- PCB Manufacturer

- PCB Assembly Service

- Automated PCB

Automated PCB Assembly Manufacturers

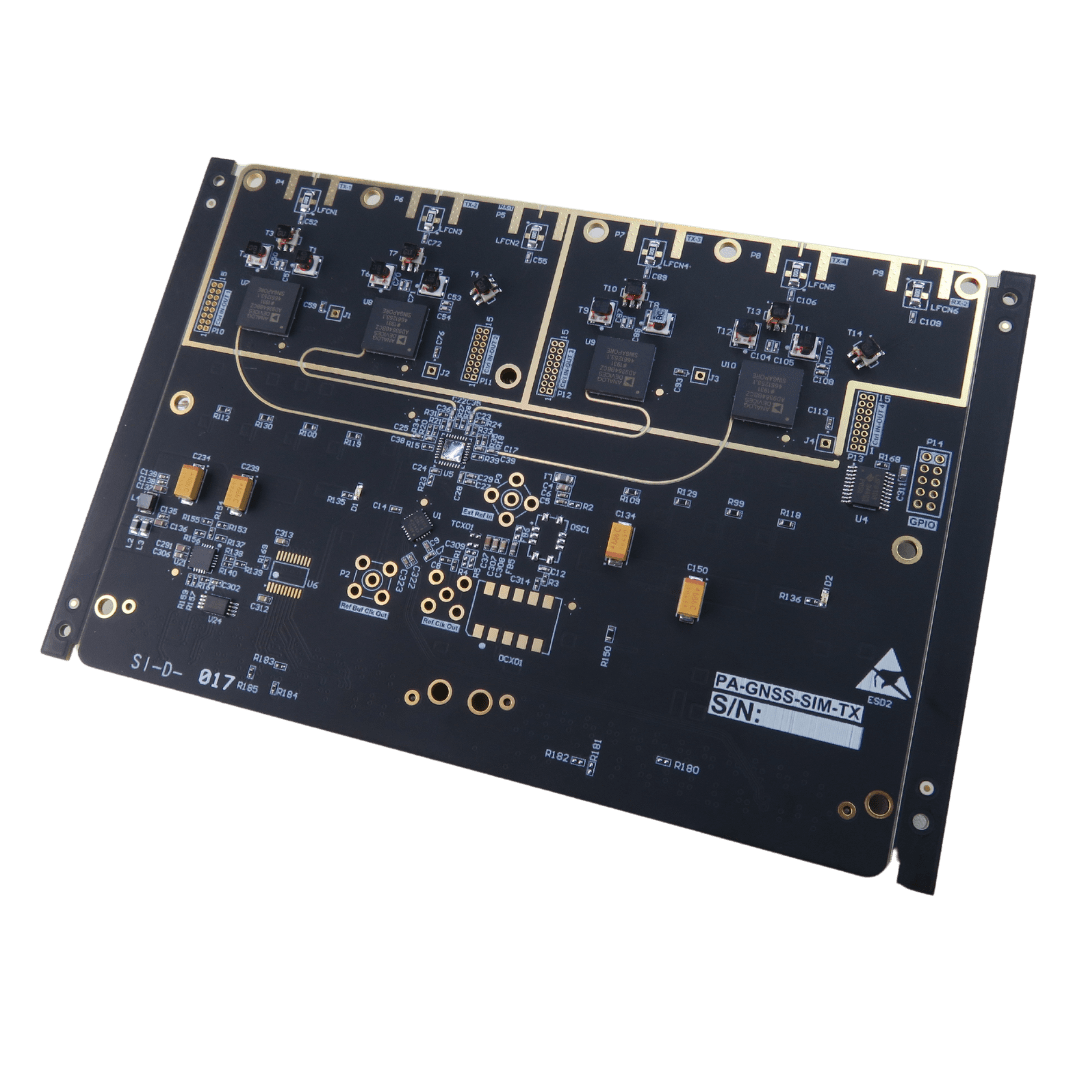

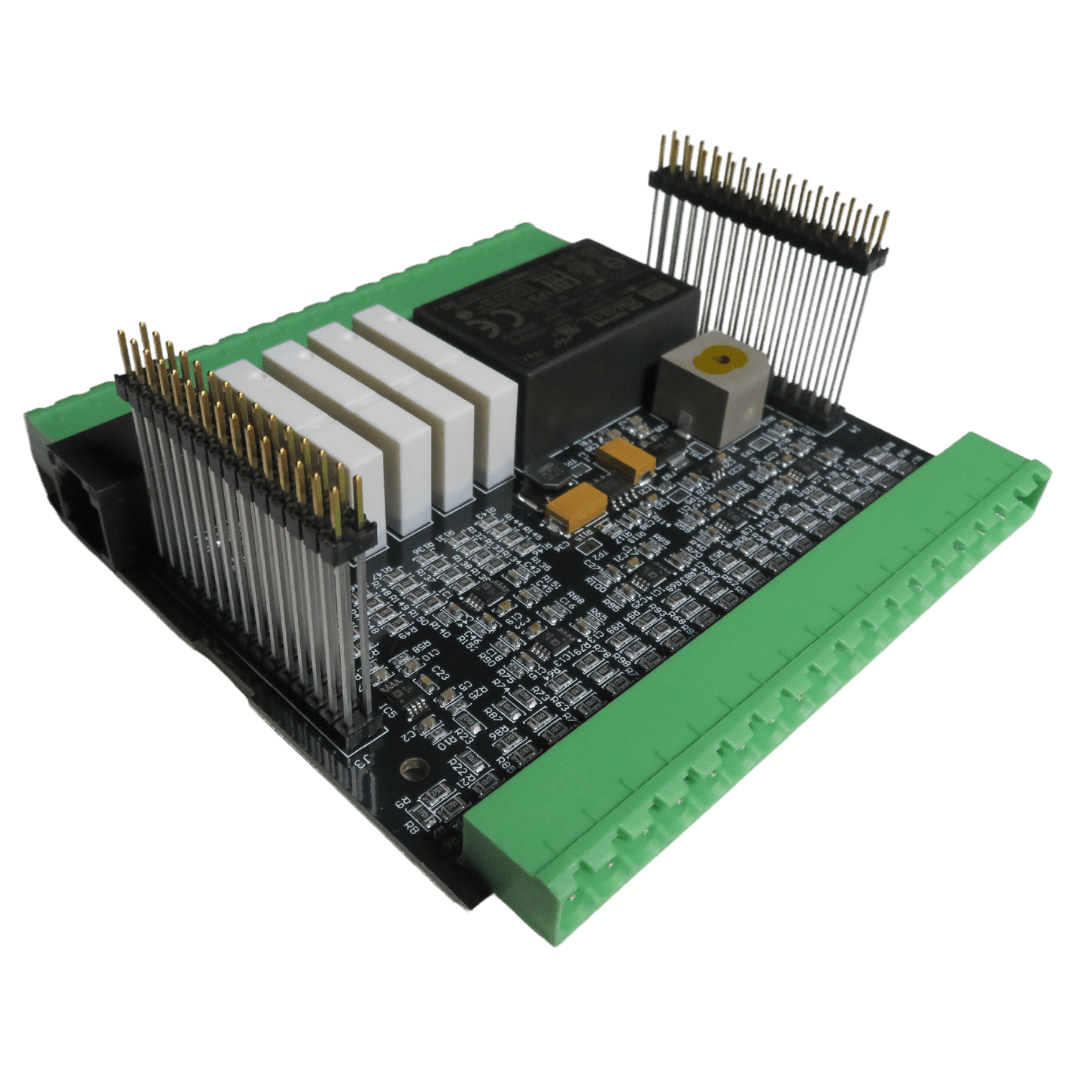

Automated PCB assembly manufacturers use advanced machines to produce printed circuit boards efficiently. OurPCB is highly skilled in these services, ensuring high-quality assembly for numerous applications.

Automation PCB Services

OurPCB offers comprehensive automated PCB assembly services. We use state-of-the-art automated PCB assembly machines to streamline production. This technology allows us to handle complex designs with precision and speed.

Automation reduces human error and increases efficiency. Our automated PCB testing machines ensure each board meets strict quality standards. This commitment to quality enhances the reliability of your products.

PCB Manufacturing Process

The Benefits of Partnering with OurPCB for Automated PCB Assembly Services

Partnering with OurPCB provides numerous advantages for your PCB assembly needs. We focus on delivering high-quality services that meet your specifications.

- Our automated processes lower production costs.

- We offer competitive pricing without compromising quality.

- Automation speeds up the production process.

- Quick delivery times help you meet tight deadlines.

- Automated systems ensure consistent quality.

- Each board undergoes rigorous testing for reliability.

- Our experienced team guides you through the process.

- We provide tailored solutions to fit your project needs.

Why Choose PCB Automation?

Choosing PCB automation enhances your manufacturing process significantly. Automation improves efficiency and reduces labor costs. Automated systems handle repetitive tasks with precision. This leads to fewer errors and higher output rates. You can focus on innovation while we manage the assembly.

- Automated machines operate continuously without breaks.

- This maximizes production capacity and reduces lead times.

- Automated testing ensures each board meets specifications.

- Consistent quality reduces the risk of defects.

- We can quickly adapt to changes in design or volume.

- Automation supports both small and large production runs.

- Reducing manual handling minimizes workplace accidents.

- Automated systems maintain a safer working environment.

PCB Assembly Services

OurPCB provides a range of PCB assembly services tailored to your needs. We ensure every step of the process meets industry standards.

We provide top-quality PCB assembly using Surface Mount Technology, perfect for compact and high-performance products.

We adapt to your needs by working with customer-supplied components or offering turnkey solutions, managing sourcing, assembly, and delivery.

We offer customized PCB assembly solutions to match your unique project requirements and design specifications.

We deliver fast and dependable PCB assembly services with quick turnaround times, maintaining outstanding quality.

We create PCB assemblies that adhere to stringent IPC Class 3 standards, ideal for critical aerospace and medical applications.

We expertly assemble all IC package types, including BGAs, POPs, CGAs, QFNs, DFNs, and CSPs, ensuring precision and reliability.

Millions of business and innovators use OurPCB

PCB Board Process

Design (1 day)

- Upload Schematic to Get a Quote

- PCB Review and Quotation

- Customer Makes Payment

- Evaluation & Confirmation of Plan

- Design Start

Layout (1 day)

- Layer Stack-up Design

- Design Rule Setting

- Component Placement Design

- Confirmation & Optimization

- Fanout

Routing (1 day)

- Fanout Optimization

- PCB Routing

- Equal-length Adjustment

- Routing Optimization

- DRC Check

- Routing Confirmation

Optimization (1 day)

- Silkscreen Adjustment

- Data Output

- Customer Final Confirmation

- Production Debugging

- Archiving Projects

- Finish

PCB Board Process

Order Received

- Component Procurement

- Preparation

- PCB Manufacture

- Make Process Flow

Soldering

- Solder Printing/Wave Soldering

- SMT/Plugging

- Inspection (repair if necessary)

- AOI (repair if necessary)

- Transfer

Parts Assembly

- Manual Assembly

- PCBCleaning

- Wire Screw

- Inspection

- Repair If Necessary

Finalization

- Final Confirmation

- Packing

- Shipping

Technical Capabilities

OurPCB boasts robust technical capabilities that support all aspects of PCB assembly. We combine cutting-edge technology with skilled expertise in electronics manufacturing. Our commitment to innovation drives us to continually improve our processes, ensuring we meet your evolving needs in the electronics industry.

Capabilities & Services

- One-stop PCBA Services (PCB Manufacturing + Components Sourcing + Assembly)

- SMT Assembly + THT Assembly, Single/double-sided Assembly Mixed PCB Assembly

- BGA Rework

- 60,000 Chips/Hour

- Down to 01005/0210 Size

- Accuracy<±40μm

- Min. QFN Pin Width/Space: 0.15mm/0.25mm

- Min. BGA Diameter/Space: 0.2mm/0.35mm

- Rigid, Flex, HDI, & High-speed Power Boards

- Up to 50 Layers

- 60GHz High Frequencies

- Min. Trace Width/Spacing: 2.5mil/2.5mil

- AOI, X-ray, ICT & FCT Testing

- Controlled Impedance

- ISO 9001, ISO 13485, ISO 14001, IATF 16949, IPC-A-610, UL Certified

- Automotive, Medical, & Military-grade PCBA Manufacturing

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Can PCB design be automated?

Yes, PCB design can be automated. Design automation accelerates creating PCBs, reducing manual design efforts significantly. It optimizes substrate layout and placements, streamlining the PCB fabrication process. This ensures compatibility with a fully automated PCB manufacturing machine for efficiency. For design support or queries, contact us for professional electronic manufacturing services.

How much does automated PCB assembly cost?

Automated PCB assembly costs range from $5 to $200 per board, depending on complexity, volume, and specific requirements like rigid-flex PCBs or through-hole components. A fully automated PCB manufacturing line with SMT ensures cost-effective solutions. Rigid-flex PCB or through-hole designs may influence total fabrication and assembly costs.

What is an automated PCB drilling machine?

An automated PCB drilling machine precisely drills holes for through-hole components. It is similar to an automated PCB milling machine. It enhances fabrication accuracy, essential for high-quality electronic components integration. Paired with AOI, it ensures solder and surface mount quality consistency. A fully automated PCB manufacturing line with SMT is critical in aerospace-grade PCB manufacturing and board assemblies.