- PCB Manufacturer

- 10 Layer

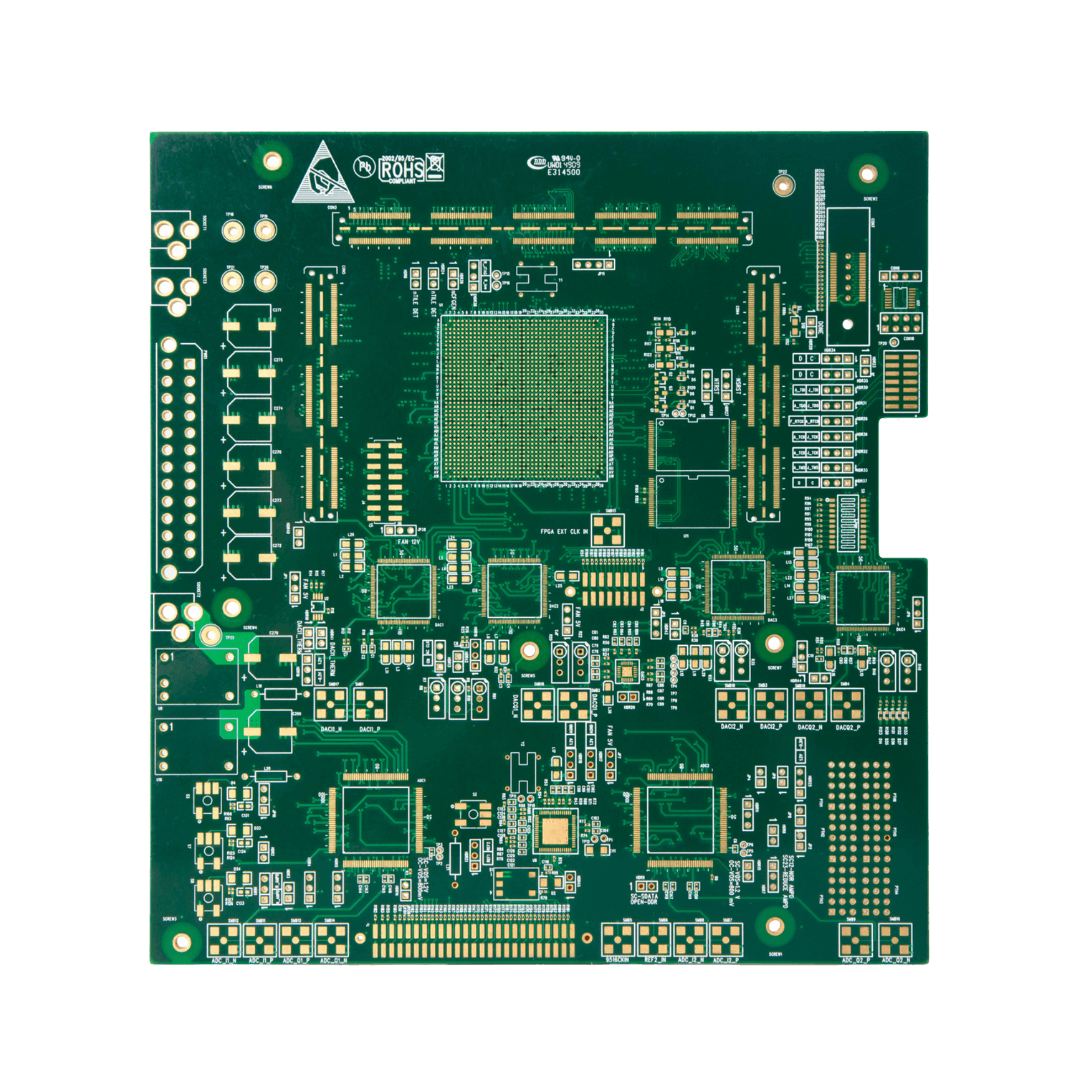

10-Layer PCB Manufacturer for Complex Electronic Applications

As a trusted 10-layer PCB manufacturer, we design and produce multilayer circuit boards for high-speed signal transmission and space-saving layouts. Some of our clients’ applications include aerospace systems, medical equipment, and advanced telecommunications, where performance and reliability are non-negotiable.

Your Reliable 10-Layer PCB Manufacturer

OurPCB manufactures high-performance 10-layer printed circuit boards with fast prototype turnaround, precise specifications, tighter tolerances, and reliable performance for RF and high-frequency applications. Our specialized manufacturing processes ensure optimal results for your most complex electronic designs.

PCB Manufacturing Process

Our 10-Layer PCB Manufacturing Capabilities

OurPCB manufactures high-performance 10-layer printed circuit boards with superior quality, precise specifications, and reliable performance. Our specialized printed circuit board manufacturing processes ensure optimal results for your most complex electronic designs.

- Precise layer alignment

- Controlled impedance with ±10% tolerance

- Sophisticated via structures

- Fine line capabilities

- Advanced AOI inspection

- X-ray verification

Why Choose OurPCB?

We combine advanced technical expertise in complex multilayer PCB fabrication with superior materials and comprehensive quality assurance to deliver advanced PCB stack-ups for demanding applications.

- ISO 9001, IATF 16949, and IPC-A-610 Class 2 & 3 certified manufacturing

- Technical support for complex design implementation

- Competitive lead times with scalable capacity

- Complete assembly and testing capabilities

- OurPCB uses premium equipment to manufacture insulated metal substrate PCBs

- Exceptional precision and consistency

- Every IMS board undergoes rigorous testing

- Automated optical inspection (AOI) and thermal analysis

- We design tailored solutions to meet unique project requirements

- OurPCB handles both multilayer and single-sided IMS boards

- Years of experience serving global industries

- OurPCB has a strong reputation as a trusted MCPCB manufacturer

Our 10-Layer PCB Manufacturing Services

- Fine trace capabilities

- Advanced interconnect options

- Application-specific substrate selection

- Thermal management solutions

- Choose from blind and buried vias

- Controlled dielectric thicknesses

- Full PCBA services

- Original component sourcing

- Electrical performance verification

- Signal integrity validation

- Multiple surface finish options

- Application-appropriate selections

Millions of business and innovators use OurPCB

PCB Board Process

Design (1 day)

- Upload Schematic to Get a Quote

- PCB Review and Quotation

- Customer Makes Payment

- Evaluation & Confirmation of Plan

- Design Start

Layout (1 day)

- Layer Stack-up Design

- Design Rule Setting

- Component Placement Design

- Confirmation & Optimization

- Fanout

Routing (1 day)

- Fanout Optimization

- PCB Routing

- Equal-length Adjustment

- Routing Optimization

- DRC Check

- Routing Confirmation

Optimization (1 day)

- Silkscreen Adjustment

- Data Output

- Customer Final Confirmation

- Production Debugging

- Archiving Projects

- Finish

PCB Board Process

Order Received

- Component Procurement

- Preparation

- PCB Manufacture

- Make Process Flow

Soldering

- Solder Printing/Wave Soldering

- SMT/Plugging

- Inspection (repair if necessary)

- AOI (repair if necessary)

- Transfer

Parts Assembly

- Manual Assembly

- PCBCleaning

- Wire Screw

- Inspection

- Repair If Necessary

Finalization

- Final Confirmation

- Packing

- Shipping

Our Technical Capabilities

OurPCB uses innovative PCB manufacturing and assembly techniques, including precise registration systems, advanced lamination processes, and multi-stage quality control to ensure consistent performance in all 10-layer PCB stack-ups.

Our Capabilities & Services

- Advanced layer bonding techniques for superior structural integrity

- X-ray and automated optical inspection for internal verification

- Specialized impedance control for high-speed applications

- Comprehensive electrical and functional testing

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

Reach us at

[email protected]

24 hours online

+86-199-30589219

Mon-Fri: 24 hours,

Sat: 9am-6pm, GMT+8

10 Layer PCB Manufacturer FAQs

What is the lead time for 10-layer PCB manufacturing?

Lead times for 10-layer PCBs depend on the processing area: 8 days for areas <1m², 14 days for 1m² to 3m², 20 days for 3m² to 30m², and 25 days for areas >30m².

What materials do you use for 10-layer PCBs?

For RF (radio frequency) and high-temperature applications in 10-layer PCBs, the most effective materials include Rogers high-frequency laminates (e.g., RO4003C, RO4350B), Teflon/PTFE-based substrates (e.g., Taconic, Arlon), high TG FR-4 (e.g., TG170 or higher), and polyimide.

Can you provide prototype services for 10-layer PCBs?

Yes, we offer comprehensive prototyping services for 10-layer PCBs with expedited timelines and complete testing to validate your design before volume production.

Do you offer assembly services for 10-layer PCBs?

Yes, we provide complete assembly services, including component sourcing, placement, various soldering techniques, and comprehensive testing for fully functional 10-layer PCBAs.

What quality standards do your 10-layer PCBs meet?

Our 10-layer PCBs comply with ISO 9001:2015, IATF 16949:2016, and IPC-A-610 Class 2 & 3 standards, ensuring consistent quality and reliability for demanding applications.

What are the challenges in designing a 10-layer PCB?

Designing a 10-layer PCB is challenging due to the need for a well-balanced stack-up, controlled impedance, effective thermal management, and precise via placement.

High-speed signals require careful trace layout and consistent dielectric spacing to avoid noise and signal loss. Managing power delivery, heat dissipation, and tight fabrication tolerances is also key to ensuring performance and reliability in complex applications.

What are the drawbacks of 10-layer PCBs?

10-layer PCBs offer high performance but come with some drawbacks. They are more expensive to manufacture due to added materials, complex lamination, and tighter tolerances. Design changes are harder to implement once the layout is finalized. Repairs and rework are also difficult because of the dense internal layers. Lastly, lead times are longer compared to simpler boards, especially when custom stack-ups or advanced materials are used.