Contents

- What is a PCB Clone?

- What is a PCB cloning service?

- Advantages of PCB cloning

- Cost-Effective and High Quality

- Simplified Production

- Custom Designs

- Improved Scalability and Freedom

- Consistent Performance

- How Does PCB Cloning Help PCB Redesign and Development?

- PCB Cloning Process

- Step-By-Step Guide

- The Legal Boundary of PCB cloning

- Streamline Production With PCB Cloning

- PCB Clones | FAQs

- What is the difference between a PCB and a microchip?

- What is the cheapest PCB material?

- Start Your Project with OurPCB

What is a PCB Clone?

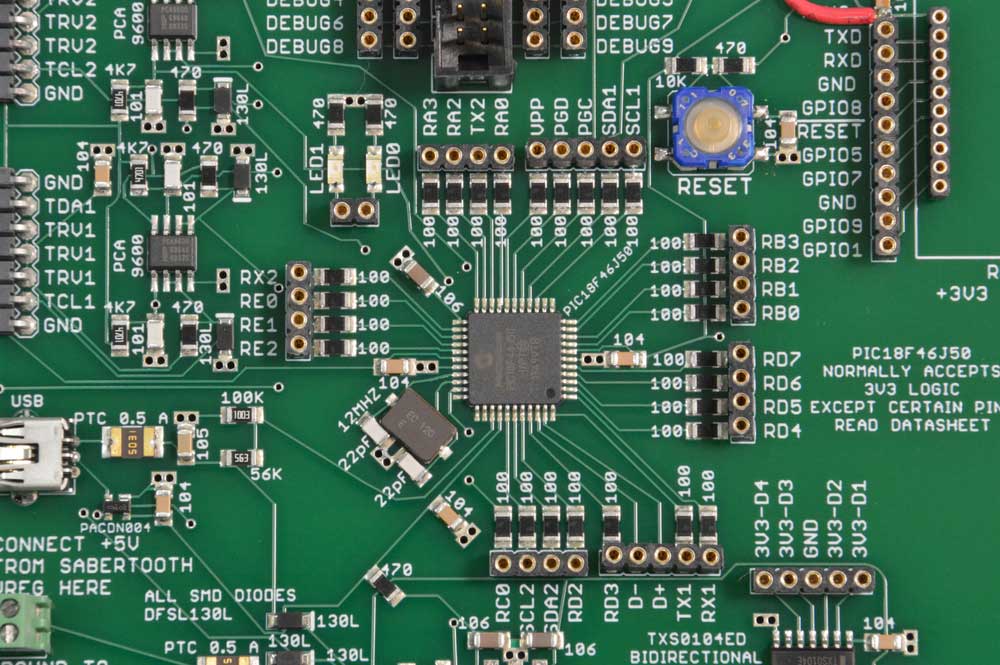

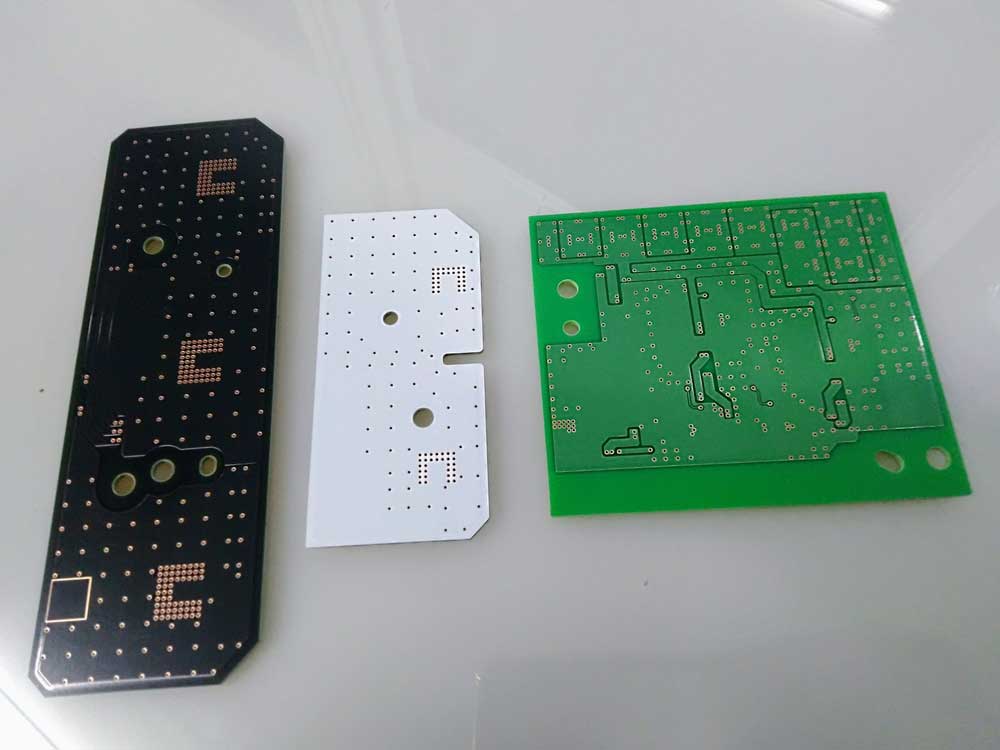

Simplified, a PCB clone is a copy of an existing PCB. Also called PCB duplication, PCB cloning is a form of reverse engineering to create copies of existing PCB circuit boards.

Reverse engineering of PCBs is primarily focused on hardware engineering, as it involves replicating the physical design and functionality of the circuit board. However, it also significantly impacts software development, particularly in extracting and replicating embedded firmware that controls the hardware's operations.

Being able to clone PCB board quickly as been a game changer for companies with multiple versions of the exact same printed circuit board. It’s also the fastest way to clone PCB design if you want to reuse pieces of an existing board for something else.

What is a PCB cloning service?

A PCB cloning service is a simple procedure that helps you create the exact design of the electronic circuit board. However, the PCB cloning service happens without undertaking the board design process. In addition, using a PCB clone service and PCB clone software is quite cost-effective.

There are a wide variety of reasons you may want to make multiple copies during the PCB development process, from testing products to creating samples for clients.

Advantages of PCB cloning

Cloning PCBs comes with multiple benefits and purposes for your company. Here are a few advantages of PCB clones:

Cost-Effective and High Quality

Usually, PCB manufacturing is incredibly time-consuming. High-quality board manufacture is also costly. On the other hand, PCB duplicates are cheaper and just as reliable. Additionally, you'll save on testing and prototypes, while designing is free. With PCB clones, you can quickly reduce time to market by shortening the development procedure, saving you money while maintaining consistent quality in the process.

Companies must analyze the board extensively if they want to adopt advanced technologies. Our analysis helps engineers create high-quality PCB artworks. Moreover, engineers can now construct temperature-reliable PCBs.

Simplified Production

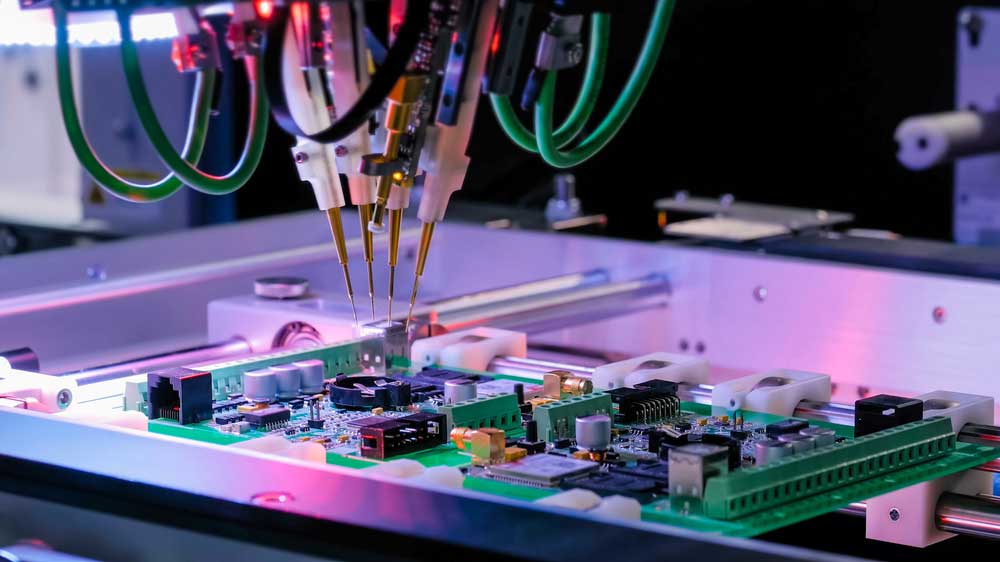

PCB cloning is completely automatic, which streamlines the productive purposes. For example, using PCB cloning in the electronic product replacement of an obsolete PCB is a much simpler process. Manufacturers identify innovative designs through reverse engineering and use them to create a new PCB.

Custom Designs

When you clone PCBs, you can tailor designs to meet the needs of your components. This also allows you to create a completely unique product or even make changes to an old design.

Improved Scalability and Freedom

PCB cloning allows mass manufacture from a single design to create several PCB board copies. Usually, the resulting PCB assemblies are custom, depending on the customer's needs. For this reason, PCB clones offer companies production flexibility.

Consistent Performance

Generally, the cloning service makes cloned PCBs look like the original and increases board performance. Also, the mechanical and electrical features make the cloned boards ideal for high-performance applications.

Special Offer: Get $100 off your order!

Email [email protected] to get started!

How Does PCB Cloning Help PCB Redesign and Development?

PCB cloning is an example of modern information technology. It uses reverse research techniques to produce a PCB design board. Usually, building a new PCB product from scratch takes many days. However, through PCB cloning, with the inclusion of reverse engineering, the PCB redesigning process is now simple.

Technology advances daily, so most electronic components require consistent upgrades. Unfortunately, most traditional methods of PCB designing cannot handle constant upgrades. Therefore, the fast adoption of reverse engineering in the new high-tech systems.

PCB Cloning Process

Cloning a PCB is a simple, automated process.

Before you begin the cloning, ensure you have the Bill of Material (BOM) and a copy of the circuit schematics. Besides these, choose a research technique from the several available. For equipment, ensure you have an Autocad, computer, scanner, and a PROTEL99.

Step-By-Step Guide

Let’s get into how to copy a PCB! Make sure to follow these steps when cloning PCB:

- Remove components and scan: First, from the PAD hole and the tin, remove all active components. Next, use an ultrasonic to clean the board. Then put the empty board on the scanner and scan it horizontally. Ensure that the contrast and brightness of the scanner are set, otherwise the images won't be viable.

- Copy the scan into Photoshop: Launch Photoshop and copy the scanner into the program. Usually, the bottom and top screen-printing methods are similar; both save the name of the custom while utilizing a color sweep.

- Polish and relaunch Photoshop: Polish the top and bottom layers of the board using paper yarn. Place the board back on the scanner and relaunch Photoshop. Complete the process by color sweeping both layers.

- Adjust lighting: Adjust the brightness, lightness, and contrast of the canvas. It will help verify whether the image lines are clear. If this is not the case, you must repeat the process or use Photoshop to correct the sketch. However, if the picture is clear, save it as a BMP file in black and white.

- Convert and generate: Convert the BMP files into a PROTEL file. Then, open PROTEL99 and create a new PCB file. Now, select import CAD from the PCB's editor's menu and place the CAD file inside it. With the PROTEL file, generate two levels. That’s not all! You will know a stage is complete and correct if the VIA and PAD are in the same place.

- Import, copy, measure, an arrange: You should open both imported CAD files. Then, copy the component package into the CAD using the PCB image as a reference. After this, put the pads and VIAs in their correct places and measure both the outside and inner sizes of the pads. This will help to get the diameters of the ring. Finally, arrange the pads according to their sizes when doing the layout.

- Install and delete: On the board, there is a silk layer. Carefully draw a line on the TOP Layer and install the device as previously described. After, delete the silk layer.

- Integrate diagrams: BOT and PCB are two different types of circuit boards. So, convert the PCB to PROTEL and integrate the two diagrams into one.

- Print and place film: Next, in a 1:1 ratio, print both layers on a clear film. Then put the film on the PCB, and it is complete. Furthermore, print the TOP LAYER and BOTTOM LAYER on clear film (1:1 ratio) on a laser printer. Then place the film on the PCB and compare for errors.

- Test it out!: Finally, test the cloned PCB to ensure it works as the original.

Remember, you need to focus on completing a successful PCB copy with the correct methods. Usually, an experienced PCB clone servicer normally carries out the process, but you can too!

The Legal Boundary of PCB cloning

You might be wondering, “Is PCB cloning legal?”

Since the start of reverse technology, a lot of doubts have ensued. Its legitimacy has constantly been in question for a long time.

For example, the court in China around January 2007 stipulated that trading information gained from reverse engineering was irrelevant. Thus, this meant that reverse engineering violated trade secrets and was hence inappropriate.

However, in the following month, the court revisited the case. Now, engineering services play a vital role in circuit industry development. However, its legitimacy is still in question.

Currently, most companies have rules on the issue. For example, anyone who wants to use reverse engineering must own design copyrights. This is necessary for legal purposes. The copyright protects the interests and legitimacy of the original designer.

Streamline Production With PCB Cloning

PCB cloning makes work easier, cuts costs, and increases PCB production capacity. Most manufacturers prefer cloning to construct a PCB schematic diagram from scratch. Before trying PCB cloning, you should understand its procedures, advantages, and legal considerations.

We truly hope this article has been beneficial to you. For any further questions regarding PCB cloning, do not hesitate to contact us. Our friendly team are more than willing to help you!

PCB Clones | FAQs

What is the difference between a PCB and a microchip?

The main difference between a PCB and a microchip is that PCBs enable connectivity between electronic components, while a microchip analyses data and sends out instructions. PCBs are boards with multiple components, including microchips.

What is the cheapest PCB material?

FR-4 is one of the cheapest PCB materials. It’s from woven glass fiber and epoxy resin. While it is cost-effective, it still has great mechanical strength and insulation.

Start Your Project with OurPCB

If you're considering PCB cloning for your project, why not take it a step further with professional PCB manufacturing? At ourPCB, we specialize in turning your designs into high-quality, reliable circuit boards. Whether you're working on a prototype or need a full production run, our expert team is ready to bring your ideas to life. Contact us today to discuss your project and discover how we can help you achieve precision and excellence in your PCB manufacturing needs.

Special Offer: Get $100 off your order!

Email [email protected] to get started!