- PCB Manufacturer

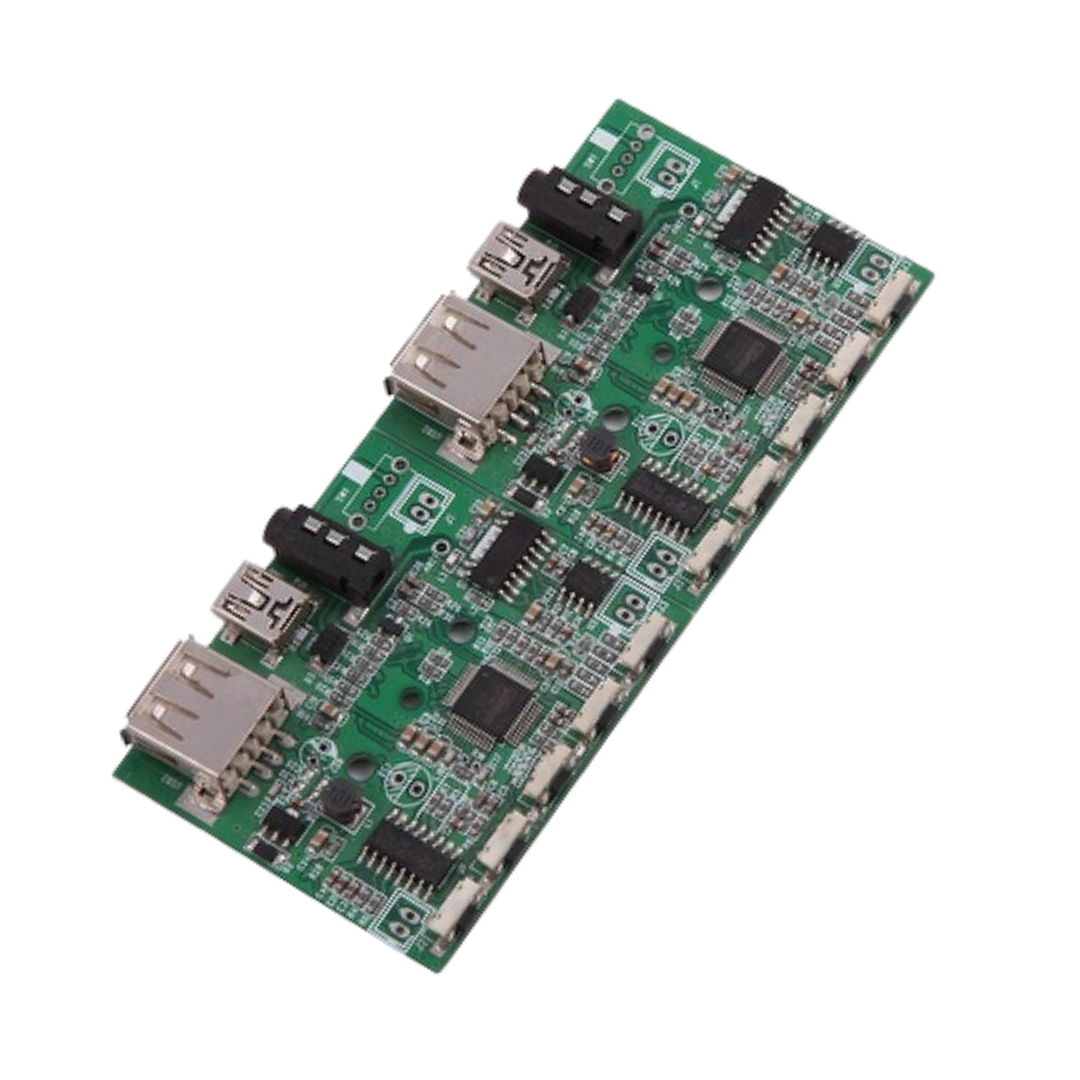

- PCB Assembly Service

- THT Manufacturing

Through-Hole PCB Assembly Service

Through-hole PCB assembly is a method of attaching components to printed circuit boards. It involves inserting component leads through pre-drilled holes in the PCB, which creates strong connections between parts and the board. OurPCB offers expert through-hole PCB assembly services for reliable electronic products.

PCB Through Hole Assembly

PCB through-hole assembly involves inserting components with leads through holes in a printed circuit board (PCB) and soldering them on the opposite side.

Through-hole PCB assembly works well for larger components and high-stress applications. It’s often used for power supplies, connectors, and specialized parts. Through-hole assembly provides strong mechanical bonds, which makes it ideal for products that may face physical stress or vibration.

PCB Manufacturing Process

The Benefits of Partnering with OurPCB as Your Through Hole PCB Assembly Suppliers

OurPCB offers top-quality through-hole PCB assembly services. We combine skilled technicians with advanced equipment to deliver reliable results. Our focus on precision and efficiency sets us apart in the industry.

- Highly trained staff with years of experience

- Skilled in handling a wide range of component types

- Premium through-hole PCB assembly machines

- Precise component placement for consistent quality

- Comprehensive testing at every stage of assembly

- Adherence to industry standards and specifications

- Ability to handle both small and large production runs

- Custom assembly options to meet unique project needs

Why Choose Through Hole PCB Assembly Manufacturers?

Through-hole PCB assembly machine services offer unique advantages for certain projects. It’s ideal for products that need durability and easy repairs. Choosing a specialized manufacturer ensures you get the best results for your specific needs.

- Strong mechanical bonds resist physical stress

- Ideal for high-vibration environments

- Components can be easily repaired or replaced if needed

- Suitable for products that require field servicing

- Works well with large components and specialized parts

- Ideal for power supplies and connectors

- Proven technology with a long track record

- Suitable for critical applications in aerospace and military

- Strong mechanical bonds resist physical stress

- Ideal for high-vibration environments

- Components can be easily repaired or replaced if needed

- Suitable for products that require field servicing

- Works well with large components and specialized parts

- Ideal for power supplies and connectors

- Proven technology with a long track record

- Suitable for critical applications in aerospace and military

PCB Assembly Services

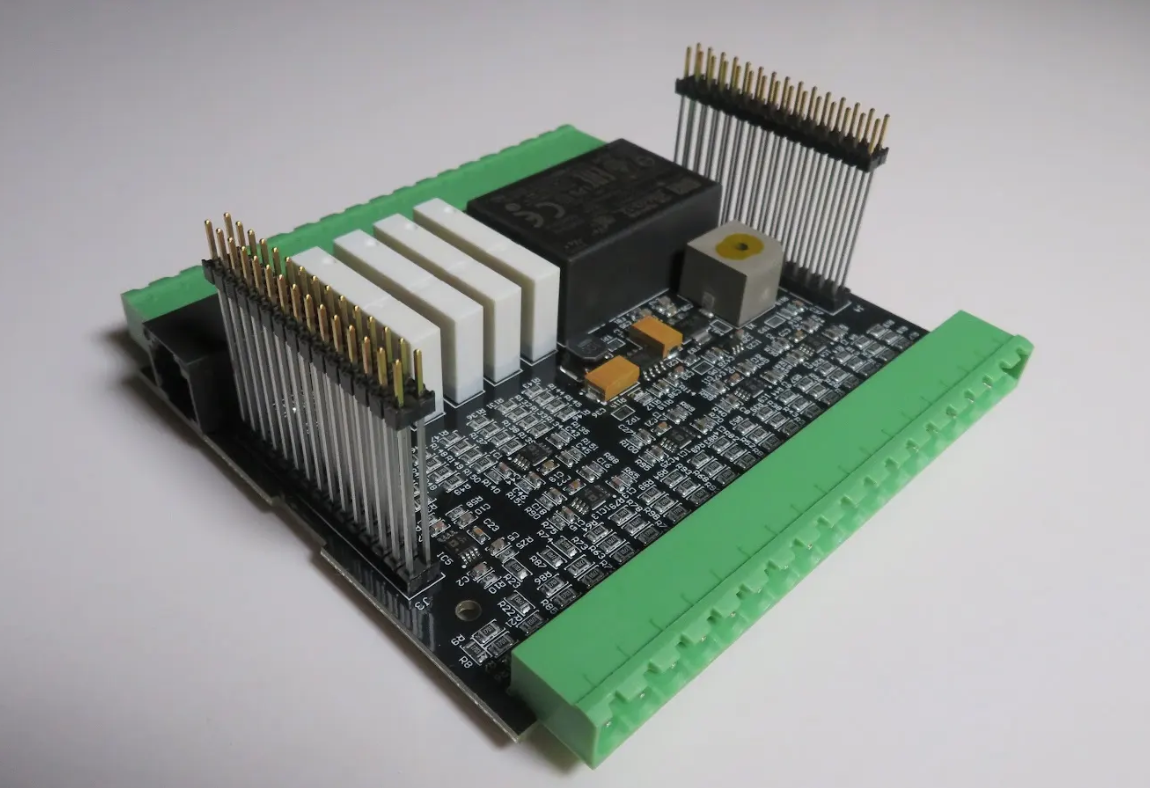

OurPCB offers a range of PCB assembly services to meet diverse project needs. We handle everything from simple boards to complex multilayer designs. Our goal is to provide high-quality, cost-effective solutions for every client.

We excel in Surface Mount Technology assembly. This method is perfect for compact, high-performance electronics. Our SMT process ensures the precise placement of tiny components.

We’re flexible in our approach. We can work with the parts you provide or handle the entire process. Our turnkey service covers component sourcing, assembly, and delivery.

Every project is unique. We tailor our assembly services to fit your specific design and requirements. Our team works closely with you to ensure the best outcome.

Need your PCBs fast? We offer rapid assembly services without sacrificing quality. Our efficient processes ensure quick turnaround times for urgent projects.

We build PCBs to the strictest IPC Class 3 standards. This level of quality is crucial for aerospace, medical, and other critical applications.

Our through hole PCB assembly factories handle all types of IC packages. This includes BGAs, POPs, CGAs, QFNs, DFNs, and CSPs. Our expertise ensures the reliable assembly of even the most complex ICs.

Millions of business and innovators use OurPCB

PCB Board Process

Order Received

- Component Procurement

- Preparation

- PCB Manufacture

- Make Process Flow

Soldering

- Solder Printing/Wave Soldering

- SMT/Plugging

- Inspection (repair if necessary)

- AOI (repair if necessary)

- Transfer

Parts Assembly

- Manual Assembly

- Cleaning

- Wire Screw

- Inspection

- Repair If Necessary

Finalization

- Final Confirmation

- Packing

- Shiping

Technical Capabilities

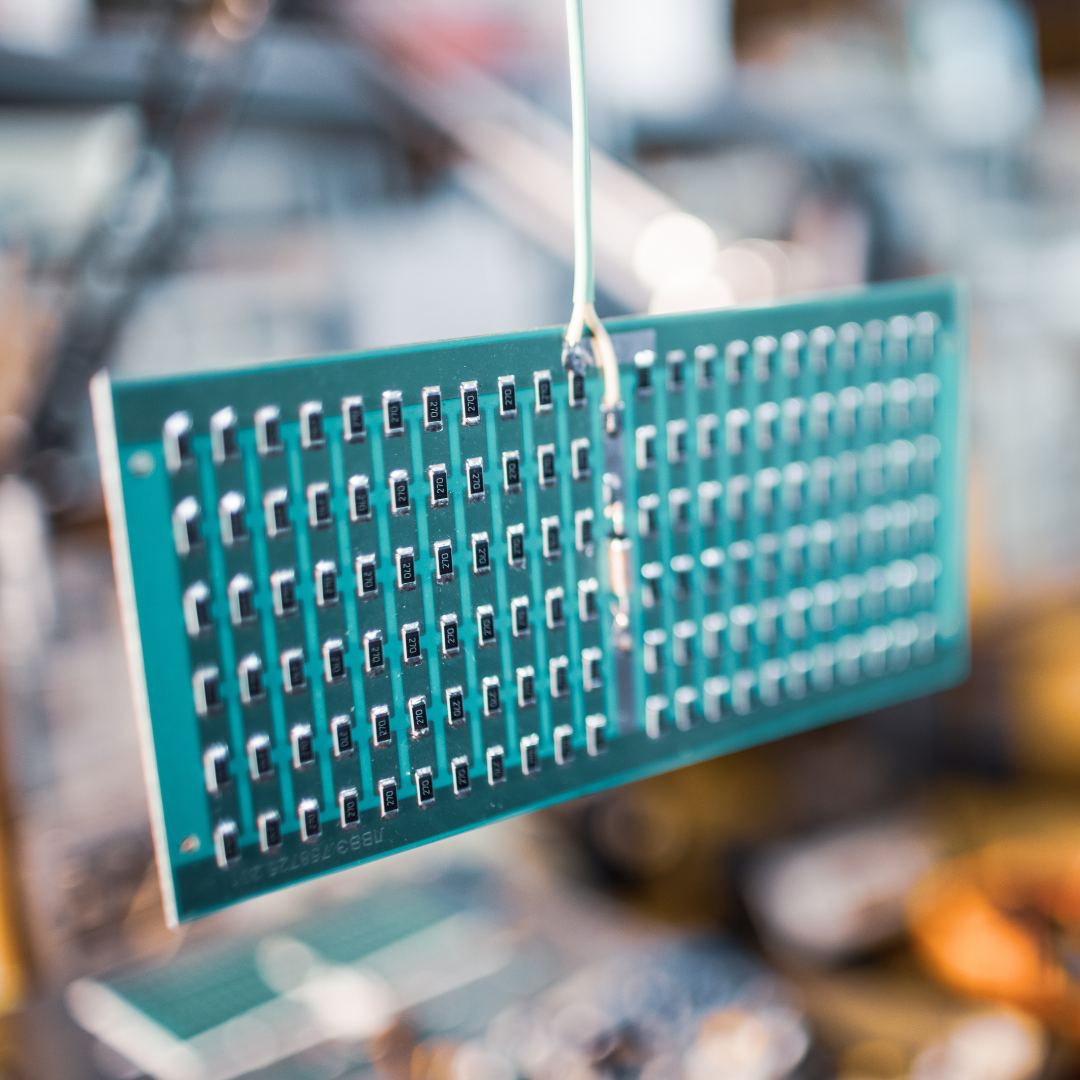

OurPCB’s through-hole PCB assembly factory equipment is top-of-the-line. We use advanced insertion machines for accurate component placement. Our soldering techniques ensure strong, reliable connections, and we can handle boards of various sizes and complexities. Our facility is equipped with capabilities to manage both prototype and high-volume production runs efficiently.

Capabilities & Services

- One-stop PCBA Services (PCB Manufacturing + Components Sourcing + Assembly)

- SMT Assembly + THT Assembly

- BGA Rework

- 60,000 Chips/Hour

- Down to 01005/0210 Size

- Accuracy<±40μm

- Min. QFN Pin Width/Space: 0.15mm/0.25mm

- Min. BGA Diameter/Space: 0.2mm/0.35mm

- Rigid, Flex, HDI, & High-speed Power Boards

- Up to 50 Layers

- 60GHz High Frequencies

- Min. Trace Width/Spacing: 2.5mil/2.5mil

- AOI, X-ray, ICT & FCT Testing

- Controlled Impedance

- ISO 9001, ISO 13485, ISO 14001, IATF 16949, IPC-A-610, UL Certified

- Automotive, Medical, & Military-grade PCBA Manufacturing

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Through-Hole PCB Assembly Services | FAQs

What is the difference between SMT and through-hole?

Through-hole technology (THT) requires drilling holes for through-hole components, however, SMT directly attaches parts. Through-hole vs. SMT components is a debate focused on mounting techniques in PCB manufacturing. Through-hole mounting offers stronger solder joints, whereas SMT allows compact PCB design for modern applications. Moreover, through-hole PCB assembly factories use a through-hole PCB assembly machine for large-scale production.

Which is better: SMD or through-hole connectors?

SMD connectors are smaller, making them ideal for high-speed PCB prototype applications. In contrast, through-hole PCB assembly cost is higher due to extra processing in a through-hole PCB assembly factory. PCBA services for volume PCB assembly often favor SMT for automation efficiency. However, through-hole mounting provides better mechanical stability for large parts like a capacitor.

What about stubs in through-hole PCB mountable connectors?

Stubs in through-hole PCB assembly equipment create signal integrity issues during the assembly process. Printed circuit board assembly services must consider stub effects in THT connectors to prevent interference. Additionally, high-speed designs using through-hole technology require careful layout in PCB manufacturing. Through-hole PCB assembly factories mitigate stub problems with precise drilling and shorter lead lengths.