- PCB Manufacturer

- PCB Assembly Service

- Aerospace PCB

Aerospace PCB Assembly Manufacturers

Aerospace PCB assembly manufacturers produce printed circuit boards for aerospace applications. These manufacturers ensure high-quality standards and reliability in their products. OurPCB specializes in aerospace PCB assembly, meeting the industry’s stringent requirements.

Aerospace PCB Assembly and Manufacture

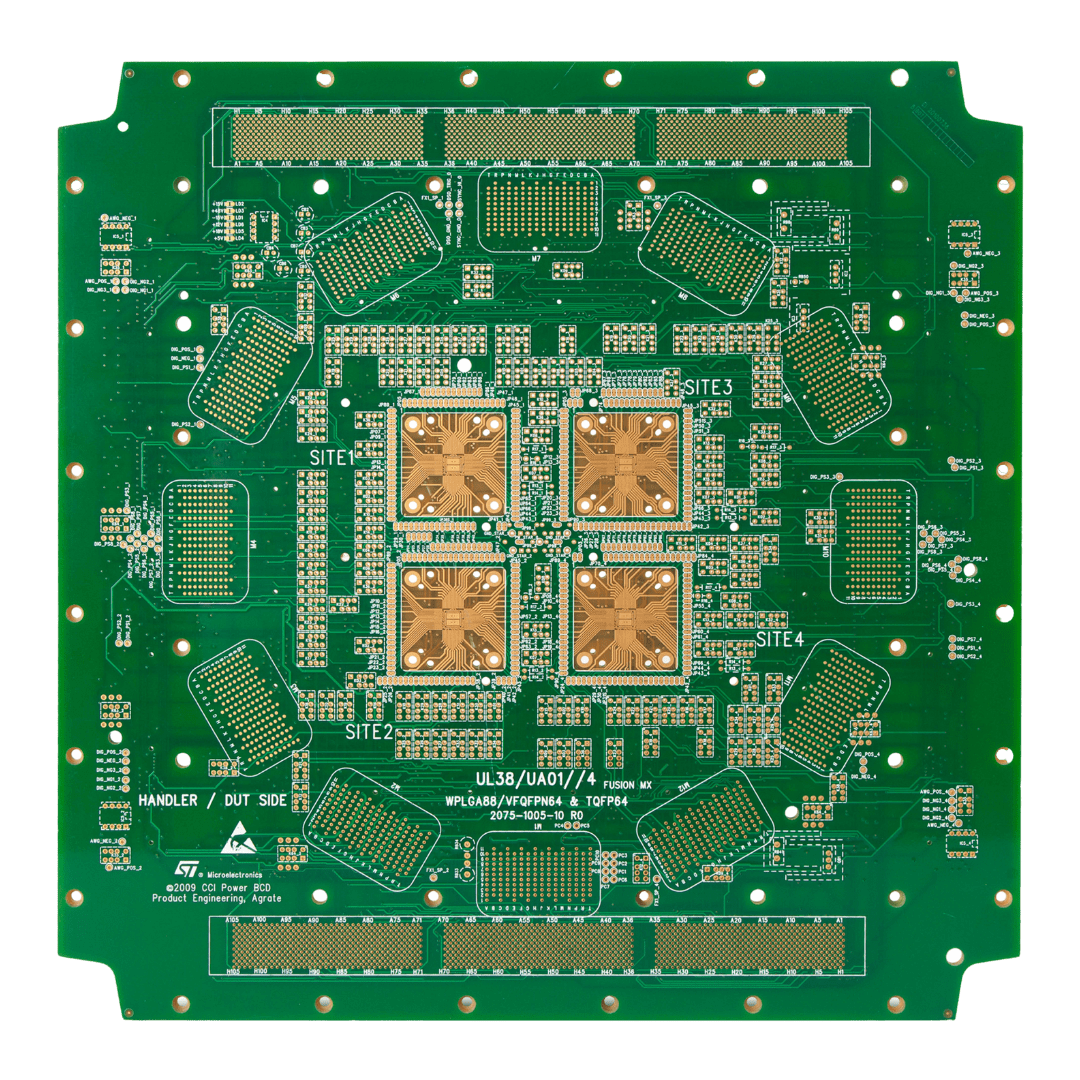

Aerospace PCB assemblers and manufacturers focus on creating PCBs specifically designed for aerospace applications. These boards must meet rigorous standards due to their critical role in aircraft and spacecraft operations. Manufacturers use advanced technology to ensure precision and reliability in their products.

OurPCB is committed to providing aerospace-approved PCBs. We adhere to industry standards such as IPC 6012 Class and MIL-PRF-31032. This commitment ensures that our PCBs perform well in harsh aerospace environments.

PCB Manufacturing Process

The Benefits of Partnering with OurPCB for Aerospace PCB Services

Partnering with OurPCB brings numerous advantages for aerospace PCB assembly needs. Our experience and technical capabilities distinguish us from competitors. We prioritize customer satisfaction by delivering high-quality products on time.

- We maintain strict quality control processes.

- Our products meet the highest industry standards.

- We utilize state-of-the-art manufacturing equipment.

- Our processes ensure the accurate production of complex designs.

- Our team offers valuable expertise in aerospace applications.

- We provide tailored solutions to meet specific project needs.

- We understand the importance of timely delivery in aerospace projects.

- Our efficient processes help us meet deadlines consistently.

Why Choose Aerospace PCB Manufacturers?

Choosing aerospace PCB manufacturers is essential for ensuring product reliability and safety. We understand the unique challenges of the aerospace industry. OurPCB provides solutions that meet demanding specifications. Aerospace PCBs must withstand extreme conditions, including temperature fluctuations and vibrations. Manufacturers employ rigorous testing methods to ensure performance under these circumstances.

- Aerospace PCBs must comply with strict regulations.

- We follow established design standards for safety.

- Aerospace PCB manufacturers like OurPCB have specialized knowledge in the field.

- We can address specific challenges related to aerospace applications.

- OurPCB offers tailored services to fit unique project requirements.

- We can accommodate various designs, including rigid-flex and multi-layer boards.

- We provide ongoing support throughout the project lifecycle.

- Our expertise helps clients navigate complex requirements efficiently.

PCB Assembly Services

OurPCB offers comprehensive PCB assembly services tailored for the aerospace industry. We handle everything from design to production, ensuring high-quality results at every stage.

We deliver high-quality PCB assembly using Surface Mount Technology, ideal for compact and high-performance applications.

We cater to your needs by working with customer-supplied components or providing turnkey solutions, managing everything from sourcing to delivery.

We provide tailored PCB assembly services to meet your unique design and project requirements.

We offer reliable and fast PCB assembly with quick turnaround times, ensuring top-notch quality.

We produce PCB assemblies that comply with rigorous IPC Class 3 standards, suitable for demanding industries like aerospace and healthcare.

We specialize in assembling all IC package types, including BGAs, POPs, CGAs, QFNs, DFNs, and CSPs, with precision and care.

Millions of business and innovators use OurPCB

PCB Board Process

Design (1 day)

- Upload Schematic to Get a Quote

- PCB Review and Quotation

- Customer Makes Payment

- Evaluation & Confirmation of Plan

- Design Start

Layout (1 day)

- Layer Stack-up Design

- Design Rule Setting

- Component Placement Design

- Confirmation & Optimization

- Fanout

Routing (1 day)

- Fanout Optimization

- PCB Routing

- Equal-length Adjustment

- Routing Optimization

- DRC Check

- Routing Confirmation

Optimization (1 day)

- Silkscreen Adjustment

- Data Output

- Customer Final Confirmation

- Production Debugging

- Archiving Projects

- Finish

PCB Board Process

Order Received

- Component Procurement

- Preparation

- PCB Manufacture

- Make Process Flow

Soldering

- Solder Printing/Wave Soldering

- SMT/Plugging

- Inspection (repair if necessary)

- AOI (repair if necessary)

- Transfer

Parts Assembly

- Manual Assembly

- PCBCleaning

- Wire Screw

- Inspection

- Repair If Necessary

Finalization

- Final Confirmation

- Packing

- Shipping

Technical Capabilities

OurPCB boasts extensive technical capabilities in aerospace PCB manufacturing. We combine advanced equipment with skilled technicians to deliver precise solutions. Our commitment to quality ensures that every product meets rigorous industry standards. By focusing on these key areas, OurPCB stands out as a trusted partner for aerospace PCB assembly needs.

Capabilities & Services

- One-stop PCBA Services (PCB Manufacturing + Components Sourcing + Assembly)

- SMT Assembly + THT Assembly

- BGA Rework

- 60,000 Chips/Hour

- Down to 01005/0210 Size

- Accuracy<±40μm

- Min. QFN Pin Width/Space: 0.15mm/0.25mm

- Min. BGA Diameter/Space: 0.2mm/0.35mm

- Rigid, Flex, HDI, & High-speed Power Boards

- Up to 50 Layers

- 60GHz High Frequencies

- Min. Trace Width/Spacing: 2.5mil/2.5mil

- AOI, X-ray, ICT & FCT Testing

- Controlled Impedance

- ISO 9001, ISO 13485, ISO 14001, IATF 16949, IPC-A-610, UL Certified

- Automotive, Medical, & Military-grade PCBA Manufacturing

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

FAQ's

What are some aerospace PCB applications?

Aerospace PCBs are essential for navigation systems, avionics, and communication electronics. Rigid flex PCBs support compact, lightweight designs required for aerospace and defense PCB fabrication. HDI boards are used in satellites and high-performance aerospace electronics applications. For specialized needs, contact us for tailored aerospace PCB assembly services expertise.

Are there different kinds of aerospace PCB connectors?

Yes, aerospace PCBs use connectors designed for durability and secure electronics integration. Flexible circuits often require custom connectors to handle dynamic aerospace and defense conditions. ITAR compliance and ISO standards ensure reliable connectors for aerospace PCB assembly services. For guidance, consult our manufacturing team experienced in aerospace PCB assembly manufacturing processes.

Can the manufactured range of aerospace PCBs hold up in a harsh environment?

Yes, aerospace PCBs can hold up in a harsh environment. Aerospace PCBs are built using robust FR-4 and flexible circuits for durability. Double-sided and rigid flex designs withstand thermal and mechanical stresses in harsh conditions. PCB fabrication processes ensure long-term reliability with advanced electronics manufacturing capabilities. For specialized solutions, contact us to discuss aerospace PCB manufacture and assembly options.