China High-Temperature, High TG PCB Manufacturer & Wholesale

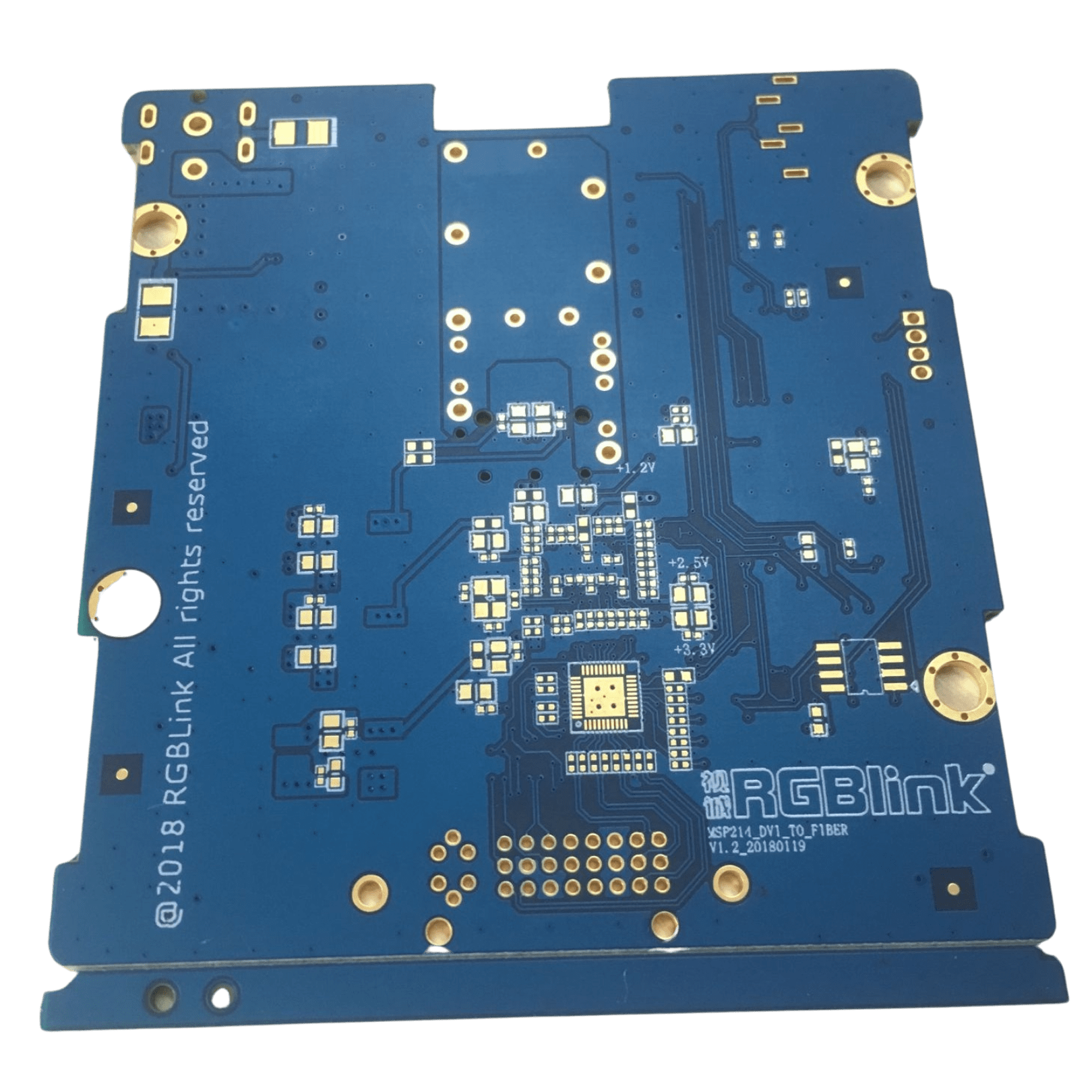

Looking for a Chinese PCB manufacturer for high TG circuit boards and assembly? OurPCB specializes in producing high-quality, high-temperature, high-TG PCBs typically exceeding 170°C. We provide durable, reliable solutions for your high-performance circuit board needs.

China's Premier High-Temp, High-TG PCB Provider

OurPCB, founded in 2007, is China’s premier provider of high-temperature, high-TG PCB solutions. High-TG PCBs, with a glass transition temperature above 170 °C, are built to perform in extreme thermal environments. Trusted by aerospace, automotive, and industrial automation sectors, they resist deformation and maintain performance under stress. OurPCB supports over 3,000 global customers with high-performance PCB fabrication, assembly, wire harnesses, housing, and final testing. With three advanced manufacturing facilities and four global sales offices, the company ensures strict quality, fast delivery, and expert support.

PCB Manufacturing Process

The Benefits of Partnering with OurPCB for High-Temperature PCB Fabrication, China

Partnering with OurPCB ensures you receive high-quality high-temperature PCBs tailored to your needs. We leverage advanced technology and expertise in PCB manufacturing.

- Our team understands the importance of selecting the right materials.

- We use high Tg materials to improve board performance.

- We employ state-of-the-art fabrication processes.

- Our methods ensure precision and reliability on every board.

- We offer tailored solutions to meet specific project requirements.

- Our flexible approach allows for unique designs and specifications.

- Our wholesale pricing model provides cost-effective solutions.

- We guarantee the best price without compromising quality.

Why Choose High-Temperature PCBs?

High-temperature PCBs offer incredible stability, effective heat management, and enhanced durability. These PCBs are essential for applications that require reliable performance under extreme conditions. High Tg PCBs offer several advantages that make them a preferred choice in various industries.

- High Tg materials provide excellent heat and chemical resistance.

- They minimize the risk of internal damage from thermal stress.

- These boards effectively manage heat generated by high-power density devices.

- They prevent overheating, ensuring consistent performance.

- High-temperature PCBs are perfect for multilayer and HDI configurations.

- They maintain reliability in compact, densely packed circuits.

- The durability of high Tg PCBs leads to longer product lifespans.

- They reduce common failures like short-circuiting, enhancing overall reliability.

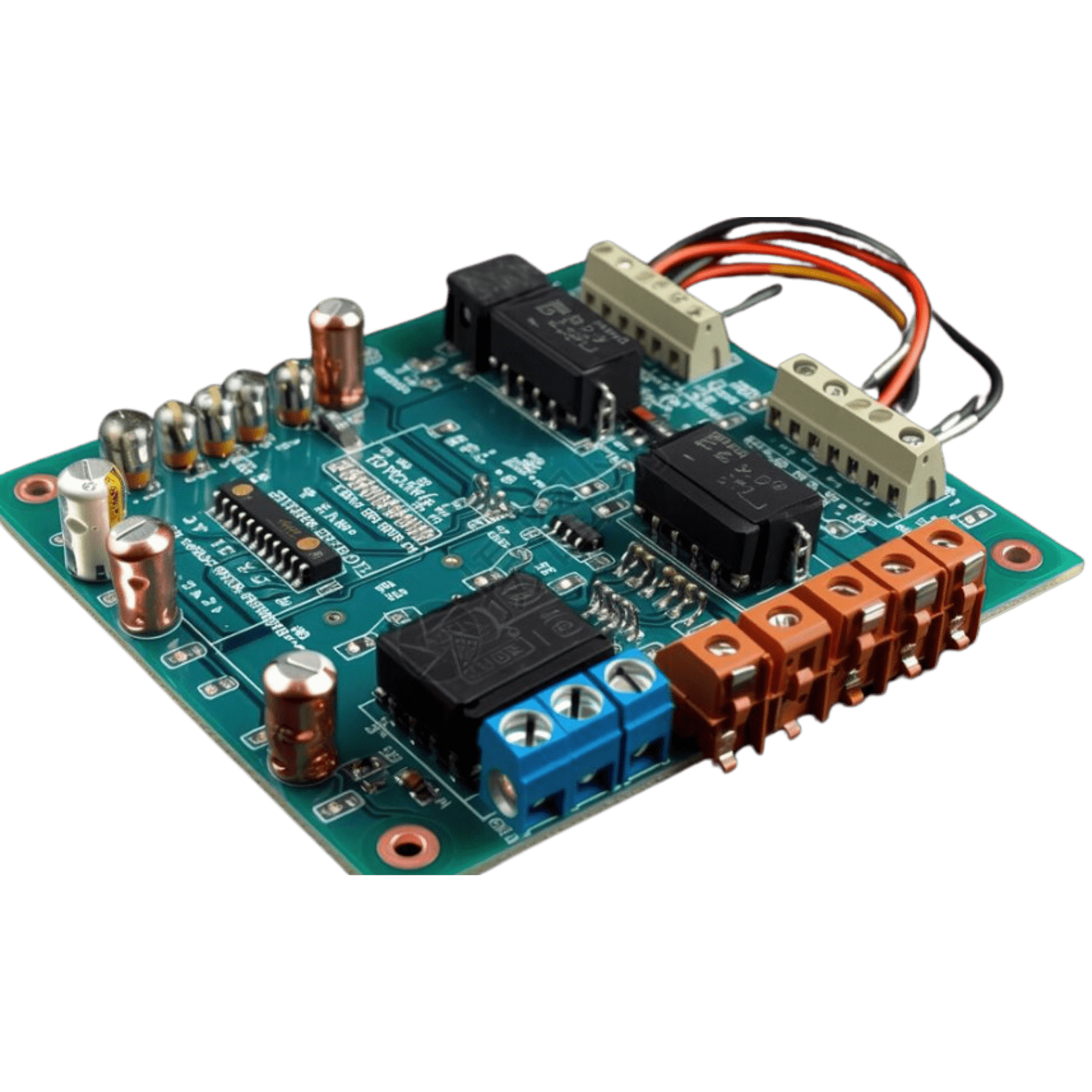

PCB Assembly Services

OurPCB offers comprehensive PCB assembly services to complement our manufacturing capabilities. We ensure each assembly meets the highest standards of quality and performance.

We deliver high-quality PCB assembly using Surface Mount Technology, perfect for compact and high-performance designs.

We handle both customer-supplied components and complete turnkey solutions, managing sourcing, assembly, and delivery.

We provide customized PCB assembly solutions tailored to meet your unique design and project requirements.

We offer rapid PCB assembly services with quick turnaround times, ensuring high quality even under tight deadlines.

We produce PCB assemblies that meet strict IPC Class 3 standards, ideal for critical applications in aerospace and medical industries.

We assemble all IC package types, including BGAs, POPs, CGAs, QFNs, DFNs, and CSPs, with precision and reliability.

Millions of business and innovators use OurPCB

PCB Board Process

Design (1 day)

- Upload Schematic to Get a Quote

- PCB Review and Quotation

- Customer Makes Payment

- Evaluation & Confirmation of Plan

- Design Start

Layout (1 day)

- Layer Stack-up Design

- Design Rule Setting

- Component Placement Design

- Confirmation & Optimization

- Fanout

Routing (1 day)

- Fanout Optimization

- PCB Routing

- Equal-length Adjustment

- Routing Optimization

- DRC Check

- Routing Confirmation

Optimization (1 day)

- Silkscreen Adjustment

- Data Output

- Customer Final Confirmation

- Production Debugging

- Archiving Projects

- Finish

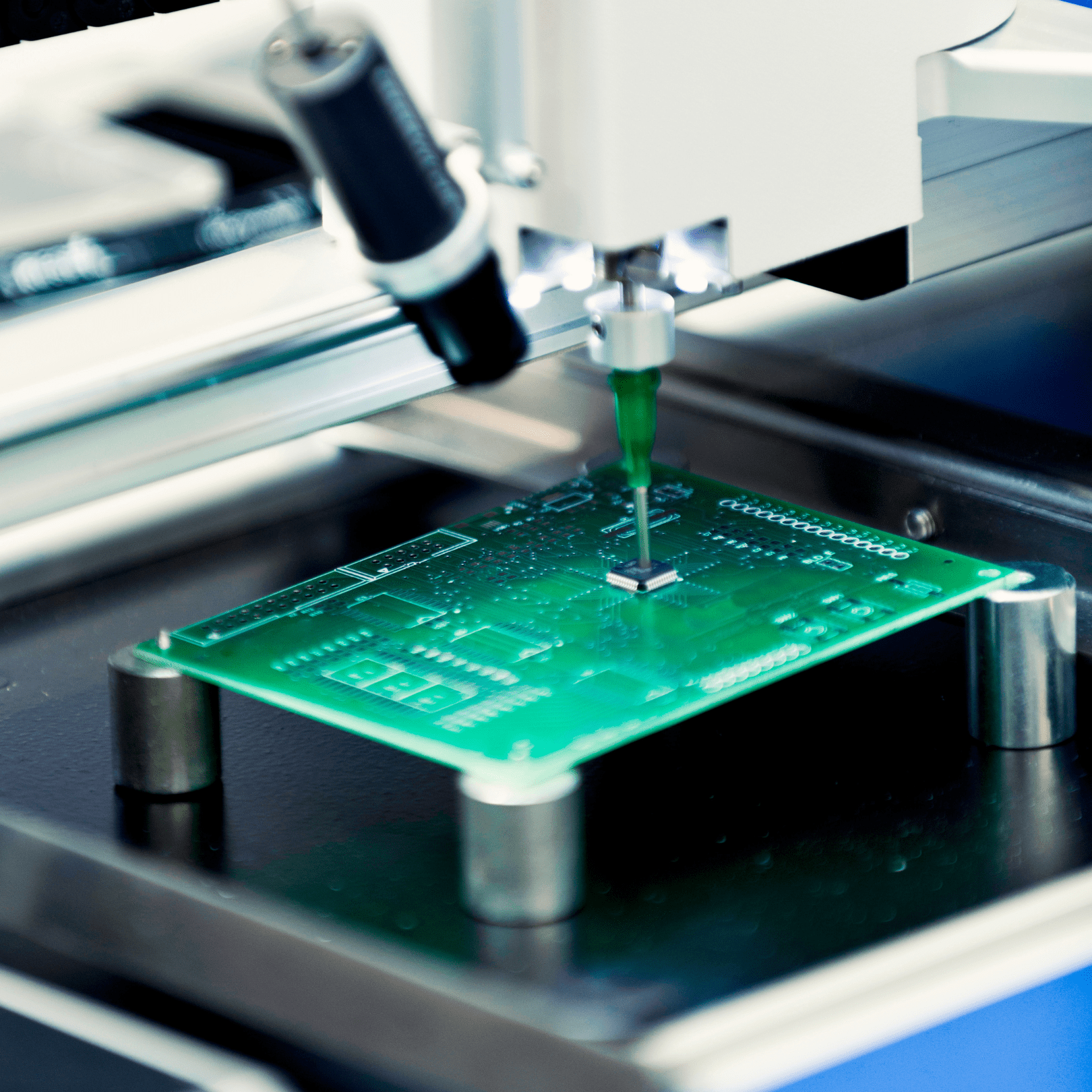

PCB Board Process

Order Received

- Component Procurement

- Preparation

- PCB Manufacture

- Make Process Flow

Soldering

- Solder Printing/Wave Soldering

- SMT/Plugging

- Inspection (repair if necessary)

- AOI (repair if necessary)

- Transfer

Parts Assembly

- Manual Assembly

- PCBCleaning

- Wire Screw

- Inspection

- Repair If Necessary

Finalization

- Final Confirmation

- Packing

- Shipping

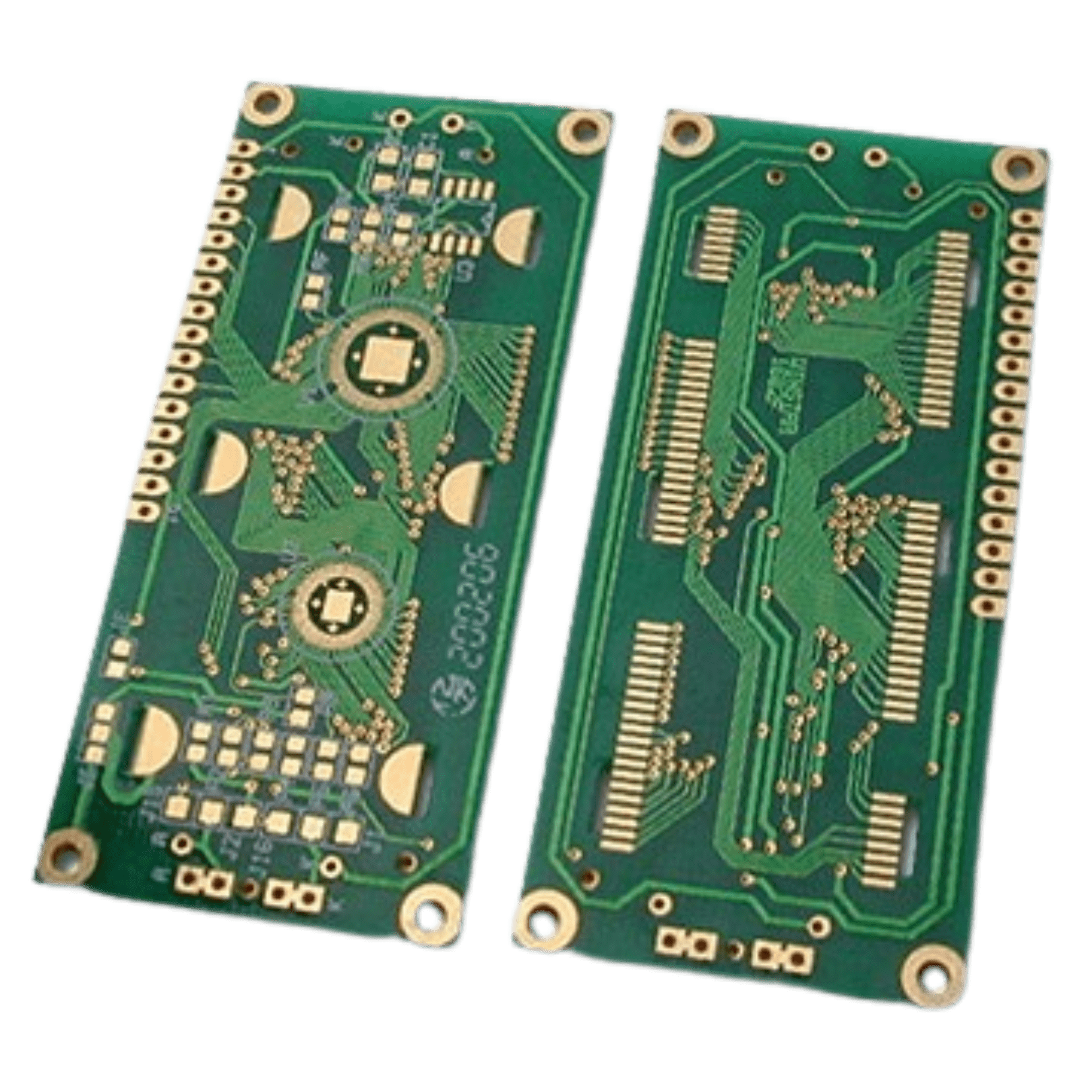

Technical Capabilities

OurPCB boasts advanced technical capabilities in high-temperature PCB manufacturing. We use cutting-edge technology and skilled professionals to deliver top-quality products. Our commitment to quality ensures that we meet the demands of various industries effectively.

Capabilities & Services

- One-stop PCBA Services (PCB Manufacturing + Components Sourcing + Assembly)

- SMT Assembly + THT Assembly

- BGA Rework

- 60,000 Chips/Hour

- Down to 01005/0210 Size

- Accuracy<±40μm

- Min. QFN Pin Width/Space: 0.15mm/0.25mm

- Min. BGA Diameter/Space: 0.2mm/0.35mm

- Rigid, Flex, HDI, & High-speed Power Boards

- Up to 50 Layers

- 60GHz High Frequencies

- Min. Trace Width/Spacing: 2.5mil/2.5mil

- AOI, X-ray, ICT & FCT Testing

- Controlled Impedance

- ISO 9001, ISO 13485, ISO 14001, IATF 16949, IPC-A-610, UL Certified

- Automotive, Medical, & Military-grade PCBA Manufacturing

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

FAQ's

How are rigid PCBs manufactured?

Rigid PCB manufacturing begins with creating the multilayer PCB layout and selecting materials such as high Tg FR4 or aluminum PCB. A PCB manufacturer typically uses precision machinery in a factory to layer and etch the circuits, ensuring a high-density PCB. Final assembly includes drilling, plating, and testing to meet the standards of the high-temperature PCB manufacturer for high-quality electronic product performance.

Which precautions must be taken with a high Tg PCB?

When working with a high Tg board, you must maintain proper temperature control during assembly to avoid damaging the high Tg value material. Consult a high Tg circuit board manufacturer for compatibility with high frequency PCB and high voltage applications. Always take special care to ensure the design matches the requirements of your China customized high led PCB products.

What is the TG value of a PCB laminate?

The PCB Tg value, or glass transition temperature, indicates the point at which the circuit board material transitions from rigid to soft. A high Tg FR4 laminate typically has a high Tg value above 170 °C, making it suitable for multilayer PCB as well as China high density designs. Collaborating with a PCB wholesale factory or supplier like OurPCB ensures access to materials meeting the demands of flexible PCB or high-density PCB applications.