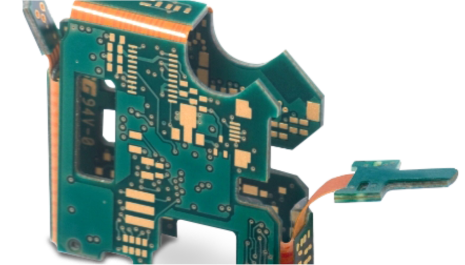

Semiflex PCBs for One-Time Applications

✅ Up to 12 layers

✅ Cost-effective FR-4 material

✅ Rapid prototyping for validation

✅ Maximum bending angle of 180°

Semiflex PCBs for Flex-to-Install Projects

At OurPCB, we’re highly experienced in the design and manufacture of high-quality semiflex printed circuit boards (PCBs) — a cost-efficient solution for applications that require limited but reliable flexibility.

Our semiflex PCBs are engineered to provide particularly excellent performance in “flex-to-install” cases, where the board is bent once during installation to fit the final product assembly. As such, semiflex PCBs are a durable blend of rigid PCBs, temporary flexibility, and cost-savings — suitable for saving space without compromising on reliability.

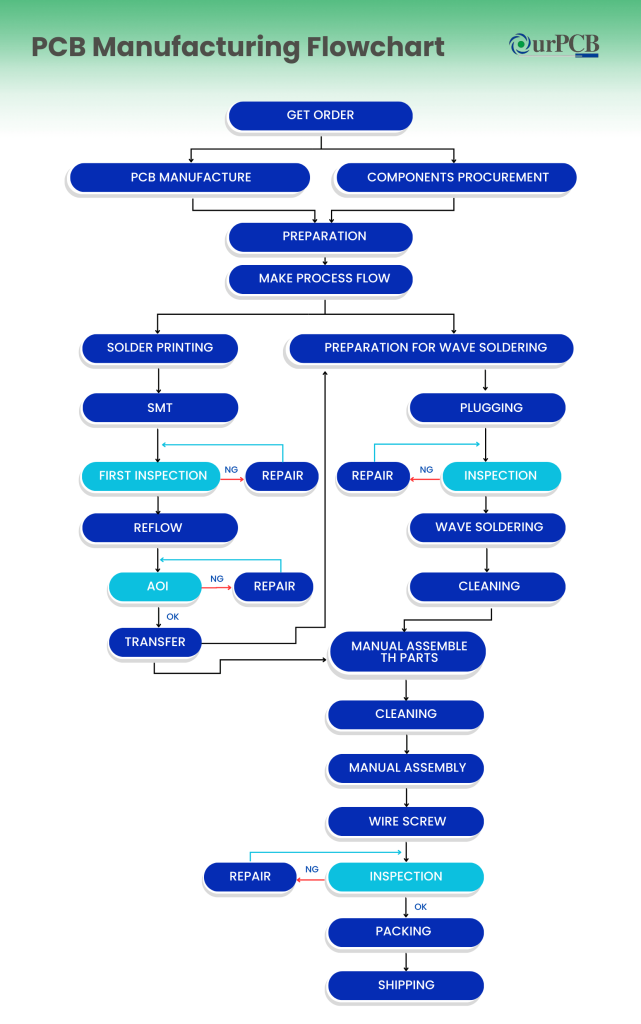

PCB Manufacturing Process

Why choose OurPCB?

We bring creativity, deep knowledge, and passion to every aspect of PCB design, manufacturing, and development, making us a reliable and forward-thinking partner.

- We have two factories in China with advanced technology for seamless manufacturing.

- We’ve partnered up with the best suppliers in the world to provide you with quality parts and materials.

- No order is too small for us. We can help you even if you only need a few PCBs for a minor electronics project.

Semiflex PCB manufacturing is only one of our offerings. Why go elsewhere when you can get all your PCB needs met under one roof?

Your Trusted PCB Partner

- 15+ Years in the Industry

Our team understands PCBs inside and out, thanks to 15+ years of experience in the field.

- Trusted by 3,000+ Customers

Thousands of people can’t be wrong! You could be our next happy PCB customer.

- With up to 12 multilayer configurations and 1 to 2 conductive layers in the bending area, accommodating various needs

- Controlled-depth routing to create flexible sections within a rigid PCB

- Minimum bend radius of 3 mm and a maximum bending angle of 180°

HASL (SnPb), Lead-Free HASL (SnNiCu), OSP, ENIG, Immersion Tin, Immersion Silver, Electrolytic Gold, Gold Fingers, and more

Our Semiflex PCB Manufacturing Capabilities

Our expert team crafts semiflex PCB designs tailored to your unique requirements.

We offer rapid and precise prototyping services for real-world testing before full-scale production.

Our factories provide sophisticated fabrication processes for high-quality, reliable semiflex PCBs.

With accurate, efficient, and fast assembly, we can assemble anything from simple to complex PCBs.

Our scalable manufacturing capabilities guarantee consistent quality and on-time delivery.

We thoroughly test every PCB to ensure it meets the highest standards of performance and durability.

Millions of business and innovators use OurPCB

PCB Board Process

Design (1 day)

- Upload Schematic to Get a Quote

- PCB Review and Quotation

- Customer Makes Payment

- Evaluation & Confirmation of Plan

- Design Start

Layout (1 day)

- Layer Stack-up Design

- Design Rule Setting

- Component Placement Design

- Confirmation & Optimization

- Fanout

Routing (1 day)

- Fanout Optimization

- PCB Routing

- Equal-length Adjustment

- Routing Optimization

- DRC Check

- Routing Confirmation

Optimization (1 day)

- Silkscreen Adjustment

- Data Output

- Customer Final Confirmation

- Production Debugging

- Archiving Projects

- Finish

Technical capabilities

Our creativity, extensive expertise, and passion make us a dependable partner in advanced PCB design, manufacturing, and development.

Capabilities & Services

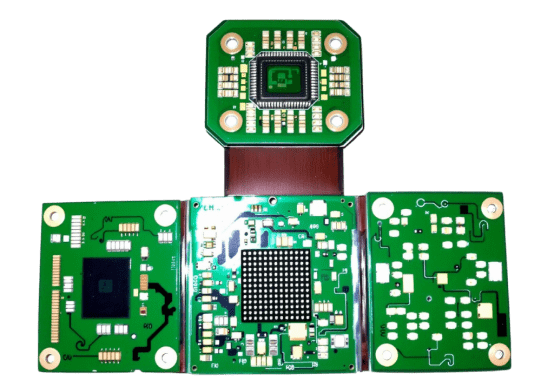

- One-stop PCBA Services (PCB Manufacturing + Components Sourcing + Assembly)

- SMT Assembly + THT Assembly, Single/double-sided Assembly Mixed PCB Assembly

- BGA Rework

- 60,000 Chips/Hour

- Down to 01005/0210 Size

- Accuracy<±40μm

- Min. QFN Pin Width/Space: 0.15mm/0.25mm

- Min. BGA Diameter/Space: 0.2mm/0.35mm

- Rigid, Flex, HDI, & High-speed Power Boards

- Up to 50 Layers

- 60GHz High Frequencies

- Min. Trace Width/Spacing: 2.5mil/2.5mil

- AOI, X-ray, ICT & FCT Testing

- Controlled Impedance

- ISO 9001, ISO 13485, ISO 14001, IATF 16949, IPC-A-610, UL Certified

- Automotive, Medical, & Military-grade PCBA Manufacturing

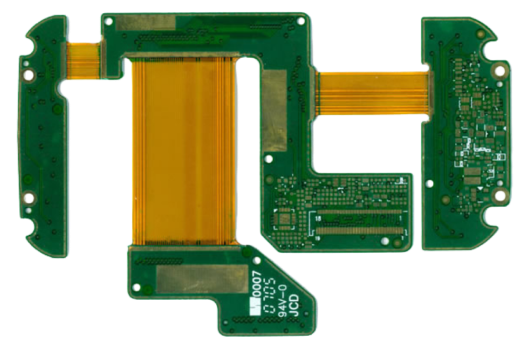

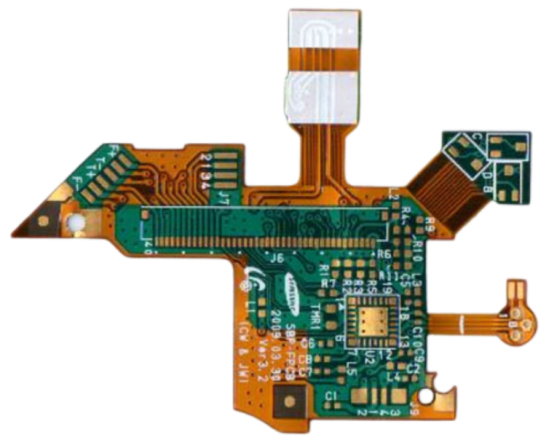

Semiflex PCBs vs. Rigid-Flex PCBs vs. Flex PCBs

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

What’s the difference between semi-flex and rigid-flex PCB?

A semi-flex printed circuit board is a rigid board with flexibility in certain areas, designed for a one-time bend during installation. In contrast, rigid-flex PCBs combine rigid and flexible layers, which enable continuous bending in movable or bendable devices.

Can semi-flex PCBs be bent multiple times?

No, semi-flex PCBs are designed to be bent once, during installation, and are not suitable for repeated flexing. Instead of a semi-flex PCB, consider investing in a flex PCB if you’re looking for ongoing flexibility.

What is your production capacity?

We have the capacity for both small and large quantity orders, thanks to our two fully equipped factories and experienced engineers.