RF PCB Manufacturer

RF PCB manufacturers produce specialized circuit boards for radio frequency applications. These boards handle high-frequency signals in wireless devices and telecommunications equipment. OurPCB offers expert RF PCB manufacturing services, combining precision engineering with advanced materials. We deliver top-quality RF PCBs for various industries.

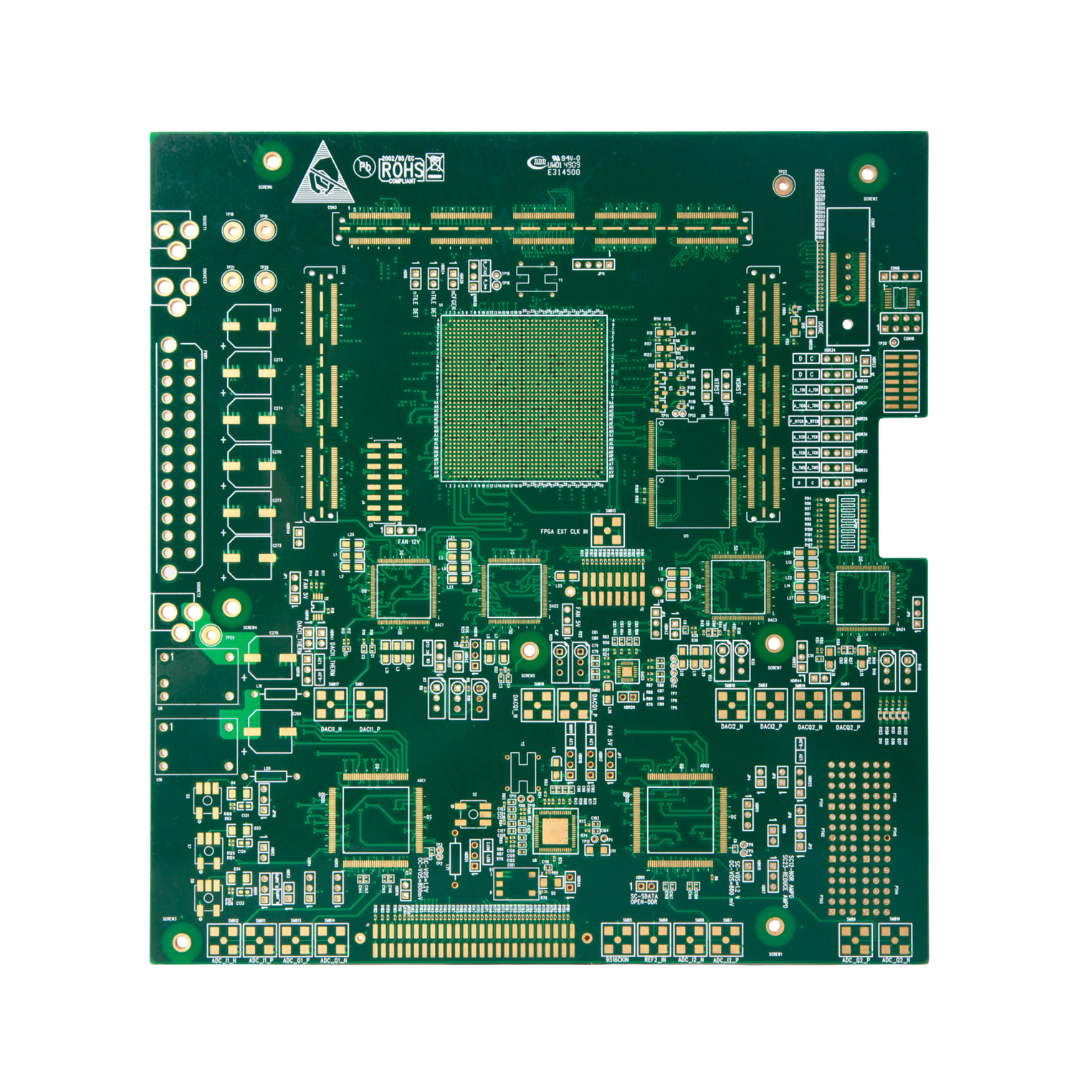

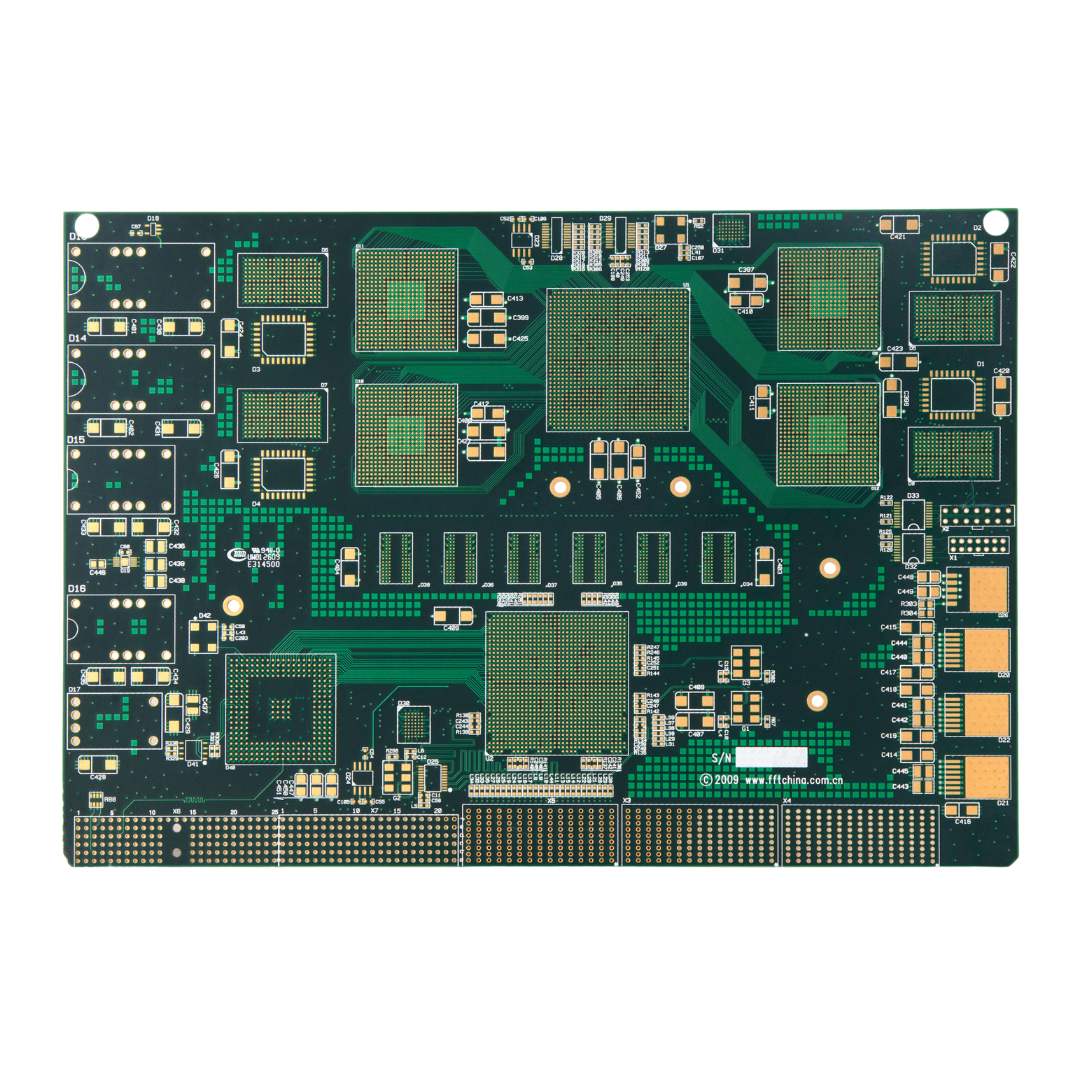

RF Microwave PCBs

RF microwave PCBs are circuit boards designed to work with high-frequency signals. They use special materials and layouts to minimize signal loss and interference. These boards support frequencies from 500 MHz to over 30 GHz, making them crucial for wireless communication systems.

RF microwave PCBs require precise manufacturing techniques. Tight tolerances and careful material selection ensure optimal performance. These boards often feature controlled impedance traces, ground planes, and specialized components. They’re used in radar systems, satellite communications, and 5G networks.

PCB Manufacturing Process

The Benefits of Partnering With OurPCB As Your RF PCB Manufacturers

OurPCB offers expert RF PCB manufacturing services with numerous advantages. Our team combines technical knowledge with cutting-edge equipment to deliver superior results. Here are the key benefits of choosing OurPCB:

- Advanced equipment for tight tolerances

- Strict quality control measures

- Wide range of RF-suitable materials

- Guidance on optimal material selection

- Experienced engineers for design review

- Suggestions for performance improvements

- Efficient production processes

- Fast prototyping and volume manufacturing

Why Choose a Microwave PCB Board?

Microwave PCB boards offer unique advantages for high-frequency applications. They provide excellent signal integrity and low losses at microwave frequencies. These boards are essential for modern wireless and radar systems. Here’s why you should consider microwave PCB boards:

- Optimized for signals above 1 GHz

- Minimal signal distortion and loss

- Allows for smaller device footprints

- Supports high-density component placement

- Better heat dissipation properties

- Suitable for high-power applications

- Stable performance over time

- Resistant to environmental factors

- Optimized for signals above 1 GHz

- Minimal signal distortion and loss

- Allows for smaller device footprints

- Supports high-density component placement

- Better heat dissipation properties

- Suitable for high-power applications

- Stable performance over time

- Resistant to environmental factors

PCB Assembly Services

OurPCB provides comprehensive PCB assembly services to complement our manufacturing capabilities. We offer a range of options to meet diverse project needs. Our assembly services ensure high-quality, reliable PCB products for various applications.

We use Surface Mount Technology for high-quality PCB assembly. This method is ideal for compact and high-performance products. SMT allows for higher component density and improved electrical performance.

We offer flexible assembly options to suit your needs. We can work with customer-supplied components or provide full turnkey solutions. Our turnkey service covers sourcing, assembly, and delivery of completed PCBs.

Our custom assembly services cater to unique project requirements. We adapt our processes to match specific designs and specifications. This ensures optimal results for specialized or complex PCB assemblies.

We deliver fast and reliable PCB assembly with quick turnaround times. Our efficient processes maintain high-quality standards even for urgent projects. This service is ideal for prototyping or time-sensitive production runs.

We produce PCB assemblies that meet strict IPC Class 3 standards. These high-reliability assemblies are perfect for demanding industries. Aerospace, medical, and defense sectors often require this level of quality.

We handle assembly for all types of IC packages with precision. This includes BGAs, POPs, CGAs, QFNs, DFNs, and CSPs. Our expertise ensures reliable connections and optimal performance for complex ICs.

Millions of business and innovators use OurPCB

PCB Board Process

Order Received

- Component Procurement

- Preparation

- PCB Manufacture

- Make Process Flow

Soldering

- Solder Printing/Wave Soldering

- SMT/Plugging

- Inspection (repair if necessary)

- AOI (repair if necessary)

- Transfer

Parts Assembly

- Manual Assembly

- Cleaning

- Wire Screw

- Inspection

- Repair If Necessary

Finalization

- Final Confirmation

- Packing

- Shiping

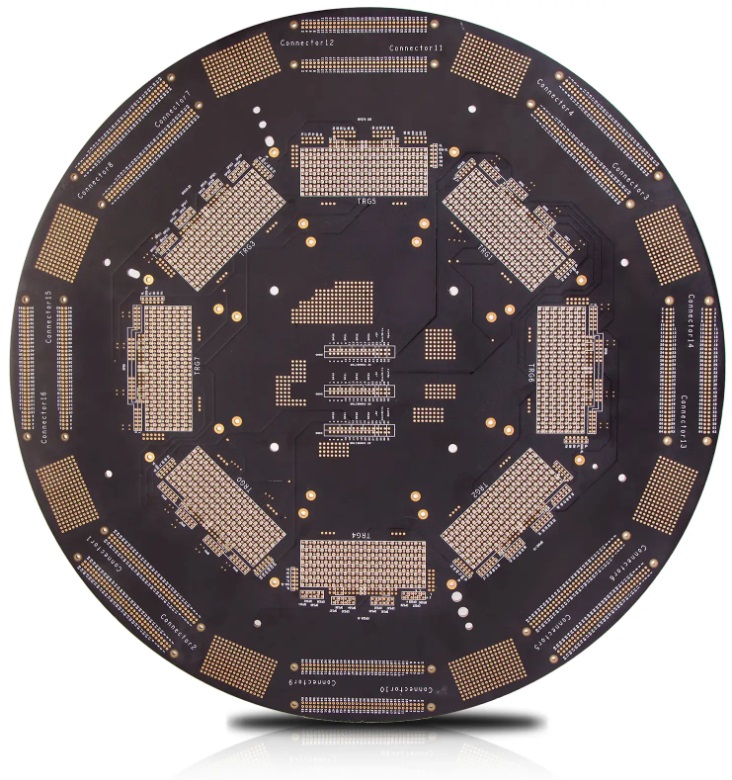

Technical Capabilities

OurPCB possesses advanced technical capabilities for RF PCB manufacturing. We work with a wide range of materials suitable for high-frequency applications. Our equipment can handle complex multilayer boards and fine-pitch components. We maintain tight control over impedance and spacing of features. Our engineering team excels in analog circuit design and PCB layout optimization. We offer comprehensive services from prototyping to volume production.

Capabilities & Services

- One-stop PCBA Services (PCB Manufacturing + Components Sourcing + Assembly)

- SMT Assembly + THT Assembly, Single/double-sided Assembly Mixed PCB Assembly

- BGA Rework

- 60,000 Chips/Hour

- Down to 01005/0210 Size

- Accuracy<±40μm

- Min. QFN Pin Width/Space: 0.15mm/0.25mm

- Min. BGA Diameter/Space: 0.2mm/0.35mm

- Rigid, Flex, HDI, & High-speed Power Boards

- Up to 50 Layers

- 60GHz High Frequencies

- Min. Trace Width/Spacing: 2.5mil/2.5mil

- AOI, X-ray, ICT & FCT Testing

- Controlled Impedance

- ISO 9001, ISO 13485, ISO 14001, IATF 16949, IPC-A-610, UL Certified

- Automotive, Medical, & Military-grade PCBA Manufacturing

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

RF PCB Manufacturer | FAQs

Can a microwave PCB manufacturer offer custom quotes for RF printed circuit boards?

Yes, a microwave PCB manufacturer like OurPCB can offer custom quotes for RF circuit boards. The PCB fabrication process considers PCB material and dielectric constant for accurate estimates. Leading RF PCB suppliers provide high-quality RF circuit boards and microwave solutions. Accurate quotes depend on PCB design, RF material, and frequency PCB requirements.

Do you cater to multi-layered RF microwave printed circuit boards?

Yes, we cater to multi-layered RF microwave printed circuit boards for complex applications. The PCB manufacturing process involves advanced PCB fabrication services and specialized PCB fabric. High frequency PCBs require careful management of coefficient of thermal expansion. Best PCB manufacturing and assembly practices ensure reliable performance in various PCB applications.

Do you cater to prototype quantities for RF PCBs?

Yes, we cater to prototype quantities for RF PCBs with tailored PCB fabrication. This allows testing high-frequency range and refining RF board designs efficiently. The difference between RF PCBs and microwave ones lies in frequency and material choice. Prototyping aids in addressing challenges when RF and microwave designs are difficult to design.

Are there any important considerations for RF microwave designs?

Important considerations for RF microwave designs include selecting appropriate RF material and PCB fabric. Controlling dielectric constant and coefficient of thermal expansion is crucial. Managing signal integrity for radio frequency printed circuit boards ensures optimal performance. Effective PCB design mitigates losses in high frequency range PCB applications.