Top 10 Classic Car Wiring Harness Manufacturers | Full Guide

Finding the right wiring harness manufacturer for your vintage ride can be a real headache. Those beautiful old machines need special wiring that looks period-correct

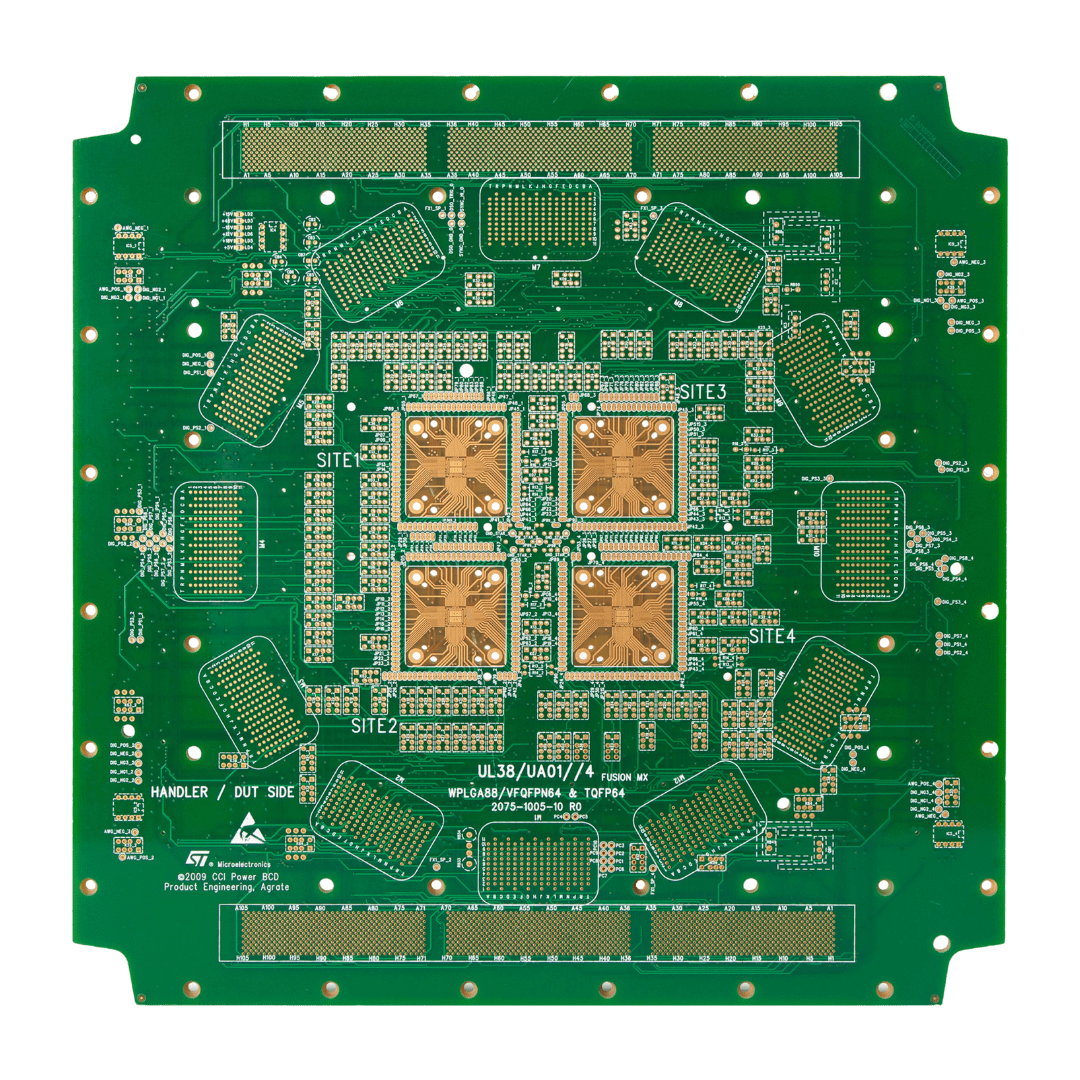

PCB sub-assembly manufacturing creates smaller sections of a printed circuit board (PCB) before final assembly. This process is crucial for ensuring high-quality electronic products. At OurPCB, we take pride in providing reliable PCB sub-assembly services.

PCB sub-assembly manufacturing is a vital step in the production of electronic devices. It involves assembling various components onto a PCB before integrating it into a larger system. This process allows for efficient testing and quality assurance at an early stage.

OurPCB uses advanced techniques and equipment to ensure precision in every assembly. We focus on using high-quality materials and components. Our commitment leads to durable and reliable sub-assemblies that meet industry standards.

Partnering with OurPCB offers numerous advantages for your PCB sub-assembly needs. Our expertise ensures that you receive high-quality products tailored to your specifications. We prioritize customer satisfaction and timely delivery.

Choose PCB sub-assembly manufacturing to streamline your production process. It allows for better quality control and reduces the risk of errors during final assembly. This method also improves overall efficiency.

OurPCB offers comprehensive PCB assembly services to meet diverse needs. We provide solutions from design to final product assembly, ensuring high standards throughout the process.

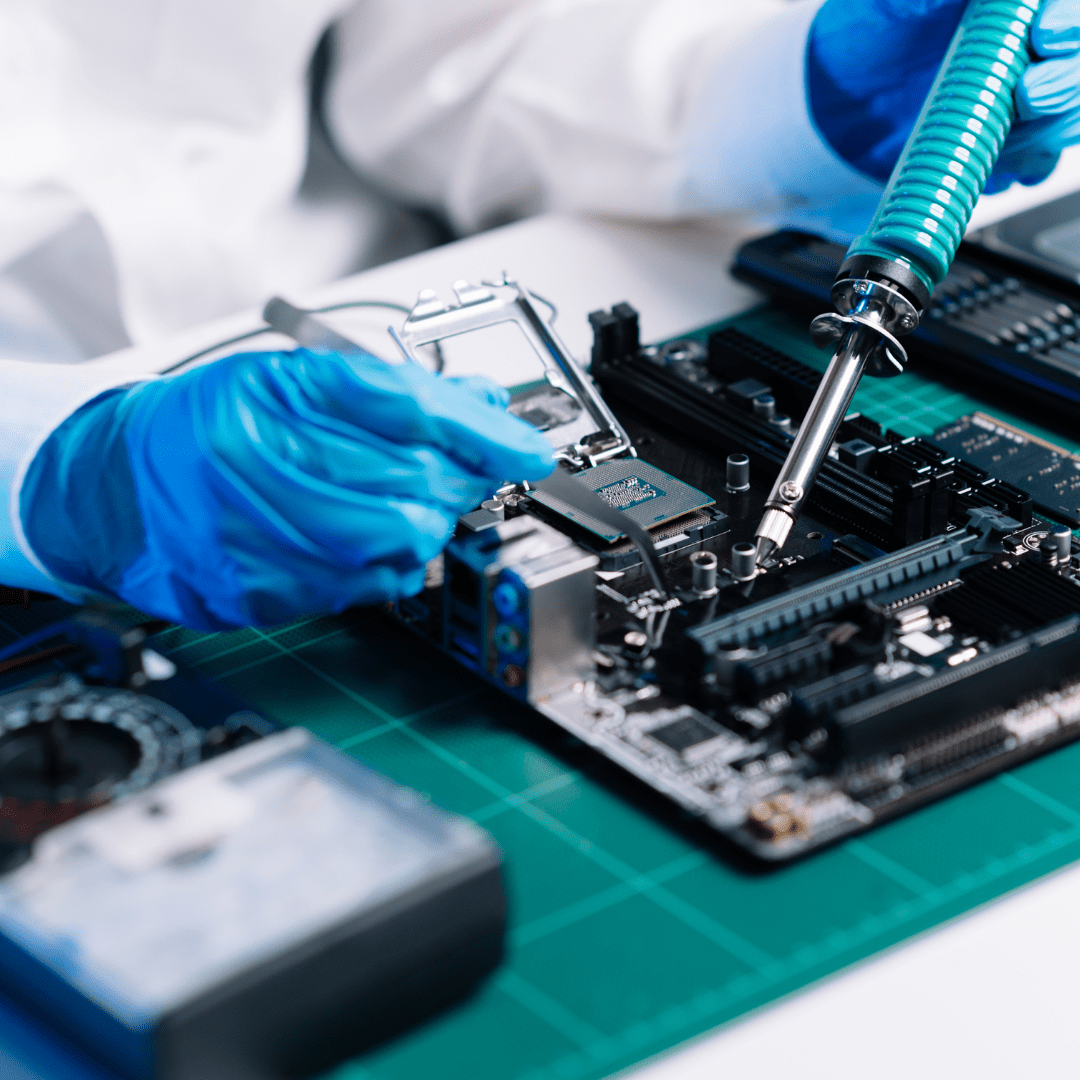

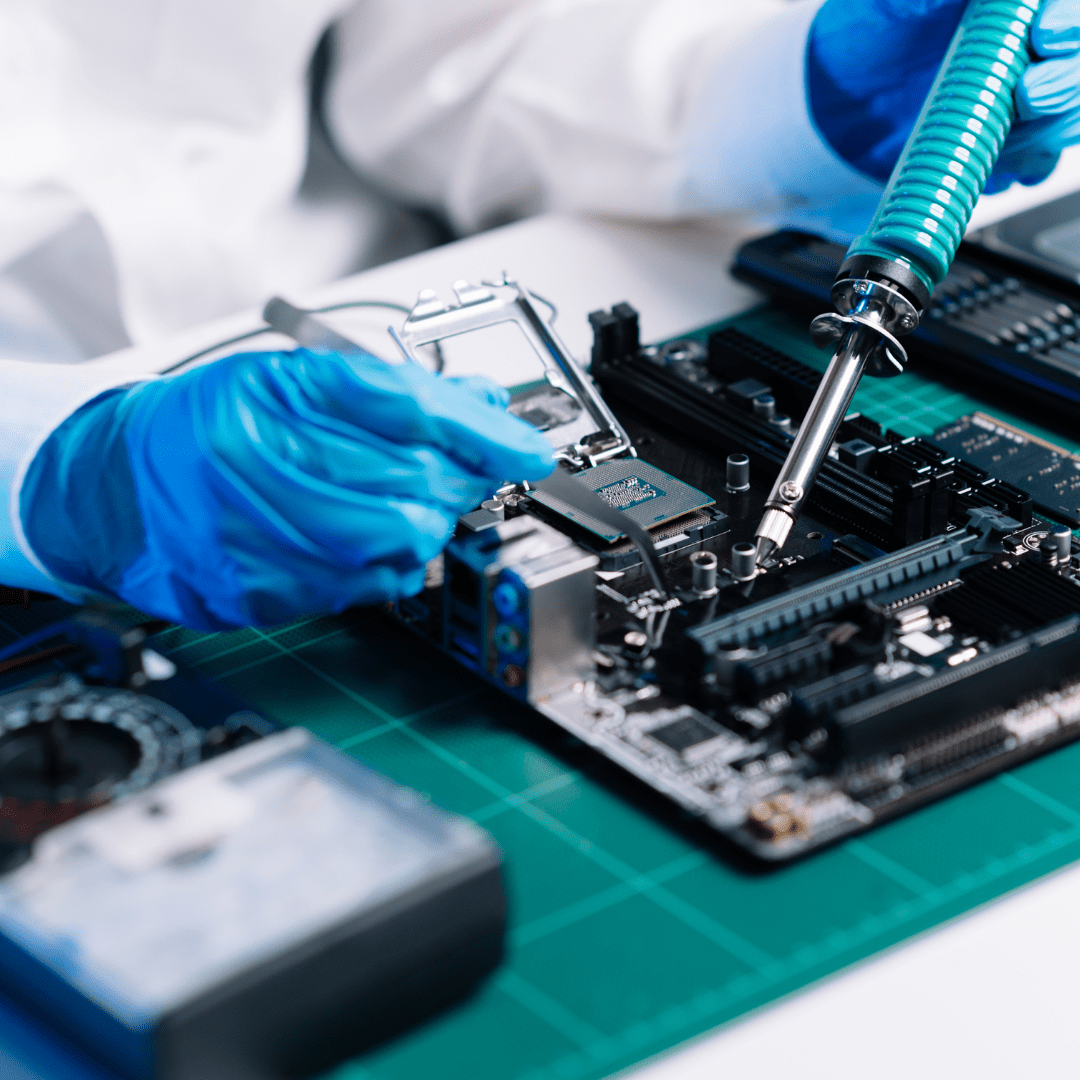

We specialize in precise PCB assembly using Surface Mount Technology, ideal for compact and high-performance products.

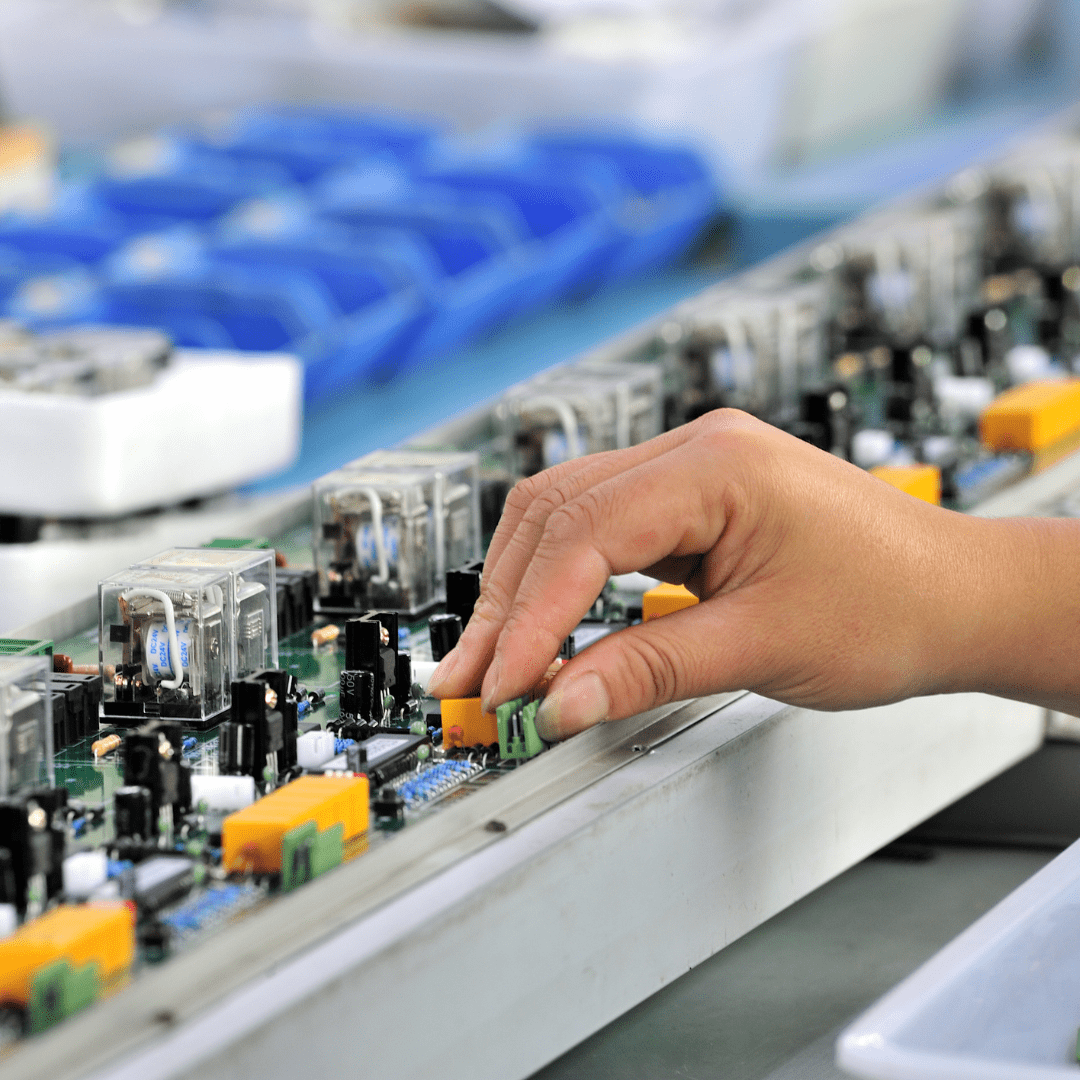

We manage both customer-supplied components and complete turnkey solutions, taking care of sourcing, assembly, and delivery.

We provide bespoke PCB assembly services tailored to meet your specific design and project needs.

We offer rapid and dependable PCB assembly services with quick turnaround times, ensuring superior quality.

We produce high-reliability PCB assemblies that meet strict IPC Class 3 standards, perfect for critical applications like aerospace and medical.

We expertly handle the assembly of all IC package types, including BGAs, POPs, CGAs, QFNs, DFNs, and CSPs, ensuring precision and dependability.

OurPCB delivers advanced technical capabilities in PCB manufacturing and assembly. We use state-of-the-art machinery to ensure precision and efficiency in every project. Our commitment to quality assurance guarantees that we meet industry standards consistently. At OurPCB, we take pride in being a leading provider of PCB sub-assembly manufacturing services.

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

PCB sub-assembly costs range from $0.50 to $200+ per board, depending on complexity, volume, and design requirements like impedance control or flex PCB. SMT and solder requirements significantly influence PCB production costs. Moreover, impedance control and multilayer boards generally raise sub-assembly rates. Flex PCB or double-sided designs cost more in circuit board assembly.</

PCB sub-assembly involves partial integration of components into the PCB board, whereas complete PCB assembly includes full integration and testing of all components. Circuit board design dictates whether sub-assembly requires advanced SMT processes. Notably, sub-assembly may involve specific tasks like solder application or impedance control.

Circuit board manufacturers focus on PCB fabrication and raw board manufacturing, while assembly providers handle SMT, soldering, and full circuit board assembly processes. One-stop providers combine manufacturing capabilities and assembly for consumer electronics. Additionally, manufacturers source materials, while providers integrate components into circuit board designs.

Finding the right wiring harness manufacturer for your vintage ride can be a real headache. Those beautiful old machines need special wiring that looks period-correct

Would your car be able to run without wire harnesses? Not a chance. Wire harnesses connect all the electrical parts together. No harness means no

Making wire harnesses isn’t complicated. At OurPCB, we create custom wire harnesses for an expansive range of industries every day. While it’s a complicated process,

Prototype cable assemblies are the very important place in between PCB design ideas and interconnects. OurPCB brings prototype assemblies with PCB solutions to your tables.

PCB thermal management prevents component overheating through strategic heat transfer techniques. Without proper thermal control, electronics are at risk of electronic failures through weakened solder

ContentsKey TakeawaysWhat is a Multilayer-Printed Circuit Board?How do Multilayer PCB Boards Work?Multilayer PCB ApplicationsMultilayer PCB Manufacturing Process: StepsMultilayer PCB Manufacturing MachinesBenefits of Multilayer Circuit BoardsWhat

We use cookies to improve your browsing experience, which may include personal information. By clicking "Agree," you accept our Privacy Policy and cookie use. You can change your cookie settings in your browser anytime.

Agree