Contents

- Table of Contents

- What Is DFM?

- DFM Principles

- What are DFM Tools?

- Signal Checks

- Plane Checks

- Solder Mask Checks

- Drill Checks

- Silkscreen Checks

- Factors Affecting Design for Manufacturability

- Reduce the Number of Components

- Standardize Materials and Component Selection

- Build Modular Assemblies

- DFM Tools: Efficient Design Joints

- DFM Tools: Minimize Parts Reorientation During Machining/Assembly Processes

- DFM Tools: List the Acceptable Surface Finishes

- Streamline the Number of Manufacturing Processes

- Wrap Up

Table of Contents

- What Is DFM?

- What are DFM Tools?

- Factors Affecting Design for Manufacturability

- Reduce the Number of Components

- Standardize Materials and Component Selection

- Build Modular Assemblies

- DFM Tools: Efficient Design Joints

- DFM Tools: Minimize Parts Reorientation During Machining/Assembly Processes

- DFM Tools: List the Acceptable Surface Finishes

- Streamline the Number of Manufacturing Processes

- Wrap Up

Special Offer: Get $100 off your order!

Email [email protected] to get started!

What Is DFM?

Design for Manufacturing (or Design for Manufacturability) is an engineering practice used to design products in a way that they are easy to make and at the lowest unit price. DFM allows you to fix potential errors, such as alignment issues, in the design phase because it is the cheapest production phase to address them. Otherwise, your product can have performance and reliability issues throughout its operational life cycle. And it is vital to note that each manufacturing process has its own design rules. For instance, 3D printing (an additive manufacturing process) has different design guidelines than CNC machining (a subtractive manufacturing process).

A 3D printer

So it is vital to follow design guidelines for a specific manufacturing process when designing product parts. With PCBs, you should monitor the board thickness, minimum via hole diameter, surface finish, and minimum trace width. In addition to reducing the unit price and potential errors, DFM can reduce turnaround time.DFM Principles

Design for Manufacturability comprises these five principles.Process

The selected manufacturing process must be the most appropriate one for your product. And when determining the manufacturing process, DFM should consider factors like surface complexity, secondary process requirements, required tolerances, etc.

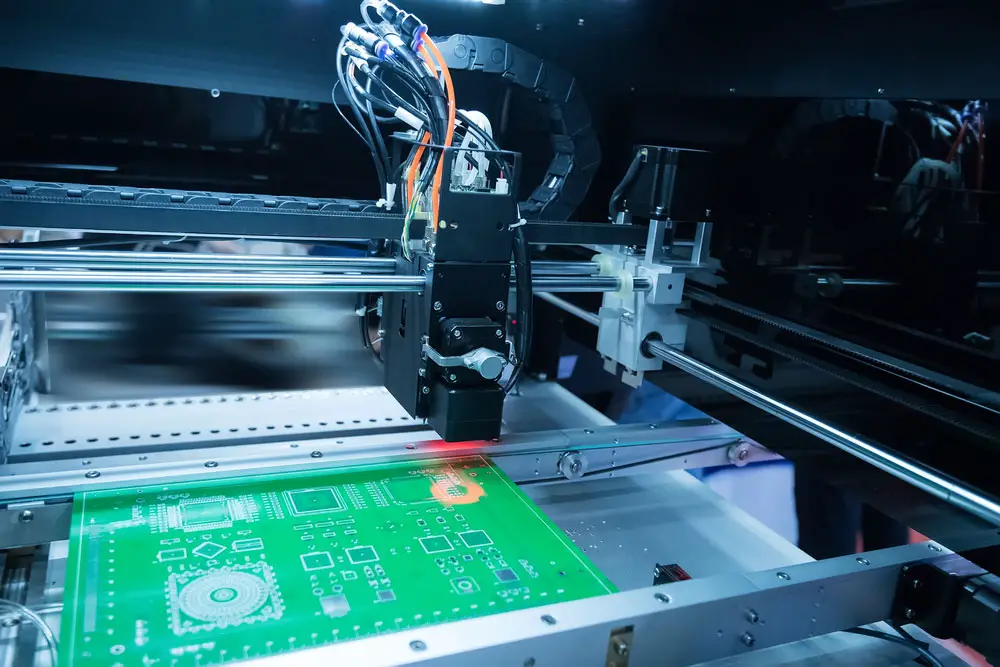

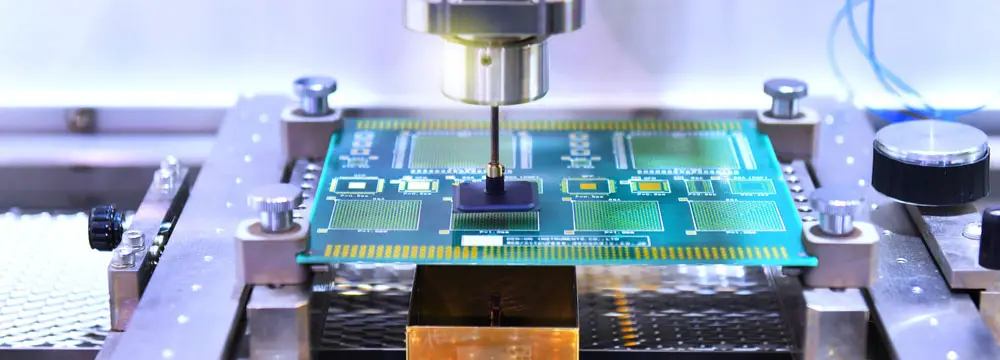

PCB processing on a CNC machine

Design

Design is the most critical DFM principle because it lets you customize the product, giving it an optimized layout that reduces manufacturing costs, faults, and turnaround time. You must consult your manufacturer about the product design to ensure it conforms to the best manufacturing processes.

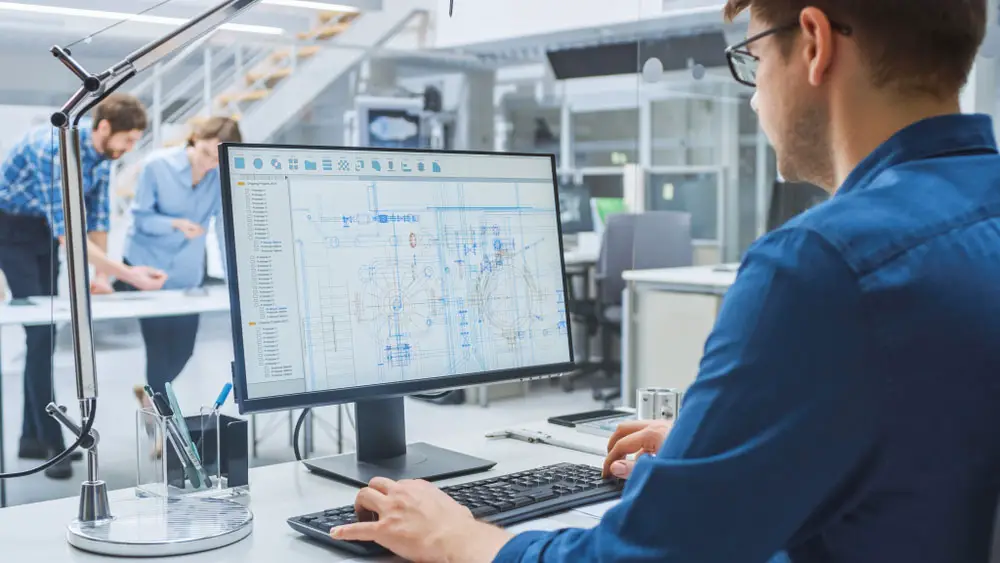

Electronics engineers working on a PCB design using CAD software

Material

DFM requires you to pick the material based on properties like mechanical strength, flammability, color, thermal resistance, electrical conductivity, etc. Also, remember to consider the material cost.Environment

The product should withstand its intended operating environment and function without any hiccups.Testing/Compliance

Lastly, the product should meet the required quality and safety standards, which can be third-party, industry-specific, or internal company standards.

A quality control inspector checking a circuit board

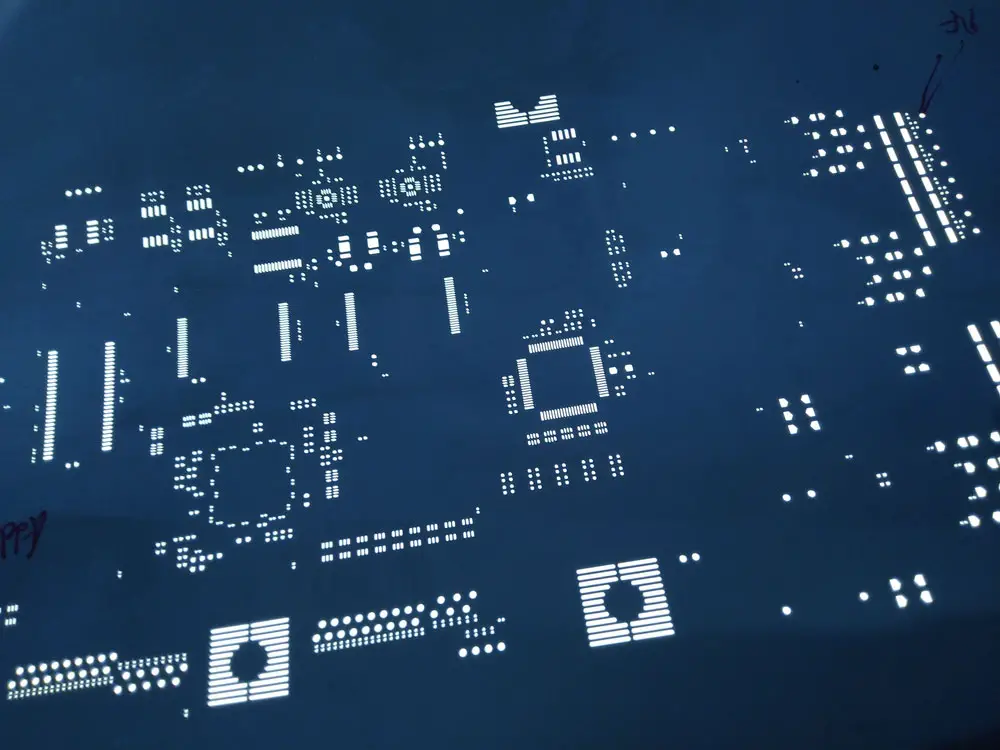

What are DFM Tools?

While PCB clearance rules were easy to define in the past, current DFM rules depend on several factors, such as trace width, hole spacing/diameter, etc. These factors create multiple design rule checks that printed circuit design software must monitor. So you need to set up CAD design applications to check these rules, making them the initial DFM tools in the PCB production process. Besides printed circuit design software, several DFM tools in the market can indicate which board layers have manufacturing issues. Usually, these tools have a checklist for comprehensive PCB design layout analysis. And most look at these five aspects.Signal Checks

With signal checking, DFM tools look at these factors.- Copper conductor width

- Annular ring

- Spacing

- Drill-to-copper

- Text features

- Features connection

- Missing copper & holes

- Rout to copper

- Unconnected lines

- Hole registration

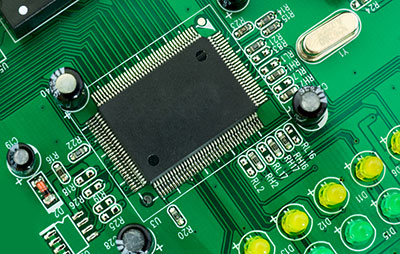

An unassembled PCB

Plane Checks

The plane checks are slightly fewer and comprise the following.- Annular ring

- Drill-to-copper

- Conductor width

- Spacing

- Spoke width/thermal air gap

- Rout to copper

- Clearance (tinier than the hole)

- Missing copper

- Drill registration

Solder Mask Checks

They include:- Coverage

- Rout to mask

- Exposed lines

- Partial clearance

- Missing solder mask clearance

- Spacing

- Solder mask clearance

Drill Checks

Drilling checks cover the following.- Duplicate holes

- Hole size

- Touching holes

- Holes to rout

- Missing holes

- Hole spacing

- Plane shorts

Silkscreen Checks

Lastly, DFM tools conduct silkscreen checks in the following areas.- Silkscreen-mask spacing

- Silkscreen-copper spacing

- Silkscreen-rout spacing

- Silkscreen-hole spacing

- Text height

- Silkscreen over copper text

- Line width

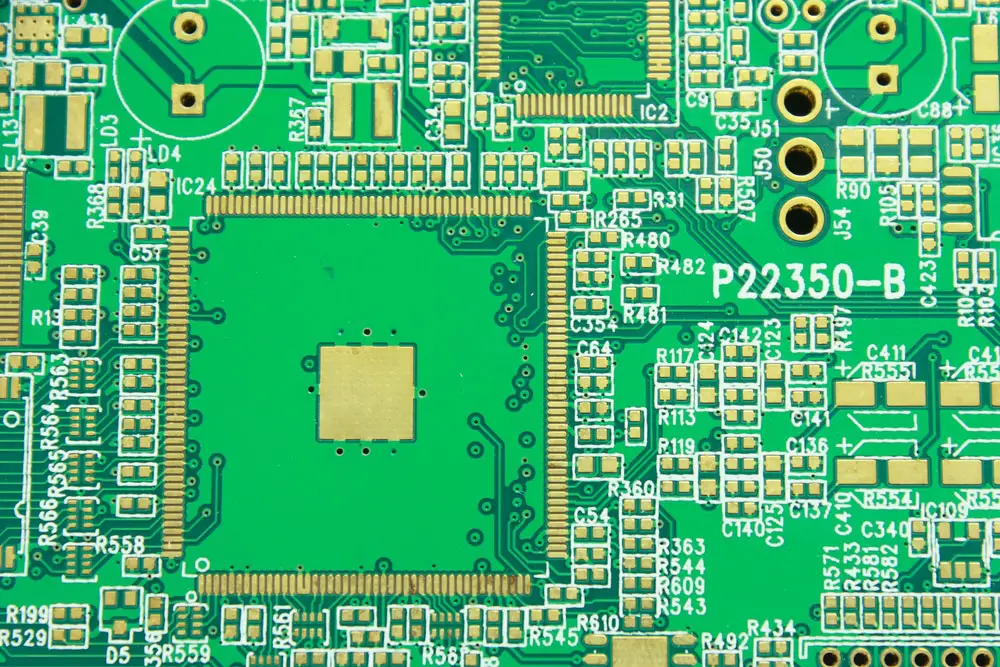

A laser-cut stainless steel stencil for solder paste application

As you can see, DFM tools do multiple checks to enhance design manufacturability. And since you might not know the processes the fabricator uses to make PCBs, it is better to have the manufacturer do the DFM checks and give you a Design for Manufacturing report. So when placing an order with OurPCB, upload your CAD files, and we'll analyze the design for each part by checking its information against our manufacturing database. Once complete, we'll send you a detailed assessment showing the okay design elements and those requiring changes.Factors Affecting Design for Manufacturability

DFM tries to minimize manufacturing costs without affecting performance. So besides the DFM principles, these factors can affect DFM.Reduce the Number of Components

Minimizing the component count is the easiest way to lower the cost of components and overall unit price because it reduces the required materials, labor/processes, engineering requirements, shipping costs, etc.

The process of soldering components during assembly

Standardize Materials and Component Selection

Although customization/personalization creates unique products, it is expensive. But using standardized quality products can lower the cost and reduce the turnaround time. Plus, such components and materials are readily available and bring about consistency in quality.Build Modular Assemblies

If possible, consider creating a modular design assembly to allow you to make modifications without affecting the board's functionality.

A PCB under inspection after fabrication and assembly

DFM Tools: Efficient Design Joints

An interlocking design is also desirable to avoid using adhesives, fasteners, or screws. And if you must use them, go for the standard type with chamfered, self-tapping designs for better placement. Also, use the minimum screw number, variation, and size. Avoid tapped holes, too short or long fasteners, washers, flatheads, and roundheads.DFM Tools: Minimize Parts Reorientation During Machining/Assembly Processes

Design parts that require minimal physical interaction during manufacturing and assembly.DFM Tools: List the Acceptable Surface Finishes

Always pick functionality over flashiness when picking the board's surface finish unless it's an exhibition-grade board.Streamline the Number of Manufacturing Processes

Complex manufacturing processes are expensive and introduce higher chances of error occurrences. Streamlining these operations eliminates errors that would be expensive to repair in later production stages.

An engineer optimizes designs before manufacturing.

Wrap Up

In conclusion, DFM touches on the customer part (due to product designs) and the manufacturer part (due to manufacturing). So the design and manufacturing teams should constantly communicate to refine the design for manufacturability guidelines. Therefore, go to our contact page and send your information with the Gerber design files. We'll be in touch to discuss any DFM issues that arise.Special Offer: Get $100 off your order!

Email [email protected] to get started!