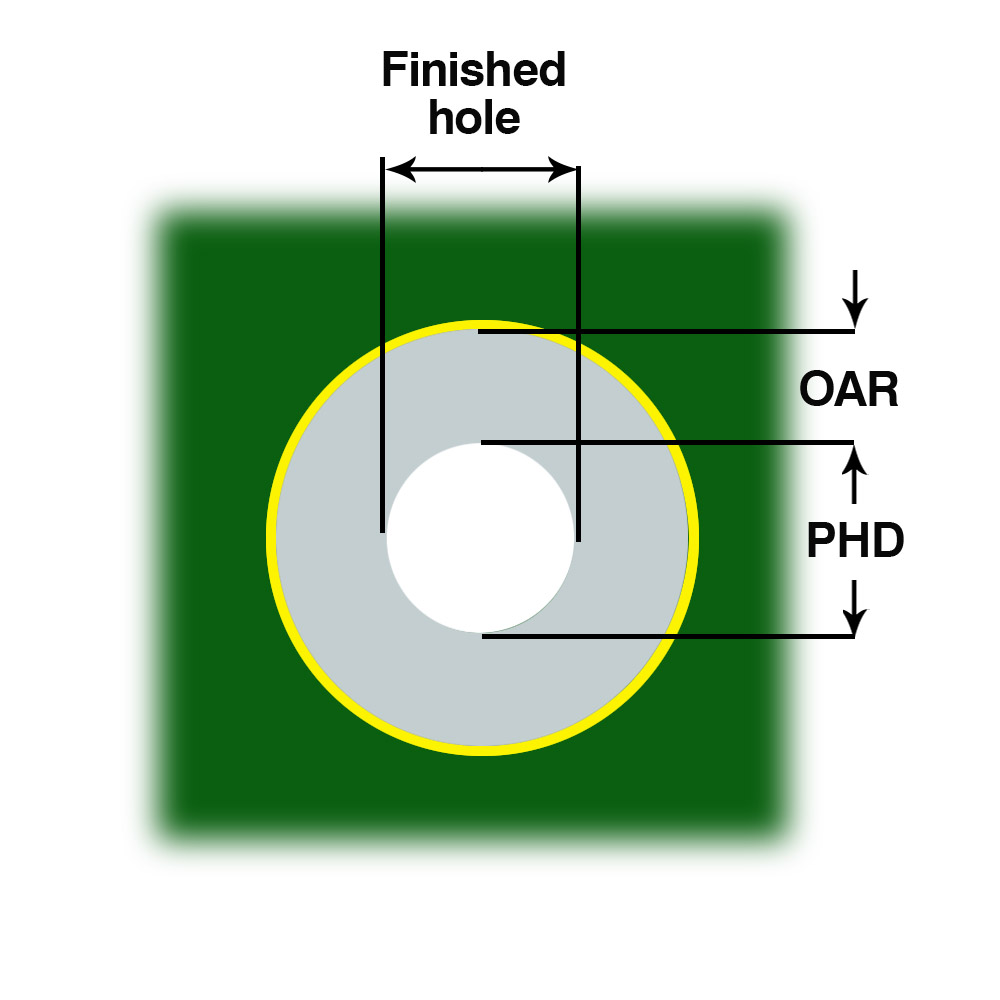

A hole diameter or PHD refers to a production tool’s diameter that you use to drill holes.

So, the calculation of a hole size diameter differed for non-plated through holes and plated through holes.

For a non-plated through-hole, the calculation is the sum of the finished hole size and +0.00mm/0mil.

But, plated through-hole, on the other hand, is the sum of the finished hole size and +0.10mm/4mil.

PCB hole diameter

Special Offer: Get $100 off your order!

Email [email protected] to get started!

Production Holes Diameter/PHD

The calculation for the PHD =

- Finished hole size + 0.00mm/0mil for Non-Plated Through Holes

- Finished hole size + 0.10mm/4mil for Plated Through Holes

- PHD – finished hole size = copper plating finish + applied finish

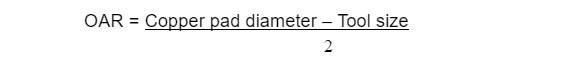

Hole Diameter--OAR (Outer layer Annular Ring)

The OAR is the outer layer annular ring. And you can calculate it by dividing the difference between the copper pad diameter and tool size by 2.

FAR (Finished Annular Ring)

The Finished Annular Ring is the part that lies between the solder hole and the external solder pad rim.

Plus, the annular ring breaks when the drilled hole is off the center.

But it's all dependent on the external diameter of the solder pad against the nominal hole size diameter.

Calculation of FAR;

The width (T1) of the finished annular ring on external layers should be >= 0.050 mm for the board.

The width (t2) of the annular ring on inner layers should be >= 0.0100 mm for the board.

Special Offer: Get $100 off your order!

Email [email protected] to get started!