Who are the Top 6 Data Cable Manufacturers in China?

When considering the best places for manufacturing data cables, China immediately comes to mind. It’s no surprise either — the country has rapidly ascended in

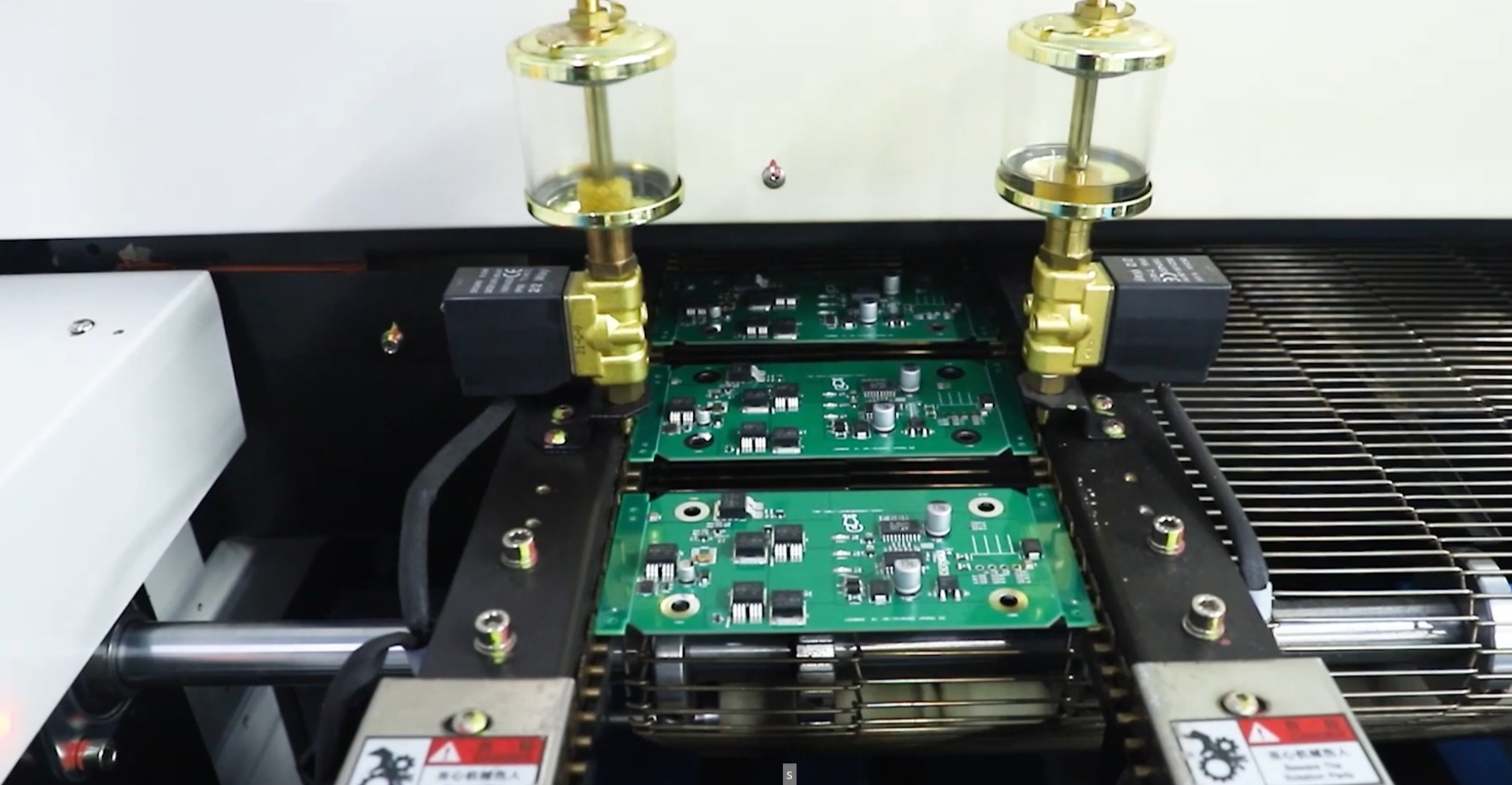

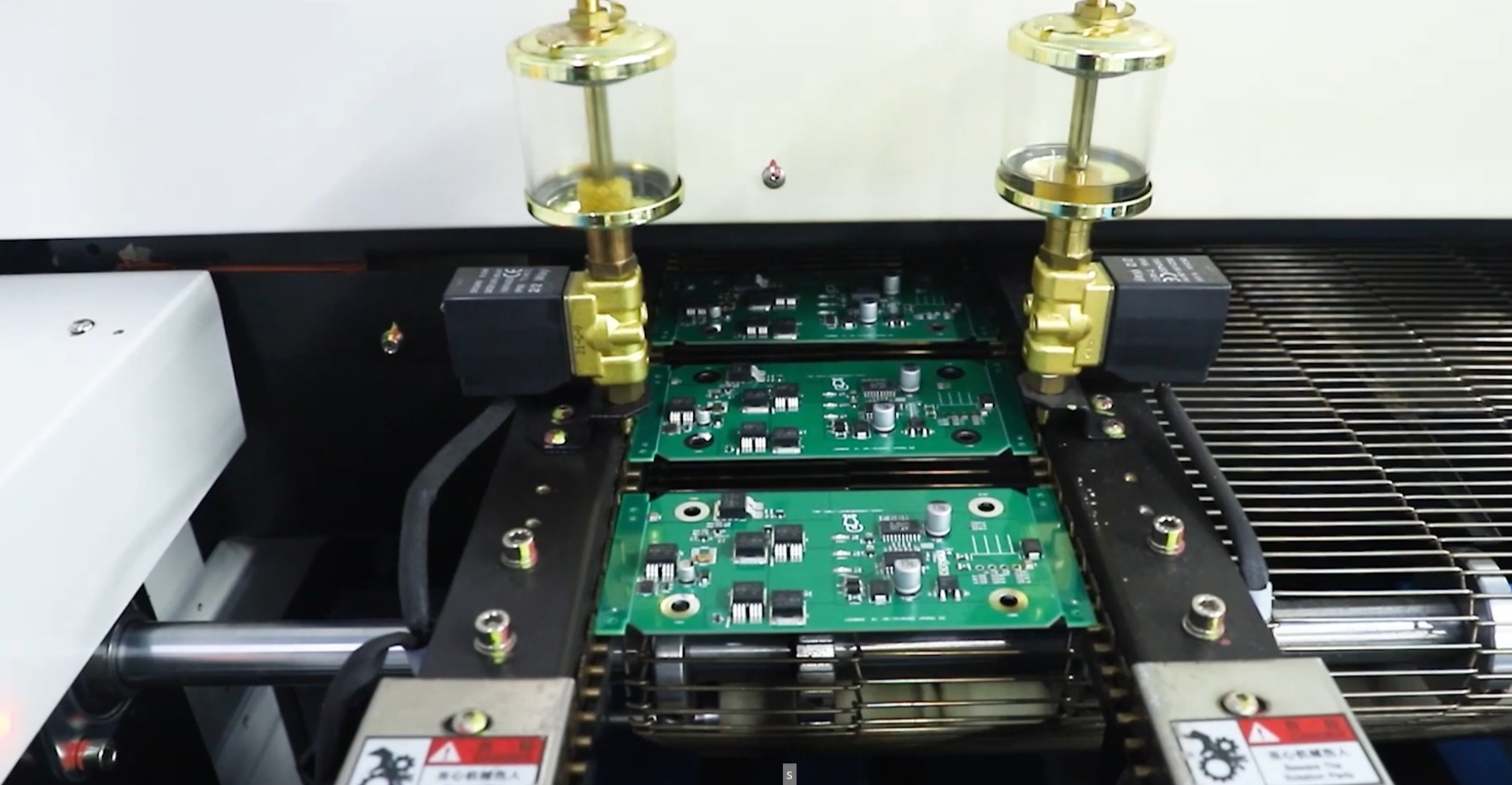

OurPCB provides professional PCB assembly services with precision and reliability. Based in China, we deliver high-quality PCB assembly directly to customers in the USA and across the globe. Our end-to-end solutions include component sourcing, SMT, and through-hole assembly, ensuring efficient production and consistent quality from a single trusted PCB manufacturer.

We also specialize in circuit card assembly solutions, ensuring all your components are properly placed and connected for optimal performance. Whether you’re working with HDI PCBs or need specialized testing such as In-Circuit Testing for PCBs, our services provide you with a one-stop solution for all your needs.

For more advanced applications, we also offer selective gold plating processes to enhance your PCB’s performance in sensitive areas that require high conductivity and corrosion resistance. Additionally, effective PCB Thermal Management is crucial for maintaining component reliability and preventing overheating in high-performance electronic assemblies.

| Specification | PCBA Capability |

|---|---|

| Placer speed | 600,000 chips/hour |

| Lead Time | 25+ Days (To Be confirmed) |

| SMT | SMT, Through Hole Assembly Single/Double-Side SMT, Single/Double-Sides Mixture Assembly |

| PCB Size | 50mm×50mm ~610mm×508mm |

| PCB Thickness | 0.5mm~4.5mm |

| Min. diameter /space of BGA | 0.2mm/0.35mm |

| Qualifications | ISO 9001:2015 |

| Accuracy | <±30µm, under the condition of 3σ,CPK≥1 |

| Minimum width/space of QFP | 0.15mm/0.25mm |

| Minimum Diameter /Space of BGA | 0.2mm/0.35mm |

| Reliability Test | Flying Probe Test/Fixture test, Impedance Test, Solderability Test, Thermal Shock Test, Hole Resistance Test, and Micor Metallographic Section Analysis, etc. |

Our state-of-the-art equipment and technology allow us to provide a seamless assembly experience no matter what you need. Below are the expert PCB assembly services we offer:

✔️ SMT, THT, and mixed technology

✔️ Automated process for precision

✔️ Detailed inspection and quality control

✔️ Functional testing

✔️ Fast turnaround times

✔️ From 25 to 5,000 units

✔️ Quick turnaround (1 to 7 days)

✔️ Rigorous checking and testing

✔️ All component sizes

✔️ Leaded or lead-free solder

✔️ 24-hr to 7-day turnaround time

✔️ Fabrication and assembly

✔️ Low- to high-volume

✔️ RoHS-compliant circuit boards

✔️ Rapid prototyping

✔️ Design and assembly

✔️ Quality component sourcing

✔️ Electrical safety testing

✔️ Fortify existing cables

✔️ Off-the-shelf cables available

The PCB assembly cost for 50 units, each with 100 square inches, will range from $100.00 to $250.00, based on an assembly rate of $0.02 to $0.05 per square inch.

| PCB Specifications | Quantity | Cost per PCB (USD) | Total Cost (USD) |

|---|---|---|---|

| PCB Manufacturing (Size: 10x10cm, FR4 Material, 2 Layers) | 50 | $1 to $5 | $50.00 to $250.00 |

| PCB Assembly (Square Inch Assembly Cost) | 50 | $0.02/inch² (100 inch²/PCB) to $0.05/inch² (100 inch²/PCB) |

$100.00 to $250.00 |

This is a general estimate, and actual costs may vary based on several factors. For detailed pricing information, please visit our cost page.

| Service Type | Lead Time |

|---|---|

| Standard PCB Manufacturing | 5-6 days |

| Expedited Manufacturing | 24-48 hours |

| PCB Prototyping (Quick Turn) | 1-12 layers: within 72 hours |

| 12+ layers: within 120 hours | |

| PCB Assembly | 4-25 days, depending on complexity and order volume |

Our PCB assembly service is designed to exceed your expectations. Here’s why Our PCB is the ideal PCB assembly and manufacturing partner:

We’ve provided over 3,000 happy customers with cost-effective high volume PCB assembly services. You could be next!

We’ve been a one-stop PCB assembly service for over 17+ years. Our capabilities are built on years of industry expertise.

Our exceptional PCBs and our electronic manufacturing processes meet all safety standards.

OurPCB is committed to validating, fabricating, assembling, and shipping your finished products with rapid turnaround times.

We’re proud to own two ISO 9001:2015 certified PCB assembly factories; one in Shenzhen and one in Shijiazhuang.

We work with only the best suppliers to provide you with durable, high-quality parts that perform.

We’re committed to providing you with the best service possible, even after you’ve received your product. Contact us at any time for help from our experts.

Whether you need a PCB prototype, component sourcing, or full-scale production, we can help. We’re your one-stop solution for all your PCB needs.

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

To try our PCB design and assembly services, start by getting your online quote now with $100 off your first order with us! Then, you’d upload your Garber File, pay, and production will start. If you don’t have a Gerber file yet, contact us anyway and we can help you design the perfect PCB. Once production is complete, delivery will take place and your order will be sorted out.

PCB fabrication and assembly are two separate parts of the manufacturing process. PCB fabrication assembly is when you transcribe a circuit board design onto the physical board.

When designing PCBs, especially those involving high-speed signals, using an oscilloscope can help visualize the waveforms of the electrical signals. This helps in debugging and ensuring the signals behave as expected, especially for more complex designs like high-density interconnect technology (HDI) PCBs. For a guide on how to operate an oscilloscope in PCB testing, we offer resources to help get you started.

PIR sensors (Passive Infrared Sensors) are commonly used in electronics for motion detection, especially in security systems and automated lighting. Understanding PIR sensors and how to integrate these sensors into your circuit board design is crucial. When designing a PCB that uses PIR sensors, it’s important to consider factors like power management, sensor sensitivity, and proper component placement to ensure the functionality of the sensor in detecting movement. OurPCB offers comprehensive assembly services that ensure these components are placed and integrated correctly into your designs.

Schematic drawings are essential in the PCB design process, as they represent the electrical connections between components. A well-drawn schematic diagram helps engineers visualize how components interact and guides the placement of components on the PCB. The Principles of Schematic Drawing involve accurately representing the components, their values, and their connections using standard symbols. At OurPCB, we provide detailed design services to ensure your schematic drawings are clear and meet all necessary specifications before moving on to the assembly stage.

When considering the best places for manufacturing data cables, China immediately comes to mind. It’s no surprise either — the country has rapidly ascended in

Finding the right wiring harness manufacturer for your vintage ride can be a real headache. Those beautiful old machines need special wiring that looks period-correct

Would your car be able to run without wire harnesses? Not a chance. Wire harnesses connect all the electrical parts together. No harness means no

Making wire harnesses isn’t complicated. At OurPCB, we create custom wire harnesses for an expansive range of industries every day. While it’s a complicated process,

Prototype cable assemblies are the very important place in between PCB design ideas and interconnects. OurPCB brings prototype assemblies with PCB solutions to your tables.

PCB thermal management prevents component overheating through strategic heat transfer techniques. Without proper thermal control, electronics are at risk of electronic failures through weakened solder

We use cookies to improve your browsing experience, which may include personal information. By clicking "Agree," you accept our Privacy Policy and cookie use. You can change your cookie settings in your browser anytime.

Agree