- Home

- Military PCB

Military PCB Assembly Manufacturer Services & Supplier

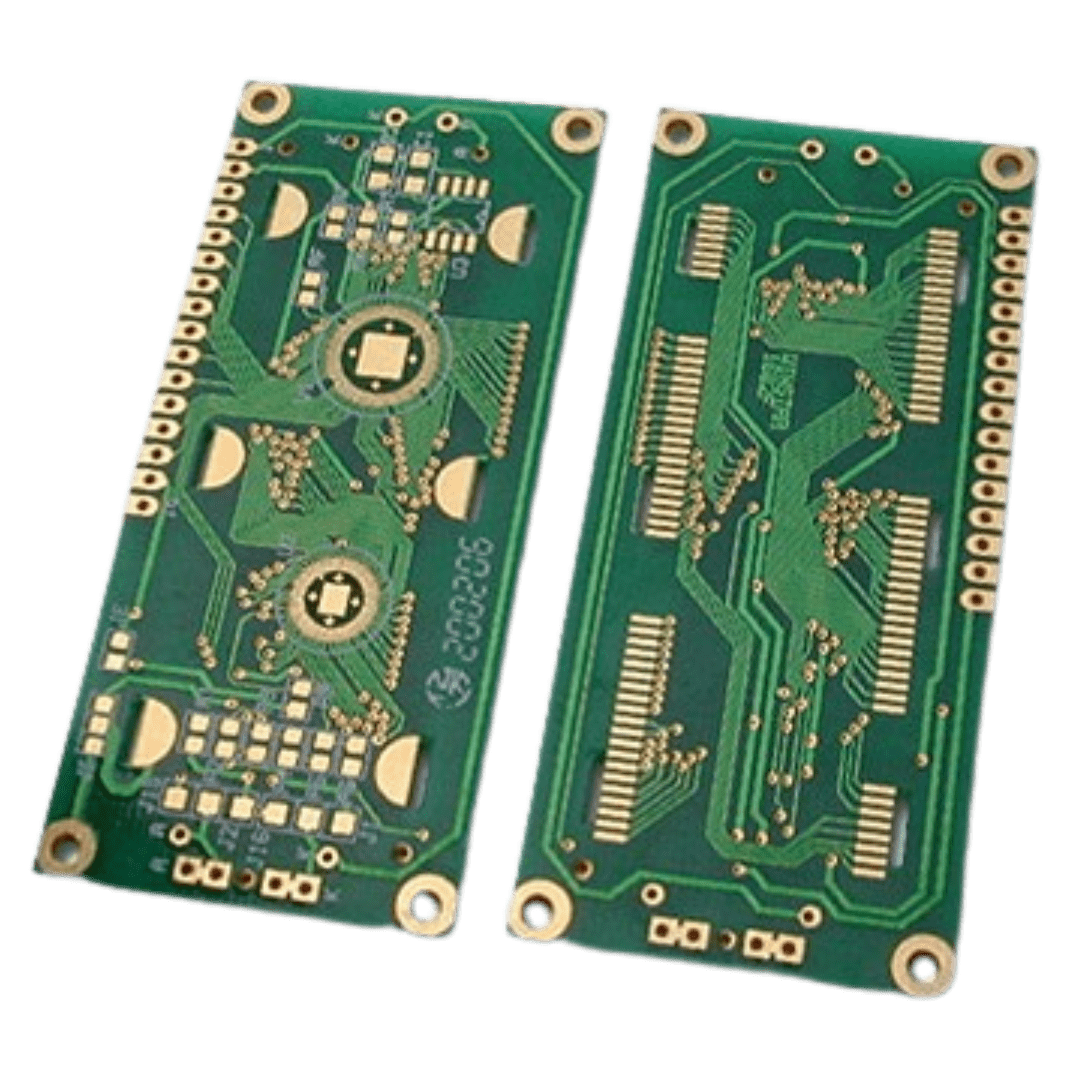

Military PCB assembly services focus on producing high-quality printed circuit boards for defense applications. These services ensure reliability and performance in demanding environments. OurPCB specializes in military-grade PCBs, including five-pin magnetic connectors.

Military PCB Assembly Services

OurPCB offers comprehensive military PCB assembly services. We cater to the unique requirements of the military and defense sectors. Our team understands the stringent standards that military applications demand.

We use advanced technologies for efficient assembly processes. Our commitment to quality ensures that every PCB meets military specifications. We follow IPC class 3 standards for all our assemblies.

PCB Manufacturing Process

The Benefits of Partnering with OurPCB for Military Circuit Boards

Partnering with OurPCB provides many advantages for your military circuit board needs. We ensure high quality, dependable military products every time.

- We ensure every PCB meets rigorous quality standards.

- Our processes comply with ISO and ITAR regulations.

- Our PCBs perform reliably in extreme conditions.

- We design for mission-critical applications.

- We use cutting-edge manufacturing techniques.

- Our equipment includes state-of-the-art AOI and X-ray systems.

- Our engineers have over 50 years of experience.

- We specialize in complex military and defense projects.

Why Choose Military PCB Assembly Services?

Choosing military PCB assembly services ensures that you receive high-quality military products from one of the top circuit board assembly companies.

- We adhere to international traffic in arms regulations.

- Our processes comply with MIL-PRF-31032 standards.

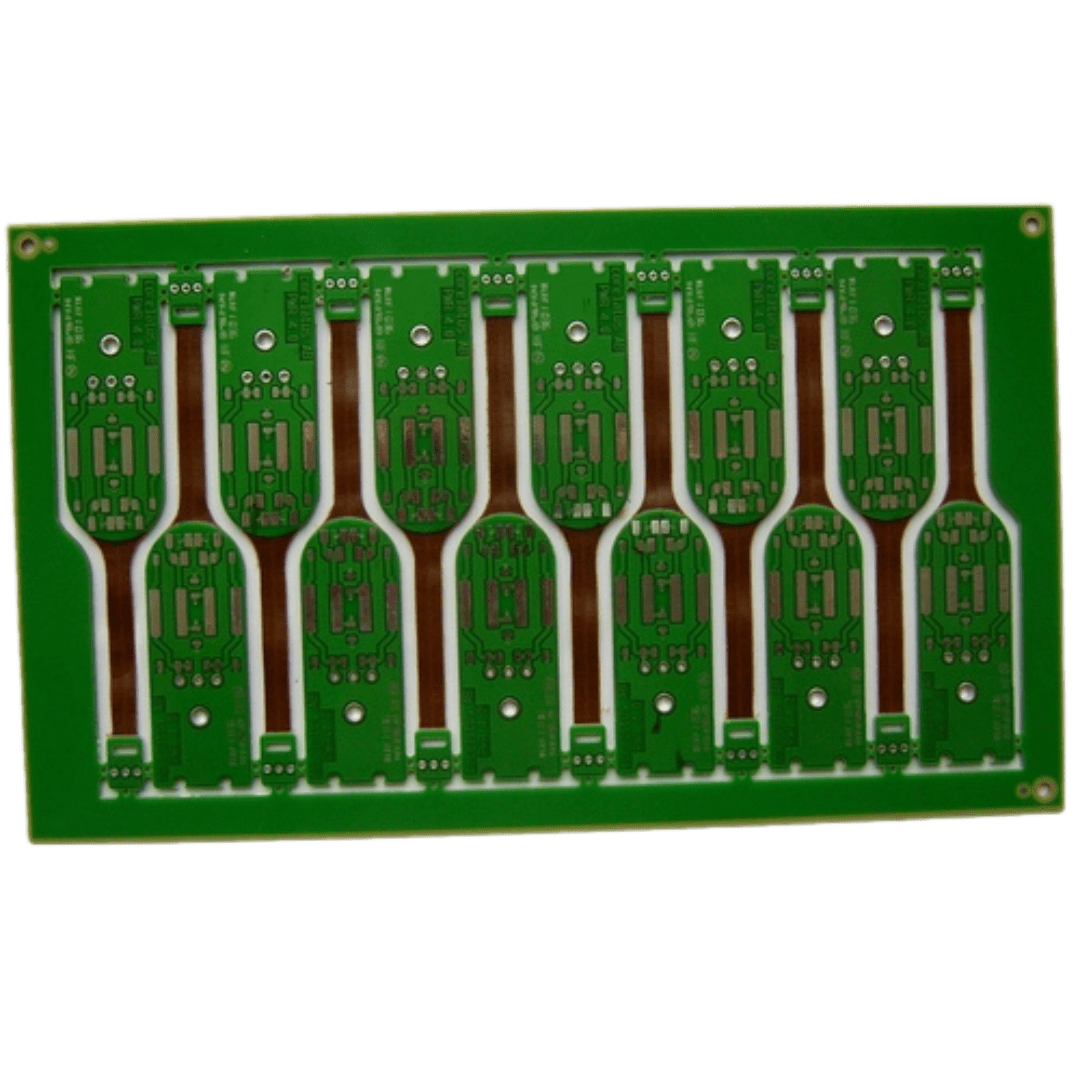

- We offer custom designs for rigid and flex PCBs.

- Each project receives personalized attention from our team.

- Our efficient processes reduce overall production costs.

- We deliver exceptional value without compromising quality.

- We maintain strong relationships with trusted suppliers.

- Our logistics ensure the timely delivery of all assemblies.

PCB Assembly Services

Our PCB assembly services cover various stages, from design to final assembly, ensuring that each board meets the specific requirements of your project. At OurPCB, we focus on delivering high-quality assemblies tailored to military and defense applications.

We efficiently assemble PCBs using Surface Mount Technology for high-quality, reliable electronic products. Ideal for compact, high-performance designs.

OurPCB supports consigned components and provides a complete turnkey solution, managing everything from sourcing to assembly. Ensures flexibility and convenience.

We offer tailored PCB assembly solutions to meet specific requirements, including unique designs and specialized applications.

We provide fast and efficient PCB assembly services with quick turnaround times to meet tight deadlines without compromising quality.

Our team delivers high-reliability PCB assemblies that meet IPC Class 3 standards, suitable for critical applications like aerospace and medical.

Expert assembly for all IC packages, including BGAs, POPs, CGAs, QFNs, DFNs, and CSPs, ensuring precision and compatibility.

Millions of business and innovators use OurPCB

PCB Board Process

Order Received

- Component Procurement

- Preparation

- PCB Manufacture

- Make Process Flow

Soldering

- Solder Printing/Wave Soldering

- SMT/Plugging

- Inspection (repair if necessary)

- AOI (repair if necessary)

- Transfer

Parts Assembly

- Manual Assembly

- Cleaning

- Wire Screw

- Inspection

- Repair If Necessary

Finalization

- Final Confirmation

- Packing

- Shiping

Technical Capabilities

OurPCB possesses extensive technical capabilities in military PCB assembly services. We focus on delivering high-quality printed circuit board assemblies. Our expertise covers various manufacturing processes, including surface mount technology (SMT) and through-hole assembly.

Capabilities & Services

- One-stop PCBA Services (PCB Manufacturing + Components Sourcing + Assembly)

- SMT + THT Assembly

- BGA Rework

- 60,000 Chips/Hour

- Down to 01005/0210 Size

- Accuracy<±40μm

- Min. QFN Pin Width/Space: 0.15mm/0.25mm

- Min. QFN BGA Diameter/Space: 0.2mm/0.35mm

- Rigid, Flex, HDI, & High-speed Power Boards

- Up to 50 Layers

- 60GHz High Frequencies

- Min. Trace Width/Spacing: 2.5mil/2.5mil

- AOI, X-ray, ICT & FCT Testing

- Controlled Impedance

- ISO 9001, ISO 13485, ISO 14001, IATF 16949, IPC-A-610, UL Certified

- Automotive, Medical, & Military-grade PCBA Manufacturing

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

FAQ's

What is PCB Assembly for military applications?

PCB assembly for the military industry involves specialized manufacturing and assembly processes to create durable defense PCB solutions. These manufacturing services are provided by our PCB assembly company, OurPCB. They require advanced certification to ensure reliability under harsh conditions. A PCB manufacturer focuses on design and manufacturing to meet the unique needs of military equipment and the defense industry.

What are examples of military PCB applications?

Examples of military PCB applications include control systems for vehicles, communication devices, and navigation systems in aerospace. Rigid-flex and specialized PCBs are used in mission-critical electronics to provide compact and durable solutions. These designs are tailored by military PCB manufacturers to withstand extreme conditions and meet stringent operational demands.

Are there specific PCB requirements for the military?

Yes, military PCBs have specific requirements, including the use of high-quality solder and materials capable of withstanding extreme environments. Printed circuit board assembly companies must meet strict certification standards to ensure reliability in sensitive applications. Military PCB fabrication involves robust testing and adherence to exacting specifications set by the manufacturer of printed circuit boards for the defense industry.