High-frequency printed circuit boards (PCB) are specifically designed to operate at high frequencies. A high-frequency PCB design makes it easy to achieve fast data transmission and improved signal integrity. There is a much higher demand these days for high-speed communication and wireless technologies, so it's important to understand the ins and outs of high-frequency PCBs.

OurPCB is committed to making sure you have the best guidelines for high-speed PCBs. Let's get into what these PCBs are, some design guidelines to get you started, and for more details, you can always request a PCB quotation online.

Contents

- Key Takeaways

- What are High Frequency PCBs?

- What are High-Frequency PCB Properties?

- What Materials are Used for Fabricating High-Frequency PCBs?

- Guidelines for High-Frequency PCB Designs

- High-Frequency PCB Applications

- Benefits of High-Frequency PCBs

- Our PCB: High-Frequency PCB Manufacturing

- FAQs on What is a High-Frequency PCB Communication Circuit?

- What is the maximum frequency of a PCB?

- What is the difference between high-speed and high-frequency PCBs?

Key Takeaways

- High-frequency PCBs are designed for efficient signal transmission at high frequencies (500 MHz to 2 GHz or higher) to reduce interference and signal loss.

- Specialized materials like PTFE, Rogers, and ceramic composites are used to optimize electrical performance and maintain stability at high frequencies.

- Effective design involves controlled impedance, proper trace routing, electromagnetic interference (EMI) management, and thermal handling for reliable performance.

- High-frequency PCBs are important for industries like wireless communication and aerospace, offering faster data transmission, improved signal integrity, and higher power efficiency.

What are High Frequency PCBs?

High-frequency PCBs, sometimes called HF PCBs, are a special kind of printed circuit board designed to run at high frequencies. This usually ranges from hundreds of MHz to several GHz. These boards are built to handle the various problems caused by high-frequency signals, such as EMI, signal loss, and impedance mismatches.

They are different from standard PCBs because they are optimized for signal integrity and transmission efficiency at higher frequency ranges. They use specific design considerations and materials in RF PCB design to minimize signal distortion, reduce noise, and maintain consistent impedance throughout the board.

The design and manufacture of high-frequency PCBs need specialized knowledge and techniques. This is because you have to address the complicated behavior of electromagnetic waves at high frequencies.

It's always best to go to a professional like OurPCB for this because these boards typically need sophisticated layout strategies, careful material selection, and accurate impedance control.

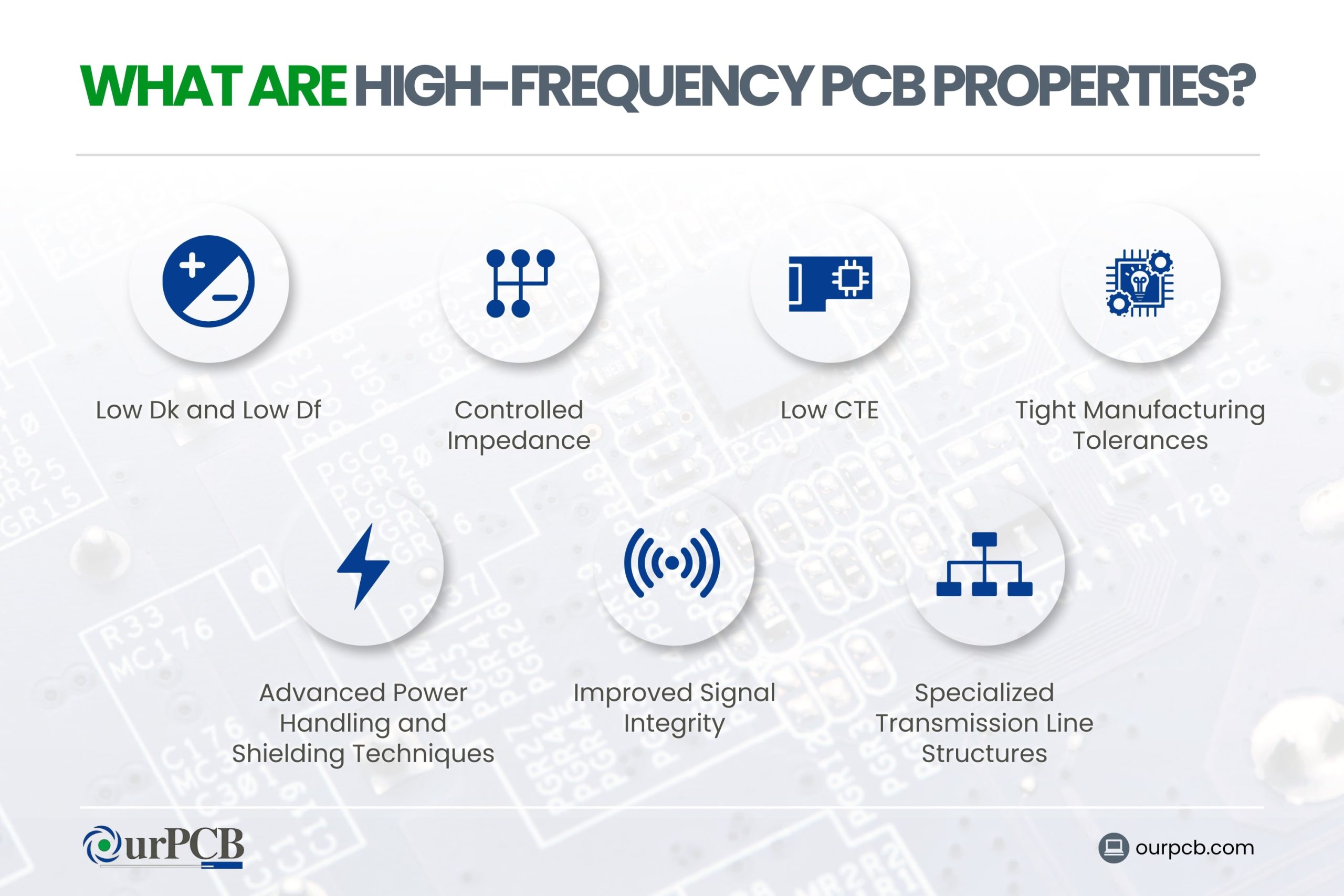

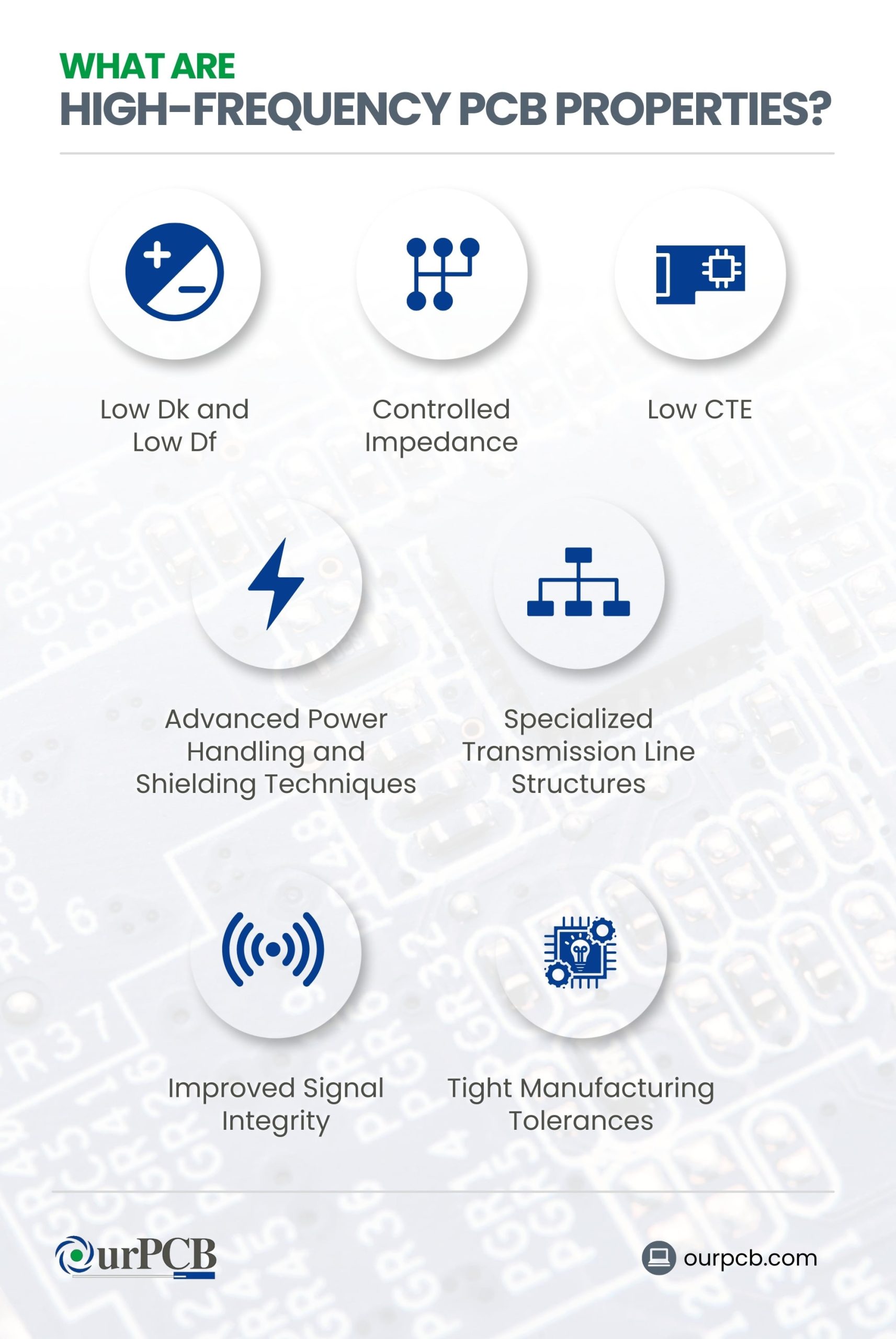

What are High-Frequency PCB Properties?

High-frequency PCBs are incredibly unique in comparison to standard PCBs. Here are a few important properties that make them different:

- Low Dielectric Constant (Dk): A high-frequency PCB material has a low Dk. This reduces signal propagation delay and minimizes signal loss.

- Low Dissipation Factor (Df): A low Df makes sure that there is minimal energy loss as signals travel through the board. This maintains signal integrity.

- Controlled Impedance: High-frequency PCBs keep consistent impedance throughout the board to prevent signal reflections and make sure there is efficient transmission.

- Low Coefficient of Thermal Expansion (CTE): High-frequency material with low CTE is used to prevent board warping. This also maintains the dimensional stability at high frequencies.

- Smooth Copper Foil: Ultra-smooth copper foil is used to lower skin effect losses at high frequencies.

- Tight Manufacturing Tolerances: High-frequency PCBs need incredibly accurate manufacturing to keep consistent electrical properties.

- Improved Signal Integrity: These boards are engineered to minimize crosstalk, EMI, and signal distortion.

- Advanced Power Handling: High-frequency PCBs usually have better thermal management to handle the increased power densities that come with high-frequency operation.

- Specialized Transmission Line Structures: Microstrip and stripline configurations are typically used to control impedance and reduce radiation from frequency signals.

- Advanced Shielding Techniques: High-frequency PCBs often have extra shielding layers or structures to cut down on EMI.

These special properties allow radar PCBs to easily manage challenges with high-frequency and high-speed signals. They make sure that there is high reliability and powerful performance in the most demanding applications!

Special Offer: Get $100 off your order!

Email [email protected] to get started!

What Materials are Used for Fabricating High-Frequency PCBs?

The PCB materials used in a high-frequency printed circuit board must have very specific electrical and mechanical properties. This is to make sure that the high-frequency board performs well at higher frequencies. Here are some of the most common materials used.

| Material | Properties |

|---|---|

| FR-4 | Even though standard FR-4 is not ideal for high frequencies, specialized high-frequency versions with lower Dk and Df can definitely work. |

| Rogers Materials | Rogers Corporation makes a range of high-performance laminates like RO4350B and RT/duroid, which can provide powerful electrical properties for high-frequency PCB applications. |

| Taconic Materials | Taconic has materials like RF-35, TLY, and TLX, which are designed for high-frequency and microwave applications. |

| PTFE (Teflon) Based Materials | These materials can give you very low Dk and Df, making them great for extremely high-frequency applications. |

| Ceramic-Filled PTFE Composites | These materials bring together the strong electrical properties of PTFE with a higher dimensional stability. An advanced ceramic substrate is usually used for applications that need powerful thermal stability and low signal loss. |

| Liquid Crystal Polymer (LCP) | LCP has fantastic electrical properties and can be used for both rigid and flexible high-frequency PCBs. |

| Polyimide | This material is popular because it has a high temperature resistance. Polyimide is used in high-frequency applications that need thermal stability. |

| Low-Loss Prepregs | Specialized prepreg materials can be used to bond layers in multilayer high-frequency PCBs while ensuring low signal loss. |

Choosing the right material can be tough. Your choice will depend on a bunch of different factors, such as the operating frequency range, required performance, environmental conditions, and budget, especially when designing an FM transmitter circuit.

Every single material on this list will give you a special combination of electrical, thermal, and mechanical properties. This allows you to optimize your high-frequency PCB for specific applications.

Guidelines for High-Frequency PCB Designs

Designing high-frequency PCBs can be quite complex. Here's our step-by-step guide to designing high-frequency PCBs.

- Understand Your Needs: Find out the operating frequency range, power requirements, and environmental conditions for your high-speed PCB designs.

- Choose Your Materials: Choose PCB materials with suitable Dk, Df, and CTE for your frequency range and application.

- Plan PCB Stackup: Design a stackup that minimizes crosstalk and keeps a controlled impedance. Consider using ground planes for shielding.

- Establish Controlled Impedance: Calculate and maintain consistent trace widths to get your target impedance (usually 50 Ω or 75 Ω).

- Optimize Trace Routing: Use short, direct traces. Avoid right angles at all costs! Rather, use 45-degree or curved traces to minimize reflections.

- Manage Signal Integrity: Separate high-speed signals from low-speed ones. Use differential pairs for critical signals in your high-frequency design. This can also help limit common-mode noise by rejecting electromagnetic coupling from external sources.

- Use Ground Planes: Use solid ground planes to provide a low-impedance return path and reduce EMI.

- Proper Via Design: Use small, tightly spaced vias for ground connections. You might want to use buried or blind vias for high-frequency signals.

- Follow Proper Termination: Use the right termination techniques to minimize signal reflections.

- Think About EMI/EMC: Make sure you use proper shielding and grounding techniques to keep out EMI.

- Thermal Management: Be prepared and plan for effective heat dissipation, especially for high-power RF circuits.

- Simulate and Analyze: Use electromagnetic simulation tools to check your design before fabrication.

- Design for Manufacturability: Consider manufacturing requirements and capabilities when designing your board.

High-Frequency PCB Applications

PCBs are used in a variety of important industries. Here are a few applications for this type of PCB:

- Wireless communication

- Satellite communication

- Aerospace and defense

- Medical equipment

- Automotive

- Broadcasting

- Industrial Automation

- Research and Development

- Devices operating at radio frequency (RF) and microwave frequencies

Benefits of High-Frequency PCBs

High-frequency PCBs come with tons of benefits that make them essential when it comes to modern electronics:

- Improved Signal Integrity: High-frequency PCBs maintain signal quality at high speeds. This reduces distortion and loss.

- Faster Data Transmission: These PCBs allow for fast data transfer, which is essential for high-speed digital and wireless applications.

- Reduced EMI: Proper design and materials help reduce EMI, which improves the overall system performance.

- Higher Bandwidth: High-frequency PCBs can support wider frequency ranges, which means an increased data capacity.

- Miniaturization: Advanced designs allow smaller form factors without affecting performance.

- Improved Reliability: Specialized materials and design techniques improve long-term reliability in high-pressure environments.

- Higher Power Efficiency: High-frequency PCBs can handle higher power densities with better thermal management.

- Versatility: These PCBs support tons of different applications, from consumer electronics to aerospace systems.

- Cost-Effective: Even though these PCBs can be initially more expensive, they can lower the total system costs by improving performance and reliability.

Our PCB: High-Frequency PCB Manufacturing

When it comes down to it, high-frequency PCBs are a necessity in modern electronics. They are completely optimized for signal integrity and transmission efficiency at higher frequency ranges. Additionally, they can reduce signal distortion and noise, while maintaining consistent impedance control.

At OurPCB, we produce high-frequency counter circuits that can meet all of your demands for signal integrity, impedance control, and overall performance. Contact us for a PCB assembly quote today!

FAQs on What is a High-Frequency PCB Communication Circuit?

What is the maximum frequency of a PCB?

The maximum high-frequency signals of a PCB can reach up to several hundred GHz in specialized applications; however, the majority of commercial high-frequency PCB applications typically operate in the range of a few GHz to tens of GHz. The maximum signal will also depend on the kind of materials and the design you use.

What is the difference between high-speed and high-frequency PCBs?

High-speed PCBs focus on fast digital signal transitions, whereas high-frequency circuits are designed for efficient analog or RF signal transmission at high frequencies.

Back to Top: What is a High Frequency PCB Communication Circuits?

Special Offer: Get $100 off your order!

Email [email protected] to get started!