Contents

- Key Takeaways:

- Types of PCB Connectors Overview

- PCB Connector Types by Function & Application

- How to Choose the Right PCB Connector

- FAQs About Types of PCB Connectors:

- What are the three types of connectors?

- What is the most common form of wire termination connection found on a PCB board?

- What are the terminals on a PCB?

Key Takeaways:

- PCB connectors vary significantly in form and function, each designed for particular types of connections and environments.

- Selecting the correct connector type is crucial for performance, durability, and compatibility with your design requirements.

- Reliable, standardized connectors ensure smooth assembly, easy maintenance, and allow for design flexibility in both prototyping and final applications.

Special Offer: Get $100 off your order!

Email [email protected] to get started!

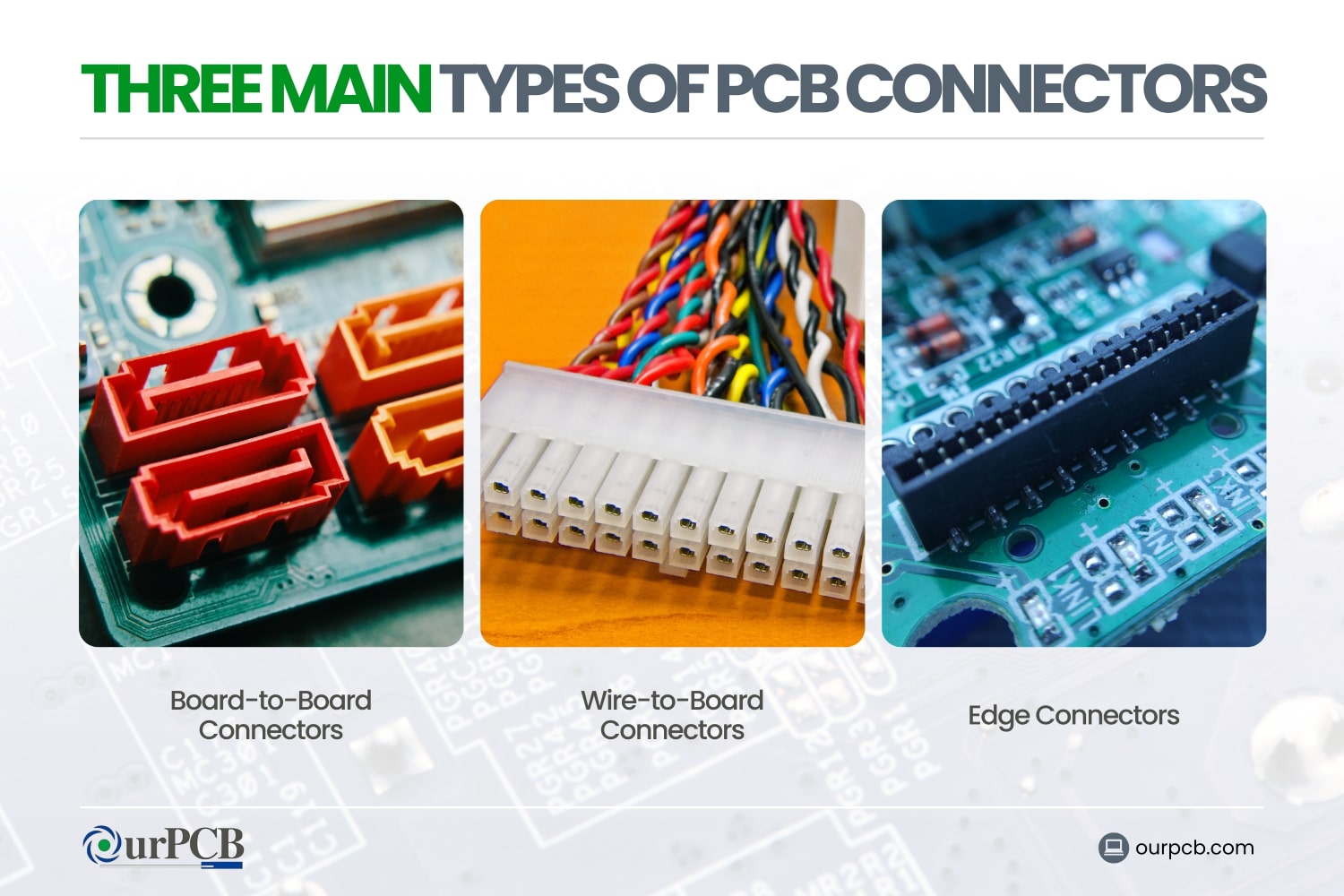

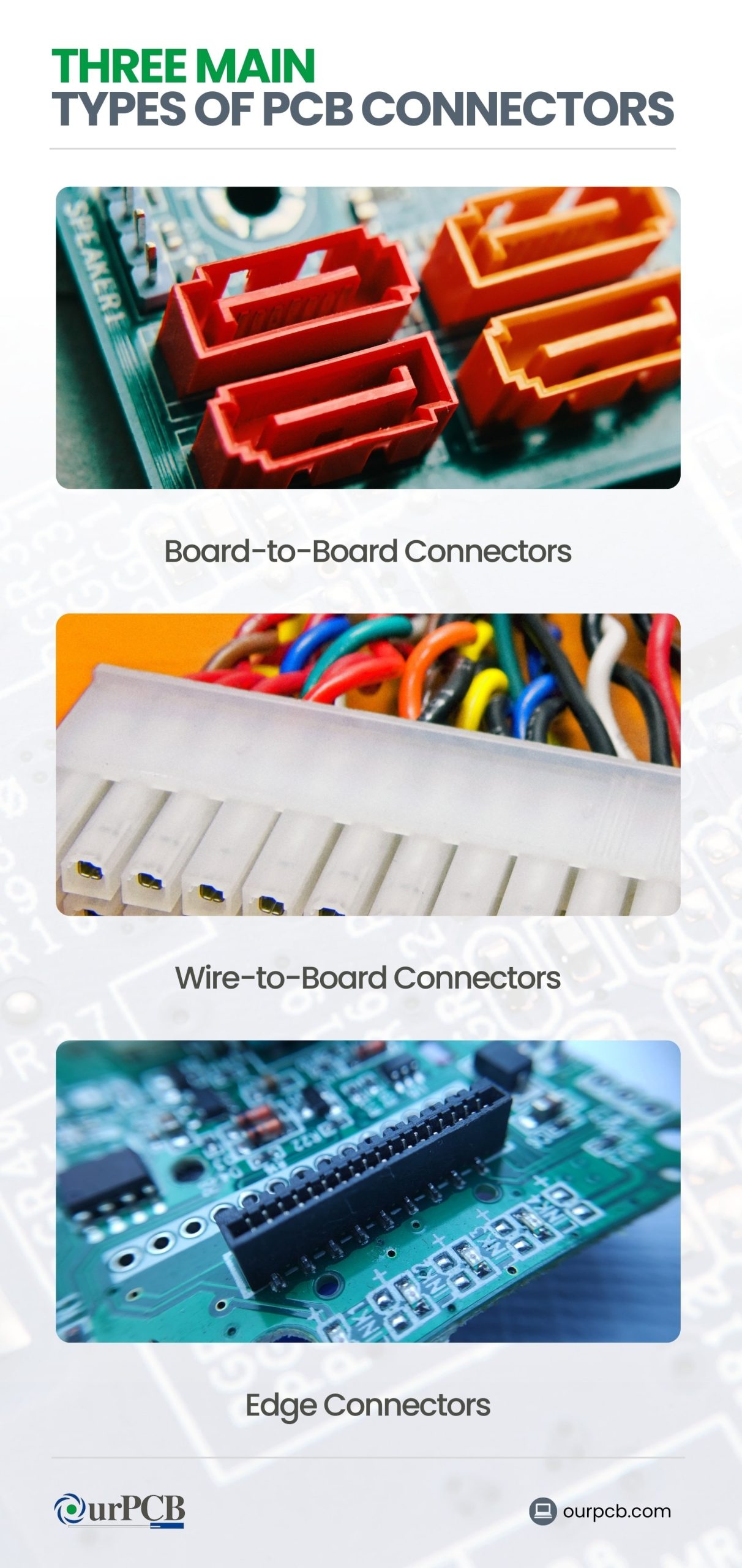

Types of PCB Connectors Overview

| Connector Type | Application | Key Features | Example Use Cases |

|---|---|---|---|

| Board-to-Board | PCB-to-PCB connections | High density, multi-pin, reliable stacking | Motherboards, expansion cards |

| Wire-to-Board | PCB-to-wire or cable connections | Secure connection, often with locking mechanisms | Power supply, motor connections |

| Edge Connectors | Board edges to female sockets | Space-efficient, direct contact points | Memory modules, expansion cards |

| Audio and Video Connectors | Signal transmission for A/V | Minimizes interference, high quality signals | Audio jacks, HDMI, RCA connectors |

| Data Connectors | Data signal transmission | High-speed, universal protocols | USB, Ethernet, serial connections |

| Power Connectors | Power supply connections | High current/voltage handling, secure locking | DC power input, computer internals |

| Fiber Optic Connectors | High-speed data via light pulses | High bandwidth, low EMI, secure coupling | Telecommunications, network equipment |

| RF Connectors | High-frequency signal transmission | Low interference, impedance matching | Antenna connections, RF signal paths |

| Industrial Connectors | Harsh environments | Durable, resistant to moisture/chemicals | Automation, process control equipment |

| Automotive Connectors | Vehicular applications | Vibration-resistant, temperature stable | Engine control units, infotainment systems |

PCB Connector Types by Function & Application

PCB connectors are available in multiple configurations to suit diverse applications and environments. Here’s a closer look at the primary PCB connector types, organized by their typical applications.

1. Board-to-Board Connectors

Board-to-board connectors are essential for linking two printed circuit boards (PCBs), allowing them to communicate and share power and data. These connectors often support both parallel and perpendicular board arrangements, making them suitable for a range of configurations and applications, from compact devices to larger systems. In compact memory devices, connector design and placement are vital, making knowledge of micro SD card pinout essential for integrating memory modules into PCB designs.

- Styles and Configurations:

- Mezzanine Connectors: Compact, high-density connectors used to connect stacked PCBs in devices where space-saving is essential.

- Backplane Connectors: Larger connectors ideal for linking multiple boards in larger systems, such as servers or telecommunications equipment.

- Applications: Motherboards, expansion modules, stacked circuit designs.

- Key Specifications:

- Pitch and Pin Count: Varying pitch sizes and pin counts support flexibility in design and signal integrity.

- Durability: Often rated for multiple mating cycles, making them ideal for modular devices.

2. Wire-to-Board Connectors

Wire-to-board connectors allow direct connections from individual wires or cables to a PCB, making them crucial for applications requiring external power sources or peripheral connections. They come in several styles, each designed to handle different voltages, currents, and assembly methods.

- Styles and Types:

- Crimp-style Connectors: Often used in high-vibration environments, where a secure, reliable connection is necessary.

- Insulation Displacement Connectors (IDC): Allow quick, solder-free connections, ideal for mass production.

- Screw Terminals: Provide a secure connection, typically used for power supply connections in industrial applications.

- Applications: Power supply connections, motor wiring, sensor assemblies.

- Key Specifications:

- Current and Voltage Ratings: Rated to handle various power levels, essential for safe operation in power circuits.

- Locking Mechanisms: Many wire-to-board connectors feature locking clips or screws to ensure a stable connection even under mechanical stress.

3. Edge Connectors

Edge connectors, also known as card-edge connectors, make use of the PCB’s edge as the contact point, which is inserted into a corresponding socket. This design is highly space-efficient, making edge connectors ideal for applications where compactness is a priority.

- Common Examples:

- Memory Card Connectors: Common in computers, where RAM modules connect to the motherboard.

- Expansion Slot Connectors: Used in PCs and gaming consoles to allow for component upgrades and expansions.

- Applications: Expansion cards, memory modules, embedded systems.

- Key Specifications:

- Durability: Typically rated for many insertion/removal cycles, which is important for modular or upgradeable systems.

- Signal Integrity: High-quality edge connectors support fast data transmission, maintaining signal integrity over repeated use.

4. Audio and Video Connectors

Audio and video connectors are specialized PCB connectors optimized for transmitting high-quality signals with minimal interference. These connectors are common in consumer electronics, such as speakers, cameras, and audio recording devices.

- Common Types:

- Auxiliary (3.5 mm) Jacks: Standard in portable audio devices, capable of supporting stereo audio signals and, in some cases, microphones.

- HDMI (High-Definition Multimedia Interface): Widely used for high-definition video and audio transmission, supporting both digital and analog signals.

- RCA Connectors: Analog connectors commonly used in older audio and video equipment.

- Applications: Consumer electronics, audio-visual systems, recording equipment.

- Key Specifications:

- Impedance and Shielding: High-quality audio and video connectors include shielding to minimize interference.

- Connector Compatibility: Many are standardized (e.g., HDMI) for broad compatibility across devices.

5. Data Connectors

Data connectors facilitate data transmission to and from a PCB, allowing communication between different components or systems. They are typically used in digital applications, such as computers and networking equipment, and support universal data protocols.

- Common Types:

- USB (Universal Serial Bus): Available in various forms, including USB-A, USB-B, and USB-C, with different connectors supporting different data rates.

- Serial Ports: DB9 and DB25 connectors, used in RS-232, RS-485, and UART protocols, ideal for long-distance communication.

- Ethernet (RJ45): Standard connectors for Ethernet networking, providing reliable data transmission in both commercial and industrial settings.

- Applications: Computers, communication devices, network equipment.

- Key Specifications:

- Data Rate and Bandwidth: Data connectors are chosen based on the speed requirements of the application.

- Durability: Many data connectors are rated for high insertion/removal cycles, supporting frequent reconnections.

6. Power Connectors

Power connectors are essential for delivering the required current and voltage to a PCB’s components. These connectors are engineered to handle various power levels safely and efficiently, depending on the application.

- Common Types:

- Barrel Connectors: Cylindrical connectors commonly found in small electronics for DC power input, such as laptops or portable devices.

- Molex Connectors: Reliable connectors frequently used in computer internals and other electronic equipment to supply power.

- ATX Power Connectors: Standardized connectors used in desktop computers, connecting the motherboard to the power supply for efficient distribution.

- JST Connectors: Compact, widely used connectors in battery-powered devices or low-power applications.

- Applications: Powering PCB components, linking to external power sources, distributing power in complex systems.

- Key Specifications:

- Current and Voltage Ratings: Power connectors are rated for specific current and voltage levels to prevent overloading.

- Safety Mechanisms: Many power connectors include features such as locking clips to maintain a stable connection and prevent accidental disconnections.

- Heat Resistance: Power connectors must often withstand heat generated by higher currents, particularly in high-power applications.

7. Fiber Optic Connectors

Fiber optic connectors are specialized connectors that use light pulses instead of electrical signals, ideal for high-speed data transmission over long distances with minimal loss and interference. These connectors are essential for applications requiring high bandwidth and low latency.

- Common Types:

- Lucent Connectors (LC): Compact connectors widely used in high-density applications, such as data centers.

- Straight Tip (ST) Connectors: Equipped with a bayonet locking mechanism, these are easy to connect and disconnect, commonly used in industrial applications.

- Subscriber Connectors (SC): Employing a push-pull locking system, these connectors are often used in network environments due to their reliability.

- Applications: Telecommunications, high-speed networking, data centers, medical imaging.

- Key Specifications:

- Bandwidth and Speed: Fiber optic connectors support very high data rates, necessary for high-speed network applications.

- EMI Immunity: Unlike copper-based connectors, fiber optic connectors are immune to electromagnetic interference (EMI), making them ideal for environments with high EMI.

- Durability and Installation: Fiber optic connectors often require specialized installation but are designed for high durability in demanding applications.

8. RF Connectors

RF (Radio Frequency) connectors are designed to manage high-frequency signals, essential in applications where minimizing interference and signal degradation is crucial. They are commonly used for connecting antennas, transmission lines, and other RF components in wireless and broadcast systems.

- Common Types:

- SubMiniature version A (SMA): Threaded connectors used for frequencies up to 18 GHz, ideal for secure, high-frequency connections in RF circuits.

- Bayonet Neill-Concelman (BNC): Common in test equipment, these connectors offer a quick-connect and disconnect feature, simplifying setup and teardown.

- Threaded Neill-Concelman (TNC): A threaded version of the BNC connector, providing improved performance at higher frequencies and under mechanical stress.

- Applications: Antennas, RF signal paths, Wi-Fi systems, broadcast equipment.

- Key Specifications:

- Frequency Range and Impedance: RF connectors are chosen based on the frequency range they can handle and their impedance, typically 50 or 75 ohms, to match transmission line impedance.

- Shielding and Interference: High-quality RF connectors provide effective shielding, reducing interference and maintaining signal integrity.

- Durability: RF connectors are often rated for numerous connection cycles, ideal for test environments or modular designs.

9. Industrial Connectors

Industrial connectors are ruggedized connectors specifically designed for harsh environments, such as those found in manufacturing plants, automation systems, and outdoor installations. These connectors must withstand high temperatures, moisture, vibrations, and exposure to chemicals.

- Common Types:

- M8 and M12 Circular Connectors: Compact, standardized connectors often used in industrial automation and sensor applications. These connectors come with coded keying to prevent mismating.

- Terminal Blocks: Versatile connectors that allow for secure, screw-based connections of field wiring directly to the PCB.

- Heavy-Duty Rectangular Connectors: Multi-pin connectors for complex industrial systems, where they allow for numerous signal and power connections in a single housing.

- Applications: Automation systems, process control, outdoor installations, heavy machinery.

- Key Specifications:

- Environmental Resistance: Industrial connectors are often rated for ingress protection (IP), specifying their resistance to water, dust, and other contaminants.

- Mechanical Robustness: These connectors are built to endure vibrations, impacts, and other mechanical stresses typical of industrial environments.

- Ease of Maintenance: Many industrial connectors are designed for easy assembly and disassembly, supporting quick installation and replacement in the field.

10. Automotive Connectors

Automotive connectors are designed for vehicular applications and must meet stringent requirements for durability under conditions such as temperature extremes, mechanical vibration, and exposure to automotive fluids.

- Common Types:

- Waterproof Connectors: Automotive connectors are often designed with waterproofing capabilities to prevent failure due to moisture.

- Circular and Rectangular Connectors: These connectors come in various shapes, designed to fit tightly in confined spaces within vehicles.

- Pin and Socket Connectors: Often used for sensor connections and control units, they provide secure and durable connections in engine control units (ECUs) and other vehicular systems.

- Applications: Engine control units, infotainment systems, power distribution, safety equipment.

- Key Specifications:

- Temperature Tolerance: Automotive connectors must handle extreme temperatures, both hot and cold, depending on the application location within the vehicle.

- Vibration Resistance: These connectors are reinforced to maintain contact integrity in high-vibration environments, crucial for moving vehicles.

- Chemical Resistance: Many automotive connectors are rated for resistance to chemicals such as oil, brake fluid, and antifreeze, ensuring reliable performance over time.

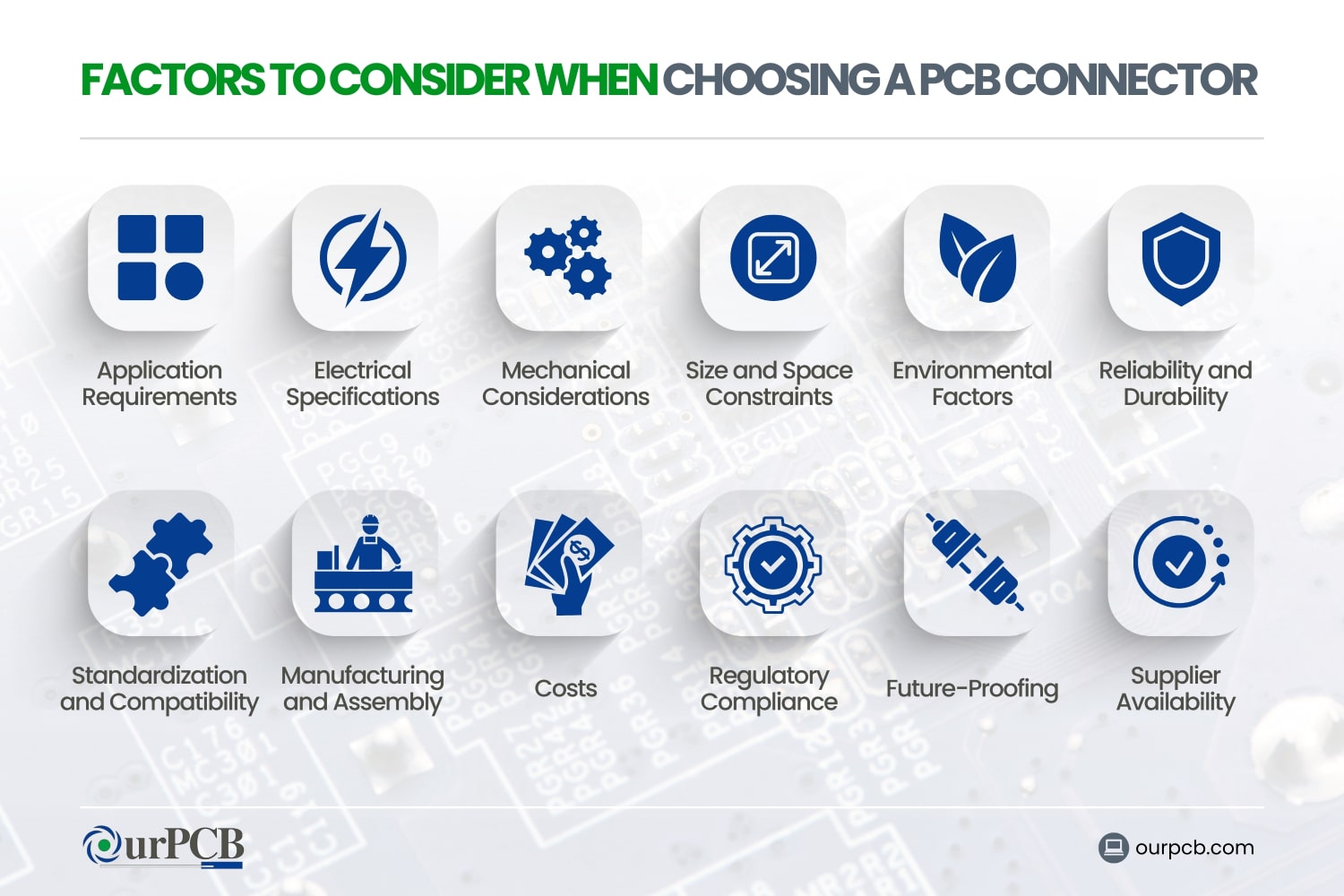

How to Choose the Right PCB Connector

Choosing the right PCB connector is essential for the longevity, reliability, and performance of any electronic design. Here’s a checklist of factors to consider:

- Application Requirements: Assess the specific needs of your project, including signal type (data, power, or RF), environmental factors, and the need for certain features like water resistance or vibration tolerance.

- Electrical Specifications: Ensure that your connector can handle the required current and voltage without overheating or degrading the connection.

- Mechanical Considerations: Choose connectors that provide the necessary robustness for your environment, such as locking mechanisms, reinforced housings, or vibration-resistant designs.

- Size and Space Constraints: Select connectors that fit within your PCB layout and do not interfere with other components. Space efficiency can be critical in compact or portable devices.

- Environmental Factors: Consider the operating temperature, moisture exposure, and chemical exposure in the intended environment. Industrial and automotive connectors, for instance, are specifically designed to endure harsh conditions.

- Reliability and Durability: For applications requiring frequent connections and disconnections, choose connectors rated for high mating cycles. Durability is also essential for connectors in heavy-use or long-term installations.

- Standardization and Compatibility: Use standardized connectors (e.g., USB, HDMI) when possible to ensure compatibility with existing devices and reduce custom manufacturing needs.

- Future-Proofing: Plan for future upgrades by selecting connectors that support higher data rates, current ratings, or environmental resistance than currently required.

- Cost Considerations: Balance the initial connector cost with long-term reliability and performance requirements, keeping in mind that high-quality connectors can prevent future repair or replacement costs.

- Supplier and Availability: Partner with reputable suppliers for quality assurance and long-term availability. Some specialized connectors may be harder to source, so ensure consistent supply chains.

FAQs About Types of PCB Connectors:

What are the three types of connectors?

The three types of connectors are board-to-board, wire-to-board, and wire-to-wire connectors. Board-to-board connectors link two separate circuit boards, while wire-to-board connectors are used to connect wires directly to the PCB. Wire-to-wire connectors enable two wires to be connected without the use of a PCB, often in modular or temporary connections.

What is the most common form of wire termination connection found on a PCB board?

The most common form of wire termination connection found on a PCB board is the pin header. Pin headers allow easy installation and removal of wires, making them popular in prototyping and modular designs. These connections typically involve male pins on the PCB and a corresponding female connector on the wire.

What are the terminals on a PCB?

Terminals on a PCB are connection points where external wires or components can be attached to the board. These terminals are crucial for establishing electrical connections between the PCB and external devices, components, or power sources. They are typically used in applications requiring direct interfacing with other hardware.

Back to Top: Types of PCB Connectors: Circuit Board Connector Types

Special Offer: Get $100 off your order!

Email [email protected] to get started!