CEM-1 is an important low-grade base material used to make printed circuit boards. Mostly, engineers and printed circuit board manufacturers use it to produce single-layer PCB boards. Even with the rise of technology and superior panels, manufacturers still prefer to use CEM-1 PCB because of its low cost and simplicity to punch. This is a fact compared to its counterpart FR-4 material, which is more costly.

What Is CEM 1 Material PCB?

High tech electronic PCB

CEM laminates are material compositions with a few minimal overall performance specifications. NEMA1 grade CEM-1 laminates consist of three components: an inner cellulose paper core compressed among non-stop woven glass fabric layers and infiltrated with a flame-resistant epoxy resin binder. The issue is that it can only effectively make single-layer printed circuit board devices. However, NEMA grade CEM-3 laminates are similar but with a chopped glass fiber core.

CEM-3 is like the usually known and most used PCB material, FR4. It is flame-retardant and has a distinct white color. It is also quite similar to CEM-4, only that it is not flame redundant.

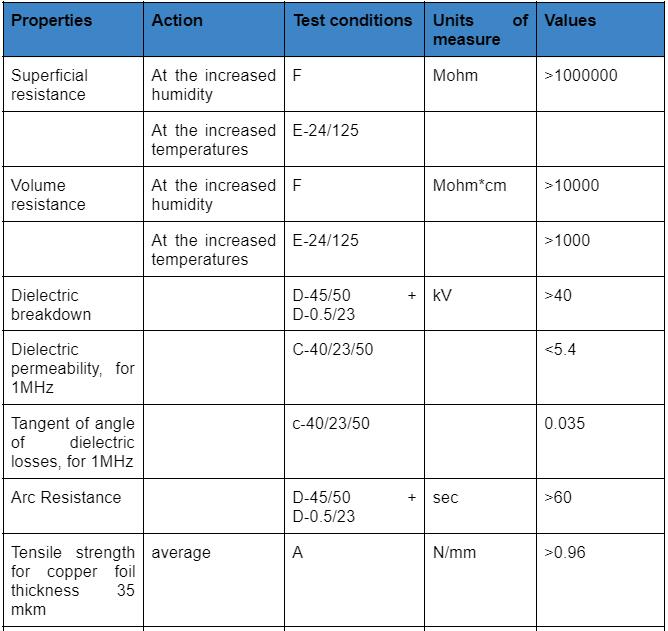

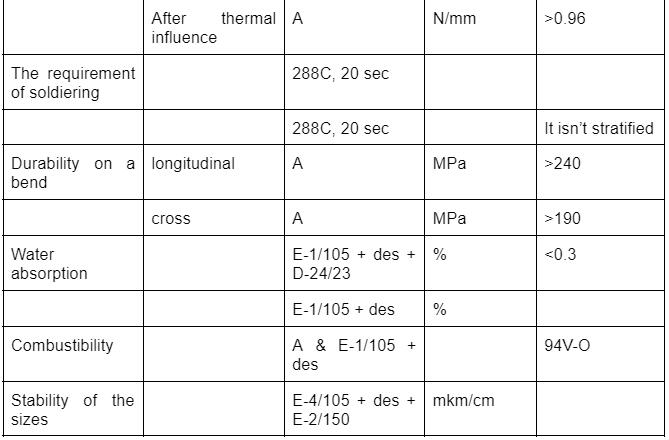

CEM-1 PCB Material Technical Parameters

The stumbling block of CEM-1 is that it may produce a single layer of PCB gadgets. This material is cheaper than FR-4 material for solitary layer PCB development.

Below is a table showing the properties.

CEM 1 vs. Fr4

The flexural capability for CEM-1 material is weaker compared to that of FR-4.

It has a more significant thermal expansion coefficient compared to FR-4. Therefore, the overall performance of CEM-1 material is a whole lot higher than that of FR-4.

Moreover, it is less costly compared to FR-4. Therefore, it is ideal to use CEM-1 when producing single-sided PCB.

Special Offer: Get $100 off your order!

Email info@ourpcb.com to get started!

CEM 1 vs. CEM 3

They are comparative here and there and distinctive in certain qualities. Both are a result of being impregnated with epoxy sap.

CEM-1 composite material consists of woven glass fabric surfaces and paper core blended with epoxy resin. Easy punching, remarkable electric capabilities, and better flexural power than paper-based grades. As a result, it affords outstanding mechanical and electrical capabilities and punches nicely up to .093″. Essentially used in the printed circuit board industry.

However, CEM-3 could be very much like FR-4. Instead of woven glass fabric, it uses a type of a 'flies.' CEM-3 has a milky white shade and could be very smooth. It is a complete replacement or an alternative for FR-4. It is a flame retardant epoxy copper-clad plate glass material typically utilized in electronics with double-sided and multilayer PCB boards. And CEM-3 is a brand new printed circuit substrate material designed based on FR-4.

Circuit Board

The Advantages and Disadvantages of CEM 1 PCB

Advantages

- It is a financially savvy choice for creating PCBs.

- Additionally, they are highly relevant in mass assembly applications such as minicomputers, radios, printers, controllers, and advanced state units.

- You can create numerous gadgets in a short period at a low dollar cost.

- It can produce lighter single-layer PCB boards compared to other materials.

- When used in LED manufacturing, It has a balanced thermal conductivity making it good at dissipating heat.

- It has a more robust physical structure; therefore, it can support heavy board components.

- It has a suitable glass transition temperature, better heat dissipation, and electric energy storage.

Circuit Board

Disadvantages

- This kind of PCB needs great mechanical perseverance. This is because its overlaps are not passable with through-hole.

- CEM-1 creates exceptionally delicate PCBs, which can break effectively on the off chance that they are not taken care of with a ton of respect.

- Solder points on CEM-1 PCBs that are not exceptionally solid and, along these lines, not dependable.

Which Software Is the Best When Designing CEM1 PCB?

These are some of the best software to design CEM-1 PCB boards.

- Eagle

- Mutism

- Easy EDA

- Altium Designer

- Ki Cad

- Circuit Maker

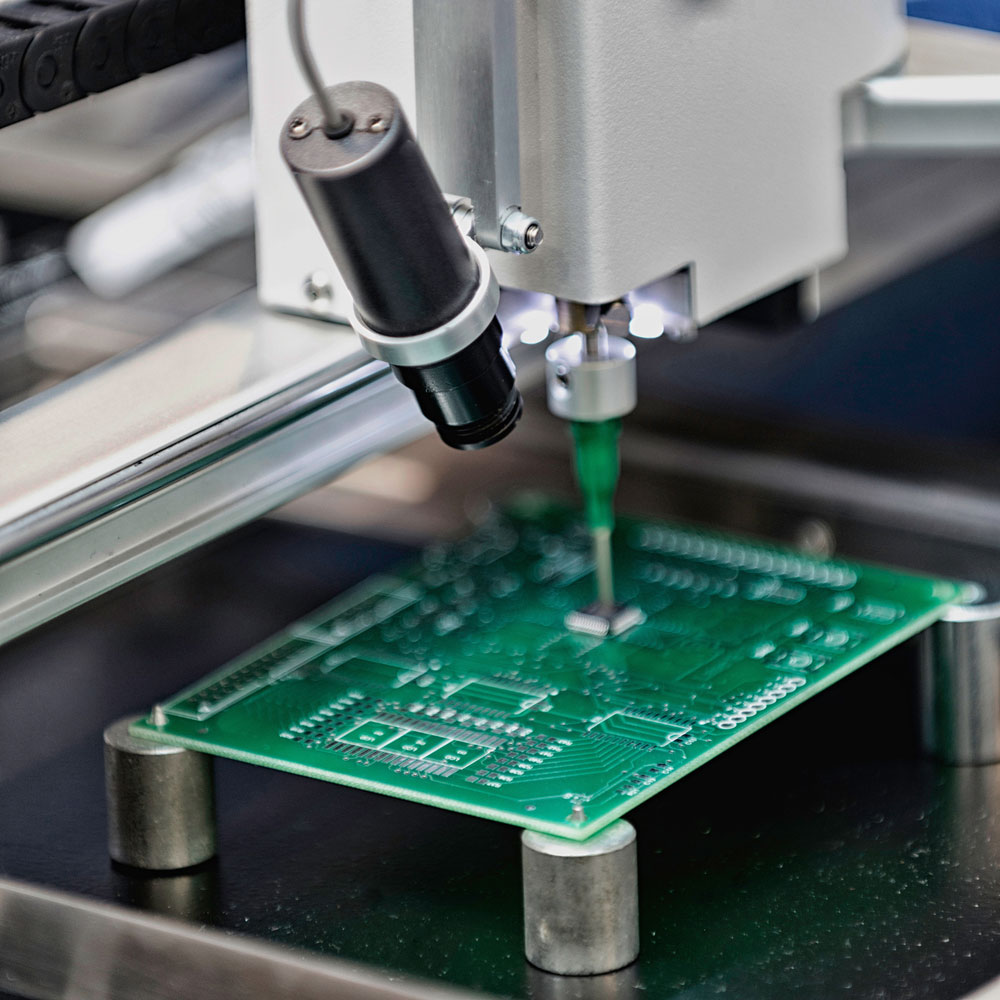

Steps in Manufacturing CEM-1 PCBs

It has eleven stages in this order:

- Design and Output

- Transfer the file to film

- Print the image on the surface

- Removing unnecessary copper

- level alignment and optical inspection

- Layer up and Bonding

- Final Etching

- Application of Solder Mask

- Surface Finish

- Silkscreen

- Testing PCB Electronically

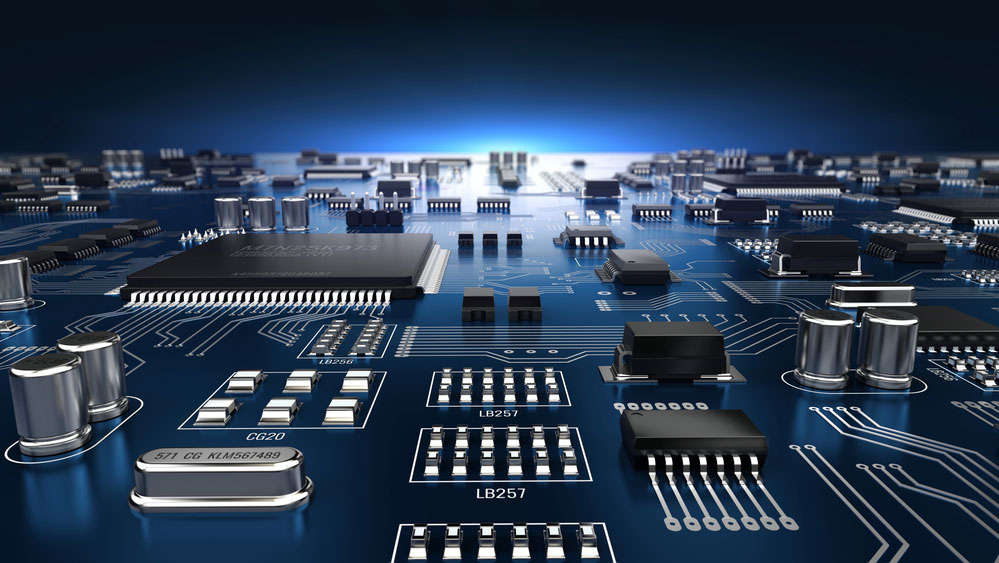

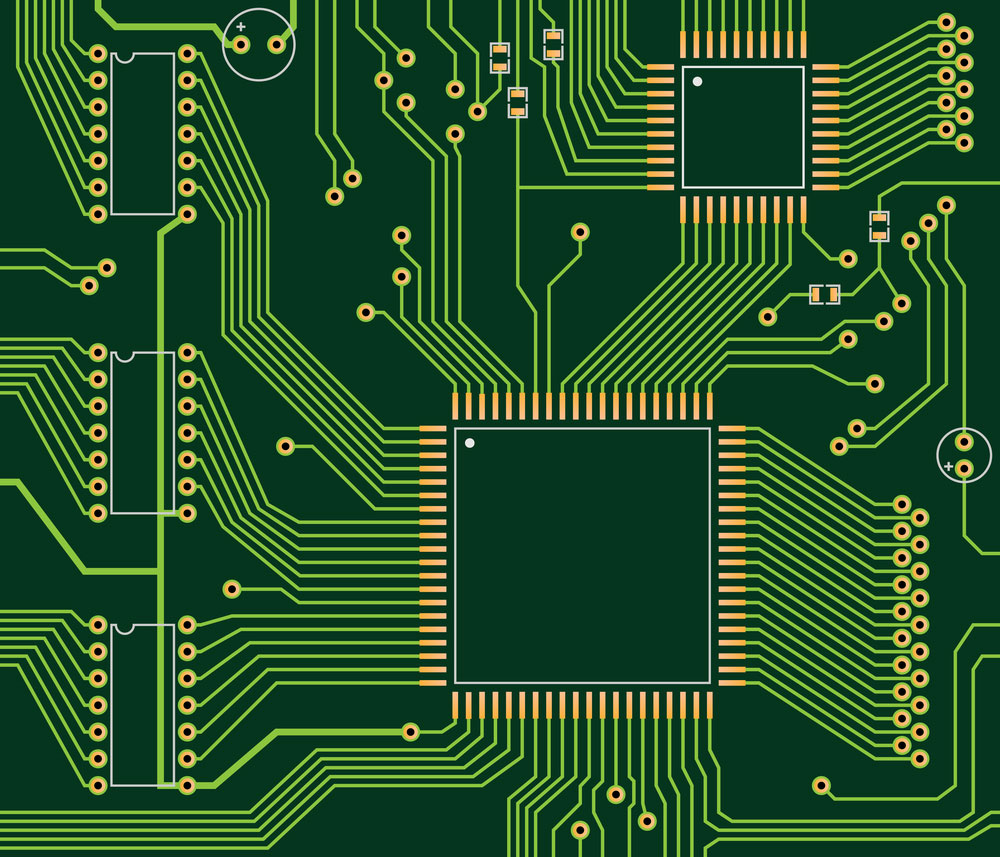

Printed circuit board manufacturing

Applications

- It applies in simplifying designs such as toys, controllers, and household appliances.

- Apart from these, this kind of PCB also applies to the design of electrical lights. For example, headlights & turn signals and brake lights.

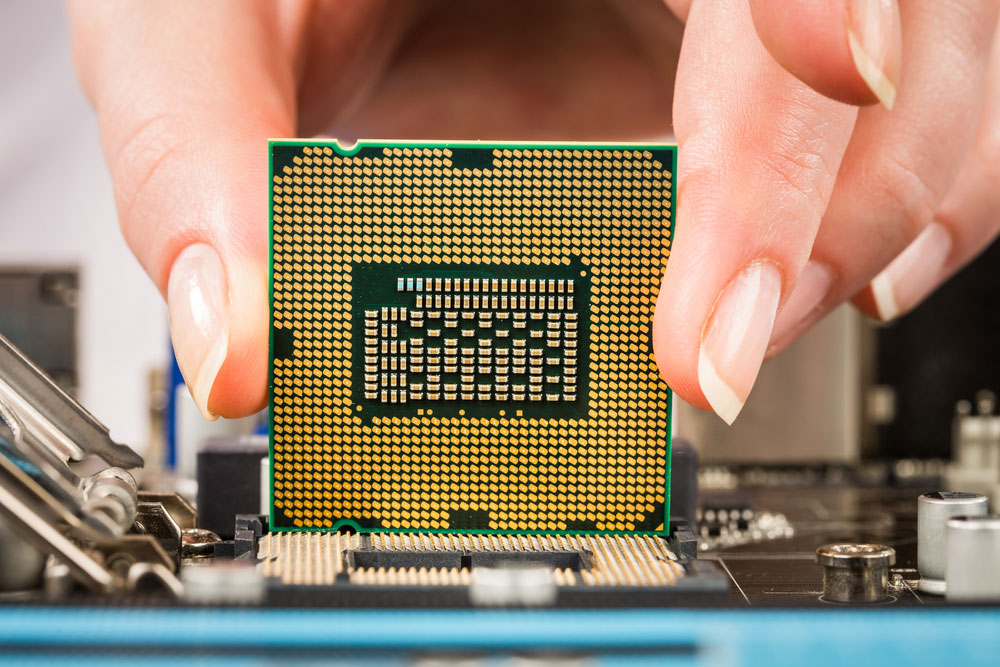

- CEM-1 PCB acts as heat redundant in PCs. Computer processors generate a lot of heat, therefore cooling PC parts like computer chips.

Modern processor and motherboard

- Floppy drives and power gadgets come as an implementation of PCBs.

- Medical scanning technology

Considerations When Choosing a CEM 1 PCB Manufacturer

A decent CEM-1 PCB producer should have a group of specialists that offer guidance and assistance over your inquiry. A good manufacturer will aid and make it easier for you by providing consultation that best suits your needs and assembling this kind of PCBs. Apart from that, they will also help distinguish the best materials for creating PCBs. Finally, a manufacturer must reach and use materials such as glass filaments and epoxy. You need to know the market cost for PCBs. This will allow you to find manufacturers who offer PCBs at the market's most conservative and actual price.

Do you have a hard time finding the best PCB board for your project? Don't worry. You are in the right place. OurPCB is the obvious choice for a high production yield, and we will build circuit boards using the best material for your project. Contact us today to get more information.

Special Offer: Get $100 off your order!

Email info@ourpcb.com to get started!