- PCB Manufacturer

- PCB Assembly Service

- Express

Express PCB Assembly Manufacturer | Express Production Process

Express PCB assembly is a rapid production process for circuit boards. It combines speed and precision to create high-quality PCBs quickly. This service meets urgent manufacturing needs across industries. OurPCB offers comprehensive express PCB assembly solutions for your projects.

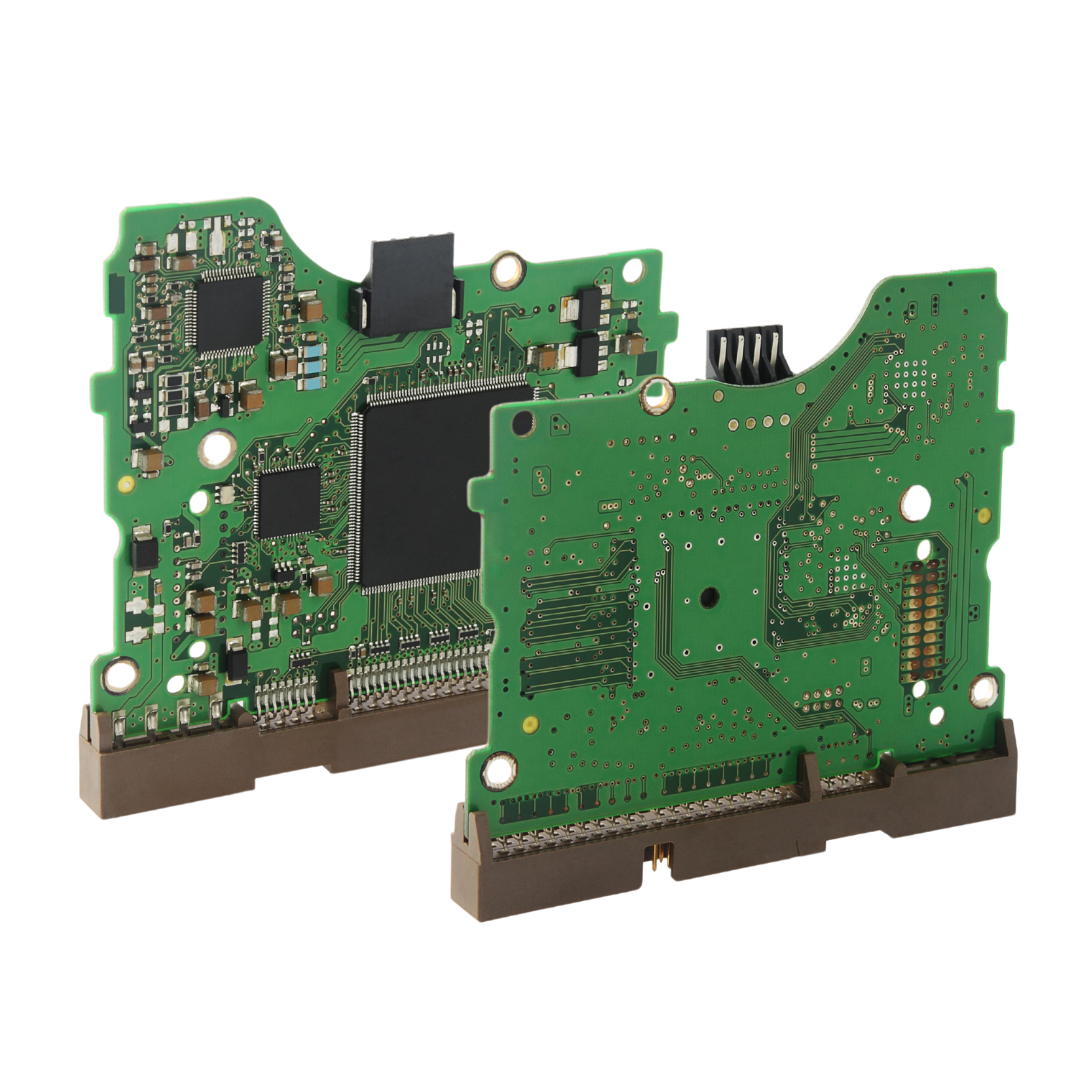

Express PCB Assembly

The express PCB assembly process speeds up the traditional PCB production procedure. It uses advanced equipment and streamlined workflows to reduce turnaround times. This method is ideal for prototypes, small batches, and urgent orders.

The process starts with design file upload and component sourcing. Next, automated machines place and solder parts onto the board. Quality checks ensure each PCB meets strict standards. Express assembly can cut production time from weeks to days without sacrificing quality.

PCB Manufacturing Process

The Benefits of Partnering With OurPCB As Your Express PCB Manufacturer

OurPCB offers many advantages as your express PCB manufacturer. Our state-of-the-art facilities and expert team ensure top-quality results. We prioritize speed without compromising on precision or reliability.

- Rapid prototyping for quick design iterations

- Expedited production for urgent market demands

- Strict quality control measures at every stage

- Use of premium materials for durable PCBs

- Efficient handling of small to medium batch sizes

- Scalable processes for varying order quantities

- Latest SMT and through-hole equipment

- Advanced X-ray and AOI systems for thorough inspections

Why Choose PCB Assembly Express?

PCB assembly express offers crucial benefits for time-sensitive projects. It allows for faster market entry and quicker design validation. This service is essential in today’s fast-paced electronic industry.

- Faster prototype to production transition

- Quick response to market opportunities

- Lower setup costs for small runs

- Efficient use of resources for prototypes

- Quick turnaround for design changes

- Faster product development cycles

- Meet tight project deadlines

- Stay ahead of competitors with faster launches

- Faster prototype to production transition

- Quick response to market opportunities

- Lower setup costs for small runs

- Efficient use of resources for prototypes

- Quick turnaround for design changes

- Faster product development cycles

- Meet tight project deadlines

- Stay ahead of competitors with faster launches

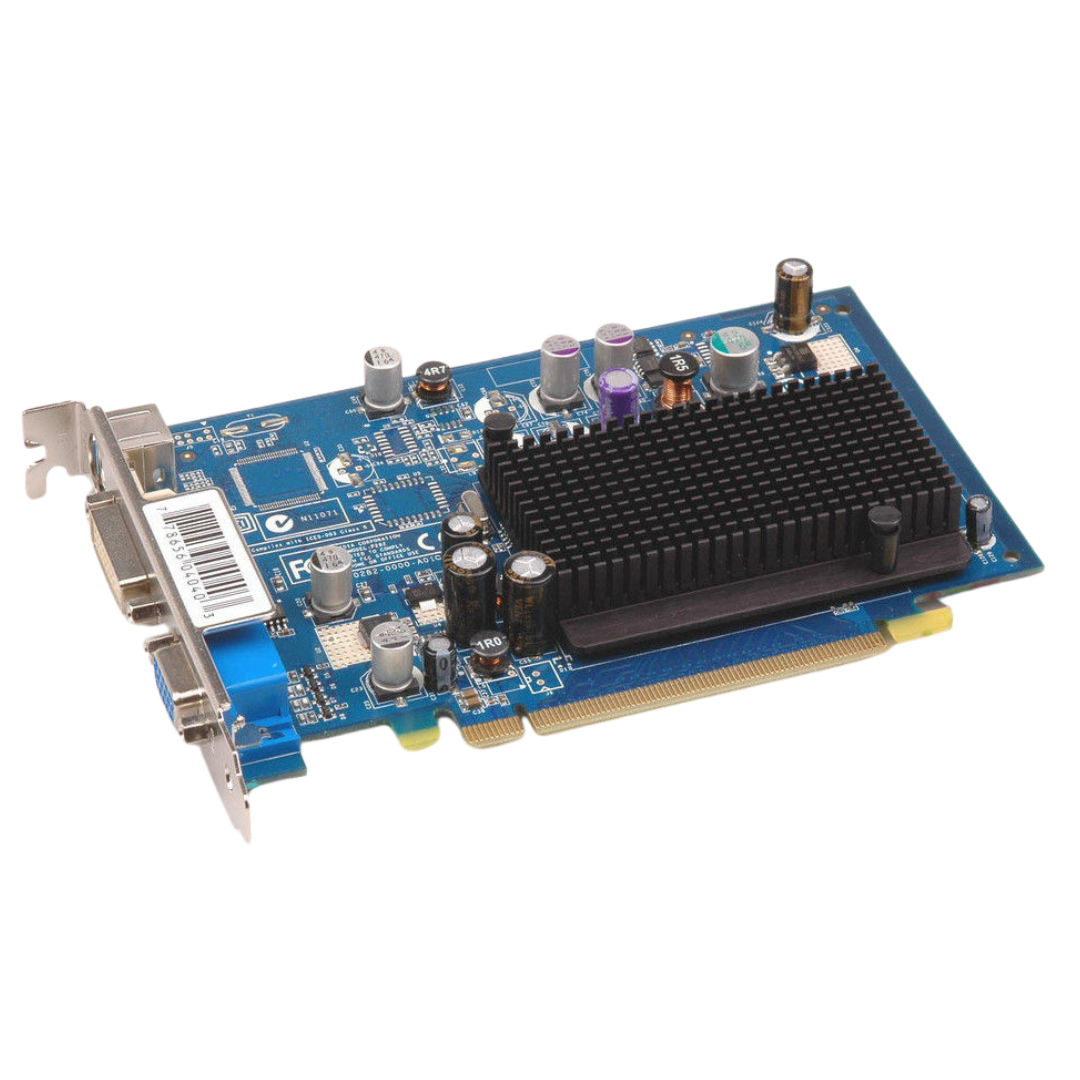

PCB Assembly Services

OurPCB provides a wide range of PCB assembly services. We cater to diverse project needs with our comprehensive offerings. Our services combine precision, speed, and quality assurance.

We excel in Surface Mount Technology assembly. Our SMT process is perfect for compact, high-performance products. We use advanced pick and place machines for precise component placement.

We offer flexible assembly options to suit your needs. You can provide your own components or opt for our full turnkey service. Our turnkey solution covers sourcing, assembly, and delivery.

Our custom assembly service adapts to your unique designs. We handle complex layouts and special requirements. Our team works closely with you to ensure your specific needs are met.

We specialize in fast, reliable PCB assembly. Our quick turn service delivers high-quality boards in record time. We maintain strict quality standards even with tight deadlines.

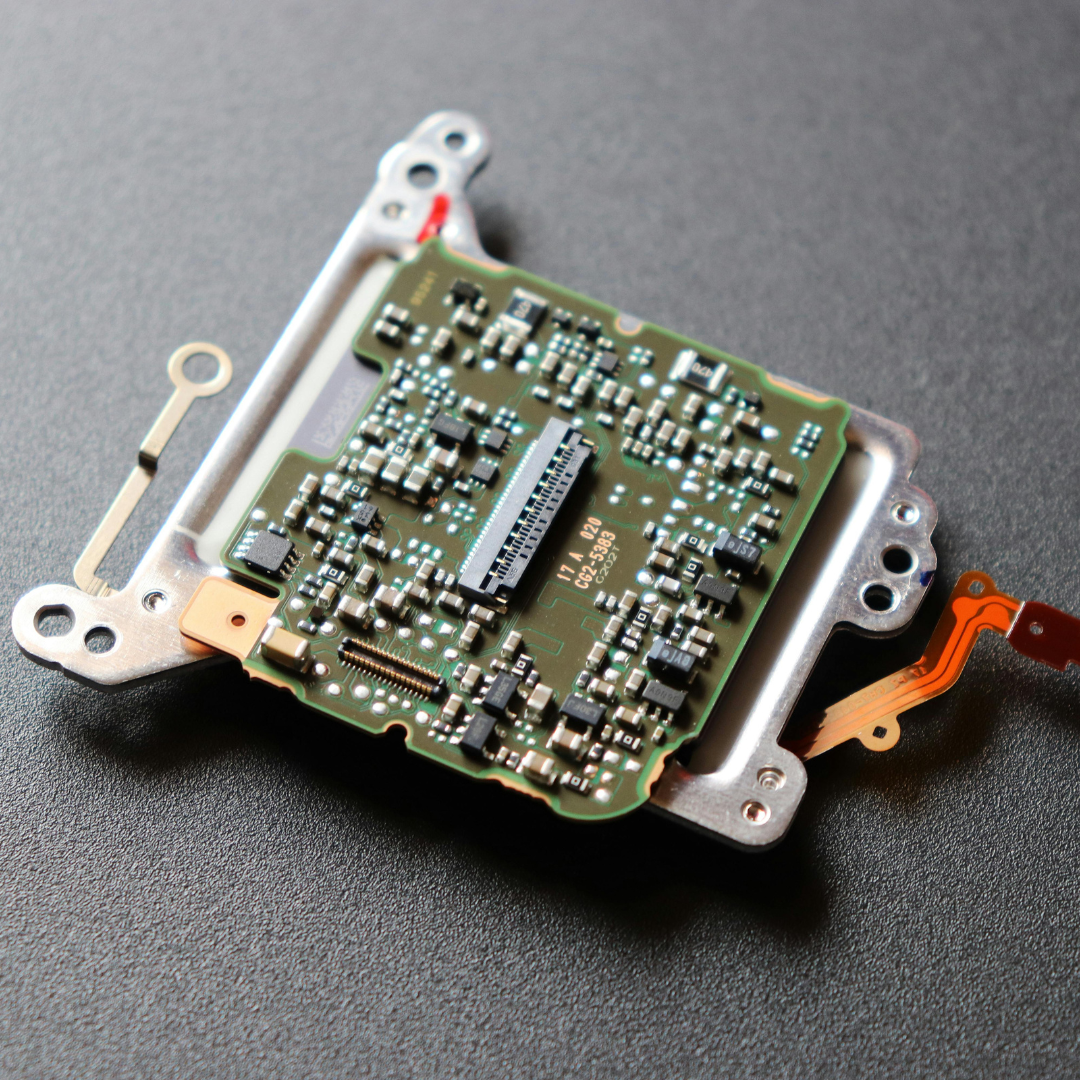

We produce PCBs that meet IPC Class 3 standards. This high-level certification is crucial for the aerospace and medical industries. Our Class 3 assemblies ensure maximum reliability in critical applications.

We assemble all types of IC packages with precision. This includes BGAs, POPs, CGAs, QFNs, DFNs, and CSPs. Our advanced equipment handles complex IC packages with ease.

Millions of business and innovators use OurPCB

PCB Board Process

Order Received

- Component Procurement

- Preparation

- PCB Manufacture

- Make Process Flow

Soldering

- Solder Printing/Wave Soldering

- SMT/Plugging

- Inspection (repair if necessary)

- AOI (repair if necessary)

- Transfer

Parts Assembly

- Manual Assembly

- Cleaning

- Wire Screw

- Inspection

- Repair If Necessary

Finalization

- Final Confirmation

- Packing

- Shiping

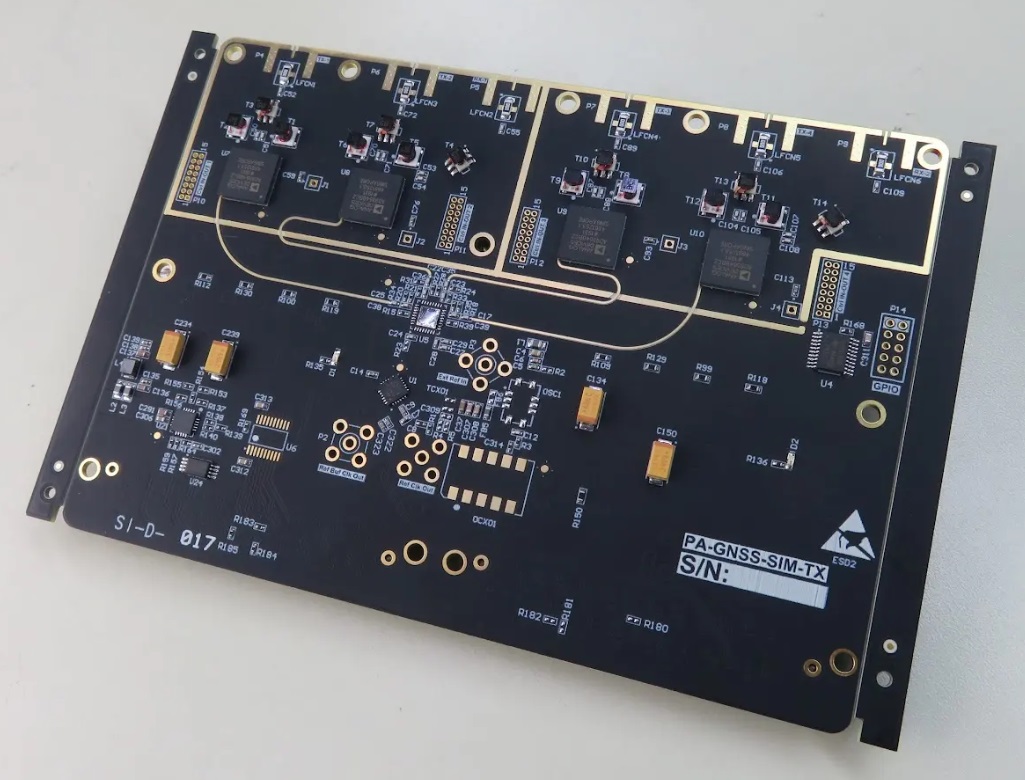

Technical Capabilities

OurPCB boasts extensive technical capabilities for express PCB assembly. We handle multi-layer boards up to 50 layers thick. Our minimum trace width and spacing is 2.5 mil. We work with various board materials, including FR-4 and high-frequency substrates. Our facilities are equipped with the latest SMT and through-hole technology. We perform thorough testing, such as in-circuit and functional tests.

Capabilities & Services

- One-stop PCBA Services (PCB Manufacturing + Components Sourcing + Assembly)

- SMT Assembly + THT Assembly, Single/double-sided Assembly Mixed PCB Assembly

- BGA Rework

- 60,000 Chips/Hour

- Down to 01005/0210 Size

- Accuracy<±40μm

- Min. QFN Pin Width/Space: 0.15mm/0.25mm

- Min. BGA Diameter/Space: 0.2mm/0.35mm

- Rigid, Flex, HDI, & High-speed Power Boards

- Up to 50 Layers

- 60GHz High Frequencies

- Min. Trace Width/Spacing: 2.5mil/2.5mil

- AOI, X-ray, ICT & FCT Testing

- Controlled Impedance

- ISO 9001, ISO 13485, ISO 14001, IATF 16949, IPC-A-610, UL Certified

- Automotive, Medical, & Military-grade PCBA Manufacturing

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

PCB Assembly Express | FAQs

What is PCB testing?

PCB testing involves verifying the functionality and reliability of printed circuit boards. It checks for defects in the PCB design, solder mask, and plate connections. Optical inspection and electrical tests are used to inspect and validate performance. Effective testing ensures that the PCB assembly process meets quality standards.

How long does a PCB board last?

A PCB board can last 10 to 20 years, depending on usage. Factors like PCB fabrication notes, environmental conditions, and electronic components affect longevity. Proper PCB manufacturing process and schematic design enhance durability. Regular maintenance and testing extend the lifespan of printed circuit boards.

What are the disadvantages of express assembly products?

The disadvantages of express assembly products include limited customization and higher costs. PCB fab express and PCB express services may rush the PCB assembly process. This can lead to errors if the design software and prototype PCB assembly are not thorough. However, OurPCB takes care to get your products delivered at the highest quality. For detailed requirements, contact us for tailored solutions.