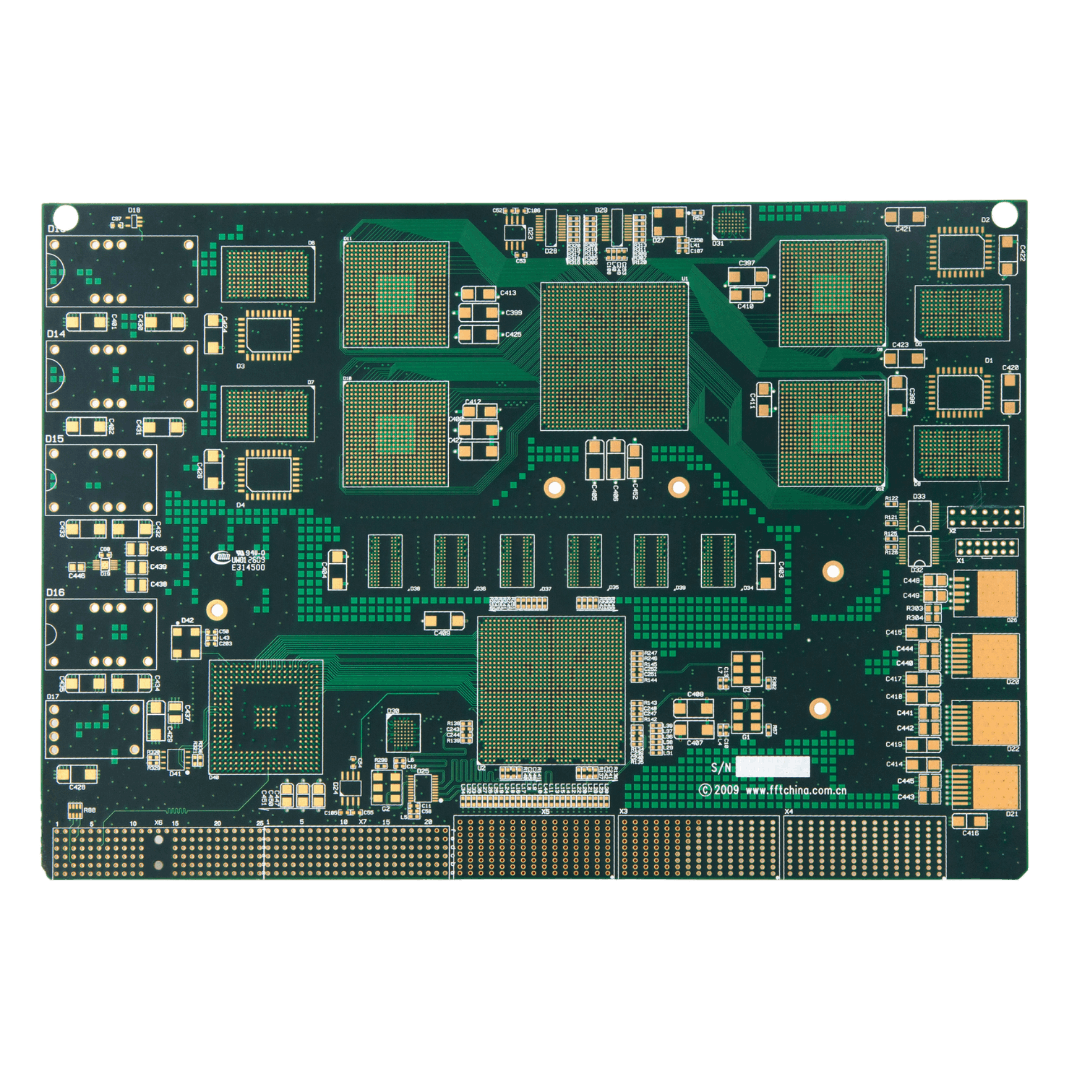

China HDI PCB Board

An HDI PCB board is a high-density interconnect printed circuit board made in China. It offers more compact designs and better performance than standard PCBs. OurPCB specializes in manufacturing these advanced boards for various industries.

China HDI PCB Manufacturers

China leads the world in HDI PCB China production. Many factories across the country like OurPCB have invested in cutting-edge equipment for laser drilling, sequential lamination, and other HDI processes. We can produce complex boards with up to 32 layers.

OurPCB stands out among China HDI PCB manufacturing companies. We have years of experience crafting high-quality HDI boards for global clients. Our state-of-the-art facilities and skilled engineers in Shijiazhuang and Shenzhen, ensure the precise fabrication of even the most intricate designs.

PCB Manufacturing Process

The Benefits of Partnering With OurPCB for China HDI PCB Boards

OurPCB offers many advantages for your HDI PCB needs. Our expertise and capabilities ensure top-quality boards are delivered on time.

- Latest laser drilling and imaging systems

- Precision sequential lamination processes

- Efficient production lowers costs

- Bulk order discounts are available

Why Choose a China HDI Circuit Board?

China HDI PCB fabrication offers excellent value and performance. They’re ideal for many modern electronic devices that need compact, high-functioning boards.

- Smaller board sizes are possible

- More components in less area

- Shorter signal paths

- Less electromagnetic interference

- More traces per layer

- Increased functionality in the same space

- Lower material costs at scale

- Efficient manufacturing processes

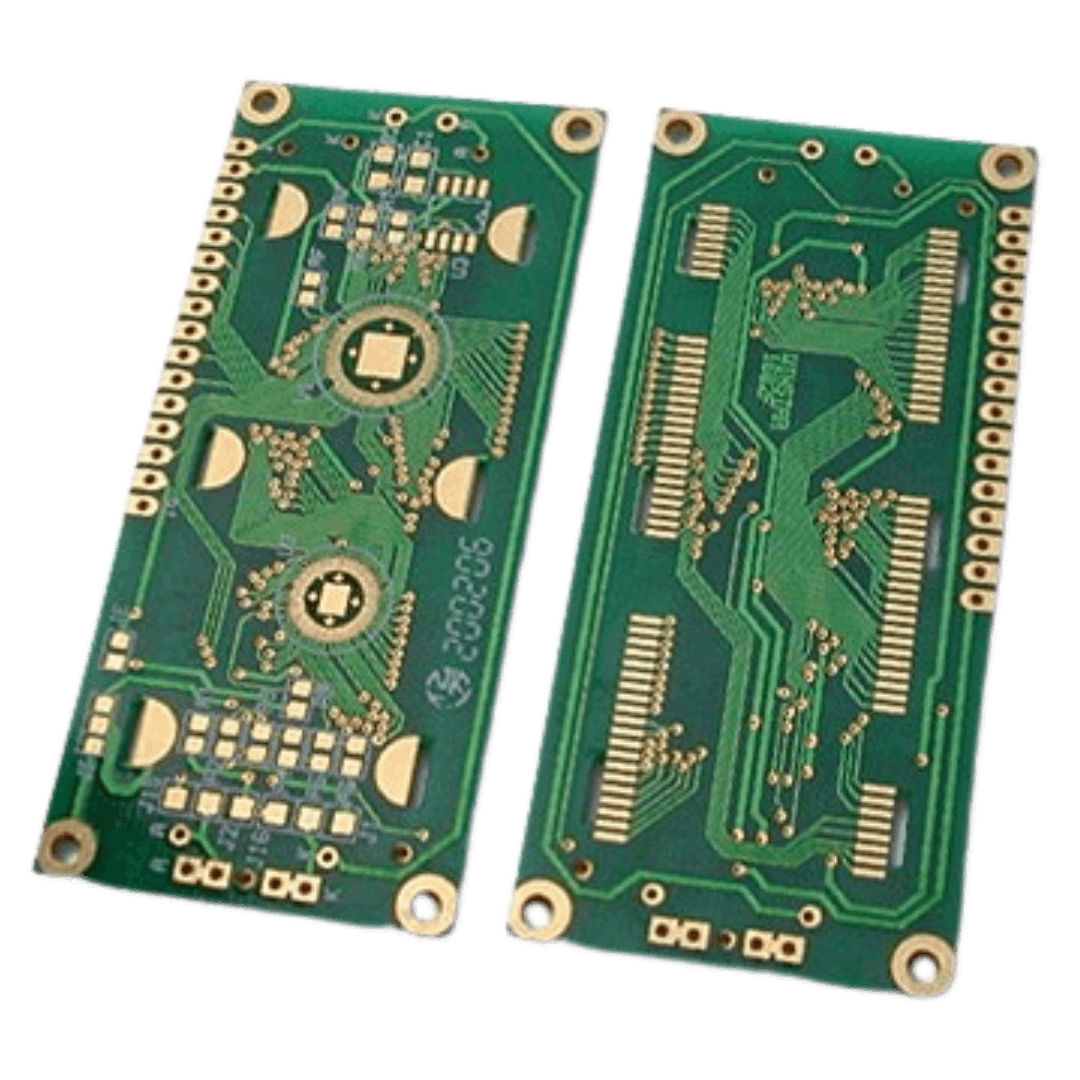

PCB Assembly Services

OurPCB provides full PCB assembly services. We can handle all aspects of bringing your China HDI PCB design to life.

We use advanced Surface Mount Technology for high-quality, compact PCB assembly. Our SMT lines can place even the smallest components with precision.

We offer flexible options. We can work with your supplied parts or manage the entire process from sourcing to final assembly.

Our team can tackle unique designs. We adapt our processes to meet your specific project needs and requirements.

Need your boards fast? We offer rapid assembly services without sacrificing quality. Our efficient processes ensure quick delivery.

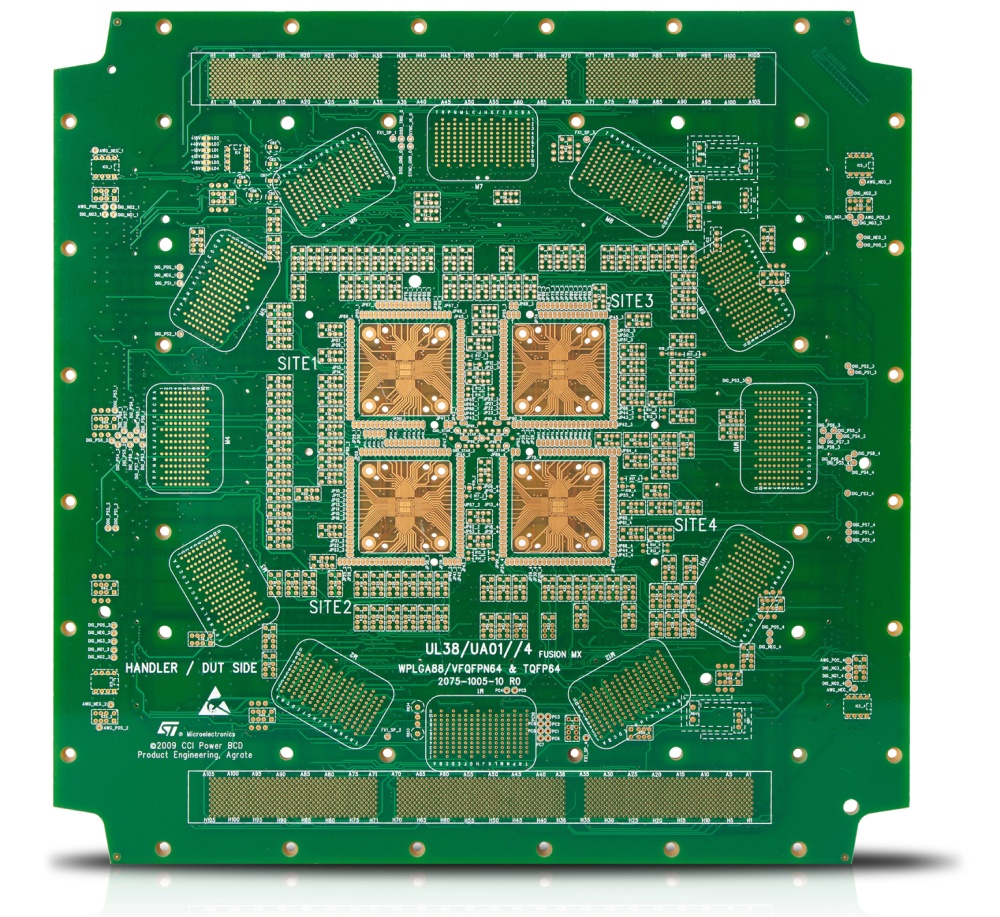

For critical applications, we build to strict IPC Class 3 standards. This ensures reliability in aerospace, medical, and other demanding fields.

We can assemble boards with any IC package type. Our expertise covers BGAs, QFNs, CSPs, and more, all with high reliability.

Millions of business and innovators use OurPCB

PCB Board Process

Design (1 day)

- Upload Schematic to Get a Quote

- PCB Review and Quotation

- Customer Makes Payment

- Evaluation & Confirmation of Plan

- Design Start

Layout (1 day)

- Layer Stack-up Design

- Design Rule Setting

- Component Placement Design

- Confirmation & Optimization

- Fanout

Routing (1 day)

- Fanout Optimization

- PCB Routing

- Equal-length Adjustment

- Routing Optimization

- DRC Check

- Routing Confirmation

Optimization (1 day)

- Silkscreen Adjustment

- Data Output

- Customer Final Confirmation

- Production Debugging

- Archiving Projects

- Finish

PCB Board Process

Order Received

- Component Procurement

- Preparation

- PCB Manufacture

- Make Process Flow

Soldering

- Solder Printing/Wave Soldering

- SMT/Plugging

- Inspection (repair if necessary)

- AOI (repair if necessary)

- Transfer

Parts Assembly

- Manual Assembly

- PCBCleaning

- Wire Screw

- Inspection

- Repair If Necessary

Finalization

- Final Confirmation

- Packing

- Shipping

Technical Capabilities

OurPCB can produce HDI PCBs with up to 32 layers, including China HDI 8 layer PCBs. We routinely work with board thicknesses from 0.2 mm to 10 mm. Our minimum trace width and spacing is 2.5 mil. Our China HDI PCB stackup company can create microvias as small as 0.1 mm in diameter. Our advanced plating techniques allow for reliable copper-filled stacked microvia structures.

Capabilities & Services

- One-stop PCBA Services (PCB Manufacturing + Components Sourcing + Assembly)

- SMT Assembly + THT Assembly

- BGA Rework

- 60,000 Chips/Hour

- Down to 01005/0210 Size

- Accuracy<±40μm

- Min. QFN Pin Width/Space: 0.15mm/0.25mm

- Min. BGA Diameter/Space: 0.2mm/0.35mm

- Rigid, Flex, HDI, & High-speed Power Boards

- Up to 50 Layers

- 60GHz High Frequencies

- Min. Trace Width/Spacing: 2.5mil/2.5mil

- AOI, X-ray, ICT & FCT Testing

- Controlled Impedance

- ISO 9001, ISO 13485, ISO 14001, IATF 16949, IPC-A-610, UL Certified

- Automotive, Medical, & Military-grade PCBA Manufacturing

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

FAQ's

What is HDI in PCBs?

HDI printed circuit board technology enables high-density interconnection for miniaturized electronics. It uses blind and buried vias to increase routing density effectively. The layers of a PCB in HDI designs are tightly packed. HDI PCB production enhances electrical performance and reduces signal loss significantly.

What is the difference between HDI and non-HDI PCB?

High-density interconnect PCBs have more complex layer structures than standard boards. The layer of the PCB in HDI designs supports finer traces and spaces. Non-HDI PCBs lack blind and buried vias for enhanced connectivity. HDI PCB made in China is widely used for advanced applications.

Are there any design guidelines for HDI PCBs I should follow?

Ensure proper HDI PCB stackup service to optimize electrical and mechanical properties. Choose a reliable China HDI PCB factory for consistent quality and precision. Leading China HDI PCB board manufacturers offer tailored solutions for complex designs. A trusted PCB supplier helps streamline PCB production for improved efficiency.