on motor controllers in one way or another, highlighting their importance in electronic circuit design and printed circuit board (PCB) assembly. Understanding how these controllers function can enhance our appreciation of the technology that powers our everyday activities.

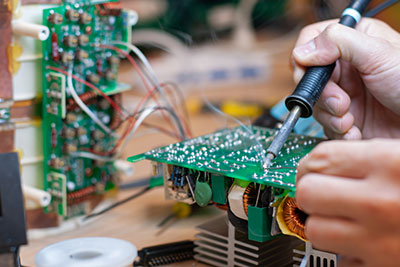

In making a motor controller, among other essential parts, printed circuit boards are one of them. Without a printed circuit board, motor controllers won't function. PCBs connect all the electric components to it.

So, how much do you know about motor control and their applications? Perhaps, just a little. Here, you'll learn more about things such as their functionality, types, and applications. Also, you'll understand how to go about choose suitable ones, among other things.

(PCB board in the motor controller)

Contents

1. What are motor controllers?

To begin, motor controllers are electronic or electric devices that regulate torque, motor speed, and position output of equipment. A motor controller may come with either an automatic or manual means to stop or start a motor. Without a motor controller, a motor lacks protection from overloads, an aspect that could result in electrical faults.

You may think that motor controllers aren't relevant, but they are a crucial piece of tools in the real sense. Motor controllers are necessary as the microcontroller usually provide Amps of around 0.1. That's too little, considering that plenty of motors need several Amps. Motor controllers may aid you to achieve the required Amps.

(Close view of an unfinished motor controller)

2. How do motor controllers work?

A lot of people do not understand how microcontrollers work. Still, hundreds of them aren't bothered in knowing how they work. So, how do these devices with several coils of wires and magnets work? It's much simpler than you can imagine or even think.

Electric power does come in two ways: The Alternating Current (AC) and the Direct Current (DC). As you may know, Direct Current always flows in the same direction. But on the other hand, the Alternating Current moves from a negative to positive direction a lot. AC motors get powered by the AC. Now, the faster the current manages to switch direction, the quicker the motor gets to spin.

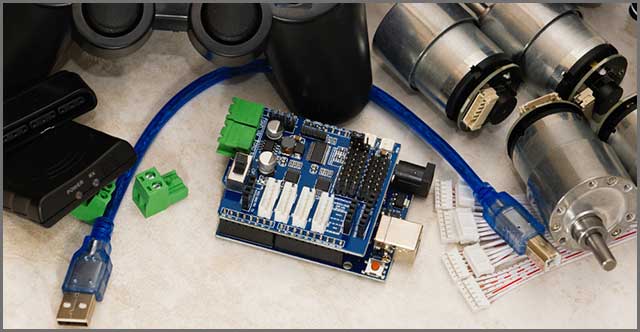

(AC, DC motor controller)

Special Offer: Get $100 off your order!

Email [email protected] to get started!

3.Types of Motor Controllers

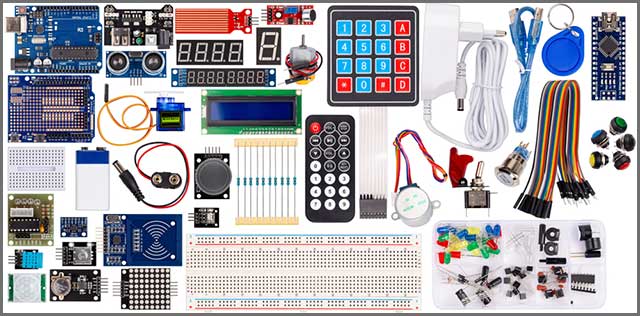

As of now, there are four basic types of motor controllers. They include the following:

-

AC

An AC motor controller is an electronic device that modifies the input power to the motor. It achieves this by adequately adjusting the frequency of the energy that goes to the engine. It does this for purposes of regulating torque and speed.

Primarily, the AC motor controller controlling the speed required in the case of many uses. That's the reason as to why they go by other names, such as AC inverters, adjustable frequency drives, or variable speed drivers.

-

DC

These are also electrical devices that efficiently modify input power. They do so by the alternating or adjusting current source to direct current output, a pulsed, or frequency. Some of the critical specifications include the motor type, voltage classification, loop system, and output signal type, among others.

DC motor controller is used to control motor speed and torque. The controller usually integrated with the driver circuit is a controller that provides control signals to the driver.

-

Servomotor

Servo Motor Controllers are those electronic devices that work by modifying the input power. Servo motor controllers do this by alternating or adjusting current source to a frequency, a pulsed, or current output of varying pulse duration. Just like the previous motor controllers, there are some applications where servo motor controllers fit best-for instance, usually used in motion control applications.

Motor control applications include those, especially in construction and manufacturing environments. They are used to control positions, motor speeds, and torques. Servo motors can also fit well in plenty of applications such as machine tools, robotics, spindle drive systems, and conveyors.

-

Stepper

Stepper Motor control is the last in the list. These are also electronic devices that modify the input power even. Stepper motor controllers do this by alternating the current source or adjusting it to a "stepped" current output. Some of the key specifications include motor type, the intended application, loop system, drive operating mode, and electrical specifications.

These controllers are mainly used to control applications' construction and manufacturing environments. Their primary role is to control the speed, position, and torque of the motor. On most occasions, machine tools, robots, conveyors, and micro-positioning machines can all use them. Stepper microcontrollers also go by the name motor indexers.

(Stepper motor controllers)

4. How to Choose Motor Controllers – AC or DC?

Choosing between AC and DC motor controllers is just a matter of personal choice. Some people see who sees goodness in one while others in the rest. But to be on the safe side, before selecting a motor control, you need to know the type of motor you have.

An AC motor controller may not be ideal in a particular motor and vice versa. AC motor controllers are excellent at controlling motor speeds. On the other hand, in DC motor controllers, rates get controlled by varying the voltage. As you can see, those are two different things.

That's not all. AC motor controllers are somewhat energy-saving, primarily if you are operating large motors. Such may not be the case when it comes to DC motor controllers. However, DC motor controllers are some of the best at controlling directional changes.

Therefore, the motor controller's choice to use depends on the type of motor you have. But above all, when you are in the market for a motor controller, you need to consider the following factors:

- Electrical specifications (supply voltage, peak output current, communication standard)

- The operating parameters (computer-controlled or aided, setup and control, hand-held devices)

- Other additional features (soft start, braking, status monitoring, self-diagnosing, design)'

(Parts of AC and DC)

5.Application Areas of Motor Controllers

As briefly noted in the beginning, motor control turns out to become part and parcel of our lives. Everywhere you go, you'll most certainly come across equipment that relies on them. The following are some examples of application areas where motor controllers find a lot of use:

- Medical Applications (medical analyzer, sleep apnea treatment)

- Automotive (HVAC motors, fuel/water pump, engine cooling fan, power steering)

- Solar Airplane

- Spacecraft

- Space Operated Vehicles

- Solar Heating System

- Fuel Pumps

- Electric Aircraft

- Chopper (DC Chopper Motor Drive)

- Cement Plants

- UAV (Propulsion System)

- Textile (Textile Rewinding Machine)

- Solar Tracking

- Hard Disk Driver

As you can see, the application area of motor control is almost endless. A lot of devices rely on them. The above is not all. There is plenty of equipment that also rely on motor controllers.

(Motor operate type for on and off)

6.Motor Control PCB Board Design Options

As of now, you are well aware that printed circuit boards do serve as the necessary foundation of almost all electronic gadgets. Motor control has printed circuit boards in them, though their design process is of great interest. The method of designing printed PCBs meant for motor controllers heavily relies on the use of the software.

There are several software design options for motor control that designers use. When used in the right way, all of them can bring about a good PCB design meant for motor controls. Several of them can bring about different PCB designs, depending on the shape of the motor control. Some of the most common ones include:

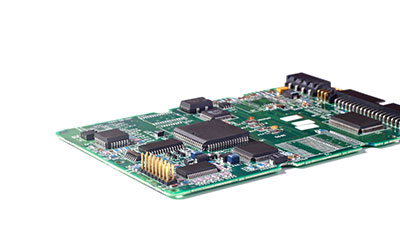

(A motor control PCB)

Summary

Motor control is electronic or electric devices that regulate torque, motor speed, and position output of equipment. Without them, life would have been somewhat backward. Motor controllers and printed circuit boards go hand in hand.

Without printed circuit boards, the functionality of motor controllers would be futile. It would be pointless as there be a platform that holds and connects all the motor controller's electronic components. When it comes to the manufacture and supply of high-end printed circuit boards meant for motor controllers, no name beats OurPCB.

Our boards are just the best of them all. Motor control makers in search of PCBs have always sought them from us. Are you on the lookout for the best-printed circuit boards for your next motor control project? Look no further than our boards. Call us today for a quick quote and see how we can be of help to you.

Special Offer: Get $100 off your order!

Email [email protected] to get started!