Different kinds of capacitor families store electrostatic energy in an electrical field and release this energy when needed. They allow the flow of AC but prevent DC flow to avoid dangerous breakdowns. If you ever intend to change your capacitor, you'll find that there are several types of capacitors. A common type is the Mylar polyester film capacitor, known for low leakage current. The main difference between Mylar capacitors and other capacitors is that they use Polyester. Polyester is known for its high capacitance per unit volume.

Here, we'll focus on Mylar capacitors and what differentiates them from other discrete capacitors. Keep reading for more!

Contents

What is a Mylar Capacitor?

FIg 1: A Mylar Capacitor

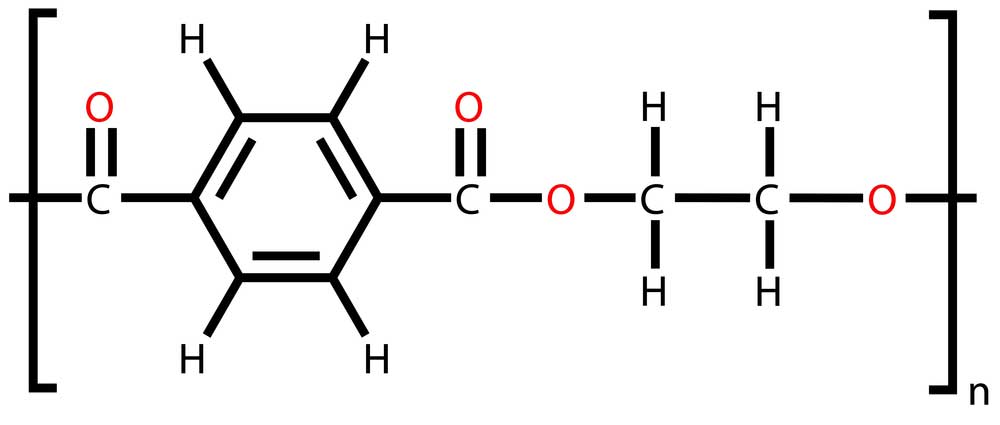

The Mylar capacitor, also known as a Polyester capacitor, is a type of film capacitor with high energy densities. It uses Polyester as the solid dielectric material for energy storage. It can also classify non-electrolytic capacitors.

Polyester dielectric has high dielectric properties, a feature that allows Mylar capacitors to be relatively smaller than electrolytic capacitors.

Its dielectric absorption is between 0.2% and 0.5%, generally highlighted with shallow dielectric losses. The conventional dielectric material used in Polyester capacitors is usually Polyethylene terephthalate, and this material allows low leakage current during energy storage.

FIg 2: Polyethylene Terephthalate (Polyester) Structural Formula

It is a type of capacitor with incredible heat and humidity resistance (low moisture absorption) properties. This makes it one of the best-metalized film capacitors to use in harsh temperatures of up to 125℃.

It can withstand sharp voltage ratings and AC current spikes. It does this while allowing low leakage current and resistive losses in resonant circuits. Has a voltage range of 50V to 650V.

Polyester film capacitors also have no polarity and you can connect them in either direction. The low ESR property allows the use of power film capacitors as filters in communication systems and high-end frequency applications.

Mylar Capacitor Features

Fig 3: Mylar Polyester Film Capacitor

Below are some highlights of these non-electrolytic capacitors that are made of quality components.

-

Super dielectric strength:

These metalized film capacitors are made of Polyester dielectric material (also called PET). This material has a very high dielectric strength.

-

Available in leaded versions:

Mylar capacitors are special capacitors that you can only find in leaded versions. You can't find these non-electrolytic capacitors in surface-mount packages.

-

High Tolerance capacitors:

Unlike ordinary film capacitors, a majority of Mylar capacitors are high tolerance capacitors. They have a tolerance level of between 5% and 10%.

-

Working Temperature:

They have a relatively low-temperature coefficient or temperature dependence. These non-electrolytic capacitors can operate in temperatures of up to 125°C without significantly reducing their lifetime. However, the voltage de-rates highly compared to when you use hybrid capacitors.

-

ESR (Equivalent Series Resistance):

Although it's not an ideal capacitor, it can provide an extremely low level of ESR and series inductance. It is one of the main reasons it uses in many practice locations where leakage current is undesirable.

-

High DV/DT:

Mylar capacitors are made to withstand the big instantaneous change of voltage over time, i.e., surge currents. Like hybrid capacitors, they are used in electric energy circuits (AC current circuits) that accommodate a high AC peak current.

Special Offer: Get $100 off your order!

Email [email protected] to get started!

Pin Configuration

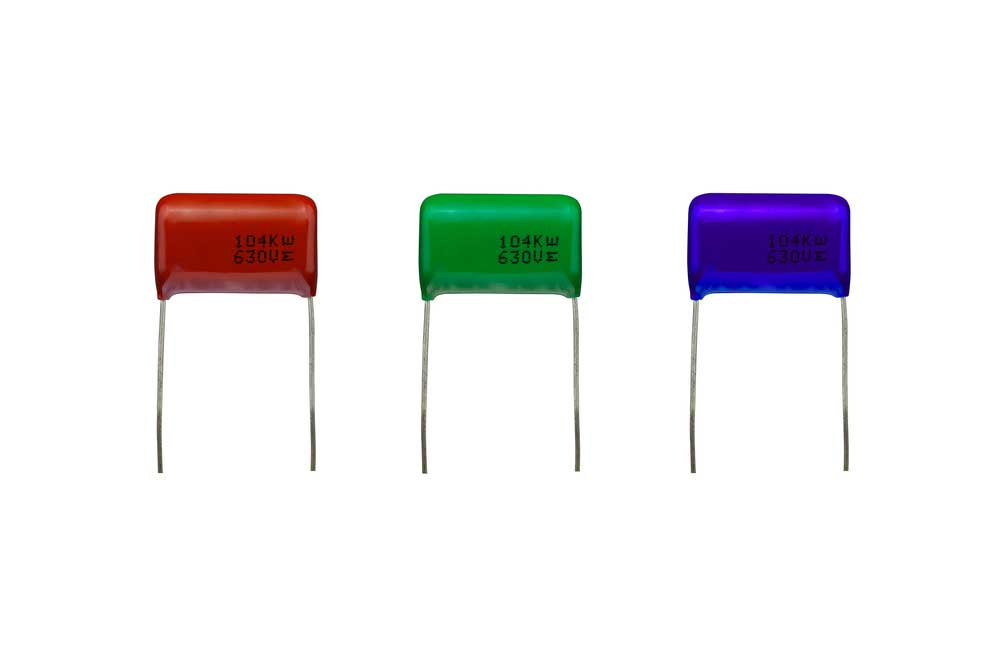

Fig 4: Mylar Polyester Capacitor

Like Ceramic capacitors, which use ceramic material and many industrial capacitors, Polyester dielectric capacitors don't have any polarity. They allow the flow of electrical energy in any direction while still maintaining minimal resistive losses and leakage current losses.

You can connect them in an AC current circuit in any direction without reducing their life expectancies (lifetime). Also, this won't reduce their response to fluctuating peak currents (electrical energy) in AC electric circuits.

Although they aren't as efficient as hybrid capacitors, they are used on breadboards (protoboards) and perf boards. Mylar capacitors are usually using two lines to signify, and they don't have any polarity.

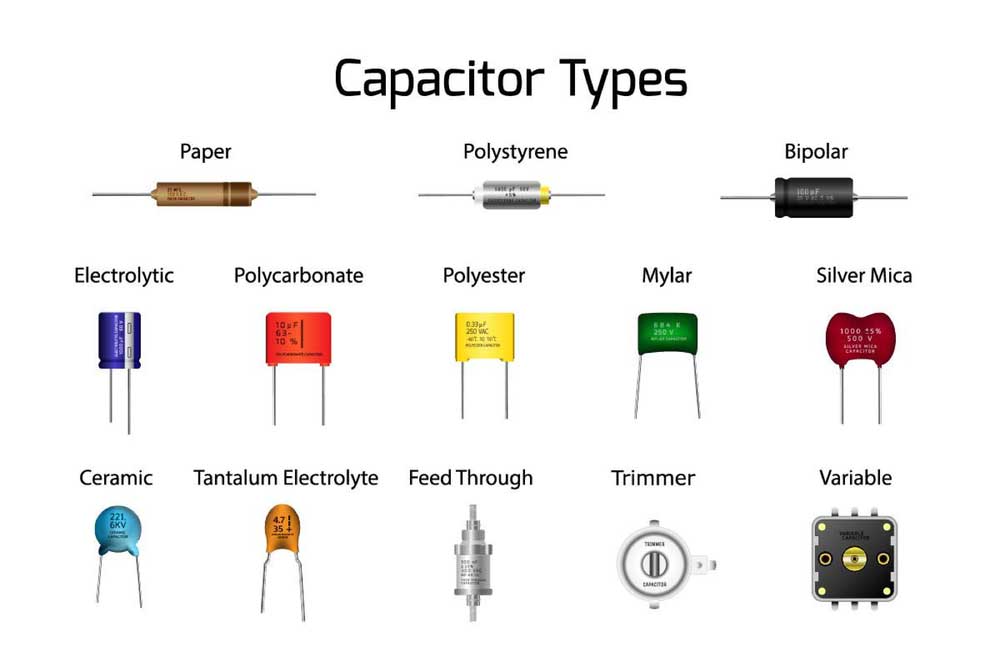

What's the Difference Between Capacitors?

Fig 5: Group of Types of Capacitors Isolated

Mylar Polyester film capacitors exist mainly in foil film capacitors or foil power capacitors and metal film capacitors.

The application of "rolled" film layers creates high actual capacitance and dissipation vs. temperature issues. Also, the operation of such metalized film capacitors at high-level frequencies is poor due to their construction.

They are highly dependent on frequency in power circuits, so not suitable for high AC current or high-end frequency applications.

Using Polyester as the dielectric medium in an electric energy circuit solves the problem due to their high dielectric constant.

Mylar Capacitor Applications

Fig 6: Electronic Components Used to Build a Circuit

Some of the most common ones are:

- Frequency filtering applications that do not require high tolerance

- Electrical circuits that have high peak ripple currents

- DC blocking in bridge circuits and general decoupling and coupling applications in a multi-layer printed circuit board.

- Like polypropylene film capacitors, you can use it in audio applications

- Power supply in applications that do not require extremely high capacitance.

- Outdoor applications where other discrete capacitors can't operate efficiently due to a moisture problem

Similar to polypropylene film capacitors, a Mylar capacitor is considered an excellent general-purpose capacitor.

However, it can't guarantee high levels of accuracy and tolerance. You can use it in AC circuits where it offers efficient volumetric capacitance.

Conclusion

Although the Mylar capacitor is not a polarized capacitor and is also different from other ordinary capacitors. However, this capacitor has high dielectric properties and heat resistance. It also serves many industrial applications. Although it is not the best, it is worth having. If you have any questions, you can contact us on our page.

Special Offer: Get $100 off your order!

Email [email protected] to get started!