Bill of Materials to an engineer or designer is like having a list of necessary ingredients and tools needed by a Chef to cook a meal.

With the list, the chef gets a clear picture of everything needed to prepare a particular meal like Honey Roast Chicken.

The list also helps the baker get every required detail—from price to brand type, without missing anything out. That way, another person can take the list to the market without getting confused.

Well, the same thing applies to the bill of materials of an engineer or designer when designing PCB boards.

In this post, we'll tell you everything you should know about BOM. The definition, types, structures, and how to prepare it.

Are you ready? Let's dive in!

Contents

- 1. What Is a Bill of Materials (BOM)?

- 1.1 Definition

- 1.2 Components Included in a Bill of Materials

- 2. Types & Structure of Bill of Materials (BOM)

- 2.1 Types of BOM

- 2.2 Structure of Bill of Materials

- 3. How to Make a Bill of Materials?

- Six Steps to Take When Making a Successful BOM

- What Are the Steps to Take to Create a BOM in SAP?

- How to Change a Bill of Materials

- How to Display BOM

- 4. What Are the Things to Consider Before Creating a BOM

- 4.1 What Product do you plan to manufacture?

- 4.2 How do you Manage your BOM?

- 4.3 How will you attach files to your BOM record?

- 4.4 Who is going to use the BOM record?

- 4.5 Should I document Consumables on my BOM record?

- 4.6 What software will I use to create my BOM?

- Closing Words

1. What Is a Bill of Materials (BOM)?

In this section, we'll be talking extensively about BOM.

So, hang in there.

1.1 Definition

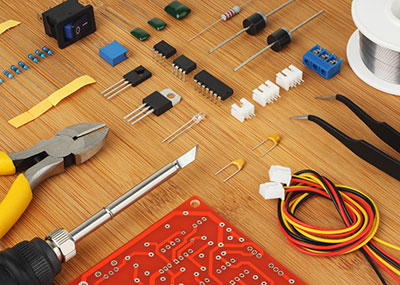

Source: Pinterest

A BOM refers to a list of items that you need to manufacture a product. And the BOM shows the quantity of every material required.

The Bill of Materials may consist of the following:

- Subassemblies

- Parts

- Raw materials

- Consumables

- Intermediate material

Also

You must note this:

The list doesn't have a breakdown of the specific time you'd be needing the materials. Or information about the location you intend to use them.

Instead, the list has its organization in a pecking order. And it maps out some of the production steps.

Sometimes, the bill of materials may include materials that are not related to production. For example, you can find enclosed documentation or shipping materials.

Why?

The reason is simple! A Bill of Materials is a subset of the BOR (Bill of Resources). And the MB (Manufacturing Bill) is a subset of the BOM—which is related to production.

So, what are the components that form a BOM?

You'll get answers to this question in the next section.

1.2 Components Included in a Bill of Materials

Before you make an effective Bill of Materials, it's crucial to have the following components:

Description

The description is a component that helps you do two things.

- Distinguish between similar materials.

- Identify parts.

So, having a comprehensive description of each material or item within a BOM is essential.

Bill of Materials Level

The Bill of Materials level is the ranking of each assembly or part within the broader BOM.

This component makes it easy for anyone to understand the elements within a BOM.

Part Name

Every material, assembly, or part should have a unique name or detail.

That way, it's easy for anyone to identify items on the BOM without cross-referencing with other sources.

Part Number

Asides the part name, every item within the BOM should have a unique part number. The part number helps people in the manufacturing cycle. With the part number, they can identify and reference parts easily.

Procurement Type

This component refers to the method a manufacturer uses to obtain each part.

So, it's crucial to identify each piece as something purchased off-the-shelf. Or better still, something produced based on the project specifications.

Quantity

Quantity is an essential component that serves as an accurate purchasing tool. It helps to specify the number of parts used in each assembly within the BOM.

Unit of Measure

It's necessary to outline the unit of measure for each material or part within the BOM. You can use terms like:

- Ounces

- Inches

- Each

- Feet

- Other similar identifiers of quantity

Thus, it ensures that you purchase and deliver precise quantities to assembly lines.

Phase

This component is the lifecycle stage of each part within the BOM. The phase is quite useful, especially during new product introductions. And it's because it allows you to track your progress easily.

For instance, you can use a term like "Unreleased" for parts that are awaiting approval. Or use other words like "In Production" for items that aren't complete.

Reference Designators

Reference designators are useful when you have a product that includes pcb board assembly manufacturers (printed circuit boards assemblies). It helps to explain in detail how the part fits on the circuit boards.

BOM Notes

BOM notes refer to additional important information. Typically, the data is different from other elements on the Bill of Materials.

Special Offer: Get $100 off your order!

Email [email protected] to get started!

2. Types & Structure of Bill of Materials (BOM)

Different types and structures of the Bill of Materials exist. But, we're focusing on the main types of Bill of Materials that are available.

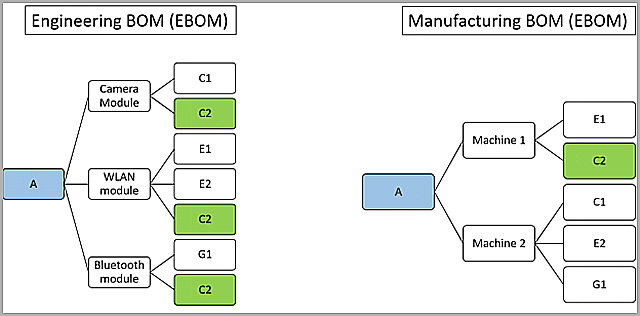

2.1 Types of BOM

Source: FusePLM.com

The three main types of BOM include:

Manufacturing Bill of Materials (MBOM)

MBOM is a well-arranged list of essential materials. And you can use it to produce shippable finished products.

It also presents two crucial information:

- Data of individual parts

- The parts that need to get refined before assembly.

Also…

It explains the relationship between different components in a single product.

The Manufacturing Bill of Materials (MBOM) data connects with the fused systems.

But that's not all.

MBOM enables building and ordering a product.

Plus…

It includes three different categories:

- MRP (material requirements planning)

- ERP (enterprise resource planning)

- MES (manufacturing execution systems)

Engineering Bill of Materials (EBOM)

The EBOM focuses on specific assemblies or parts designed by engineers.

The Engineering bill of materials shows the functional perspective of a component structure. And the component structure has a mechanical or technical drawing.

It's crucial to note that an EBOM isn't related to modular BOM concepts or configurable BOM.

Why?

Modular and configurable BOMs display the selection of materials to produce marketable end-products.

In other words, the structure of an EBOM comes from a design standpoint.

And most engineers develop the EBOM using the assistance of tools like:

- The CAD (computer-aided design)

- The EDA (electronic design automation)

It's normal to see a product that has multiple EBOM. Why? Each design undergoes a lot of revisions.

An engineering bill of materials shows the direction and essential components for building a specific product.

Also, EBOM includes things like:

- Interwoven data layers

- Items

- Parts

- Raw materials

- Sub-assemblies

It also lists materials based on the perspective of an engineer.

But, it rules out some items:

- Components necessary for a transferrable product

- Packaging

- Shipping containers

Plus, it doesn't identify the assembling of parts at different stages of production.

Since the MBOM depends on the EBOM, its accuracy is essential.

What's the implication of an inaccurate EBOM?

Any of the listed items could be an inaccurate Engineering bill of materials:

- Inaccurate accounting

- Unnecessary revision cycles

- Wrong production costs

- Manufacturing issues and details

- Incorrect inventory levels

The benefits of having an accurate EBOM includes:

- Preventing undue changes

- It's possible to make improved part-purchasing decisions.

- It offers production data to design new tools and tests.

Sales Bill of Materials (SBOM)

SBOM offers data about an item before it gets to the assembly or sales stage.

And two things in the SBOM look like separate entities:

- The components which are necessary to develop a product.

- The completed products.

So, the SBOM manages the completed product as a "sales item" instead of an inventory item.

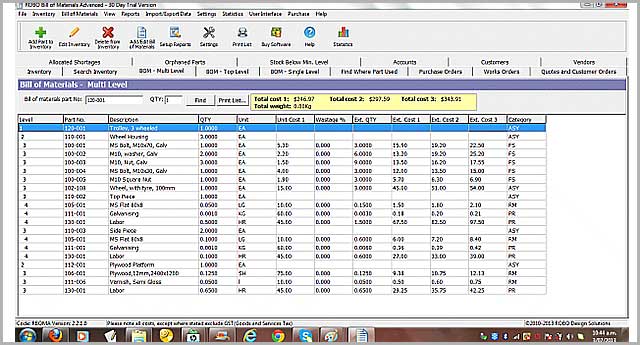

2.2 Structure of Bill of Materials

The most common ways of representing a Bill of Materials include the following:

Single-Level Bill of Materials

The single-level bill of materials is a relatively simple list. In this structure, each subassembly or assembly shows once. It usually appears with the corresponding quantity needed to make the product.

No doubt, this type of BOM structure is easy to develop. But, it's not the best structure for complex products.

The reason is simple.

Single-level BOM doesn't specify the correlation between assemblies and sub-assemblies.

For instance, if a product fails, challenges surfaces.

One of such challenges is finding which part needs repairs or replacement with the single-level Bill of Materials.

Multilevel Bill of Materials

This type of structure takes more time and work to create.

It displays specificity. Also, it shows loads of details on the major and minor parts of the product.

This structure also shows you the total material needed.

But that's not all.

The product structure has a groove that shows you one important thing.

And it's the relationship between the parent and child product. You'll also find the connection between assemblies and sub-assemblies.

3. How to Make a Bill of Materials?

Let's face it.

Creating a detailed Bill of Materials for a project could be time-consuming and tasking. Making a Bill of Materials depends on the information, the size of the program build, and complexity. But in the end, it makes the whole production process more efficient.

Six Steps to Take When Making a Successful BOM

Here are six steps to take when making a successful bill of materials.

- Answer Important questions before making a BOM for your next product. We'll be talking extensively about the questions to ask in the "factors to consider" section. So, look out for it.

- Generate the document from the selected program you plan to use. Then, name the file and place the specific project's name. The project name should be at the top of the newly created document. Don't forget to put any other essential identifying information in the title. Here's how it should look, "Business Name – Project Name – Assembly – Date."

- Organize the newly created document. The process includes: establishing user permissions, setting up change tracking, and making any required levels. This step is necessary all through the BOM process. Handle it as an ongoing activity and be consistent with it.

- Fill the columns appropriately. It involves populating the category names at the top of each column. The titles should include things like quantity, part number, part name, etc.

- The next step is to fill the rows effectively. You can do it by also populating them with information related to the column category. Every assembly, sub-assembly, process, part, etc. should have its row. Thus, you have to ensure that the information is accurate.

- Update your BOM information regularly. That way, you'll make new changes to the file. And it makes your BOM as flexible as possible during the whole production process.

Now, you've seen the necessary steps required to build a BOM. It's time for us to dig deeper and be more specific. There are various methods to create a BOM. But for this post, we'd be looking at the different steps it takes to make a BOM in SAP.

What Are the Steps to Take to Create a BOM in SAP?

Without further ado, we'll be going straight to the practical steps to take when you're making a BOM in SAP.

But before we jump into the steps of creating a BOM in SAP, you should know this.

SAP allows you to create many bills of materials categories like:

Material BOM (T-code CS01) – You can use this category to create a material bill of materials.

Document BOM (T-code-CS11) – You can create a complex document by combining multiple forms such as technical drawings, papers, programs, etc. You can connect the document object and related information as one unit with the help of a BOM.

Equipment BOM (T-code-IB01) – Engineers or designers use Equipment BOM to allow various components to equipment. It also describes the equipment structure for maintenance purposes.

Functional Location BOM (T-code-IB11) – You can create a T-code-IB11 (appropriate location BOM) separately for every technical object group.

Sales Order BOM (T-code-CS61) – The sales order bill of materials is excellent for make-to-order product production— based on a customer's production requirements.

Here are the steps to creating a BOM in SAP:

First, here's a YouTube video showing you how to create a BOM.

Source: https://www.youtube.com/watch?v=im3WMGsX3e0

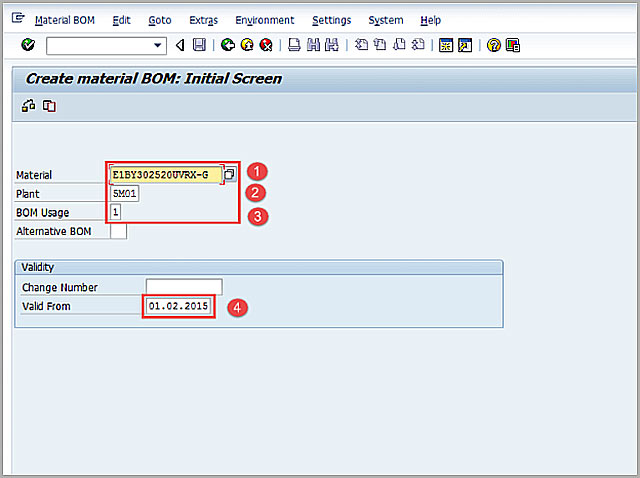

Step 1 – Make a Material BOM (CS01) From the SAP Easy Access Dashboard

- The first thing is to enter the parent material for the BOM you plan to create.

- Next, type in the Plant Code.

- Enter the Bill of Materials usage, which equals "1" intended for Creating Production Bill of Materials.

- Finally, type in a specific valid date at the "Valid From" tab—which makes the BOM useful from the selected date.

Source: Guru99.com

When you finish filling all the fields, Click Enter to move to the next screen.

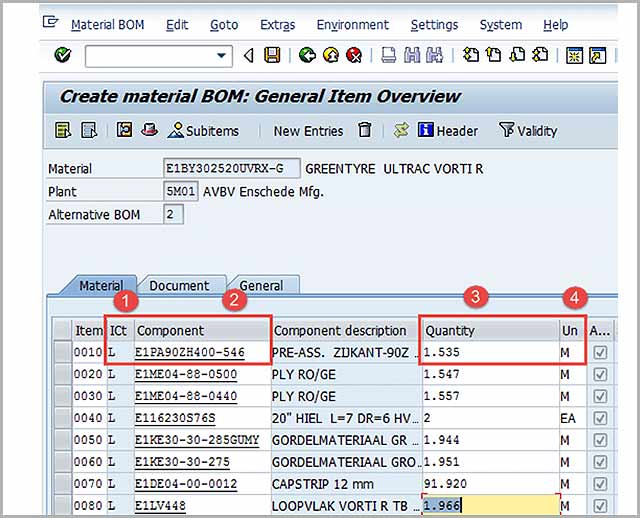

Step 2 – On the Next Screen

- Type "L" in the "ICT" or Item Category column—which comes as the default item and also used for stock items.

- In the Component Field, enter the Component Material Code.

- Then, type in the Component Quantity entry.

- After Clicking Enter, the system automatically brings out some information like the basic unit of measure of the component and description.

Source: Guru99.com

Key Notes:

Double Click the "FINISH" button in the Assembly Column. That way, you'd be digging further through the BOM for any of the components. The component will have no further BOM if you don't tick the box.

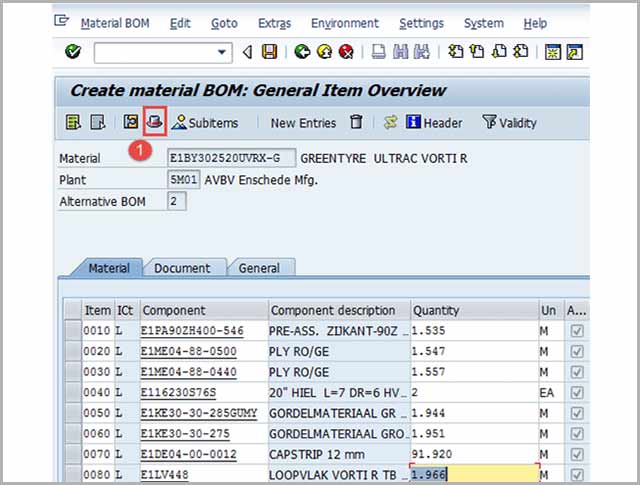

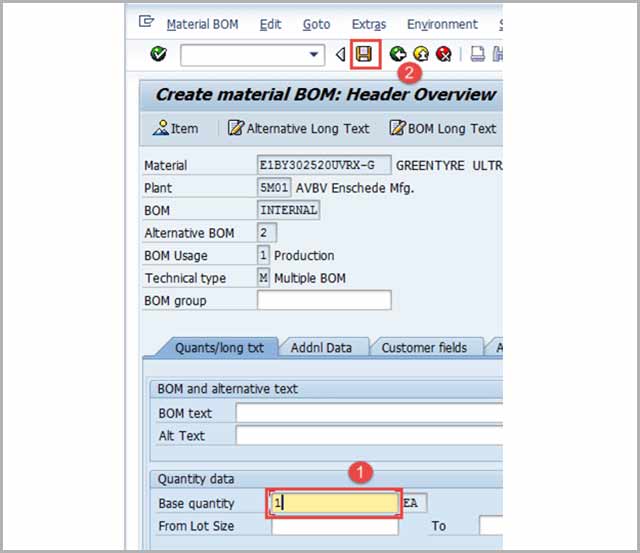

Step 3 – Move to the Next Screen

In the next screen, click this EDIT icon to locate the BOM header. Then, the system will display the BOM header screen on the next screen.

Source: Guru99

Step 4 – At the BOM Header View

At the BOM header view, you can fill the base quantity of parent material. For instance, if the base quantity is 1 EA, it means component quantity will describe the required amount to make the "1" item.

To save the new BOM, click the SAVE button. And the software will display the following message at the lower left of the software; "Creating BOM for Material."

How to Change a Bill of Materials

The option of changing a Bill of Materials comes up if there's a change in any component quantity or lists of components—used to produce the final product.

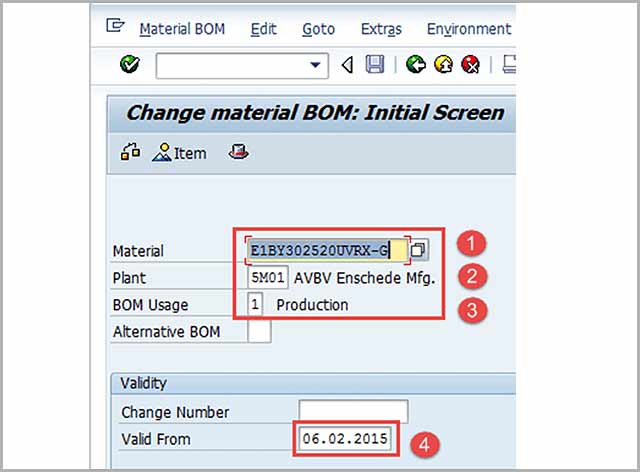

Here are the following steps to take if you want to change the Bill of Materials.

Step 1 – Open Transaction CS02 From the SAP Easy Access Dashboard

- Type in the Parent material for the BOM you need to change.

- Type in the Plant Code.

- Then, input "1" in the BOM usage tab. That way, you can use it to change the production BOM.

- After that, fill the specific values at the "Valid From" tab.

Source: Guru99

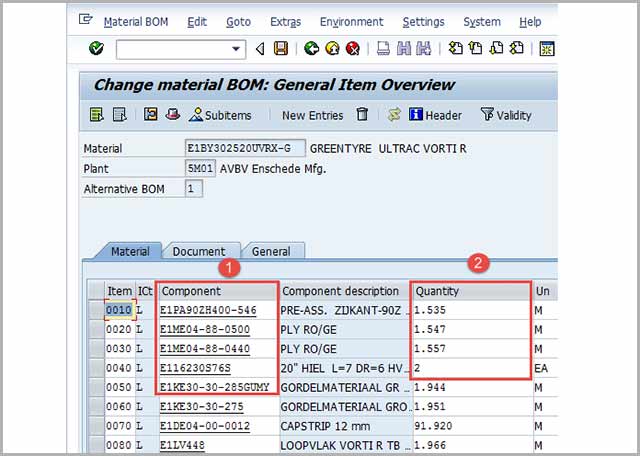

Step 2 – The Next Thing to Do After Filling the Various Fields, Click the Icon to Move to the Next Page

- Modify the component quantity or code

- The next thing is to click the SAVE icon to save the BOM after you've made your modifications. Then, you'll get the following message "BOM for Material" at the lower left of the system.

Source: Guru99

But that's not all.

You also need to know how to display a BOM in the SAP software.

How to Display BOM

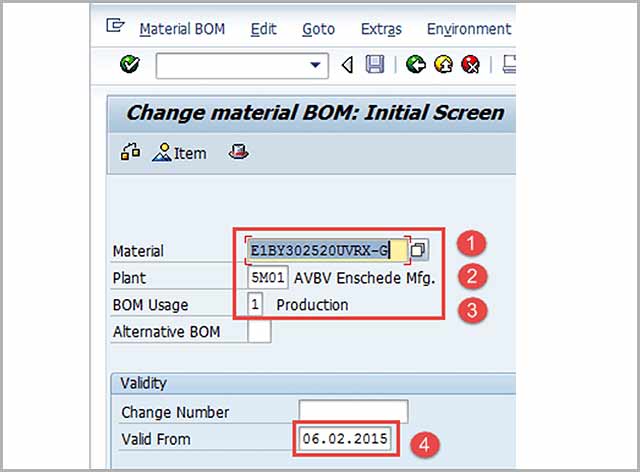

Here are the three significant steps to take if you want to display a BOM.

Step 1 – Open Transaction CS03 on the SAP Easy Access Dashboard

- Type in the parent material for the BOM you choose to display

- Type in the Plant Code

- Next, type the value "1" for BOM usage—used for changing manufacturing BOM.

- Then, print in the right "from date" value—which refers to the specific date the BOM gets valid.

Source: Guru99

Finally, click the FINISH button to move to the next page.

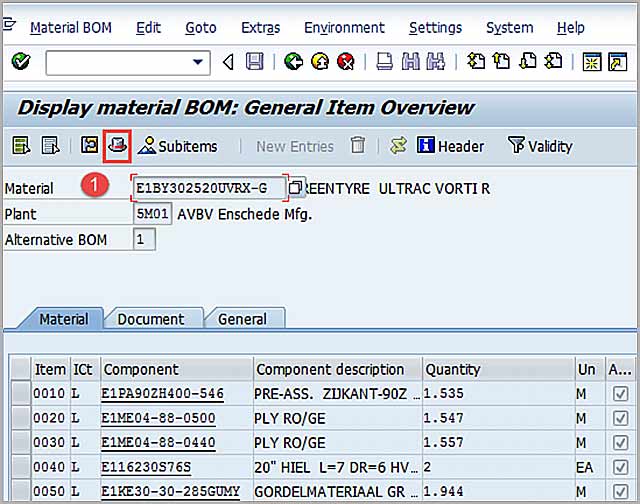

Step 2 – The Next Page Shows the List of Components and the Quantity Values

- Click the EDIT icon to display the BOM header.

Source: Guru99

You'll find the BOM header in the next step.

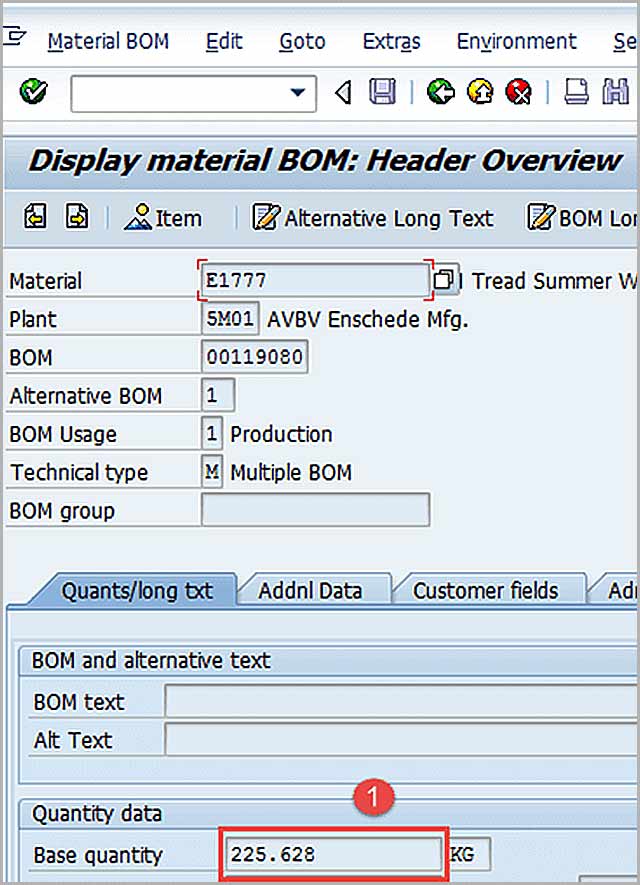

Step 3 – The BOM header Gets Displayed in This Step

The product's base quantity gets displayed.

Source: Guru99

Troubleshooting the Software (Important Things to Note)

In a scenario where component material doesn't exist, you'd need to create the material master for the component material before generating the BOM.

If you try to generate the BOM for the same product again, the system will give you a warning message—telling you that you are about to create an Alternative BOM2.

So, what's the best thing to do? Stop your action immediately, and don't ignore the system's warning message. If you don't, you'll create duplicate data.

In this situation, it's always best to know how to change the BOM.

4. What Are the Things to Consider Before Creating a BOM

We already spoke a bit about this earlier. There are questions to ask before producing the BOM for a new product.

Fortunately, answering the questions listed here can help you find out the key things to consider when creating a BOM.

The questions to ask include:

4.1 What Product do you plan to manufacture?

The first thing to consider before you start generating a bill of materials is to have an initial design. The project's design phase would have kicked off most of the time before the BOM comes in place.

So, why is it important to know the product you plan to manufacture before creating a BOM?

Simple—you'd gather enough data for the parts you require to manufacture your product.

4.2 How do you Manage your BOM?

A large number of bills of materials pass through various iterations during product manufacturing and processing. Hence, a lot of people tend to handle it.

So, before you start a Bill of Materials, ensure to find a system that can manage your BOM. And make it accessible by other people. By accessing, we mean activities like:

Making use of a live document that gives access to members of your team

Creating Identifiers for various versions

Tracking changes

4.3 How will you attach files to your BOM record?

It's essential to keep records of supporting docs like part datasheets, work instructions, and CAD drawings, before creating a BOM.

It's wise to also associate and identify the above files with specific BOM level items.

That way, attaching files to your Bill of Materials record will be more comfortable.

4.4 Who is going to use the BOM record?

Of course, you need to input as many details as you can to your BOM.

Why?

You never can tell the person or people who may use your BOM—especially if you won't see them.

Hence, it's best to include every necessary information your audience may need throughout the product's lifecycle.

4.5 Should I document Consumables on my BOM record?

A lot of manufacturers today may choose to add or include non-modeled parts on the BOM. For example, fasteners, wires, glue, etc.

The snag here is:

If any part doesn't make it to the Bill of Materials, it may not make it into the product. That's why it's crucial to document these consumable parts.

4.6 What software will I use to create my BOM?

Selecting the right software to generate and manage your bill of materials helps maintain an accurate Bill of Materials from scratch.

A lot of companies make use of Microsoft Excel at the beginning. But as they evolve and their products get more extensive, they switch to a more advanced program.

SAP is an advanced-level software most suitable for businesses.

Closing Words

A Bill of materials is, no doubt, a great tool in the hand of any engineer or designer. Hence, we talked extensively about the BOM, the different types, structure, Steps on how to create it, etc.

Are you a newbie engineer eager to understand the Bill of Materials? Then, you need to go through this blog post carefully.

Why?

The post is pretty comprehensive—explaining a lot about the BOM. So, the ball is in your court. Take action.

PS:

Do you like this article about the Bill of Materials? Are you finding it difficult to understand some parts of the Bill of Materials? If you're, please don't hesitate to drop a comment, and we'll get back to you.

Special Offer: Get $100 off your order!

Email [email protected] to get started!