Drones come with the advantage and ability to be remotely operated, meaning that they fly in hard-to-reach areas in person. That's not all. The applications across the commercial field are numerous. Drones won't fly without an electronic speed controller. An automatic speed controller is an electronic circuit controlling and regulating the speed of a drones' electric motor, route, and acting as a drone's brake.

So, how do you go about ensuring that you have the right electronic speed controller? While the printed circuit boards fitted in them are essential, there are other things to consider. This article points out seven tips for having the best electronic speed controllers for drones.

(PCB board in drone speed controller)

Contents

1. 4in 1 or Individual Electronic Speed Controllers

Just as the name suggests, there are two types of electronic speed controllers for drones: 4 in 1 automatic speed controllers or individual ESC.

4 in 1 ECS's are just 4 ECS's that have been soldered together on a PCB and stacked below a flight controller. With technology continuing to advance, 4 in 1 ESC's seem to be gaining popularity than ever before.

There's only one problem with 4 in 1 ESCs. In case you happen to burn one ESC, then the whole boar will be useless. But that's not a problem with an individual ESC. If you accidentally burn one, all you have to do is to replace it. In terms of cost, an Individual appears somewhat cost-effective in the long run.

If you are a beginner and probably on a budget, it is better if you individual ESC as you scale up the ladder. But again, it all boils down to personal preference. As a start, particular ESC's are the best option since replacing or repairing them is cheaper and economical.

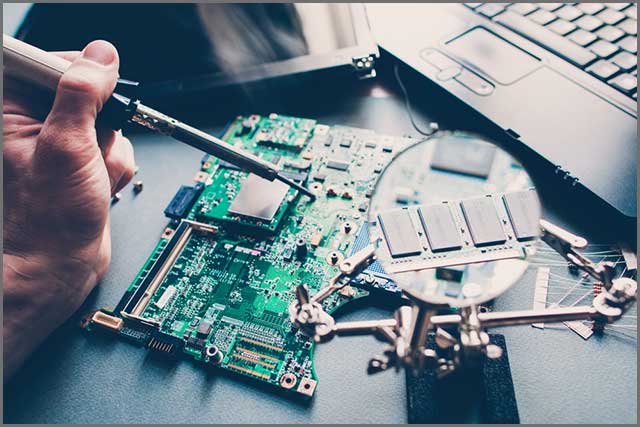

(a close picture of an electronic speed controller for a drone)

2. Weight and Size

The size and weight of an electronic speed controller depend on the latest ratings of ESCs. A majority of ECS's currently available on the market consist of more or less similar weight and dimensions. Most of them range from 4-6g. Of importance to note is that even the PCBs in them must be small in size. It's very challenging to manufacture ESC's lighter without having to compromise on performance and cooling.

Even though lighter is better, it is essential to remember that small ESC's tend to heat up fast. Much worse, they cannot be cooled adequately without constant air flowing over the ESC. While small electronic speed controllers carry heat sinks with them, in most cases, they aren't in plenty, as you may imagine.

The next time you are in the market for an electronic speed controller, check for its size and weight. The two matter a lot as they'll determine the speeds at which your drone will move.

(a medium-sized electronic speed controller)

3. External Capacitors

At full throttle, a 5-inch quad will draw more than 100A. It is a considerable current that strains the battery, thereby causing a voltage spike. Voltage spikes don't affect small quads since the cells aren't strained and can handle a lower current. Voltage spike occurs when the voltage of the battery increases rapidly due to a substantial current draw; however, using an external capacitor, voltage spikes to a minimum.

Here, the capacitor gets soldered correctly on the quad's battery leads to filter out voltage spikes. ESR capacitors are the most common types of capacitors used here. The reason for using them is: can significantly reduce voltage spikes.

You can tell and feel the difference with or without a capacitor. Even though ESC manufacturers attempt to integrate capacitors in them, they fail in minimizing these spikes. Therefore, using capacitors on an ESC is an excellent way. Therefore, when looking around for an electronic speed controller, Ensure that an external capacitor is installed. We need to solder to the PCB correctly.

(racing a drone on snow using an ESC)

Special Offer: Get $100 off your order!

Email [email protected] to get started!

4. Voltage & Current Ratings

An ESC voltage rating means the maximum amount of voltage that the ESC can manage to handle. A large number of low-cost ESCs on the market are rated at 4S. However, most of the ESC's that we have today can handle up to 6S. But this mainly depends on the voltage of the battery that runs on the drone.

Besides the voltage rating, there's the current rating. The current rating of an ESC has to be decided, but first, after choosing the motor's size. To select the ideal current rating, an engine's maximum current draw should be at 100% throttle. Therefore, we must consider the current and voltage ratings when selecting ESC for the drone.

5. BEC: With or Without?

A battery elimination circuit or BEC, in short, is a circuit whose role is to offer constant current at a specific voltage range. Airplane electronic speed controllers commonly have BEC since they provide power for the plane's needs, such as powering its electronics.

However, that is not the case when it comes to drones. In drones, there's no need for electronic circuit controllers with BEC. There are some reasons as to why battery elimination circuits aren't necessary as such in drones. The main reason, though, is based on the fact necessities such as powering the camera gets handled by a power distribution board.

The power distribution board (PDB) is more of a printed circuit board integrated into the flight controller. Electronic speed controllers that lack battery elimination circuits tend to small, lighter, and less noisy. Therefore, for ideal automatic speed controllers, ensure that they come without battery elimination circuits. Battery elimination circuits aren't a good fit for electronic speed controllers for drones.

(ESC without BEC)

6. Electronic Speed Controller and Thrust

The thrust generated by the motor depends on the electronic speed controller itself. The reason is that the task of the automatic speed controller is to rotate the motor. With the same setup, such as the same propeller and engine, two different ESC's can produce varying amounts of thrust.

Depending on the electronic speed controller type – either a cheap knock off or a good one- the thrust produced may vary more than up to 20%. That's not all. The driving force will also depend on other factors, such as solder quality or PCB quality. Another factor that may end up affecting the electronic circuit may be its size.

Solder joints and printed circuit board quality also play a vital role in the thrust generated. For instance, a poorly manufactured printed circuit board may limit the current amount that flows through the ESC. With such, there will be poor functioning of the electronic speed controller. However, the latest ESC's produced by reputed makers perform quite well.

(operating an ESC of PCB)

7. Brushed or Brushless Electronic Speed Controllers?

There are two main types of electronic speed controllers: brushed and brushless automatic speed controllers. Depending on your needs, you can select the one you find for you. Brushed electronic speed controllers have been around for quite some time now. They are very affordable and ideal to use across various Ready to Run (RTR) RC vehicles.

On the other hand, brushless electronic speed controllers are the advanced version of healthy automatic speed controls. While they are might be a little bit pricey, they compensate for that high-power performance. Better yet, they are very long-lasting compared to brushed electronic speed controllers.

So, it all depends on a user's needs and the budget at hand. If you are not on a budget as such, then there's no harm in going for brushless ESC's. But if you happen to be on a budget and looking for something cheap that will serve you, then you better go for brushed ESC's.

(a brushless ESC)

Summary

Looking around, you'll notice that there are more than a hundred electronic speed controllers available in the market from dozens of manufacturers. All tend to perform well with one attempting to do well over the other. Apart from other things, aspects that make one better than the other are the materials found.

Among some of the essential elements that you'll find in electronic speed controllers are printed circuit boards. For the best ESC's, you have to go for those that contain high-quality PCBs in them. PCB's give ESCs the mechanical support that they need.

Are you in the market for the best PCB's for your ESC's? If so, we at OurPCB can be of great help. OurPCB has served hundreds of ESC manufacturers for more than a decade, providing them with the best PCBs. Call us today for immediate assistance.

Special Offer: Get $100 off your order!

Email [email protected] to get started!