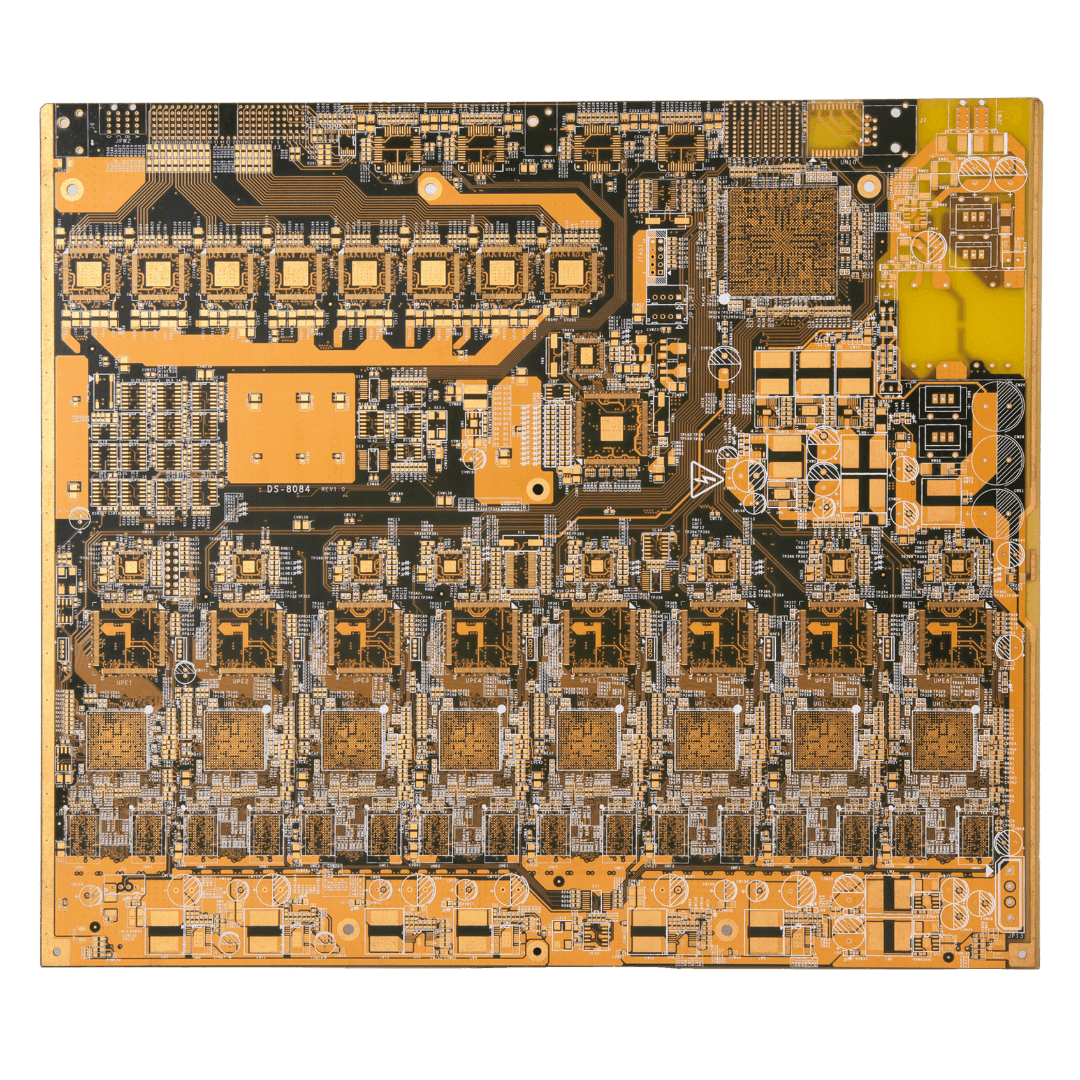

China Heavy Copper PCB

OurPCB specializes in China heavy copper PCB manufacturing. These printed circuit boards feature thicker copper layers, which allows them to manage high currents and dissipate heat effectively. OurPCB provides quality solutions tailored for various industries needing robust and reliable heavy copper PCBs. Contact us to discuss your specific needs.

China Copper Circuit Board

China is a major hub for copper circuit boards. Our factories use advanced technology to create high-quality products. These facilities offer a wide variety of copper thicknesses and layer counts, which provides flexibility for diverse applications.

Chinese manufacturers like OurPCB excel in custom designs. We produce complex, multilayer boards featuring heavy copper traces. Our team offers quick turnaround times, too. These factors, combined with competitive pricing, make China a popular choice.

PCB Manufacturing Process

The Benefits of Partnering With OurPCB for China Copper PCB Board

OurPCB delivers premium China copper-based PCB solutions. We back this up with expert design assistance, rapid production, and strict quality control. Partnering with us means getting reliable performance and support.

- We use premium materials for enhanced durability.

- Our circuit boards pass rigorous testing procedures.

- We handle simple to complex circuit layouts easily.

- Custom copper weights are available to suit your needs.

- Get quick quotes and streamlined order processing.

- Our efficient production process greatly reduces wait times.

- Take advantage of bulk discounts on large orders.

- Get cost-effective solutions for all project budgets.

Why Choose a China Copper PCB Board Factory?

China’s PCB board factories like OurPCB provide many advantages. We blend skilled labor, cutting-edge equipment, and cost-effective copper PCB manufacturing. This makes us an attractive option for global buyers.

- State-of-the-art manufacturing lines for precision.

- Precision equipment ensures accurate thick copper etching.

- Our skilled engineers and technicians ensure quality.

- Benefit from expertise in heavy copper PCB fabrication.

- Lower labor and material costs drive down prices.

- Economies of scale help reduce overall project costs.

- A wide range of copper weights are readily offered.

- Factories can handle various board sizes and complexities.

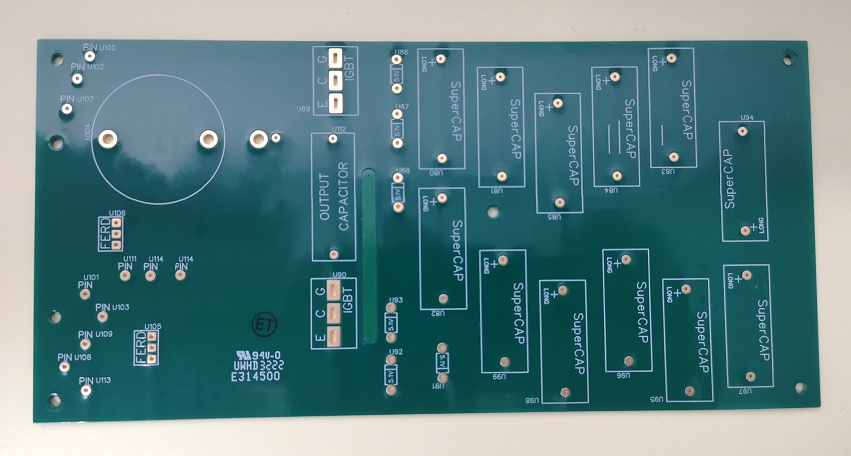

PCB Assembly Services

OurPCB provides full PCB assembly manufacture services. We handle all aspects of circuit board production and component mounting. This includes everything from parts procurement to final testing.

We use Surface Mount Technology for compact, high-performance boards. Our SMT lines place tiny parts with extreme accuracy. SMT assembly is ideal for modern, miniaturized electronic products.

We work with your parts or source everything ourselves. Our turnkey service covers all steps from design to final product. This ensures a smooth, hassle-free experience for our clients.

We build boards precisely to your unique specifications. Our skilled team can handle unique designs and special requirements. This includes everything from component selection to final testing.

We offer rapid assembly for urgent project needs. Our streamlined process ensures quality even with tight deadlines. Quick-turn assembly helps you meet critical time-to-market goals.

We meet strict IPC Class 3 standards, ensuring reliability. This high standard suits critical applications in the aerospace and medical fields. These industries require the utmost dependability and performance.

We mount all types of IC packages with precision. This includes BGAs, QFNs, and other complex chip formats. Our advanced equipment ensures accurate and reliable connections.

Millions of business and innovators use OurPCB

PCB Board Process

Design (1 day)

- Upload Schematic to Get a Quote

- PCB Review and Quotation

- Customer Makes Payment

- Evaluation & Confirmation of Plan

- Design Start

Layout (1 day)

- Layer Stack-up Design

- Design Rule Setting

- Component Placement Design

- Confirmation & Optimization

- Fanout

Routing (1 day)

- Fanout Optimization

- PCB Routing

- Equal-length Adjustment

- Routing Optimization

- DRC Check

- Routing Confirmation

Optimization (1 day)

- Silkscreen Adjustment

- Data Output

- Customer Final Confirmation

- Production Debugging

- Archiving Projects

- Finish

PCB Board Process

Order Received

- Component Procurement

- Preparation

- PCB Manufacture

- Make Process Flow

Soldering

- Solder Printing/Wave Soldering

- SMT/Plugging

- Inspection (repair if necessary)

- AOI (repair if necessary)

- Transfer

Parts Assembly

- Manual Assembly

- PCBCleaning

- Wire Screw

- Inspection

- Repair If Necessary

Finalization

- Final Confirmation

- Packing

- Shipping

Technical Capabilities

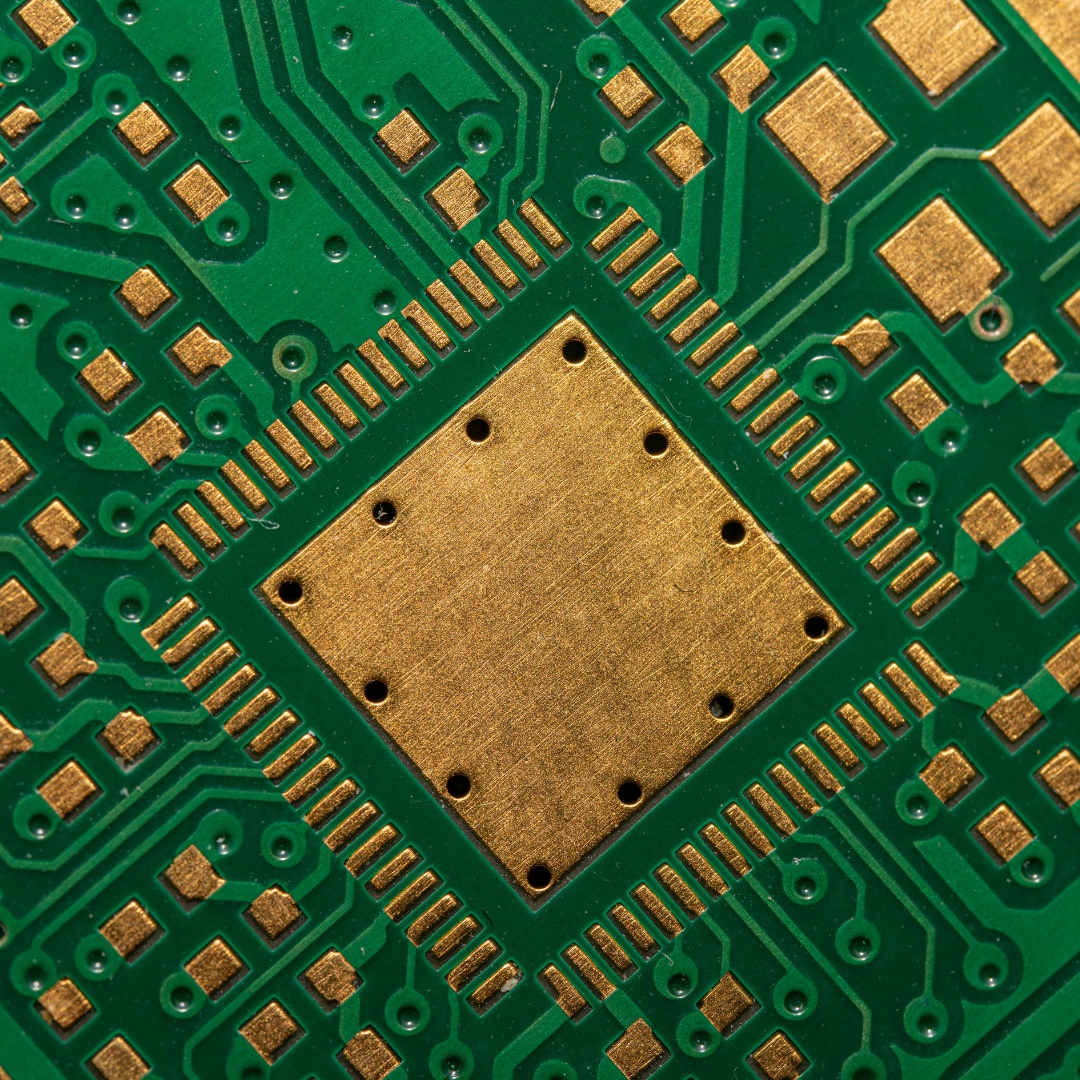

OurPCB handles copper thickness up to 15 oz, providing high current capacity. We can fabricate boards with up to 50 layers for complex designs, and our minimum trace width is 2.5 mil for standard copper applications. We offer various surface finishes like ENIG and HASL for enhanced reliability. Our advanced facilities can produce boards up to 60 inches long, and we use X-ray and AOI for comprehensive quality assurance.

Capabilities & Services

- One-stop PCBA Services (PCB Manufacturing + Components Sourcing + Assembly)

- SMT Assembly + THT Assembly

- BGA Rework

- 60,000 Chips/Hour

- Down to 01005/0210 Size

- Accuracy<±40μm

- Min. QFN Pin Width/Space: 0.15mm/0.25mm

- Min. BGA Diameter/Space: 0.2mm/0.35mm

- Rigid, Flex, HDI, & High-speed Power Boards

- Up to 50 Layers

- 60GHz High Frequencies

- Min. Trace Width/Spacing: 2.5mil/2.5mil

- AOI, X-ray, ICT & FCT Testing

- Controlled Impedance

- ISO 9001, ISO 13485, ISO 14001, IATF 16949, IPC-A-610, UL Certified

- Automotive, Medical, & Military-grade PCBA Manufacturing

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

FAQ's

What PCB characteristics help identify a board as heavy copper?

A heavy copper circuit board features an increased PCB copper thickness. The thickness of copper foil in these boards is significantly higher. Thick copper PCBs provide a higher current-carrying capacity for power applications. China copper PCB board suppliers specialize in manufacturing durable and efficient designs.

Are there any design considerations I should be aware of when designing a heavy copper PCB?

Yes, PCB design for heavy copper requires precise control of the thickness of the copper. A proper layer of copper foil placement ensures even current distribution across circuits. Thick copper plate integration helps maintain thermal stability under extreme conditions. China copper core PCB factories offer expert guidance for optimizing designs.

Do you offer multi-layer heavy copper PCBs?

Yes, we provide professional heavy copper PCB solutions with multiple layers. Each layer of copper enhances electrical conductivity and mechanical strength. Our heavy copper PCB manufacturer ensures quality production for demanding applications. China copper core PCB manufacturers produce reliable thick copper board configurations.