Contents

- Best Practices for Adhesion and Assembly

- Key Takeaways

- What is PCB Glue?

- Common Types of PCB Adhesive / Glue For Circuit Boards?

- Ultraviolet Curing Glues

- Thermally Conductive Glues

- Conductive PCB Adhesive

- Other Types of PCB Glues

- Why use Glue in PCBs?

- To Enhance Mechanical Strength

- To Improve Moisture Resistance

- To Improve Thermal Conductivity

- To Provide Electrical Insulation

- To Streamline Production

- To Increase Vibration Resistance

- To Enhance Performance and Reliability

- What are the Typical Applications of PCB Glue?

- Surface Mount Components Bonding

- Wire Tacking

- Potting and Encapsulating Electronic Components

- Conformal Coatings

- What Types of Glue are Best for Circuit Boards?

- Is Hot Glue Safe for Circuit Boards?

- How to Remove PCB Glue?

- PCB Glue FAQs

- Is Super Glue Electrically Conductive?

- What is Non-Conductive Glue for PCBs?

- What is Epoxy Glue for PCBs?

- Is There a Glue That Works Like Solder?

- Can I Use Glue Instead of Electrical Tape?

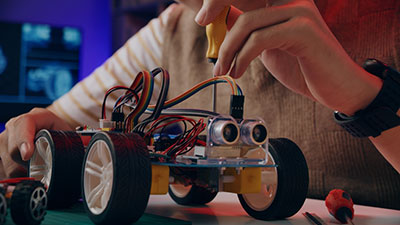

Best Practices for Adhesion and Assembly

The best practices for using electronic circuit board adhesive are using the right type of adhesive, it's as simple as that. PCB assembly and mechanical support require a great deal of knowledge around which PCB glue works best for your circuit board. Are silicone adhesives better than super glue? It's tough to tell without industry knowledge.

Thankfully, OurPCB boasts over 15 years of experience in bringing your PCB designs to life. We've written this article to help you understand what PCB glue is, the different types that are available, and which work for your electronic circuit board.

Key Takeaways

- PCB glue, or adhesive, is a critical material used in the electronics industry to bond and secure components to printed circuit boards (PCBs).

- There are several different types of PCB adhesives, including ultraviolet adhesives, conductive PCB adhesives, polyimides, silicone resins, and super glue.

- PCB glue provides thermal conductivity, electrical insulation, increases resistance to vibrations and moisture, and enhances the mechanical strength of your PCB circuit.

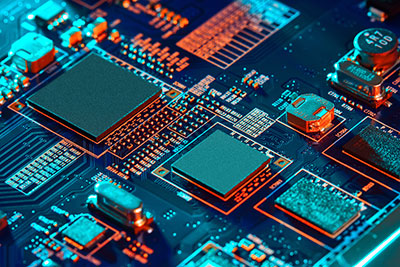

What is PCB Glue?

PCB glue is an adhesive used to attach electronic components to a printed circuit board (PCB). It helps secure components, provides insulation, and can improve thermal conductivity for your circuit board.

Common Types of PCB Adhesive / Glue For Circuit Boards?

| Type of Glue | Advantages | Disadvantages | Usability |

|---|---|---|---|

| UV-Curing Adhesives | Quickly cures under UV light | Requires UV equipment | Suitable for mass production of PC components |

| Thermally Conductive Glues | Provides a secure bond between heat sinks and components | Can be thick and expensive | Important for heat-intensive applications like gaming setups or overclocked CPUs |

| Conductive PCB Adhesive | Lead-free and environmentally friendly alternative | More expensive than soldering | Ideal for sensitive components that cannot withstand the heat of soldering (e.g., delicate PCBs) |

| Polyimides | High-temperature resistance (up to 300°C) | Requires high post-processing | More commonly used in industrial or aerospace electronics |

| Silicone Resins | Excellent temperature resistance (-60°C to +200°C) | Mostly used for specific encapsulation purposes | Common in industry for conformal coating needs |

| Cyanoacrylate (Super Glue) | Fast-curing with strong shear strength | Emits fumes when heated | Good for non-vital wire assemblies or temporary fixes |

When assembling PCBs, it’s crucial to choose the right adhesive. Non-conductive adhesives like epoxy, cyanoacrylate, or RTV silicone are ideal for securing components. If you require an electrically conductive bond, conductive glues containing silver or graphite particles are suitable for connecting electrical components.

Ultraviolet Curing Glues

Ultraviolet curing glues for PCB are light-curing and come in several types, including encapsulants, adhesives, and coatings. These bonds are common in electronics due to their compatibility with various PCB materials.

The glues are easy to relieve and do not require temperature relief. Many of these glues feature acrylic-based details and contain photo initiators that are easily actuated by bright radiation. However, UV cannot penetrate very thick coats of the glue. These adhesives are commonly applied in UV sensor devices and other components requiring precise and reliable bonding.

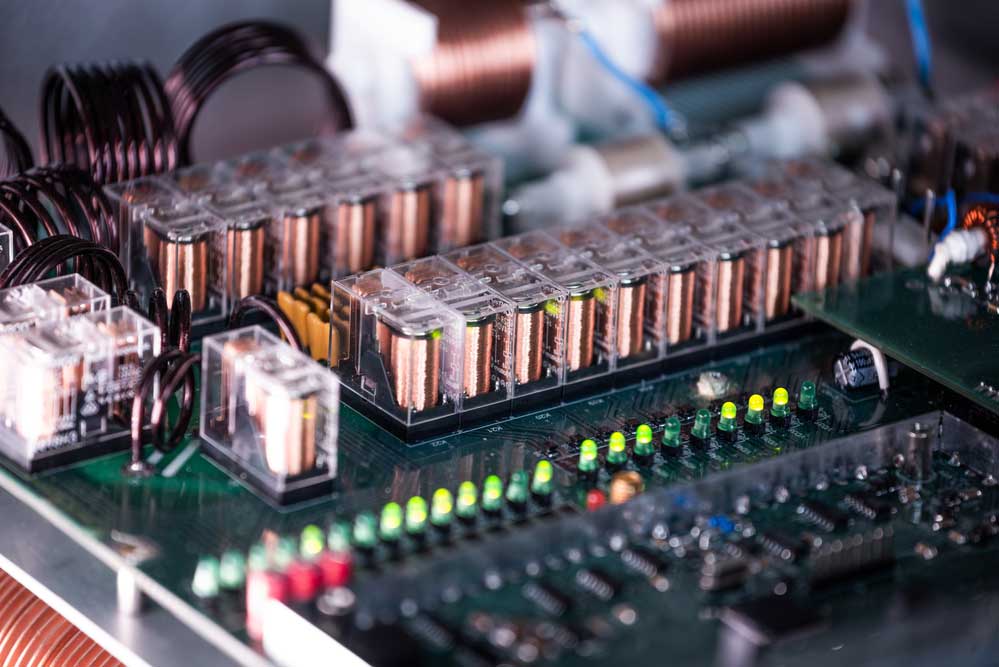

Thermally Conductive Glues

Thermally conductive glues are adhesives used to secure heat sinks to electronic components by providing an effective heat-directing path, preventing damage caused by excessive heat.

These glues can be mixed with electrically conductive or insulating powders to increase their thickness and enhance their thermal conductivity. As a result, they are essential in creating thermal conducting bonds. Various hot glue PCB formulas, often used in high-temperature PCBs, typically combine epoxy, acrylics, and silicon to ensure durability and effective performance under extreme conditions.

Conductive PCB Adhesive

Conductive PCB adhesive is a specialized glue designed to conduct electricity, unlike most standard glues that are not electrically conductive.

It is essential for applications like attaching surface-mount gadgets and integrated circuits where electrical conductivity is required.

There are two types of conductive adhesives: anisotropic sealants, which conduct electricity in all directions, and isotropic adhesives, which conduct only in one direction. For additional insights on conductive materials, visit Conductive Paint.

Other Types of PCB Glues

Other types of glues for PCB include polyimides, silicone resins, and cyanoacrylates. These are not always used as glue to hold PCB circuits together, but can be used in certain cases.

Polyimides

Polyimides are used in high-technology applications due to their ability to withstand temperatures up to 300ºC.

Silicone Resins

Silicone resins, primarily sealants, are often used as encapsulants in conformal coatings, withstanding temperatures from –60ºC to +200ºC.

Cyanoacrylates

Cyanoacrylates, commonly used for attaching wires to PCB boards, are single-part glues that dry quickly but work best when paired with activators for faster drying.

Special Offer: Get $100 off your order!

Email [email protected] to get started!

Why use Glue in PCBs?

You use glue in PCBs to secure components, improve moisture resistance, enhance thermal conductivity, provide electrical insulation, simplify production, and increase vibration resistance, which boosts overall performance and reliability. It is especially valuable during PCB prototype assembly, where reliable adhesion is critical for testing and evaluating new designs.

To Enhance Mechanical Strength

PCB glue secures components to the board during transportation and operation, creating a sturdy bond that minimizes the risk of looseness or detachment.

To Improve Moisture Resistance

Some PCB glues are moisture-resistant, which means they form water-resistant barriers that protect the PCB from corrosion and short-circuiting.

To Improve Thermal Conductivity

Some PCB glues can also operate like thermal pastes because they help to dissipate heat away from heat-generating components.

They can also evacuate heat away from temperature-sensitive components to lengthen their lifespan.

To Provide Electrical Insulation

Glue can double up as a dielectric material, separating electrically conductive components to prevent short-circuiting or ground faults.

To Streamline Production

Glue eliminates the need for clips, screws, or other types of fasteners during assembly, which simplifies the PCB production process.

It can also eliminate the need to solder some components, making the process cheaper and more efficient.

To Increase Vibration Resistance

While not as strong as solder, PCB glue holds and secures components to the PCB, preventing damage relating to vibrations when the board is in use.

PCBs in industrial and automotive applications experience tons of vibrations, but PCB glue keeps everything intact.

To Enhance Performance and Reliability

PCB glue combines benefits like enhancing mechanical strength, providing electrical insulation, improving thermal conductivity, and providing moisture resistance, making the PCB perform better and be more reliable.

What are the Typical Applications of PCB Glue?

PCB glue is used for surface mount components bonding, wire tacking, and potting to protect components from damage. It's also key in conformal coatings, shielding boards from moisture, corrosion, and temperature changes. Common adhesives include epoxies, silicones, and polyurethanes.

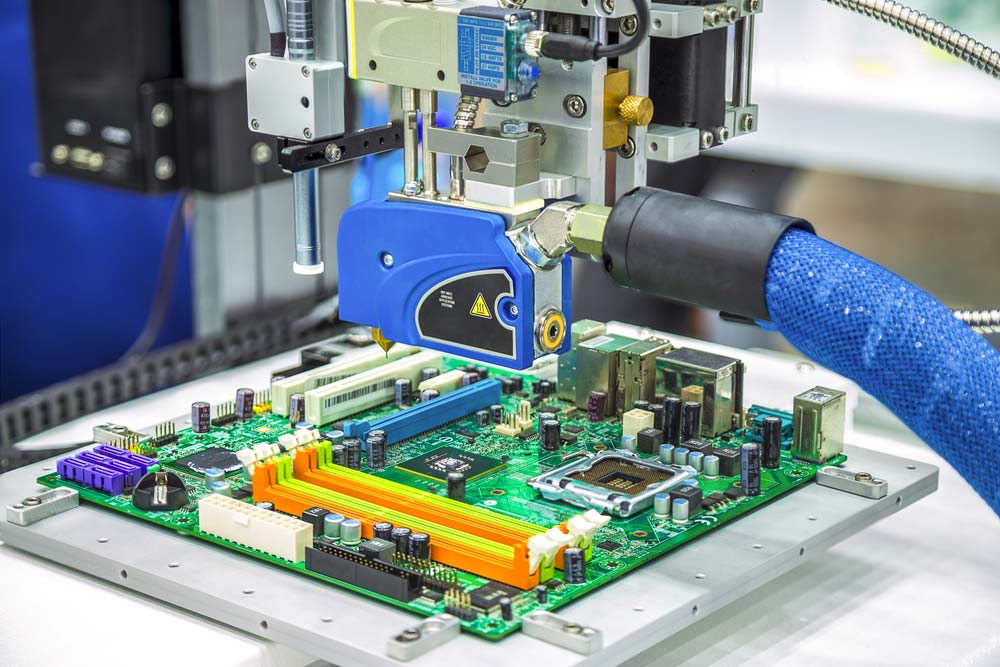

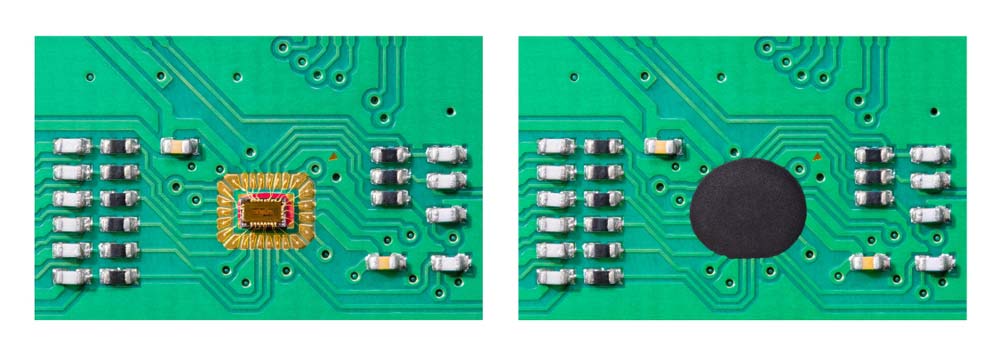

Surface Mount Components Bonding

When attaching surface mount devices (SMDs), the primary step is placing them on beads of uncured adhesive.

The next significant step is curing the glue via ultraviolet radiation or heating.

You might find others referring to the process as chip bonding.

The essence of the curing process is to facilitate firm attachment of the SMDs.

Essentially, there are two essential uses of surface mount adhesives. They include:

- Acting as a processing aid

- Helpful in enhancing stress relief to the solder attachments. Ideally, the process is significant in preventing a possible failure of the electrical connections.

Your favorite glue should have an extended shelf life. Also, it's advisable to ensure that the excess adhesive does not affect the sensitive components. The following are some of the preconditions for effective adhesive solutions with SMDs:

- Also, the glue for circuit boards should have rapid curing properties

- Ideally, it should be non-stringing.

- During coating circuit boards, the adhesive should feature high wet strength.

- Also, the bond should have excellent electrical properties after curing.

- It should be flexible and of high power.

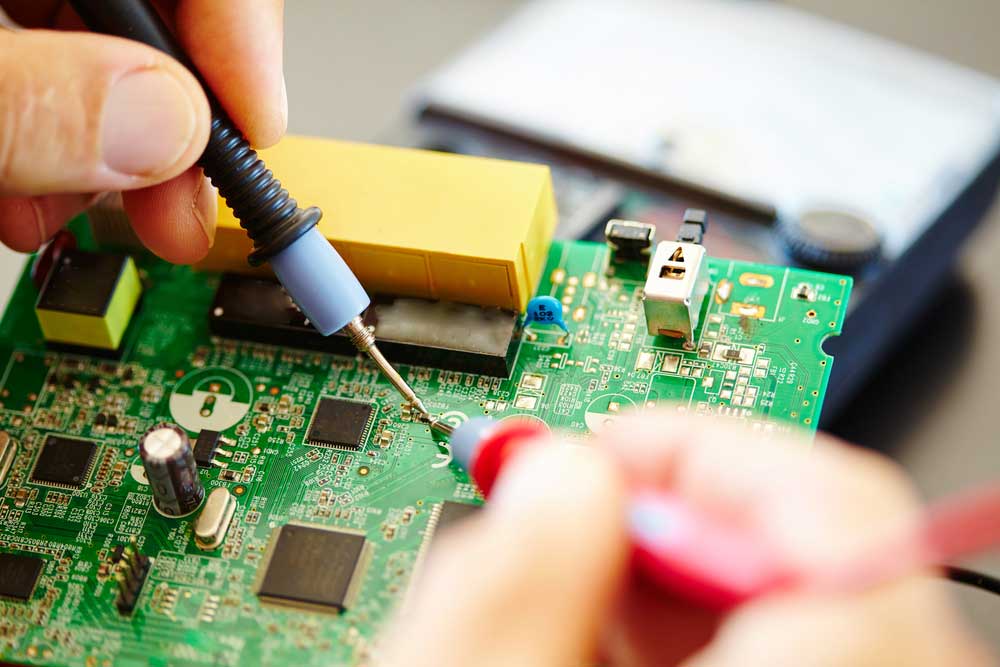

Wire Tacking

The tacking process is straightforward to carry out as long as you have PCB glue.

First, ensure that you have stripped the insulation coating when attaching components.

Next, solder the ends to the component leads. Additionally, you'll be required to bond the wires using adhesive materials to the board substrate.

You can use a wide range of glues during this process. For instance, you can use cyanoacrylates or epoxy glue.

Alternatively, you can use light-curing adhesives or acrylics.

When using the former, combining it with an ideal activator is advisable. It facilitates fast curing times to as little as 30 seconds.

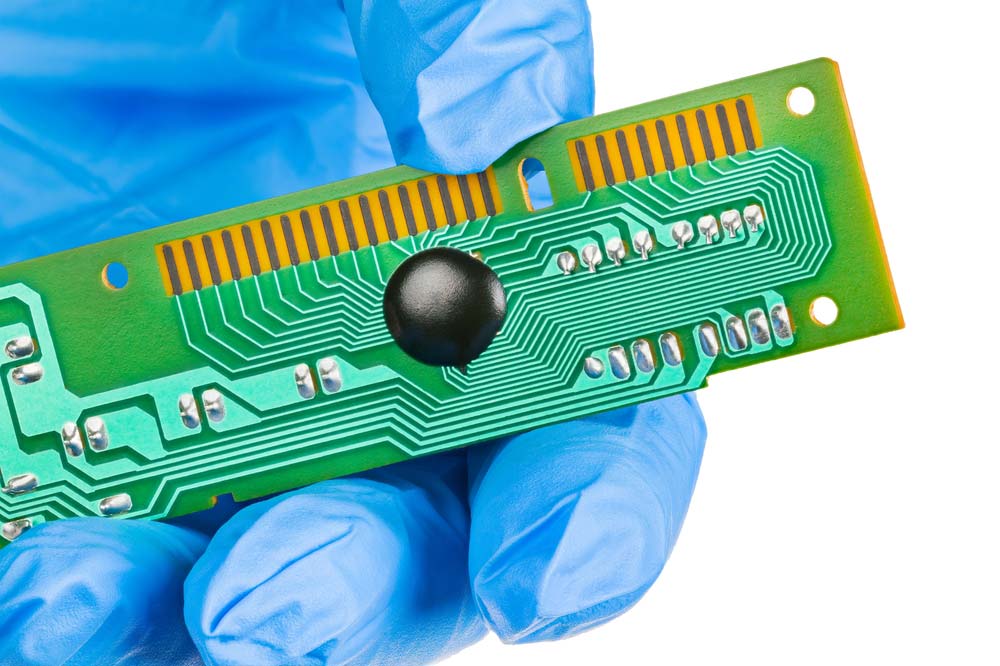

Potting and Encapsulating Electronic Components

During potting, you apply the glue to small spaces on the PCB board.

The rationale of this process is to limit physical and environmental damage.

Additionally, the method improves the insulation capability of the surface.

When choosing potting glue for PCB, ensure it has good chemical properties.

Also, ensure that it has efficient adhesion to metals and plastics. The most common bonds for PCB that you can use during potting include epoxies, silicons, acryls, and polyurethane.

Conformal Coatings

First, note that conformal coatings are not exclusively due to the adhesive bonding process.

Nonetheless, note that adhesive resins are still pertinent in enabling conformal coating.

Thus, you can use epoxies, silicones, acrylics, and polyurethanes in this process.

Essentially, the critical significance of a conformal coating is board protection from environmental factors.

They include short circuits and moisture from the surroundings.

The layers will also prevent the corroding of solder joints. Additionally, a board with the coating is safe from service temperature changes.

What Types of Glue are Best for Circuit Boards?

The best glue for circuit boards is epoxy due to its versatility. UV-curing acrylics are also effective for attaching surface-mount devices. Silicone is ideal for conformal coatings and encapsulating components, while cyanoacrylates work well for reinforcing wire connections.

Choosing the right glue depends on factors like environmental exposure, temperature sensitivity, and component weight.

Is Hot Glue Safe for Circuit Boards?

Hot glue is not electrically conductive, so it won’t short circuits, but it melts at lower temperatures than other adhesives like epoxy, making it unsafe for components that get hot.

Additionally, hot glue acts as a thermal insulator, trapping heat and potentially causing failure in power components. It can be used for securing lightweight components or temporary fixes, but it is generally unsafe for long-term use on circuit boards.

How to Remove PCB Glue?

You can remove PCB glue by using a sealant remover like isopropyl alcohol or methylated spirits. Here is a step-by-step guide to easily remove any type of PCB glue from your electric circuit board.

- Step 1: Disconnect the PCB or device’s power source to eliminate chances of electric shock, which can damage sensitive components.

- Step 2: Identify the glue type to determine the removal process. Silicone and hot glue adhesives usually require sealant removers, isopropyl alcohol, or methylated spirit plus heating, while acrylic and epoxy adhesives require acetone or isopropyl alcohol.

- Step 3: Use a heat gun or a soldering gun at low-temperature settings to apply heat gently above the glue on the PCB to soften it. If you don’t have a heat gun, a hairdryer will do. Don’t overheat one area because you can damage the PCB or components. And remember to use acetone or isopropyl alcohol solvents to soften heat-sensitive adhesives.

- Step 4: Remove the softened glue using tweezers, plastic scrapers, or dental picks, then clean the area you’ve removed the glue from using a lint-free cloth or cotton swab soaked in isopropyl alcohol or acetone.

- Step 5: Inspect the board and its components to check for signs of damage or left-over adhesive.

- Step 6: Repeat steps three, four, and five if you notice signs of sticky adhesive.

- Step 7: Once the board is adhesive-free, reassemble the device or rework the glue while ensuring all the components are secure and fully functional.

If you want to learn more about which adhesives are used for PCB circuits, our team at OurPCB can help connect your business with rigid PCBs, flex PCBs, and assembly no matter the volume. Contact us today to get your free quote.

PCB Glue FAQs

Is Super Glue Electrically Conductive?

No, super glue and Gorilla Glue are not conductive. Both glues are non-conductive and do not allow the flow of electricity, making them unsuitable for creating electrical connections on circuit boards. There are super glue for electronics that you can purchase online.

What is Non-Conductive Glue for PCBs?

Non-conductive PCB glue is an adhesive that does not conduct electricity, a property that eliminates the chances of short-circuiting or accidental grounding.

What is Epoxy Glue for PCBs?

Epoxy PCB glues are two-part adhesives that come as separate resins and hardeners.

When mixed, these two form a strong, hardened glue resistant to moisture, heat, and chemicals.

Is There a Glue That Works Like Solder?

Cyanoacrylate glue (super glue) has almost similar joint strength to solder, but anisotropic and isotropic glues are your best bet if you want electrically conductive adhesives.

You can’t get both high joint strength and electrical conductivity in one PCB glue, so none works like solder.

Can I Use Glue Instead of Electrical Tape?

You can use non-conductive glue in place of electrical tape, but avoid using hot glue; it is unsafe for printed circuit boards.

Special Offer: Get $100 off your order!

Claim your $100 discount by sending an inquiry today. Act now to save on your next project!

Please email [email protected] for details.

Back to Top: PCB Glue: Best Practices for Adhesion and Assembly

Special Offer: Get $100 off your order!

Email [email protected] to get started!