One of the most basic ways for SMD component attachment on flexible printed circuit boards involves soldering. Even though the basic principles for soldering SMD components are similar for both hard boards and flexible PCBs, soldering SMD components to flexible PCBs requires specific considerations.

Here, the nuances concern aspects such as flexibility and material handling. To get the best flex PCB soldering results, engineers, designers, and electronic enthusiasts need to keep certain conditions at the back of their minds.

Here is a list of five aspects to watch out for if the intention is to develop the best flexible PCB soldering results.

(placement of a processor on an SMT PCB)

Contents

1.Substrate Support

In the same manner that every home requires a foundation to build, all printed circuit boards must have a substrate. A printed circuit board substrate is the material that holds all the components and traces together. Selecting the right substrate to hold all the components together during the soldering process is the first step towards producing a high-quality printed circuit board.

Printed circuit boards require shape and structure. Additionally, they also need canvases or platforms that hold the entire components together. The platform is typically the substrate's job, and the characteristics of the substrate material are essential when it comes to soldering surface-mount device (SMD) components on the printed circuit board.

With the printed circuit board industry continuing to evolve on almost a daily basis, we are now witnessing the use of several different types of substrate materials, from flexible polymers to solid fiberglass. Traditionally, the fiberglass substrate material is one of the most preferred by printed circuit board designers because it is easy to seller SMD components on it.

Flexible printed circuit board materials such as RO3000 and RO4000 are very popular with PCB designers and engineers because they are very easy to machine and solder surface-mount components on it. Additionally, these materials also consist of low dielectric losses, especially at microwave frequencies.

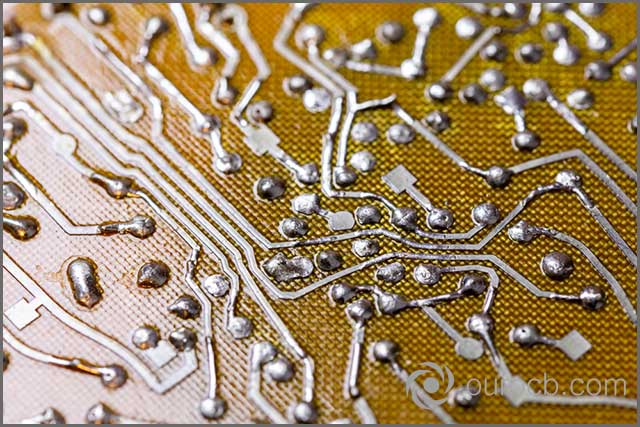

(an SMD PCB on a fiberglass material)

2.Overheating the Flex Material

A majority of flexible printed circuit board materials can withstand some amounts of heat or temperatures. But what happens when the temperatures go beyond some limits? At high frequencies, performances will take a nosedive reason why cost-effective heat-tolerant materials are necessary.

Heat-tolerant flexible printed circuit board materials can tolerate specific amounts of temperatures and heat, especially when soldering SMD components on them. To ensure that a flexible printed circuit board comes out as desired, designers need to ensure that they keep in mind different parameters regarding the materials used when temperatures rise, especially when soldering SMD components on the board.

When soldering SMD components on a flexible printed circuit board, the circuit materials will expand. The expansion is an aspect that changes the form of transmission lines to the extent of altering the printed circuit board's functionality. To ensure that you come up with the best flexible PCB soldering results, you may have to consider the use of thermal interface materials known for offering excellent thermal conductivity.

Typical thermal interface materials are preferred because they conduct heat close to 100 times better. Better yet, many flexible printed circuit board designers prefer thermal grease materials based on the fact they can withstand high temperatures, especially when soldering SMD components on the board.

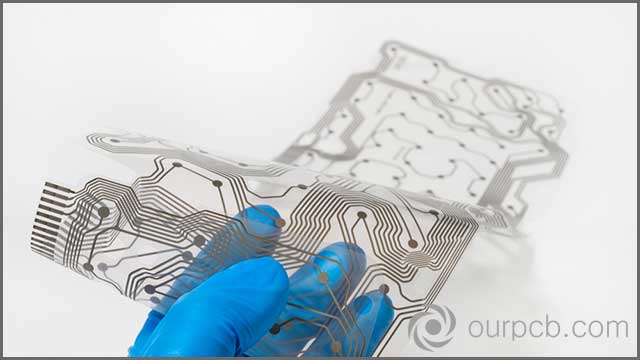

( A flexible PCB that can withstand thermal changes )

Special Offer: Get $100 off your order!

Email [email protected] to get started!

3.Proper Component Layout and Orientation

A saying goes like a flexible printed circuit board design is 10% routing and 90% layout and orientation. Scrutinized, this is true. Taking time to accurately place all the components needed in the manufacture of printed circuit boards will make the process easy for routing everything. Additionally, proper component layout and orientation ensure that a designer goes through an easy time to sell SMD components on the printed circuit board.

Proper component layout and orientation make it easy for manufacturers to install, test, and inspect all the placed parts or components of your printed circuit board. The steps are critical, especially if you are working with SMD or surface mount components requiring wave soldering. You need to have component layout and orientation, especially before soldering SMD components on a printed circuit board. So, it is advisable to orient the same parts in the same direction. Additionally, it is desirable to use correct orientation for excellent placement and soldering.

To ensure that components to be soldered on the flexible printed circuit board come out as desired, it is essential to avoid designs surrounding the solder side of SMD components all sides with PHT leads. If possible, it is advisable to place all SMD components or parts on the board's same side.

If you must glue the components, it is vital to ensure that they have at least 3mm space for excellent soldering. There has to be sufficient space between the elements to ensure that the heatsink doesn’t touch other parts.

(perfectly arranged SMT devices on a PCB board)

4.Solder Printing

When it comes to surface mount assembly, solder printing is one of the most vital processes for getting high-quality products. Solder printing is applying solder paste on the printed circuit board, a procedure performed by writing the solder paste in a stencil. The main reason for using solder paste is to ensure that electrical and mechanical connections of printed circuit board components work as desired after soldering all the parts together on a printed circuit board.

Designers face plenty of challenges when it comes to solder printing printed circuit boards, especially when they are in a rush to produce or manufacture large orders that come with tight deadlines. To ensure that solder printing goes well, designers and manufacturers of flexible printed circuit boards must respect or pay attention to some principles.

A designer first needs to come up with a perfect stencil and programming the screen printer as desired. A printed circuit board designer should also apply the right or correct amount of solder paste before soldering the SMD components on the printed circuit board. Lastly, a printed circuit board designer needs to use the right process to achieve a good print.

Solder printing is a very crucial process in the manufacture of printed circuit boards. The method of solder printing requires a lot of attention to minimizing defects that may occur. By undertaking proper solder printing, designers can eliminate more than 60% of errors during soldering.

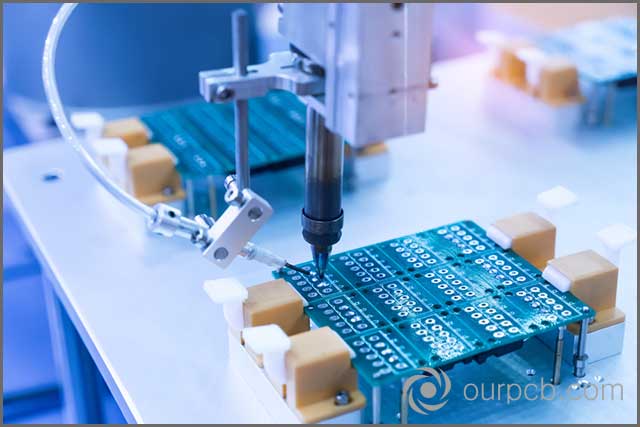

(automated solder printing for effective PCB production)

5.Planarity Problem

Planar is when you have a flat surface or level that continues or goes in all directions. When it comes to the flex circuit board manufacturers, some deformations may occur, affecting the printed circuit board's flatness. These are also known as bow and twist characteristics that may affect a printed circuit board's functionality.

Issues to do with planarity mainly occur when soldering surface mount device components on the printed circuit board. However, to avoid such cases, it is essential to use RoHS compliant's best materials. Additionally, it is also vital to add pre-preg material to the mix before undertaking the soldering process. It is better to avoid heavy thermal shocks when soldering as this may affect the flatness of the board and employ the best soldering procedures.

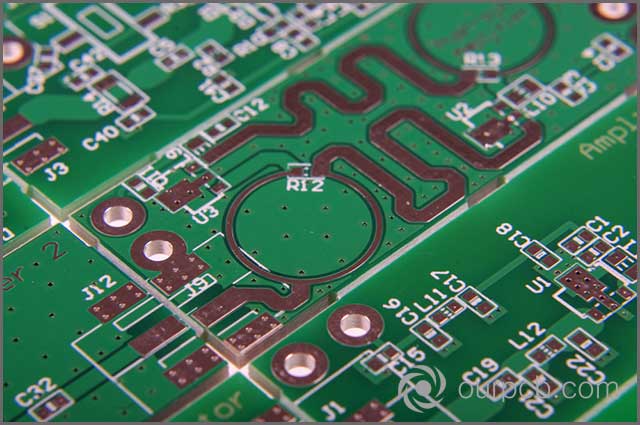

( a microwave’s PCB with a managed planar)

Summary

For more than a decade and counting, OurPCB has helped our customers turn their ideas into reality. Soldering flexible printed circuit board components is an exercise that a lot of designers and manufacturers find challenging. However, we at OurPCB have the right tools and experienced personnel trained for the job.

Regardless of your skill level or vision, we can make the road to your finished project short. Our solder pastes come with long stencil life in addition to excellent printability. We offer support for and assistance to the entire SMD soldering process.

If you need some help in soldering SMD components on your flexible printed circuit boards, feel free to contact us at your earliest convenience. We are here for you, and you can rely on us for quality services.

Special Offer: Get $100 off your order!

Email [email protected] to get started!