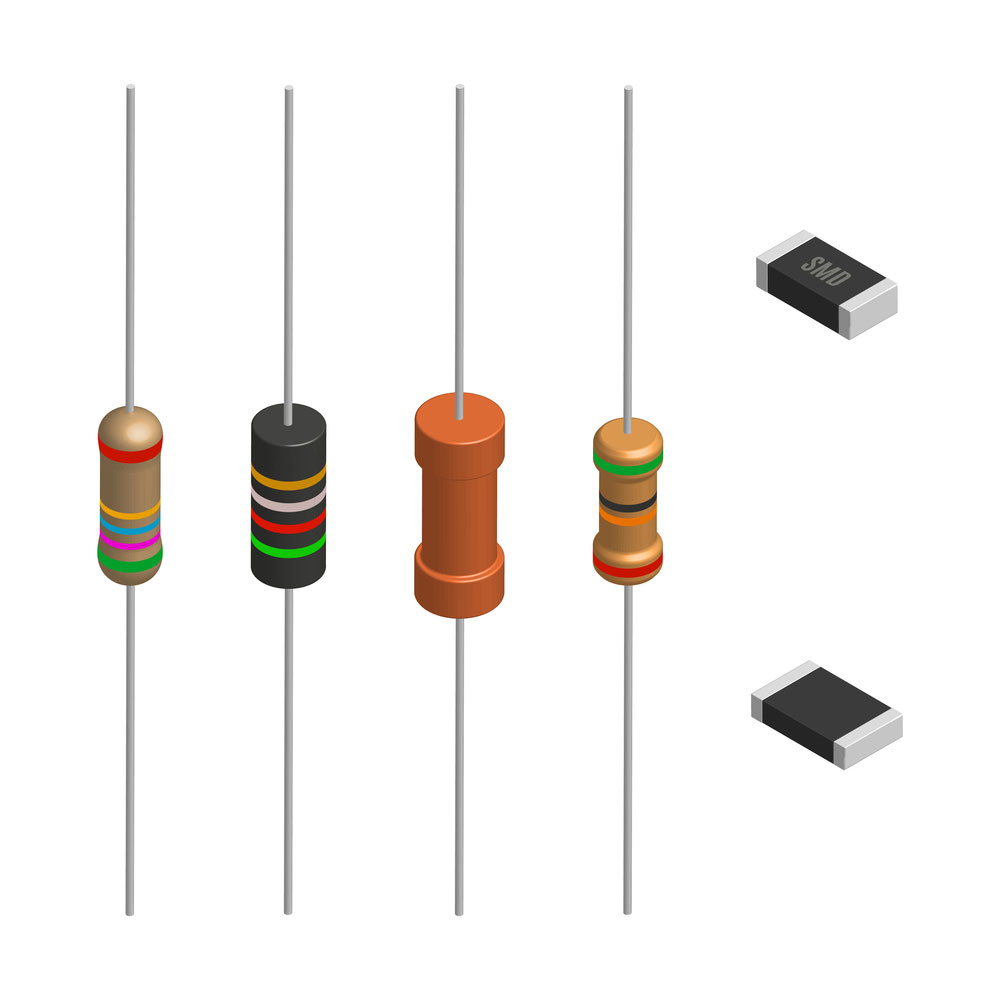

When students become acquainted with electronics, resistors are the first PCB components they're likely to encounter. However, it should be evident that resistors do not only differ in their abilities to resist. They also differ in their materials. Two of the most popular types of resistors are carbon and metal film. But what makes them different? This article will explore the differences: Carbon Film vs. Metal Film.

Contents

- What is a Carbon Film Resistor?

- Construction of The Carbon Film Resistor

- Availability of Carbon Film Resistors

- Factors Affecting the Resistance of the Carbon Film Resistor

- Advantages of Carbon Film Resistor

- Disadvantages of Carbon Film Resistors

- Applications of Carbon Film Resistor

- What is Metal Film Resistor

- Availability of Metal Film Resistors

- Factors Affecting Resistance of Metal Film Resistors

- Advantages of Metal Film Resistor

- Applications of Metal Film Resistors

- Similarities

- Identification Method

- Resistor Color

- Resistance Accuracy

- Temperature Co-Efficient

- FAQ

- What are the advantages of using metal film resistors versus carbon compo ition resistors?

- Are carbon film and m tal film resistors interchangeable?

- Are metal film resistors inductive?

- Conclusion

What is a Carbon Film Resistor?

Resistors on tape

Source: Wikimedia Commons

As the name implies, a carbon film resistor consists of a carbon film shell. Essentially, the carbon film surrounds a ceramic former. The carbon film resistor is a fixed type resistor.

As such, it means that it provides only a single resistance value. Consequently, the carbon film plays the role of the resistive material. Namely, it restricts current in a circuit.

Construction of The Carbon Film Resistor

The carbon film resistor's design is quite simple. First, we place a carbon layer on a ceramic substrate to build the carbon resistor. Consequently, the carbon film blocks electricity, while the ceramic substrate acts as insulating material.

Because the ceramic substrate protects against heat, allowing the carbon film resistor to operate and survive under massive temperatures. Never heless, we fit metallic endcaps at both ends of the carbon film. The l ads of copper adjoin at the two ends of the metallic end caps.

Next, we coat the film resistor with epoxy for additional protection. In th carbon film resistor, we can achieve the desired resistance value by trimming the thickness of the carbon layer. Alter atively, we can cut the carbon metal in a spiral manner along its length.

Availability of Carbon Film Resistors

Carbon film resistors are available in a range from 1 Ohm to 10MOhm. Addit onally, they have a power rating of 1/16, 1/8, 1/4,1/2, 1, or 2 watts. It is why people refer to them as low power resistors.

Factors Affecting the Resistance of the Carbon Film Resistor

Resistors on a circuit board

Resistors on a circuit board

The resistance of the carbon film resistor largely depends on the thickness of the carbon film layer. Addit onally, it is also dependent on the widths of the helical carbon film cut.

Thus, the resistance of the carbon film resistor is inversely proportional to the thickness of the carbon film layer. Furth rmore, the resistance of the carbon film layer is also inversely proportional to the width of the spiral carbon film cut.

Advantages of Carbon Film Resistor

- Generates less noise than carbon composition resistors

- They have a low tolerance

- Low cost

- Wide operating range

- It can operate up to temperatures of 350 degrees celsius and a voltage of 15kV

Disadvantages of Carbon Film Resistors

- Have a high negative temperature co-efficient. While hey can operate under high temperatures, the resistance decreases efficiently with increased temperature.

Applications of Carbon Film Resistor

- RADARs

- X-Rays

- Power Supplies

- Lasers

What is Metal Film Resistor

Metal film resistors (you may also refer to them as metal oxide resistors) are high-precision resistors that consist of a thin metal film surrounding a ceramic body. C nsequently, the thin metal-oxide layer acts as the primary resistive component.

Construction of the Metal Film Resistor

A collection of metal film resistors piled up.

A collection of metal film resistors piled up.

We sputter a thin layer of metal-oxide material on a ceramic core when constructing the metal film resistor whe constructing the metal film resistor. Next, we artificially age the deposited metal by keeping it or an extended period at a low temperature. It results in greater accuracy of the resistor.

We often use nickel- hromium (NiCr) for the resistance material. However, we may use other alloys, e pecially for more specialized applications. These may include tin or compositions of gold and antimony.

The stability and resistance are strongly d pendent on the thickness of the metal film. The thicker the o ter layer, the more resilient the resistor. However, it also results in lower resistance values.

Finally, we press both resistor en s with a metal cover with the leads. To alter the resistance, we create a coil-shaped sli in the outer layer of the resistor. As such, we perform this action through the utilization of a laser.

Availability of Metal Film Resistors

Metal film resistors are available in tolerances of:

- 00.1%

- 0.25%

- 0.5%

- 1%

- 2%

The temperature coefficient of resistance is usually between 50 and 100 ppm/k.

Factors Affecting Resistance of Metal Film Resistors

The resistance of the metal film resistor depends on two facto s:

- The thickness of the metal film. Essentially, its resistance is inversely proportional to the thickness of the metal film laye .

- The width of the spiral film cut. Consequently, its resistance is inversely proportional to the width of the spiral metal film cut.

Advantages of Metal Film Resistor

- Low cost

- Generates less noise than carbon composition resistors

- It has a wide operating range

- Features long-term stability

- Low tolerance

- It has a low-temperature coefficient of resistance, which does not change quickly with a temperature change.

- Very small in size

Applications of Metal Film Resistors

- High-frequency applications

- Active filters

- Bridge circuits

Special Offer: Get $100 off your order!

Email [email protected] to get started!

Similarities

Gold plated blue metal oxide resistors on green printed circuit board..

Gold plated blue metal oxide resistors on green printed circuit board..

While metal film and carbon film resistors may consist of different ma erials, you can easily confuse the two. However, to remedy this, you can:

- Firstly, both resistors often share the same small size and shape.

- Secondly, they both use a ceramic former or ceramic material as their nonconducting material.

- Also, you can control the resistance value of both types of resistors by altering the thickness of their films

Identification Method

Again, metal film resistors and arbon film resistors can easily confuse a d mix up. Thankfully, each type of resistor has distinctive characteristics which you can use to identify.

Resistor Color

Resistor olor is the first and most obvious charac eristic. For instance, metal film resistors tend to be blue, while carbon film resistors are yellow or pink.

Resistance Accuracy

Most com on carbon film resistors do not have a hi h resistance accuracy. Namely, they’re mass-produced an (depending on the manufacturer) do not f ce very strict quality assurance. Conversely, metal film resistors have hig er production requirements and more rigor us testing and quality assurance. It makes them more reliable than carbon film resistors.

Temperature Co-Efficient

The biggest reason y u may choose one resistor type over anoth r is the temperature coeff cient. Metal film resistors have a small ositive temperature co-efficient. Oppo ingly, carbon film resistors have a very egative temperature co-efficient. Besides, they start to lose their resistance value when the temperature goes above a certain threshold.

FAQ

What are the advantages of using metal film resistors versus carbon compo ition resistors?

Metal film resistors a e strict production requirements. It ma es them more stable and reliable. Addit onally, metal film resistors have a small positive temperature coefficient. An increase in temp rature does not affec the resistance val e negatively. It may increase it. On the other hand, carbon film resistors are susceptible to loss of resi tance when the temperature rises. Nevertheless, both resistors are easier and cheaper to acquire.

Are carbon film and m tal film resistors interchangeable?

It l rgely depends on he application. However, in most cases, y u can't use them interchangeably. Metal film resistors produc less thermal noise, and they don't drift as much as carbon film resistors. So if you know you're using a metal film resistor in a high-temperature situation, then you should not replace it with a carbon film resistor.

Are metal film resistors inductive?

Generally, metal film resistors with a r sistance below 100 ohms are inductive. However, resistors between 100 and 470 Ohm are true resistive - which means they have zero to very little inductiveness.

Conclusion

The a ove guide explored the differences betwee carbon film and etal film resistors. We have learned that metal film resistors are superior to carbon film resistors. Furthermore, Carbo film resistors and carbon comps are noisier and tend to drift in va ue. On the other hand, metal film resisto s are more stable, and many peopl consider them the quietest resistors. Th y are your main options if you're looking for a high-precision resistor. However, carbon film resistors are cheap, and they're gre t for beginner projects for students learning about electronic ci cuits. Nevertheless, we hope that you've found this guide to be helpful. As always, thank you for reading.

Special Offer: Get $100 off your order!

Email [email protected] to get started!