Are you looking for the best solder for circuit boards? This refers to the fusible alloy that you use to join metallic parts. One can find Solders in various industries.

Solders find applications ranging from jewelry and plumbing to electrical appliances and manufacturing.

Naturally, the solder used for a circuit board is distinct from the one used in a toilet.

Welds used in plumbing consist of distinctive alloys. These alloys, designed especially for moist and humid conditions, can withstand these conditions.

Throughout these domains, the primary function of the solder remains the same. To heat, melt, and then harden itself to join metallic components.

Today, we give you nine tips to help you choose the best solder for circuit boards.

(best solder for circuit boards)

Contents

- Solder Forms and Their Applications for Circuit Boards

- Solder Wire

- Solder Paste

- Solder Bars

- Based on the Types of Printed Circuit Board Soldering

- Soft Soldering

- Hard Silver Soldering

- Braze Soldering

- Wave Soldering

- Reflow Soldering

- Lead or Lead-Free Solders?

- Based on the Chemical Contents of Solder

- Select Solder for Circuit Boards Based on Flux Type

- Flux Content is a Consideration When Choosing the Solder for Circuit Boards.

- Spool Size is Also Important.

- The Cost of Solders

- What Should Be The Correct Dimension?

- Solder Based on Your Project

- When to choose Lead-based solder

- Lead-free solder

- Amateur application

- How to Choose a Solder Based Upon Your Electronic Product?

- What is The Perfect Solder Diameter For You?

- Solder in Circuit Board Repair

- Focus on The Shelf Life of Solder

- Summary:

Solder Forms and Their Applications for Circuit Boards

Solder Wire

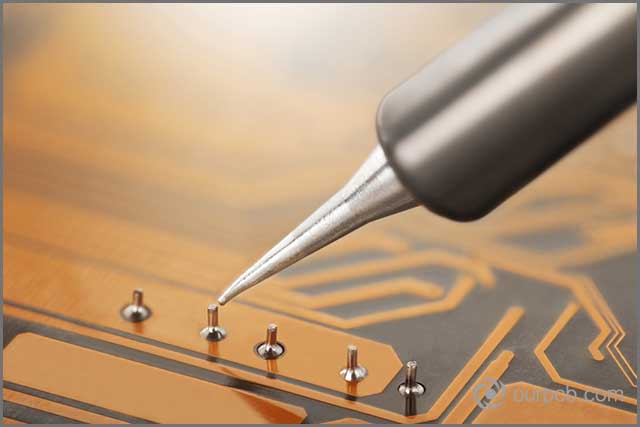

Solder wire is more suitable for manual soldering of through-hole components using a soldering iron, but you can use it for touch-up work on surface-mount parts.

And you can use solid or flux/rosin core solder wire, the latter being the better option.

Solder wire next to a soldering iron

Solder Paste

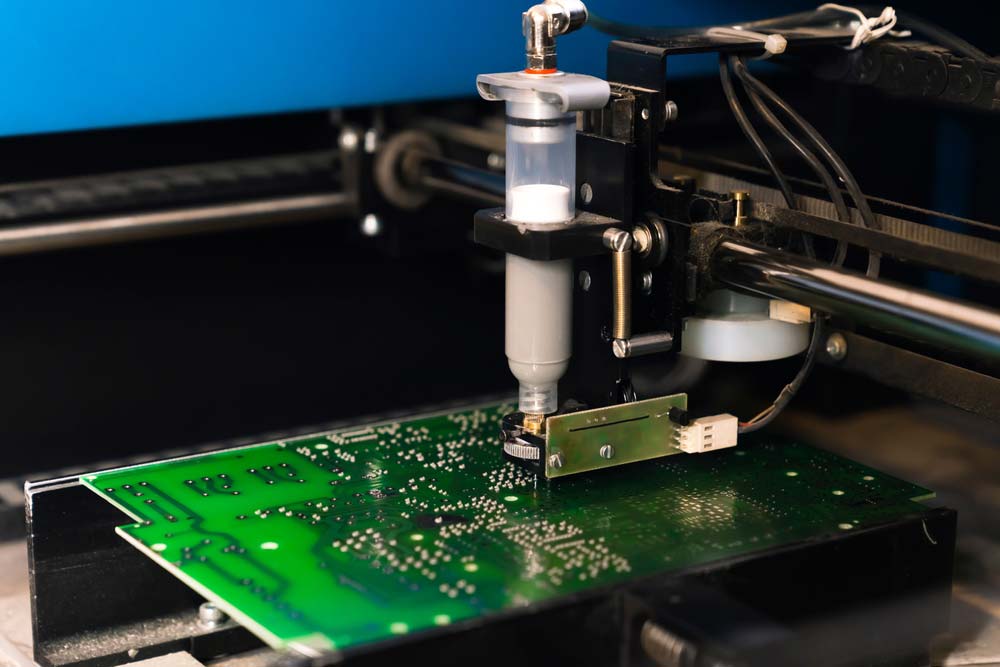

Solder paste is powdered solder mixed with flux paste, which creates a gel-like material for soldering surface-mount components.

The flux’s tackiness holds the fine solder particles in place and allows you to position the components precisely.

An automatic manipulator with solder paste in the dispenser needle

Solder Bars

You can only use solder bars in the wave soldering process, where the machine melts the metal to create the wave of molten solder to weld through-hole components.

Based on the Types of Printed Circuit Board Soldering

Soft Soldering

Soft soldering involves heating the filler metal material to temperatures below 752°F (400°C), making it ideal for welding delicate electronic components to PCB pads.

Most of these filler metals are alloys containing Lead because the material has a low melting point of 621°F (327°C).

Therefore, the melting point of the alloys is usually around 662°F (350°C).

Hard Silver Soldering

This process requires higher temperatures of about 1472°F (800°C) to melt the filler metal, usually using a carbon arc torch or flame.

Braze Soldering

Braze soldering requires higher temperatures than hard silver soldering to weld the parts.

These temperatures should be around 1832°F or 1000°C.

A plumber braze soldering a copper pipe

Wave Soldering

This bulk soldering process is ideal for welding through-hole components to PCB copper pads, and it involves passing the PCB with components placed on it above a pan of molten solder.

A pump in the machine creates an upwelling of the molten solder to create a standing wave that contacts the board to weld the components.

Reflow Soldering

Reflow soldering is the primary method used to weld surface-mount components to PCBs.

Before the board goes into the reflow oven, it must go through a solder paste printer to apply the solder paste on the copper pads, then a pick-and-place machine to place the surface-mount components on the applied paste.

The function of the reflow oven is to heat the boards to melt the solder particles in the paste, which weld the parts.

An infrared reflow oven

Lead or Lead-Free Solders?

There exist hundreds of permutations and combinations of a solder. These can be of different wire sizes, alloys, and flux types.

These factors can drastically impact your soldering experience.

The solder on a circuit is like connective tissue. It is the glue that sticks components to substrates. Solders are also providing some much-needed continuity to a circuit board.

For years, lead solders have been the go-to solders in the electronic industry.

However, lead causes many health and environment-related issues. These issues further gave rise to lead-free solders.

Lead solders consist of a mixture of lead and tin. Lead solders heat up at a much lower temperature than lead-free solders. Due to this, the thermal threat to the component decreases.

Therefore, lead-free soldiers consume less energy and time, too. Also, the solder develops a shinier appearance when compared to the lead-free solder.

Lead-based solders are Cheaper than the lead -free ones. However, the distance between the lead-based and lead-free solder is ever decreasing.

Thus, one can also go with the lead-free solder for the environment's sake.

As of now, the most used type of solder is the lead-free rosin core solder. It usually consists of tin or copper alloy.

However, due to the environment and health issues, it has started to lose popularity.

(Alt – Electronic circuit board)

Based on the Chemical Contents of Solder

There are various kinds of solders available in the market. These also include substances like silver and bismuth.

Using these materials enables you to personalize the solder based upon your requirements.

There are only three primary categories of solders to which you can narrow your search.

Lead solders were, for a long time, the go-to substance in the electronics industry. They have a melting point of around 180-190°C. The most commonly existing blend is the 60/40 (tin/lead) blend.

Tin helps maintain a lower melting point. On the other hand, lead represses the growth of tin whiskers. The better concentration of tin also ensures better shear and tensile strength.

Lead-free solders have started gaining popularity. The primary reason is the fact that the EU restricted the use of lead in electronics.

In countries like the US, manufacturers receive tax relief for using lead-free solders. Lead-free solders can, however, sometimes cause the formation of tin whiskers.

However, the use of conformal coatings can control these tin whiskers. Another alternative is to incorporate substances like nickel and silver for layers.

Flux core solder, sold as a single reel, consists of a reducing agent at the core. During the process of soldering, the flux gets released.

This flux reduces the metal at the point of contact, which results in a cleaner and neater connection. In electronics, rosin is usually a flux.

(Alt - Chemical content of solder )

Select Solder for Circuit Boards Based on Flux Type

Flux is like a cleaning agent. The corrosive liquid comes in two types; there is a more acidic compound for welding copper pipes, usually for plumbing applications.

But rosin flux is the preferred cleaning agent for electronics soldering.

Rosin flux is a plant-based, slightly acidic compound that corrodes layers of oxidation and impurity from solder surfaces to provide a clean, exposed metal surface area that wets properly when molten solder falls on it.

The material is hard, non-conductive, and corrosion-resistant and requires some heating to liquefy it to clean the soldering surface.

A block of pine rosin flux

Flux Content is a Consideration When Choosing the Solder for Circuit Boards.

Flux content varies in solder, especially the wire type. Solder paste usually has around 10% flux that suspends 90% solder powder, making it self sufficient.

But solder wire has only about 3% flux maximum, which means you need to apply additional flux to ensure maximum wetting.

Special Offer: Get $100 off your order!

Email [email protected] to get started!

Spool Size is Also Important.

Solder wire is packaged in spools or rolls like thread, and the packages can have varying weights that correspond to the wire’s length. The longer the wire, the heavier the spool.

Since these wires have a specific shelf life, you should avoid overbuying the material for your projects.

The same case applies to solder paste, which becomes less effective when you use it past its expiry date.

The Cost of Solders

Lead-based solders are cheaper than lead-free solders. However, one can use silver, bismuth, and other compounds to get the desired properties.

Silver-coated solders are expensive but provide more strength than tin. Bismuth-based solders are also costly. This is primarily due to their ability to operate at low temperatures.

What Should Be The Correct Dimension?

Solder wires with thicker diameter solder (.062) are ideal for soldering larger joints. However, it can make soldering smaller joints troublesome.

Therefore, before buying, it is essential to identify the size of the joint. However, the best solder for circuit boards can be a solder wire of a diameter of approximately 0.711 mm.

The width of this wire is perfect for circuit boards.

(Soldering an electronic circuit board)

Solder Based on Your Project

When to choose Lead-based solder

There is still much conjecture surrounding lead-based solders. Researchers are still analyzing their impact on health and the environment.

With that said, the ideal welds for aerospace or medical electronics are lead-based. There is not enough proof to back the usage of lead-free solders in critical applications.

Therefore, aerospace and medical industries use lead solders to this day.

Lead-free solder

Off late, lead-free solders have replaced the conventional lead-based solders.

These lead-free solders are ideal for use in electronics. An additional benefit is that they do not cause any harm to the health or the environment.

Amateur application

Lead-free solders can be expensive. So, one can opt for the standard Sn60Pb40 welding for amateur and hobby use.

(Alt – Solder circuit board )

How to Choose a Solder Based Upon Your Electronic Product?

Another factor to keep in mind is the nature of electronic products and their attributes. Using dissimilar metals can cause corrosion.

An ideal solder consists of a specific mixture of elements that give the desired results. For instance, the lead solder melts in a particular range of 180°C - 190°C.

However, a eutectic blend of Sn63Pb37 melts at exactly 183°C.

70Pb30 works well with gold contacts (less gold leaching). 70Pb30 also provides high resistance to fatigue during thermal cycling.

Therefore, you can choose a custom solder based on the properties you desire. While choosing, keep in mind factors like thermal resistance, corrosion resistance.

(PCB electronic products with different solders)

What is The Perfect Solder Diameter For You?

The gauge number determines the diameter of the solder. A gauge number is a unit of thickness for metal sheets and wires.

For amateur and hobbyists, gauge numbers 18, 20, and 21 are the numbers that work well. The diameters of these numbers are 1.22, 0.914, and 0.813 mm, respectively.

Staying in this range is a good idea for amateurs and beginners. Using wires of this diameter reduces solder wastage.

For Plastic Dual In-line Package (PDIP) with a pin spacing of 0.1-inch, gauge 18 (1.22mm) is ideal.

22-gauge numbered wires are suitable for smaller PCBs. Cables with gauge numbers 22 have a diameter of 0.711 mm.

Pins are much closer in SMD and SOIC packages, making this wire ideal due to their small diameter.

Pin spacing in old circuits is much more than the current channels. These circuits have more significant solder tags.

Gauge 16, owing to their larger diameter of 1.63mm, are the perfect choice for old courses.

(The workplace of the engineer. Soldering iron for PCB Assembly.)

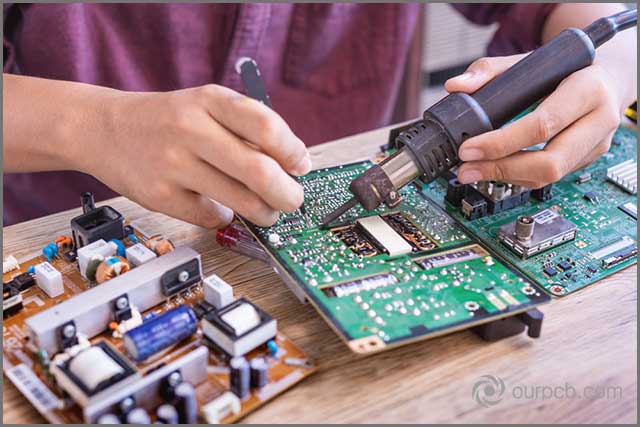

Solder in Circuit Board Repair

Ideally, you can use any solder to repair a circuit board. However, one must make a note of the factors like thermal resistance and pin spacing.

Yet, one can use a lead-free solder with a small diameter to conduct any circuit board repairs. Smaller diameters help in catering to the lower joints and junctures.

(Alt–Circuit board repair)

Focus on The Shelf Life of Solder

The alloy used in a solder determines the shelf life of Flux-cored solder wire. Alloys with more than 70% lead have a shelf life of 2 years. Other alloys have a shelf life of 3 years.

Lead-free solders have a longer shelf life than lead-based welds. Thus, you can go for lead-free solders if you do not intend to finish the entire solder reel in one go.

Summary:

There are many different types of solder doing the rounds of the market. Choosing the right solder may seem like a daunting task. However, there are a few things one must keep in mind.

Simplify the solder-choosing process for you. Order custom made solders according to your needs from us. Wiring offers it all – with state-of-the-art technology that you will love.

Our welding is sure to give you the best results and quality. We even offer custom-printed circuit boards that meet your needs. Contact OurPCB to learn much more about solders and soldering from our experts.

Special Offer: Get $100 off your order!

Email [email protected] to get started!