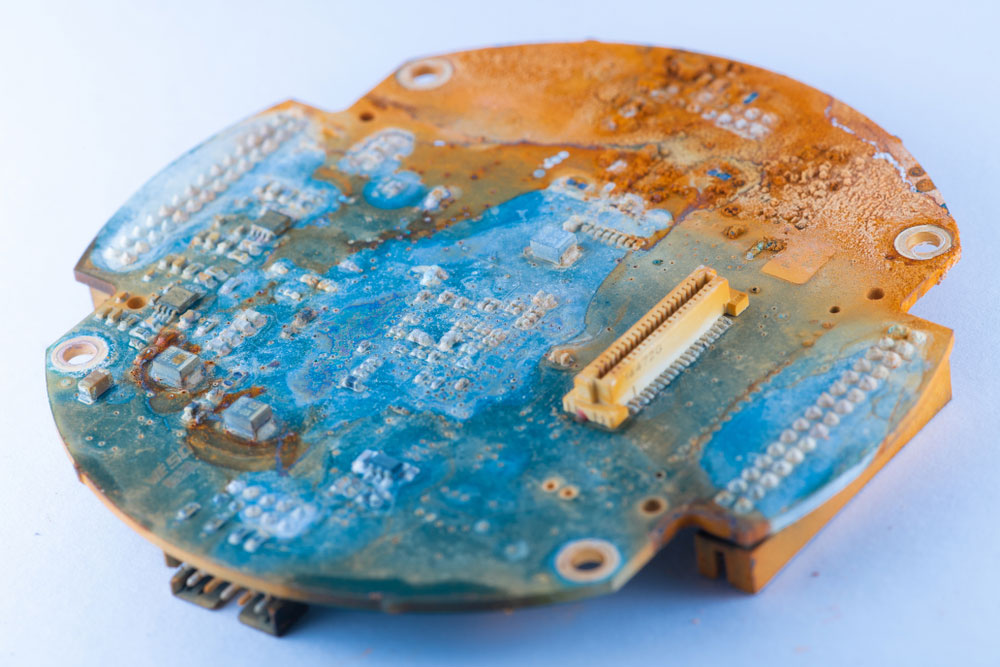

Unless you place your PCB in a vacuum environment or fully sealed enclosure, dust and grime inevitably accumulate on the PCB over time. This is especially true for electronics PCB used in large industrial environments that are dusty all the time.

When not cleaned in a regular maintenance schedule, Dirty PCB can cause problems for the machinery or system it controls. At the same time, dust and dirt may not cause physical harm to the PCB. Water moisture trapped between the soil can cause a short circuit to the electronics component.

A dirty PCB may also attract insects to nest on the PCB. Insects like ants can be acidic and may destroy the PCB eventually. This often causes irreparable damage to the tracks and component pads.

The resulting downtime in operation, indirectly caused by a dirty PCB, can be easily prevented by active and passive preventive measures. Here are some helpful guides for doing so.

Special Offer: Get $100 off your order!

Email [email protected] to get started!

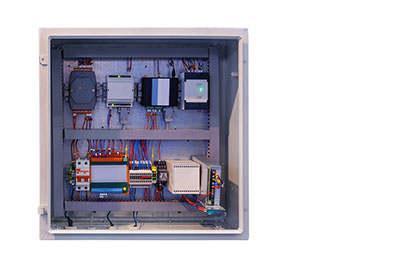

1. Dirty PCB--Using A Proper Enclosure

If your PCB is required to function in a dusty environment, it’s prudent to house it in a tightly sealed enclosure. If your PCB involves ventilation, install an appropriate filter mat on the opening to prevent dust from entering the compound.

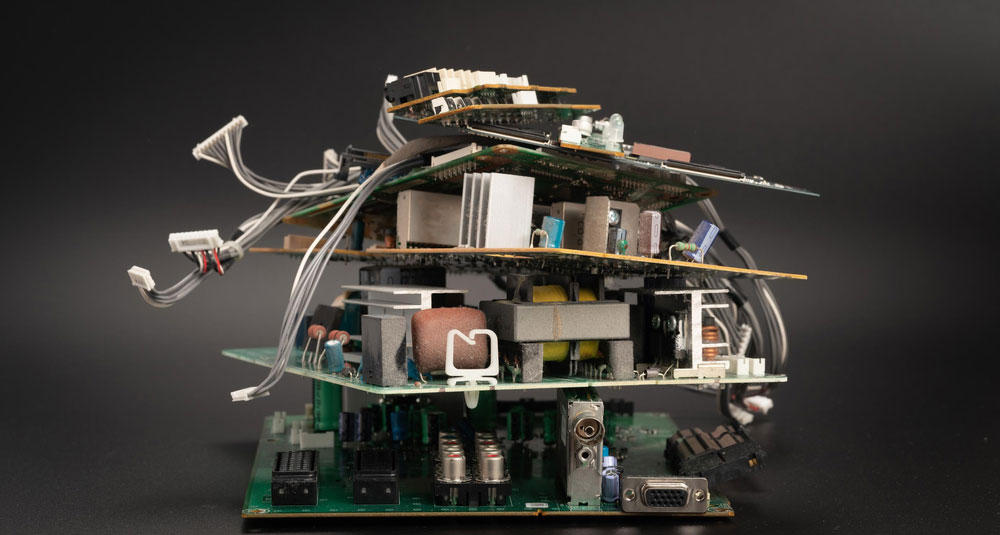

2. Dirty PCB--Preventive Maintenance

When placed in an environmentally challenging environment, electronics PCB needs to undergo scheduled preventive maintenance. This is necessary to remove dust from the PCB and its enclosure before it builds up and damages the PCB. The suitable cleaning solution can also remove dirt and grime from the PCB, especially between tiny pitches of the components.

3. Conformal Coating

If you expect your PCB to be used in a polluted environment, you can get the assembled PCB coated with a conformal coating. This coating prevents moisture and dust from coming in contact with the conductive elements of the circuit.

Special Offer: Get $100 off your order!

Email [email protected] to get started!