- PCB Manufacturer

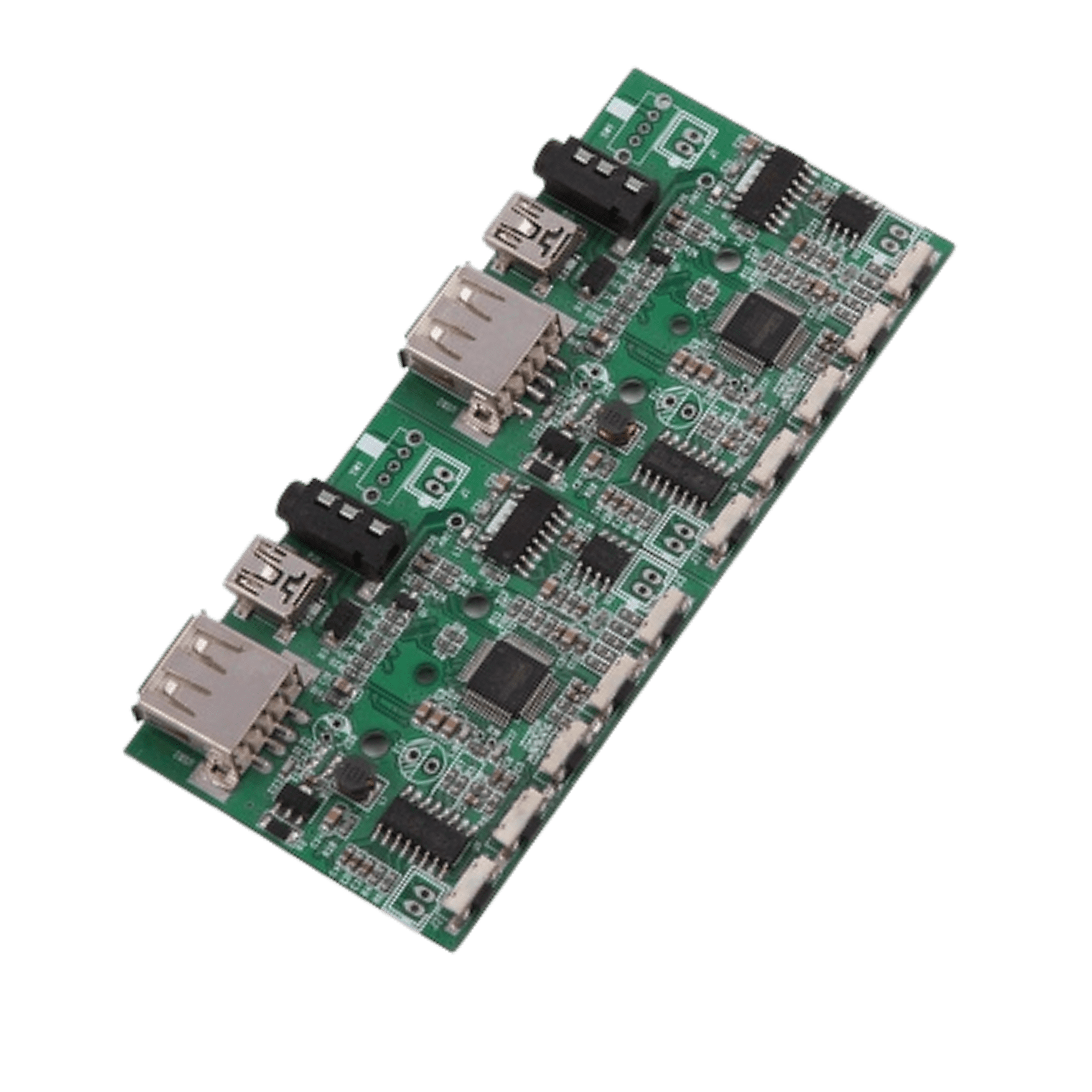

- PCB Assembly Service

- Manual PCB

Manual PCB Assembly Manufacturers

Manual PCB assembly involves the skilled placement and soldering of components on printed circuit boards. This process ensures high-quality assembly for various electronic devices. At OurPCB, we deliver premium manual PCB assembly services.

Manual PCB Assembly

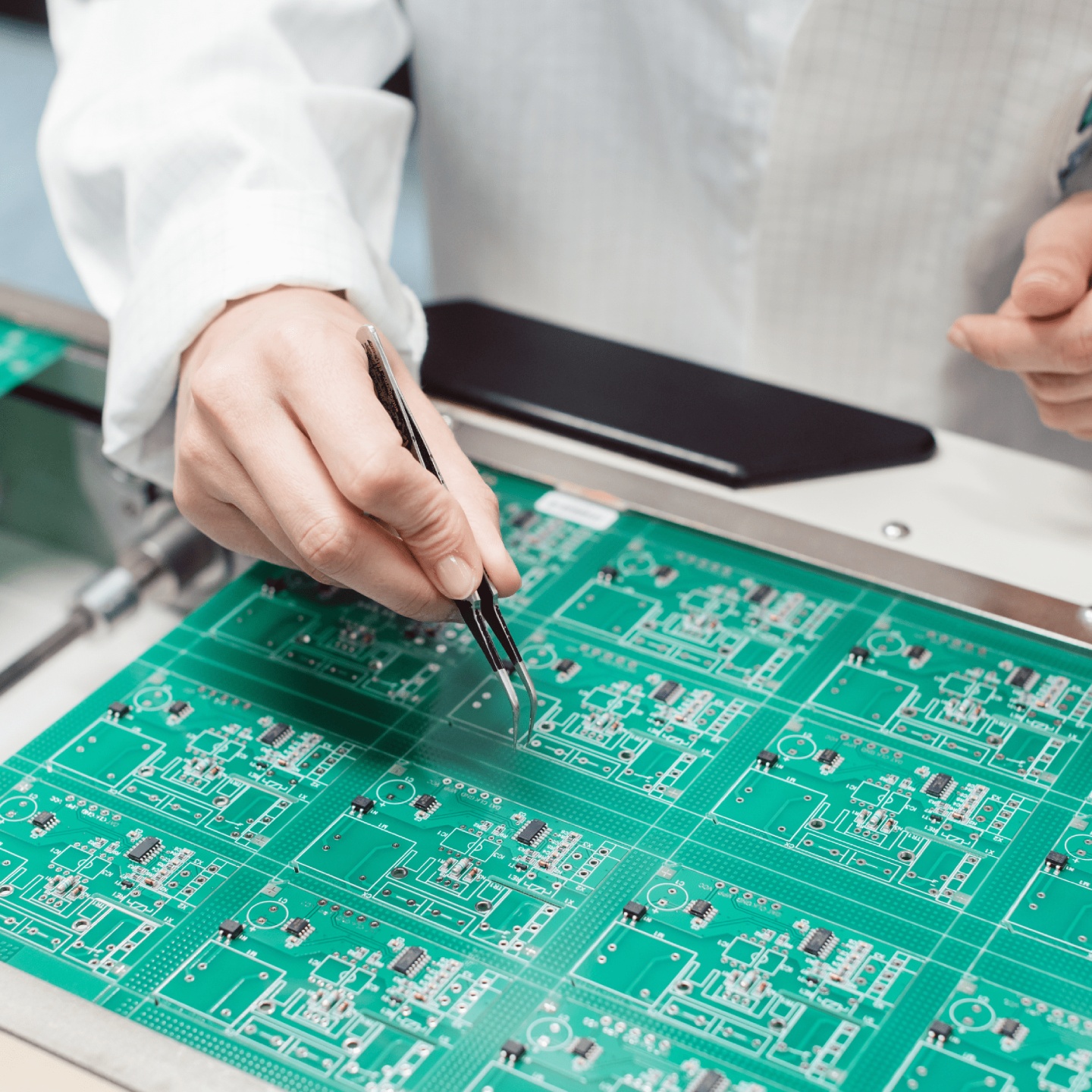

Manual PCB assembly is a hands-on process where technicians place components on printed circuit boards (PCBs) and solder them in place. This method is ideal for low-volume production and prototypes, where precision and attention to detail are crucial. Skilled workers use tools like soldering irons and tweezers to ensure each component is correctly positioned.

The manual PCB assembly process includes several steps. First, technicians prepare the PCB by cleaning its surface to remove any contaminants. Next, they place the components according to the design specifications. After placement, they solder the components using either through-hole or surface mount techniques. Each board undergoes a thorough inspection to guarantee quality.

PCB Manufacturing Process

The Benefits of Partnering with OurPCB for Manual PCB Assembly

Partnering with OurPCB for manual PCB assembly offers many advantages. Our experienced team ensures high-quality assembly tailored to your needs. We focus on delivering precision and reliability in every project.

- We provide fast service without compromising quality.

- Timely delivery ensures you meet your project deadlines.

- Our assembly process adheres to strict quality control measures.

- We use certified materials for reliable performance.

- Our skilled technicians have years of experience in PCB assembly.

- They ensure each component is accurately placed and soldered.

- We offer competitive pricing for our manual assembly services.

- Our efficient processes help reduce overall costs.

Why Choose a China Manual PCB Assembly Line?

Choosing a manual PCB assembly line in China provides several benefits. China is known for its advanced manufacturing capabilities and cost-effective solutions. Partnering with Chinese manufacturers can lead to significant savings on production costs.

- Chinese manufacturers have extensive experience in electronics assembly.

- We understand global standards and requirements.

- Many facilities use state-of-the-art equipment for precision assembly.

- This technology enhances the overall quality of PCBs.

- Manufacturers can easily scale production based on demand.

- This flexibility supports both small and large orders.

- Many companies offer full turnkey solutions, from design to final assembly.

- This one-stop-shop approach simplifies the production process.

PCB Assembly Services

OurPCB offers a range of PCB assembly services tailored to meet diverse needs. We ensure that every project receives the attention it deserves, from prototypes to full-scale production runs.

We specialize in high-quality PCB assembly using Surface Mount Technology, ideal for compact and performance-driven products.

We offer flexibility by working with customer-supplied components or providing turnkey solutions, covering sourcing, assembly, and delivery.

We deliver tailored PCB assembly services designed to meet your specific project requirements and unique designs.

We provide fast and reliable PCB assembly services with quick turnaround times, ensuring exceptional quality.

We manufacture PCB assemblies that comply with strict IPC Class 3 standards, perfect for demanding industries like aerospace and healthcare.

We handle the assembly of all IC package types, including BGAs, POPs, CGAs, QFNs, DFNs, and CSPs, with precision and reliability.

Millions of business and innovators use OurPCB

PCB Board Process

Design (1 day)

- Upload Schematic to Get a Quote

- PCB Review and Quotation

- Customer Makes Payment

- Evaluation & Confirmation of Plan

- Design Start

Layout (1 day)

- Layer Stack-up Design

- Design Rule Setting

- Component Placement Design

- Confirmation & Optimization

- Fanout

Routing (1 day)

- Fanout Optimization

- PCB Routing

- Equal-length Adjustment

- Routing Optimization

- DRC Check

- Routing Confirmation

Optimization (1 day)

- Silkscreen Adjustment

- Data Output

- Customer Final Confirmation

- Production Debugging

- Archiving Projects

- Finish

PCB Board Process

Order Received

- Component Procurement

- Preparation

- PCB Manufacture

- Make Process Flow

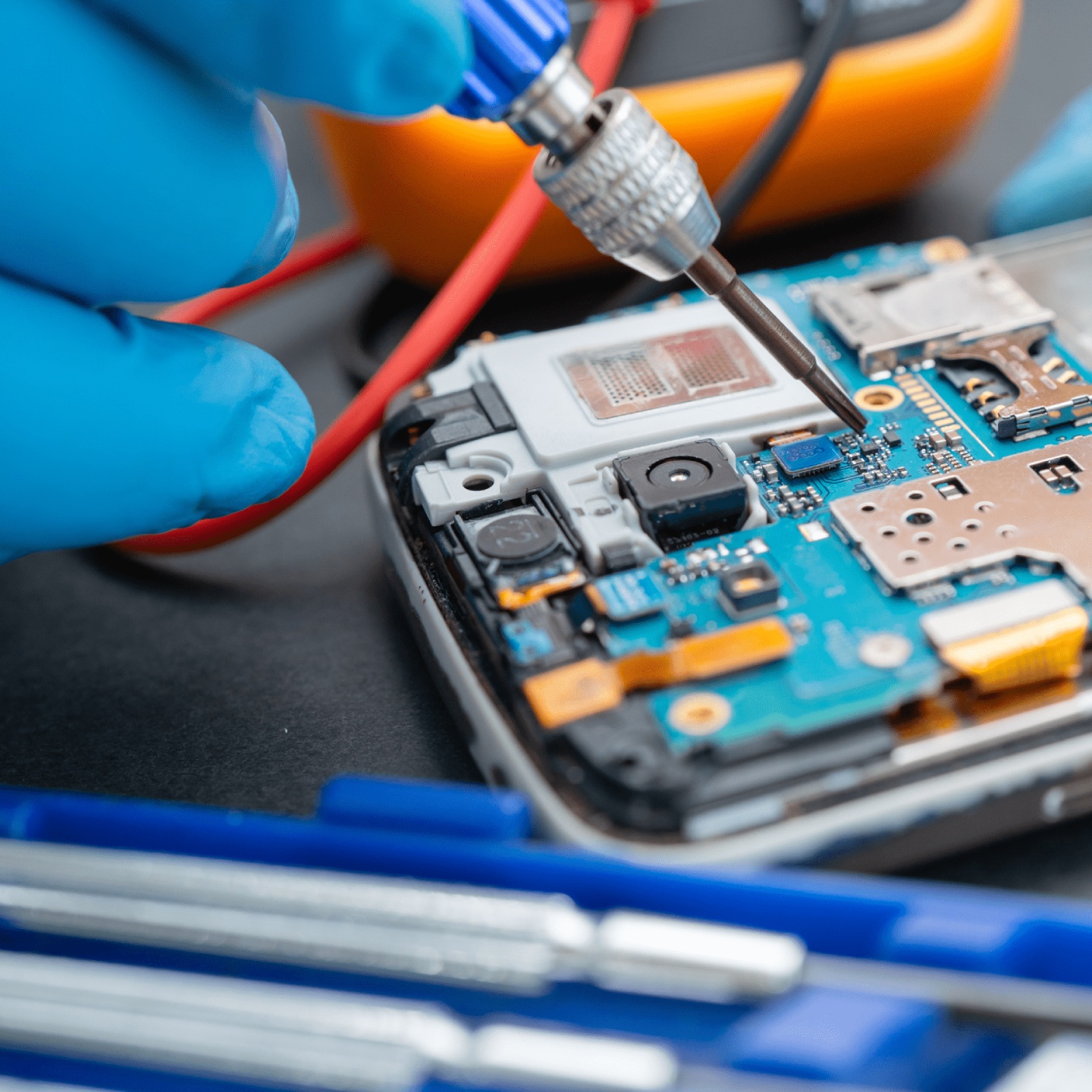

Soldering

- Solder Printing/Wave Soldering

- SMT/Plugging

- Inspection (repair if necessary)

- AOI (repair if necessary)

- Transfer

Parts Assembly

- Manual Assembly

- PCBCleaning

- Wire Screw

- Inspection

- Repair If Necessary

Finalization

- Final Confirmation

- Packing

- Shipping

Technical Capabilities

OurPCB boasts advanced technical capabilities that enhance our service offerings. We utilize modern equipment and techniques for efficient PCB assembly processes. Our commitment to quality ensures that every product meets industry standards. OurPCB stands out as a leading provider of manual PCB assembly services, ensuring high-quality results tailored to your specific needs.

Capabilities & Services

- One-stop PCBA Services (PCB Manufacturing + Components Sourcing + Assembly)

- SMT Assembly + THT Assembly, Single/double-sided Assembly Mixed PCB Assembly

- BGA Rework

- 60,000 Chips/Hour

- Down to 01005/0210 Size

- Accuracy<±40μm

- Min. QFN Pin Width/Space: 0.15mm/0.25mm

- Min. BGA Diameter/Space: 0.2mm/0.35mm

- Rigid, Flex, HDI, & High-speed Power Boards

- Up to 50 Layers

- 60GHz High Frequencies

- Min. Trace Width/Spacing: 2.5mil/2.5mil

- AOI, X-ray, ICT & FCT Testing

- Controlled Impedance

- ISO 9001, ISO 13485, ISO 14001, IATF 16949, IPC-A-610, UL Certified

- Automotive, Medical, & Military-grade PCBA Manufacturing

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Is a manual insertion PCB assembly line better than other assembly methods?

Manual insertion suits THT components but lacks speed compared to SMT assembly lines. Automated assembly processes excel in surface mount technology for high-volume production. Conformal coating and precision placement are easier with automated electronic assembly systems. For tailored PCB fabrication needs, contact us to explore assembly capabilities.

What data files do you require for assembly orders?

We require a complete BOM and Gerber files for printed circuit board assembly services. Stencil files are needed for surface mount technology processes in SMT assembly lines. Ensure PCB prototype data includes placement and orientation details for successful PCB manufacturing. For clarity, get a quote or contact us with specific supplier requirements.

Is manual PCB assembly affordable?

Manual PCB assembly is affordable for low-volume or specialized electronic assembly needs. THT processes often require manual insertion, especially for unique or niche components. Compared to automated SMT assembly lines, labor costs make manual methods less scalable.