A PCB circuit board is at the heart of most electronic devices because it provides a platform for connecting and supporting electronic components. The underlying material is non-conductive (usually fiberglass) and has thin copper lines etched between the non-conductive layers.However, since this PCB assembly goes through harsh environments while in use, it is possible to catch fire if it becomes too hot. Therefore, there's a need to grade the underlying material to determine which electronic circuit board is safe for your project. 94V-0 circuit boards are some of the safest; we will look at them in detail below.

Contents

- What is 94v0?

- What is the UL 94 Flammability Standard Test?

- Flame Resistant

- Flame Retardant

- High Temperature

- All About The 94v0 Circuit Board (Single-Sided & Double-Sided PCB)

- Single-Sided PCB

- Double-Sided PCB

- Why Do You Need 94V-0 Circuit Board?

- From The Manufacturer's Point of View

- From The Electronics Developer's Point of View (Student or Independent)

- From The Consumer's Point of View

- Properties of 94v0 Circuit Board

- Applications of 94v0 Circuit Board

- 94v0--Professions Prone To High Levels of Heat

- 94v0--Professions Requiring Uncompromised Quality and Durability

- 94v0--Professions Requiring Extra Reliable Electrical Devices

- Summary

What is 94v0?

94v0 is a standard in the flammability test, and it measures the extent to which plastic materials can withstand and resist burning. Underwriters Laboratories (UL) developed the safety standard, which explains the commonly used term, UL 94.

A printed circuit board

Since there are other global safety organizations, having different standards can be confusing. UL harmonized this standard with ISO 9772 & 9773 and IEC 60695-11-10 & 60695-11-20.

The standard determines the plastic material's tendency to spread or put out the flame after ignition.

Therefore, we can define the 94v0 circuit board as one with circuits and insulator materials that have met the UL 94 flammability test.

What is the UL 94 Flammability Standard Test?

The UL 94 flammability test checks for flame resistance, but how is it done? First, the specimen (plastic) should be 127 x 12.7 mm (5 x 0.5 in.) of the minimum approved material thickness. The sample then gets exposed to a flame, and UL classifies the results into six categories.

- HB: This rating indicates a slow burn on the horizontal specimen. For a material measuring less than 3 mm in thickness, the burning rate should not exceed 76 mm per minute or stop before 100 mm.

- V-2: V stands for vertical, which indicates burning stops within 30 seconds when testing the specimen vertically. Also, the category allows burning drips from the flaming particles.

- V-1: V-1 is similar to V-2, but the difference is in the drips of particles, which should not get inflamed.

- V-0: With V-0, burning on a vertical specimen stops within 10 seconds, and the drops of burning particles should not get inflamed.

In the last two classifications, UL tests both bar and plaque specimens. Also, the flame source is roughly five times as severe as the one used in the upper four classifications.

- 5VB: Burning should stop within 60 seconds on both specimens when tested vertically. The plaque sample may develop a hole, but both should not form burning particles.

- 5VA: Burning stops within 60 seconds on the vertical samples, and the plaque may not develop a hole. There should be no drips as well.

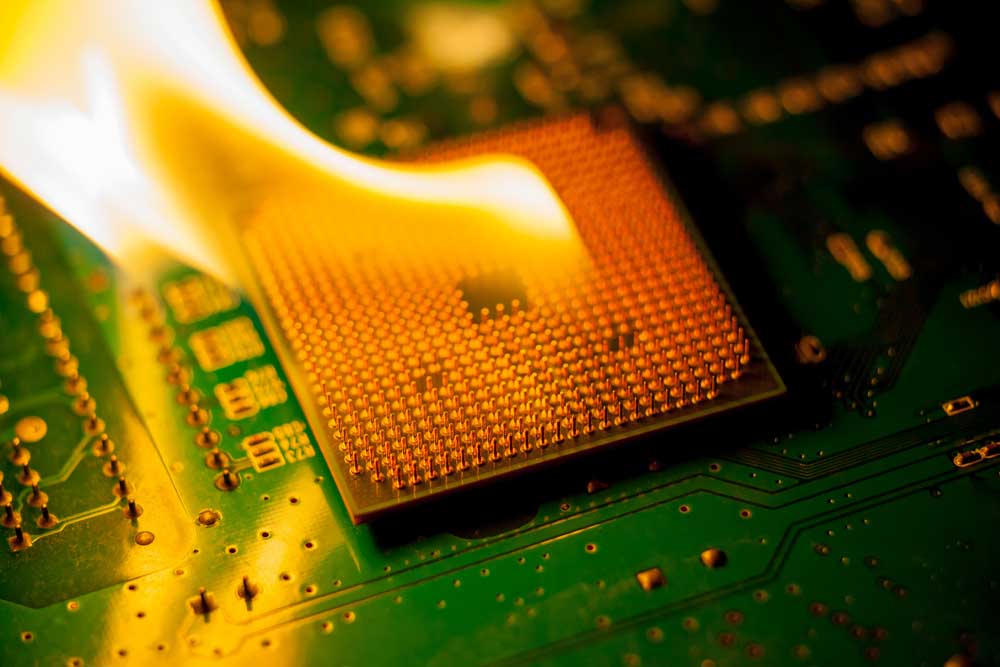

Fire Burning CPU on circuit board with electronic

We can place the plastic PCB materials into either of the following general categories from these classifications.

Flame Resistant

Flame-resistant materials prevent flames from spreading but can only do this for a short period. Continued exposure will incinerate them. HB, V-1, and V-2 specimens fit into this category.

Flame Retardant

Flame retardant materials can withstand direct flame exposure for extended periods compared to resistant materials and will retain their composition & shape during this time. V-0 specimens fall into this category.

The V-0 in 94V-0 comes from the fourth classification in the above list, and its specific standard testing criteria for vertical burning samples are as follows:

- After applying a controlled flame, the combined combustion time does not exceed 50 seconds for five specimens (10 seconds per sample).

- None of the specimens should burn the mounting clamp directly by flame or glowing combustion.

- No specimen exhibits glowing combustion 30 seconds after removing the second flame source.

- None of the samples drips.

High Temperature

High-temperature materials offer the best flame resistance performance and can maintain their shape & composition after exposure to heat for long periods.

5VA and 5VB-rated materials fall into this category and make the best product types for the harshest conditions. However, they are also very costly, which leaves the flame retardant V-0 classification at the sweet spot (between price and heat resistance).

Laptop with hot red surface and high temperature

Special Offer: Get $100 off your order!

Email [email protected] to get started!

All About The 94v0 Circuit Board (Single-Sided & Double-Sided PCB)

Apart from withstanding high heat levels, the 94V-0 circuit board usually features modulation and temperature control panels for better temperature regulation.

PCB assembly manufacturers use the best-rated PCB materials and conduct reliability tests to ensure the board meets the expectations. Other checks include shock, fixture, solder, and power tests.

A printed circuit board without components

94V-0 circuit boards have varying degrees of thickness and come in different sizes but are generally single-sided or double-sided.

Single-Sided PCB

As the name suggests, a single-sided PCB has only one conductive copper layer above the substrate. It allows you to mount and solder electrical components to a single side, and the entire circuit is visible from both sides of the board.

Advantages

- Easy to design and manufacture

- Affordable to produce, hence cheaper to customers

- Easy to repair and fix if something gets damaged

Disadvantages

- Low assembly density due to the single conducting layer

Uses

Simple, low-cost electronic units such as timers, calculators, FM radios, and LED lighting boards use single-sided PCBs.

Double-Sided PCB

Although it has a single base substrate layer, a double-sided PCB has two conductive copper layers on each side of the substrate.

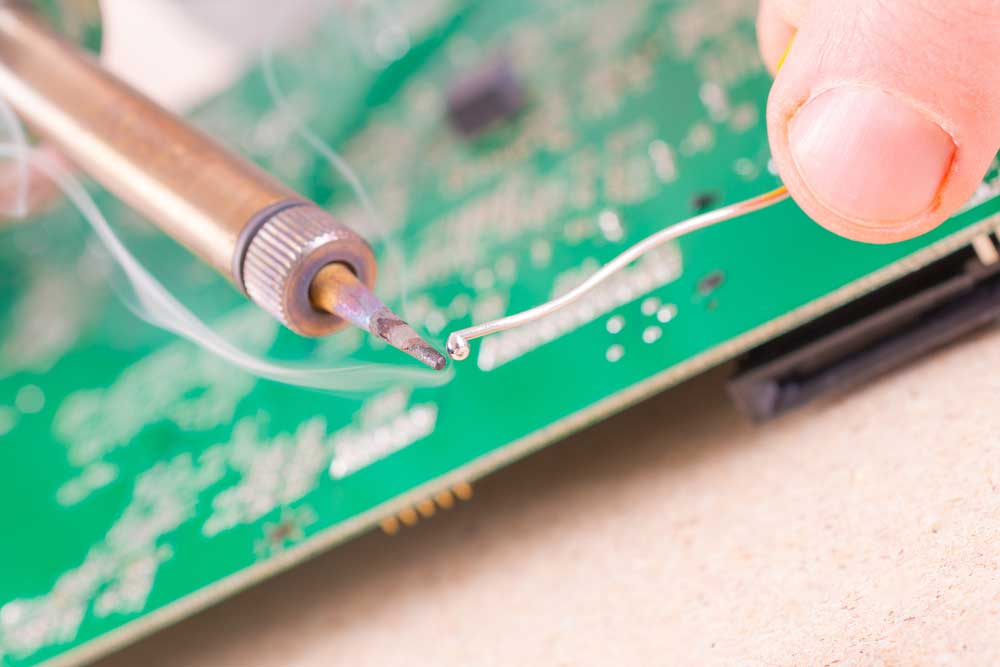

An electrician soldering a wire onto a double-sided PCB

Holes run through the board to enable conductivity between the two circuits, making it possible to mount circuits on either side. You can also solder electronic components on either side because of the dual-sided design.

Advantages

- Holds more components

- Ideal for advanced devices due to its dense circuit

- Smaller board size for the same circuit size as the single-sided type

- Flexible connection options

- Cost-effective due to the reduced board size

- Suitable for a wide range of industries

Disadvantages

- Complex and difficult to manufacture

- Difficult to repair if something gets damaged

Uses

Double-sided PCB-equipped devices include:

- HVAC systems

- Phones and printers

- Traffic control systems

- Vending machines

- UPS and converter systems

- LED lighting

- Industrial control and instrumentation devices

- Computer hard drives

- Amplifiers

- Line reactors and more

Why Do You Need 94V-0 Circuit Board?

There are three ways to look at this factor.

From The Manufacturer's Point of View

Manufacturers have a reputation to uphold; therefore, if you build substandard electrical equipment, negative reviews will affect your business and lead to lower sales.

Some devices don't need high-quality PCB boards because the cost is the most significant factor. However, it is better to fit in the 94V-0 printed circuit board if you manufacture devices for highly demanding applications.

Introducing such quality to your products will lead to higher ratings, better brand recognition, credibility, and higher profits. You can even raise the price of your products to rake in more revenue.

Alternatively, you can introduce a grading system that places electrical equipment with 94V-0 circuit boards a grade higher than standard PCBs. The customers can then decide which factor is more important, price or quality.

On your end as the manufacturer, you can charge a competitive price for the low-grade devices and a premium price for the high-grade device,

From The Electronics Developer's Point of View (Student or Independent)

A man using a soldering iron on a circuit board

Like manufacturers, independent electronics developers have a better chance of getting recommended for jobs or other projects if they create durable electrical equipment.

Incorporating this electronic circuit board into your project is one of the ways to ensure your product meets and exceeds expectations.

Electrical engineering students also need to build reliable electrical circuits in their school projects to get high grades. Such devices will easily pass the respective tests when subjected to extreme conditions.

From The Consumer's Point of View

Lastly, you have two options as a customer. Either buy an affordable electrical device and risk quality or get one with high-quality components. The latter might be expensive but will last longer.

In most cases, non-branded electronic equipment features low-grade PCB circuit boards that are not flame retardant.

However, branded quality products that display authenticity are more likely to have advanced circuit boards tested to withstand extreme heat. The second option is also safer and works as promised.

Remember, the manufacturer is also trying to build a reputation and strong brand image, so many electrical products are of high standards.

Properties of 94v0 Circuit Board

- Not readily flammable: The material used to make the circuit board 94v0 has a high rating in the UL 94V-0 flammability test, so it is flame retardant.

- Standardized design: 94v0 circuit boards have standardized connector pins, making mounting and soldering electronic components easy.

- Assembly density: PCB design improvements include a multi-layer circuit board structure that overlays conductive copper linings and insulating materials. The result is a large circuit on a compact board.

Applications of 94v0 Circuit Board

The 94v0 PCBA circuit board is ideal for building rugged devices or high-quality electronic equipment used in the following areas.

94v0--Professions Prone To High Levels of Heat

Mining, metal molding, and other professions with high exposure to heat (boilers, furnaces, etc.) need circuits that can withstand extreme temperatures without failure. Such 94V-0 circuit boards should also be resistant to water for maximum durability.

Consumer devices like CCTV cameras also use this PCB board to remain functional in a fire emergency. The idea is to have a reliable system that guides trapped people out of the building or directs the rescue team to the people inside.

94v0--Professions Requiring Uncompromised Quality and Durability

Circuit boards are critical in some electrical equipment, and failure can lead to fatal accidents. Hospital, spacecraft, and aeronautical devices are a few examples of this equipment, so they need 94V-0 boards to prevent chances of failure.

94v0--Professions Requiring Extra Reliable Electrical Devices

Some occupations like metallurgy are demanding and need reliable printed circuit boards that will not fail despite repeated exposure to heat.

Summary

To wrap up, the 94V-0 PCB circuit board is a durable and reliable component that allows electrical devices to withstand high heat levels in extreme working conditions. The UL94V-0 inflammability test ensures the part operates seamlessly for maximum reliability.

As the top PCB manufacturer, we offer a one-stop PCB assembly service and can make any custom pcb board 94v-0 circuit you need for your project. Contact OurPCB for more details and get the best deals on PCB design & assembly.

Special Offer: Get $100 off your order!

Email [email protected] to get started!