Top 10 Classic Car Wiring Harness Manufacturers | Full Guide

Finding the right wiring harness manufacturer for your vintage ride can be a real headache. Those beautiful old machines need special wiring that looks period-correct

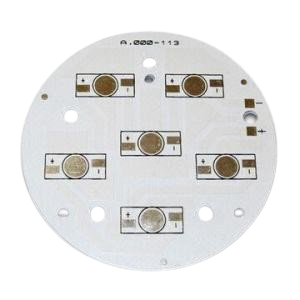

With advanced manufacturing capabilities, precise engineering, and competitive pricing, OurPCB delivers IMS boards that meet the highest industry standards.

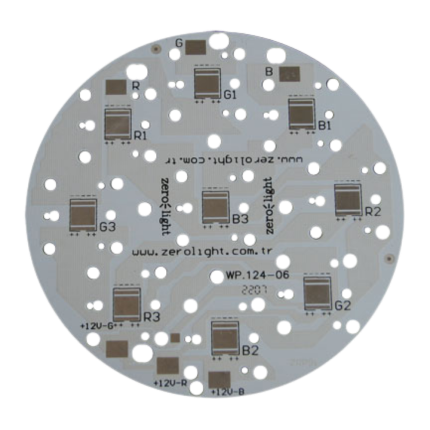

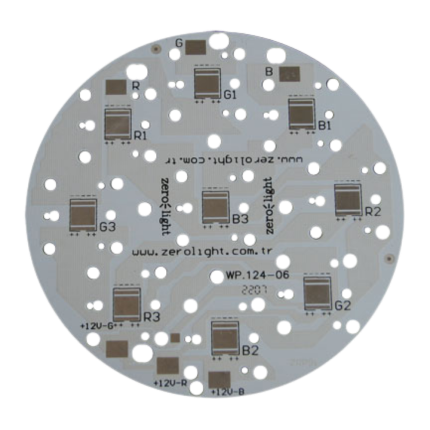

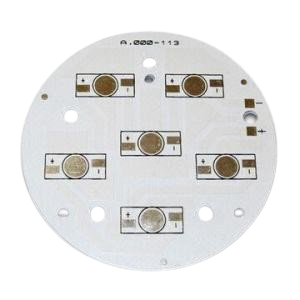

Devices require reliable performance under demanding thermal conditions. As a trusted metal core PCB manufacturer, OurPCB specializes in IMS PCBs (Insulated Metal Substrate PCBs), offering durable, thermally efficient solutions for a wide range of applications.

Choosing a specialized IMS PCB manufacturer ensures your electronic devices perform reliably by addressing heat dissipation challenges. IMS boards are essential for applications requiring efficient thermal management, such as LED lighting, power supplies, and automotive electronics.

As a leading MCPCB manufacturer, OurPCB designs reliable insulated metal substrates for high-performance applications. With our $100 off IMS PCBs deals, businesses of all sizes can access durable, heat-efficient solutions.

Partnering with an experienced IMS PCB manufacturer like OurPCB ensures your project benefits from advanced materials and precision engineering. OurPCB stands out as a metal core PCB manufacturer by offering unmatched expertise, cutting-edge facilities, and industry-leading solutions for IMS PCBs.

For businesses seeking cost-effective thermal solutions, you can get $100 off our IMS PCBs, combining affordability and heat efficiency.

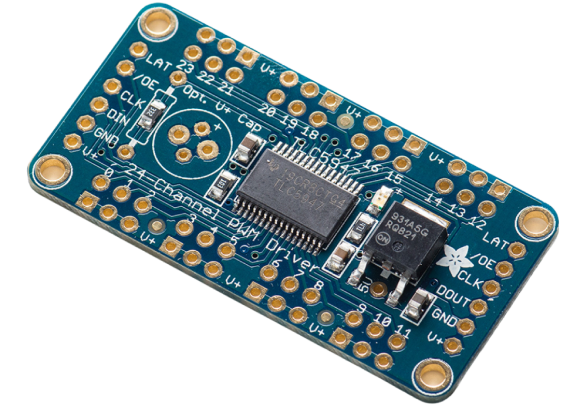

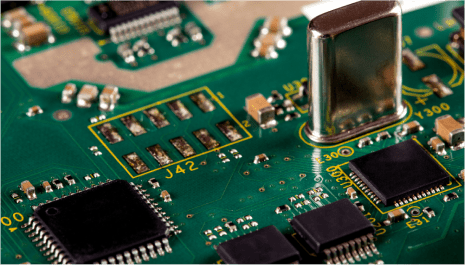

We provide precise and reliable PCB assembly using Surface Mount Technology, ideal for compact and high-performance applications.

We offer flexible services, either working with your supplied components or providing complete turnkey solutions, managing everything from sourcing to delivery.

We deliver tailored PCB assembly solutions designed to meet your unique project specifications and design needs.

We provide fast and efficient PCB assembly services with quick turnaround times, ensuring superior quality at every step.

We produce PCB assemblies that adhere to stringent IPC Class 3 standards, perfect for critical applications in aerospace, healthcare, and other demanding fields.

We specialize in the precise assembly of all IC package types, including BGAs, POPs, CGAs, QFNs, DFNs, and CSPs, with exceptional reliability.

OurPCB delivers advanced solutions for projects requiring compact yet robust insulated metal substrates. For complex designs, our multi-layer metal core PCBs offer durability and heat resistance.

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

An IMS PCB (Insulated Metal Substrate PCB) is a circuit board designed with a metal base

for superior heat dissipation, commonly used in high-power electronics like LEDs and

power converters.

Industries like automotive, LED lighting, power electronics, and renewable energy rely on IMS boards for their heat management and performance advantages.

OurPCB’s pricing is competitive and transparent. For example, PTFE-based insulated metal substrate PCBs are available starting at $150-$200 for 5 units (100 mm x 100 mm).

Every IMS PCB undergoes multiple tests, including AOI, X-ray inspections, and thermal analysis, ensuring consistent performance and reliability.

Finding the right wiring harness manufacturer for your vintage ride can be a real headache. Those beautiful old machines need special wiring that looks period-correct

Would your car be able to run without wire harnesses? Not a chance. Wire harnesses connect all the electrical parts together. No harness means no

Making wire harnesses isn’t complicated. At OurPCB, we create custom wire harnesses for an expansive range of industries every day. While it’s a complicated process,

Prototype cable assemblies are the very important place in between PCB design ideas and interconnects. OurPCB brings prototype assemblies with PCB solutions to your tables.

PCB thermal management prevents component overheating through strategic heat transfer techniques. Without proper thermal control, electronics are at risk of electronic failures through weakened solder

ContentsKey TakeawaysWhat is a Multilayer-Printed Circuit Board?How do Multilayer PCB Boards Work?Multilayer PCB ApplicationsMultilayer PCB Manufacturing Process: StepsMultilayer PCB Manufacturing MachinesBenefits of Multilayer Circuit BoardsWhat

We use cookies to improve your browsing experience, which may include personal information. By clicking "Agree," you accept our Privacy Policy and cookie use. You can change your cookie settings in your browser anytime.

Agree