- PCB Manufacturer

- PCB Assembly Service

- 12 layer

12 Layer PCB Stack-up Manufacturer & Supplier

OurPCB is a leading 12 layer PCB manufacturer and supplier. We specialize in creating high-quality, multi-layer printed circuit boards for complex electronic devices. Our team uses advanced technology and strict quality control to ensure reliable performance. With years of experience, OurPCB delivers custom solutions tailored to your specific needs.

12 Layer PCB Stack Up Manufacturers

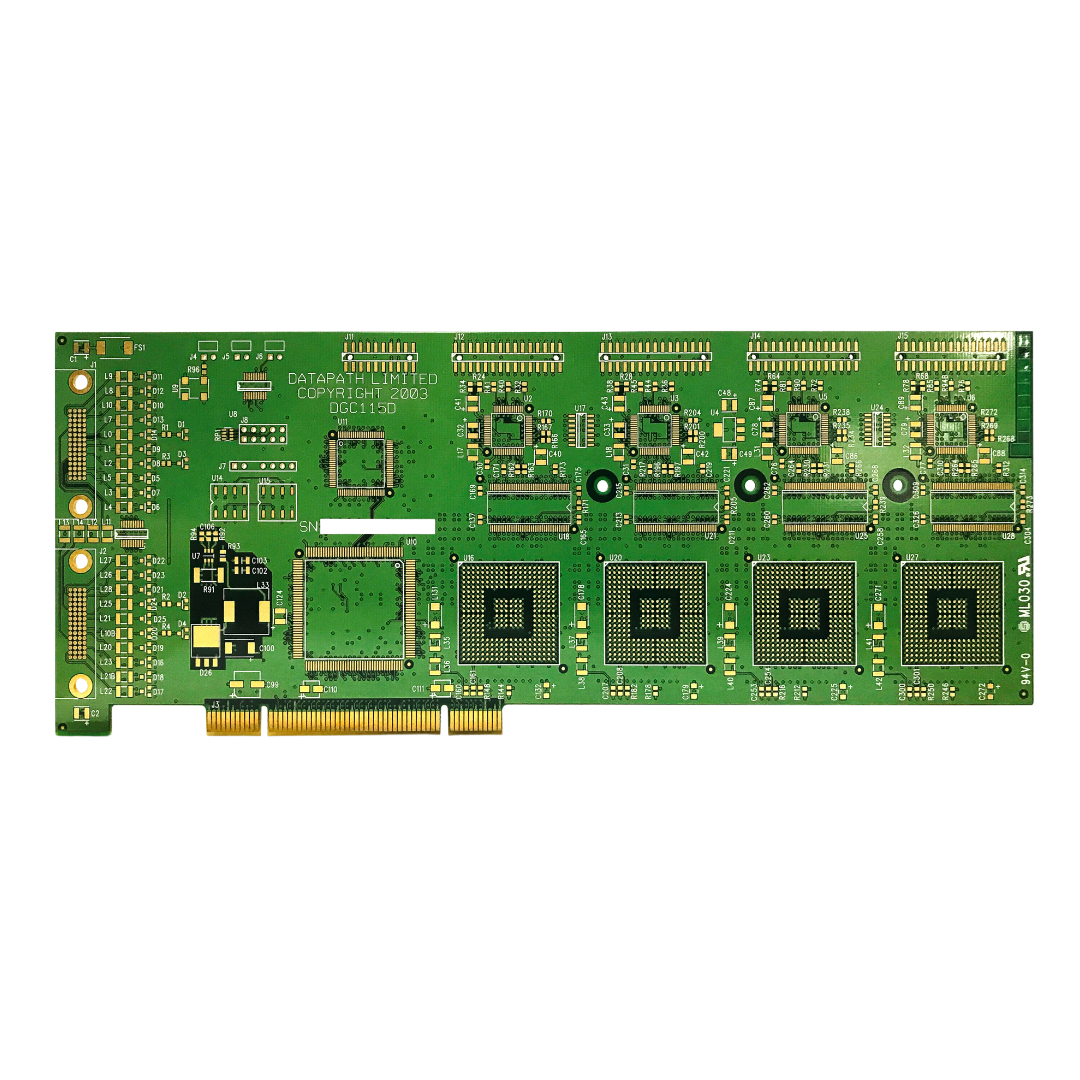

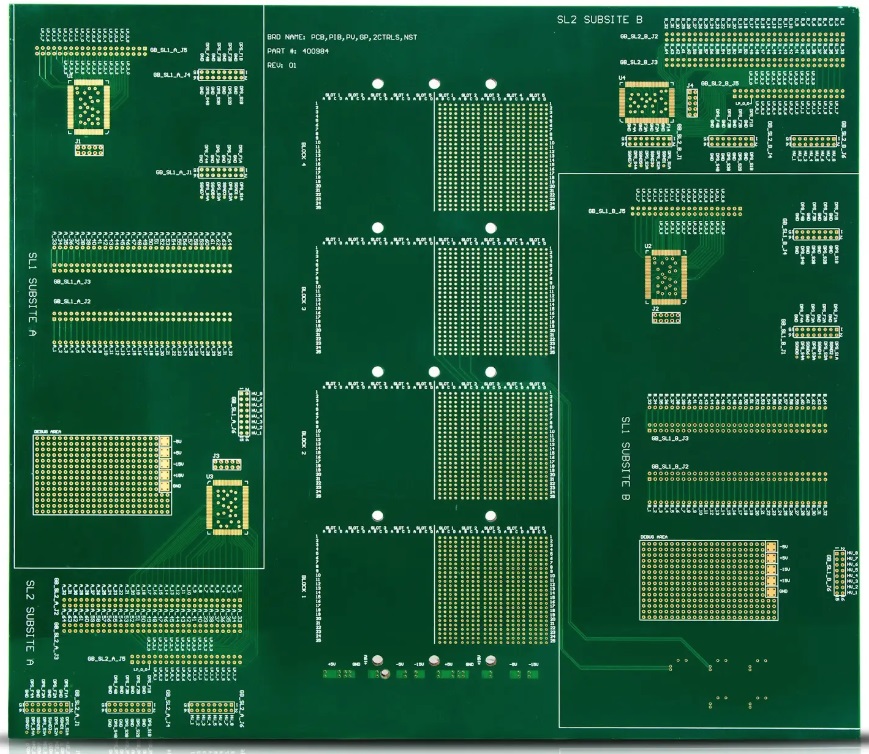

12 layer PCB stack-up manufacturers produce complex circuit boards with multiple conductive layers. These boards are essential for high-density electronic devices that require advanced functionality. Manufacturers like OurPCB use specialized equipment and techniques to create precise layer alignments and connections.

The production process involves careful planning of the PCB stackup design. This includes determining the placement of signal layers, power planes, and ground planes. Manufacturers must also consider factors like impedance control and signal integrity. Quality control is crucial throughout the fabrication process to ensure the final product meets strict industry standards.

PCB Manufacturing Process

The Benefits of Partnering With OurPCB As Your 12 Layer PCB Manufacture Supplier

Partnering with OurPCB as your 12 layer circuit board supplier offers numerous advantages. We combine technical expertise with customer-focused service to deliver top-quality PCBs. Here are the key benefits of choosing OurPCB:

- Assistance with stackup optimization for improved signal integrity

- Guidance on material selection for specific performance requirements

- High-quality equipment for precise layer alignment

- Rigorous quality control processes at every production stage

- Quick-turn prototyping services for faster time-to-market

- Scalable production capacity to meet varying order volumes

- In-house electrical testing to ensure board functionality

- Compliance with industry standards and regulations

Why Choose a 12 Layer PCB Stackup?

A 12 layer PCB stackup offers significant advantages for complex electronic designs. It provides more routing options and better signal management. Here’s why you might opt for a 12 layer PCB:

- More layers allow for higher component density

- Enables miniaturization of electronic devices

- Better control over electromagnetic interference

- Reduced crosstalk between signal traces

- Dedicated power and ground planes for stable voltage supply

- Improved thermal management in high-power applications

- More routing options for complex circuit layouts

- Ability to separate high-speed and low-speed signals

- More layers allow for higher component density

- Enables miniaturization of electronic devices

- Better control over electromagnetic interference

- Reduced crosstalk between signal traces

- Dedicated power and ground planes for stable voltage supply

- Improved thermal management in high-power applications

- More routing options for complex circuit layouts

- Ability to separate high-speed and low-speed signals

PCB Assembly Services

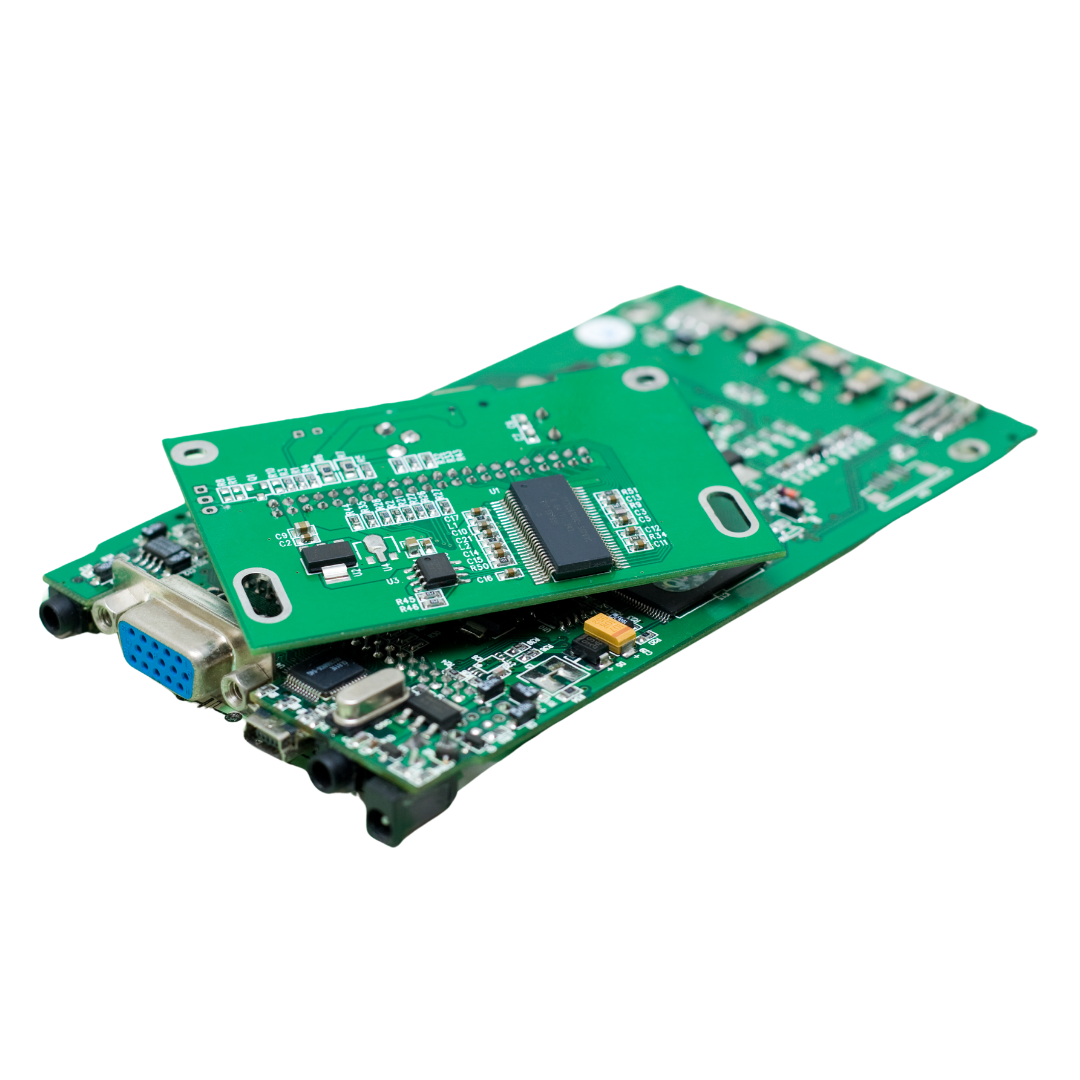

OurPCB offers comprehensive PCB assembly services to complement our fabrication capabilities. We handle projects of various sizes and complexities. Our assembly services include:

We use Surface Mount Technology for high-density, compact PCB assemblies. Our SMT process ensures precise component placement and reliable solder connections.

We accommodate both customer-supplied components and full turnkey solutions. Our turnkey service covers component sourcing, assembly, and final delivery.

Our team works closely with clients to deliver tailored assembly solutions. We adapt our processes to meet unique design requirements and specifications.

We offer fast turnaround times without compromising quality. Our efficient processes enable rapid prototyping and small-batch production.

We adhere to strict IPC Class 3 standards for high-reliability applications. This service is ideal for aerospace, medical, and other critical industries.

We have expertise in assembling various IC package types. This includes BGA, POP, CGA, QFN, DFN, and CSP components.

Millions of business and innovators use OurPCB

PCB Board Process

Order Received

- Component Procurement

- Preparation

- PCB Manufacture

- Make Process Flow

Soldering

- Solder Printing/Wave Soldering

- SMT/Plugging

- Inspection (repair if necessary)

- AOI (repair if necessary)

- Transfer

Parts Assembly

- Manual Assembly

- Cleaning

- Wire Screw

- Inspection

- Repair If Necessary

Finalization

- Final Confirmation

- Packing

- Shiping

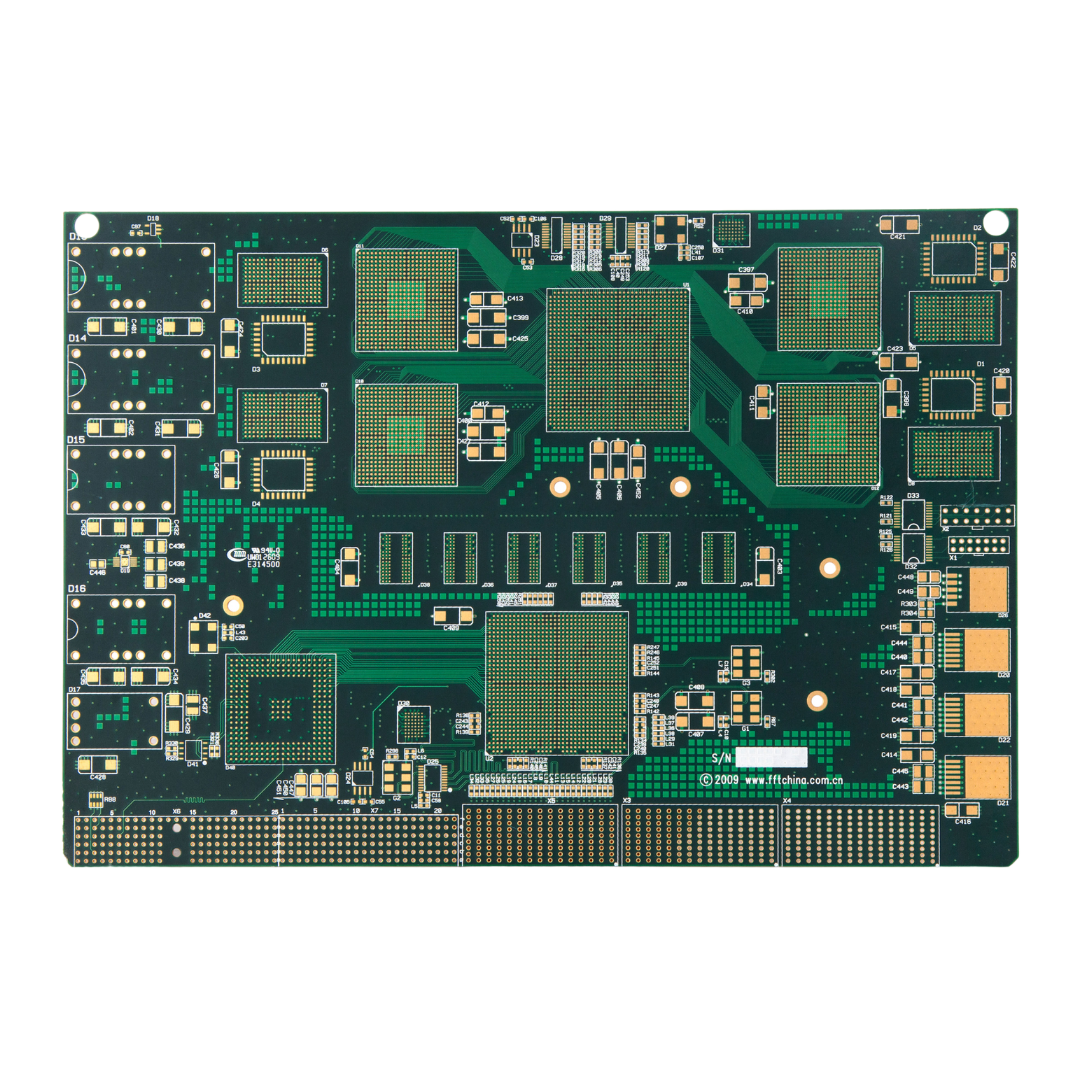

Technical Capabilities

OurPCB possesses advanced technical capabilities for 12 layer PCB fabrication. We use high-precision drilling and lamination equipment to achieve tight tolerances. Our facility can produce boards with minimum trace widths of 2.5 mil and minimum via sizes of 0.1 mm. We offer a range of surface finishes, including ENIG, HASL, and immersion silver. Our in-house testing equipment ensures every board meets strict quality and performance standards.

Capabilities & Services

- One-stop PCBA Services (PCB Manufacturing + Components Sourcing + Assembly)

- SMT Assembly + THT Assembly, Single/double-sided Assembly Mixed PCB Assembly

- BGA Rework

- 60,000 Chips/Hour

- Down to 01005/0210 Size

- Accuracy<±40μm

- Min. QFN Pin Width/Space: 0.15mm/0.25mm

- Min. BGA Diameter/Space: 0.2mm/0.35mm

- Rigid, Flex, HDI, & High-speed Power Boards

- Up to 50 Layers

- 60GHz High Frequencies

- Min. Trace Width/Spacing: 2.5mil/2.5mil

- AOI, X-ray, ICT & FCT Testing

- Controlled Impedance

- ISO 9001, ISO 13485, ISO 14001, IATF 16949, IPC-A-610, UL Certified

- Automotive, Medical, & Military-grade PCBA Manufacturing

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

12 Layer Circuit Board Manufacturer | FAQs

How thick is a 12 layer PCB board?

A 12 layer PCB board typically has a board thickness of 1.6 mm to 2.4 mm. This thickness depends on the laminate, prepreg, and copper layer configuration. 12 layer PCB fabrication suppliers ensure precise control of these materials. Consistent thickness is crucial for reliability and durability in multilayer PCB design.

Does the 12-layer PCB stackup with a heat sink?

Yes, the 12-layer PCB stack-up can include a heat sink for better thermal management. HDI techniques and vias help dissipate heat efficiently through the outer layer of the PCB. A proper 12-layer PCB stack-up design integrates a substrate with high thermal conductivity. This approach enhances the manufacturing process and extends the board’s durability.

What are the applications of a 12-layer PCB?

12-layer PCBs are used in applications requiring high reliability and complex circuitry. They are common in telecommunications, aerospace, and advanced computing systems. The multilayer PCB design supports HDI features for compact and efficient interconnects. Choosing a reliable PCB supplier ensures high-quality 12 layer PCBs with effective dielectric properties.