PCB camera modules comprise image sensors, optical components, and complex circuitry to capture, process, and transmit high-quality images and video. When it comes to digital imaging, PCB camera modules have become an important part of modern visual technology.

These compact, high-tech devices easily combine advanced camera capabilities with printed circuit boards (PCBs). This makes applications from consumer electronics to industrial surveillance systems run smoothly and without interruption.

The team at OurPCB is highly experienced with camera printed circuit boards, and we’ve compiled this article to fill you in on their components, functions, and challenges. Here's our complete guide to understanding camera PCBs.

Contents

- Key Takeaways

- What are the Components of a PCB Cam?

- Image Sensor

- Lens

- Image Processing Unit

- Memory

- Interface Connectors

- Power Management Circuit

- PCB (Printed Circuit Board)

- Extra Components of the Camera

- The Functions of a Camera PCB

- Image Capture

- Signal Processing

- Power Distribution

- Data Transmission

- Control and Coordination

- Image Compression

- Other Features

- The Challenges of a Printed Circuit Cam

- OurPCB: Bring Your PCB Vision to Life

- PCB Camera Module: Understanding PCB Camera FAQs

- Are Camera PCBs Waterproof?

- Can Camera PCBs Transmit Wireless Signal?

- Does the Color of a Camera PCB Matter?

Key Takeaways

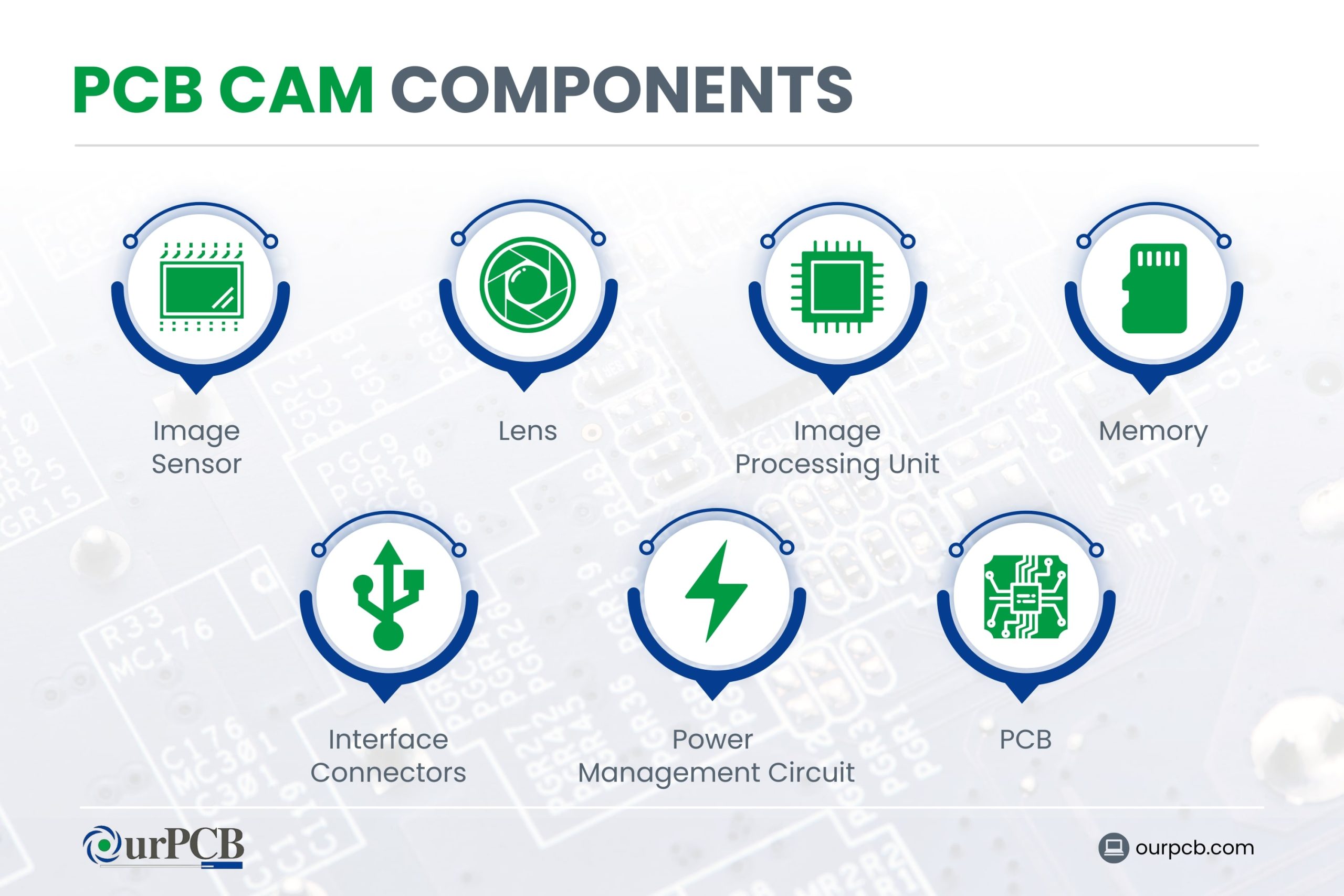

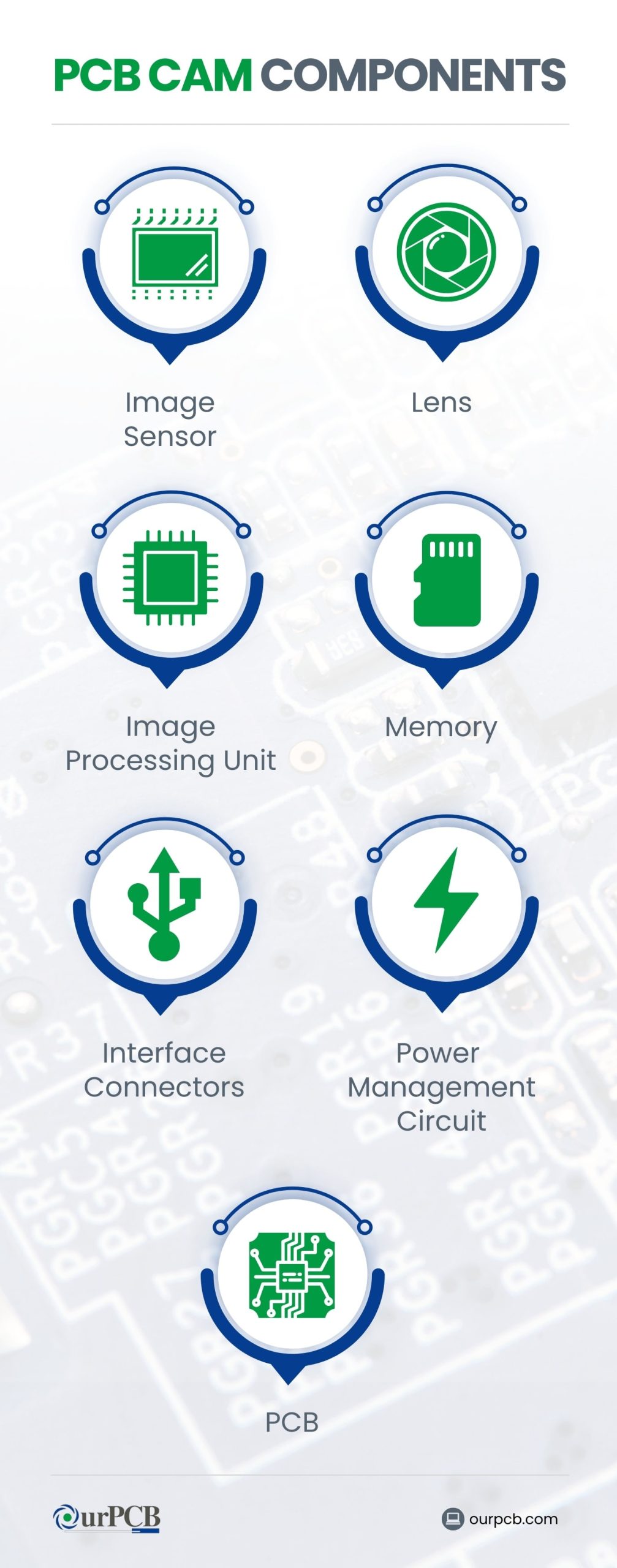

- The main components of a PCB camera are the image sensor, lens, image processing unit, memory, interface connectors, power management circuit, and PCB.

- The primary functions of a PCB camera include image capture, signal processing, power distribution, data transmission, control and coordination, and image compression.

- The challenges of a PCB camera relate to miniaturization, heat management, signal integrity, power optimization, manufacturing precision, cost management, durability, and software integration.

What are the Components of a PCB Cam?

A PCB camera module is a complicated assembly of a few different electronic and optical components working together. Let's examine the components of a video camera circuit board:

Image Sensor

In PCB manufacturing, an image sensor is the core of your digital camera. There are two main types:

- Charge-Coupled Device (CCD): These are known for high-quality images, fantastic low-light performance, and improved color accuracy. CCD sensors are usually used in high-end cameras and scientific applications.

- Complementary Metal-Oxide-Semiconductor (CMOS): This image sensor offers lower power consumption, faster readout speeds, and is more cost-effective. CMOS sensors are often used in smartphones and consumer-grade cameras.

Lens

This is the optical component responsible for focusing light onto the image sensor. There are a few different types:

- Fixed lens: This provides you with a set focal length and is common in compact cameras.

- Zoom lens: These lenses have variable focal lengths, allowing for closer or wider shots.

- Wide-angle lens: This one captures a broader field of view, making it a great choice for landscape or CCTV camera surveillance applications.

Image Processing Unit

This component processes the raw data from the image sensor. It handles tasks such as:

- Color correction: Adjusting color balance for an accurate representation of every pixel

- White balance: Compensating for different lighting conditions

- Image enhancement: Improving sharpness, contrast, and overall image quality

Memory

When it comes to camera PCB assembly, memory is one of the most important parts of the PCB design. Memory is temporary storage for image data before it's transmitted or processed further. This can include both volatile (RAM) and non-volatile memory in your camera module PCB.

Interface Connectors

Interface connectors in the camera system allow the camera module to communicate with other devices or systems. Here are some common interfaces:

- USB (Universal Serial Bus)

- CSI (Camera Serial Interface)

- MIPI (Mobile Industry Processor Interface)

Power Management Circuit

This part of the camera PCB module regulates voltage and manages power consumption throughout the camera module:

- Voltage regulators ensure that there is a stable power supply for the sensitive components of your camera equipment.

- Power distribution efficiently routes power to various camera parts of the module.

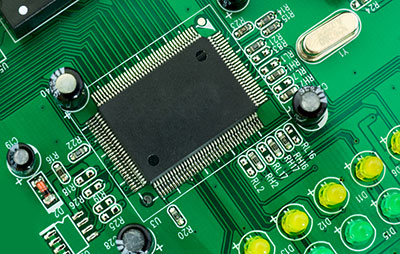

PCB (Printed Circuit Board)

The foundation of the camera module is the printed circuit board, which is brought to life by a PCB manufacturer like OurPCB. The PCB layout contains:

- Copper traces for features like the electrical connections between components.

- Solder pads are used for attaching components to the board.

- Multiple layers to accommodate complex circuitry in a small box build assembly space.

Extra Components of the Camera

A camera PCB also has a few extra components, such as:

- Aperture control: Regulates the amount of light entering the lens

- Autofocus mechanism: Adjusts lens focus automatically

- Flash or LED light: For low-light photography to improve machine vision

Special Offer: Get $100 off your order!

Email [email protected] to get started!

The Functions of a Camera PCB

When it comes to camera PCB production, it's important to understand its uses. A camera in a circuit board assembly has the following main functions that are important for the overall operation of a digital camera or imaging system:

Image Capture

The main function of the camera is to capture high-quality images or video. The image sensor on the PCB converts light into electrical signals, which are then processed and stored. This involves:

- Pixel-level light detection

- Analog-to-digital conversion of sensor data

- Initial photo or video signal amplification

Signal Processing

The PCB has circuitry that processes the raw data from the image sensor, applying a few different algorithms:

- Image enhancement improves the sharpness, contrast, and detail of photos captured by the camera.

- Color correction makes sure that there is accurate color reproduction.

- Noise reduction minimizes digital noise, especially in low-light conditions.

- White balance adjustment compensates for different lighting temperatures for a variety of camera PCB applications.

Power Distribution

The PCB manages power supply and distribution to all components, ensuring:

- Stable voltage levels for the sensitive components, even in the best camera

- Enough power consumption to extend battery life in portable devices responsible for capturing important images

- Protection against power surges or fluctuations

Data Transmission

The components of a camera are designed to facilitate the transmission of image data to other parts of the camera system. It can also facilitate data transmission to external devices through various interfaces. This includes:

- Compressing image or video data for efficient storage and transmission

- Managing data flow between the sensor, processor, and storage components

- Interfacing with external devices via USB, HDMI, or wireless protocols

Control and Coordination

The PCB coordinates a few different operations across the entire camera. Here are some examples of these camera operations:

- Autofocus: Adjusts lens elements for sharp images from circuit board cameras

- Exposure control: Manages shutter speed, aperture, and ISO settings used in PCB cameras

- White balance: Adapts to different lighting conditions

- Frame rate control: Manages the capture speed for video or burst photography

Image Compression

For digital cameras, the PCB main board usually has hardware for compressing images or video to save storage space. This might involve:

- JPEG compression for still images

- H.264 or H.265 encoding for video

Other Features

Depending on the application, the camera PCB assembly offers a variety of other features for the camera to capture. Possible functions include:

- Facial recognition: Identifying and tracking faces in the frame

- Motion detection: Triggering recordings or alerts based on movement

- Low-light enhancement: Raising sensitivity in dark conditions

- High dynamic range (HDR) processing: Combining multiple exposures for better detail in high-contrast scenes for the processing module

The Challenges of a Printed Circuit Cam

While a camera PCB may offer tons of benefits, there are also a few challenges in PCB fabrication, design, and manufacturing:

- Miniaturization: As devices become smaller, fitting all the necessary components onto a small PCB while maintaining image quality can be difficult.

- Heat Management: Challenges of assembly include the dense arrangement of components. This can lead to heat buildup, possibly affecting image quality and device longevity.

- Signal Integrity: High-speed digital signals can cause electromagnetic interference. This requires careful PCB layout and shielding techniques.

- Power Optimization: Balancing power consumption with performance is important, especially for battery-operated devices.

- Manufacturing Precision: The assembly of tiny components needs high-precision manufacturing processes and diligent quality control.

- Cost Management: Incorporating high-quality image sensors and optics while keeping costs low is an ongoing problem.

- Durability: Making sure that the camera module can withstand environmental factors like temperature changes, humidity, and physical shock is challenging. This can be especially difficult for CCTV systems.

- Software Integration: Developing and integrating software that can comprehensively use the hardware capabilities of the PCB camera module.

OurPCB: Bring Your PCB Vision to Life

PCB camera modules are incredibly useful for consumer electronics, surveillance systems, or highly advanced machine vision applications. The right PCB camera module can make all the difference.

If you're ready to take your imaging project to the next level, OurPCB is ready to be your PCB manufacturing partner. Our exceptionally skilled team can guide you through the entire process, from PCB design to camera module assembly. Contact us to bring your PCB vision to life!

PCB Camera Module: Understanding PCB Camera FAQs

Are Camera PCBs Waterproof?

No, camera PCBs are not designed to be waterproof, but they can be made water-resistant or waterproof through extra protective measures. These can be conformal coatings, encapsulation, or housing the PCB in a waterproof enclosure.

Can Camera PCBs Transmit Wireless Signal?

Camera PCBs can be designed to transmit wireless signals if they are equipped with the right components and circuitry. This usually involves integrating a wireless module (such as Wi-Fi or Bluetooth) into the PCB, allowing for the wireless transmission of image or video data.

Does the Color of a Camera PCB Matter?

No, the color of a camera PCB does not affect its functionality or performance. However, different PCB colors can be chosen for aesthetic reasons. For example, they can be helpful to differentiate between board revisions or to improve visual inspection during manufacturing.

Back to Top: PCB Camera Module: Understanding PCB Camera

Special Offer: Get $100 off your order!

Email [email protected] to get started!