Contents

- Expert 2 Layers PCB Manufacturing Services by OurPCB

- 2 Layers PCB Manufacturer: OurPCB Advantage

- 2 Layers PCB Case Study

- 2 Layers PCB Structure

- 2 Layers PCB Stack-Up and Design

- Standard 2 Layers PCB Stack-Up

- Critical Design Elements for 2 Layers PCB

- 2 Layers PCB Thickness

- 2 Layers PCB Manufacturing Process

- 2 Layers PCB Cost Factors

- 2 Layers PCB vs. 4 Layers PCB: Making the Right Choice

- 2 Layers PCB Advantages:

- When to Consider 4 Layers PCB:

- Applications of 2 Layers PCB

- Consumer Electronics

- Industrial Applications

- Automotive Electronics

- Medical Devices

- 2 Layers PCB Design Methods

- Through-Hole Technology

- Surface Mount Technology (SMT)

- Single-Sided vs. 2 Layers PCB

- Single-Sided PCB

- 2 Layers PCB (Double-Sided PCB)

- Benefits of 2 Layers PCB

- How to Choose Between 2 Layers PCB and Multi-Layer Options

- Project Factors to Consider:

- Why Choose OurPCB as Your 2 Layers PCB Manufacturer

- Request Your 2 Layers PCB Quote Today

Expert 2 Layers PCB Manufacturing Services by OurPCB

At OurPCB, we specialize in manufacturing high-quality 2 layers PCB solutions that combine performance, reliability, and cost-effectiveness. As a leading 2 layers PCB manufacturer, we bring decades of expertise to your projects, ensuring precise fabrication and exceptional results for your double-sided circuit boards.

Get Your 2 Layers PCB Quote Today! ✓ Fast Turnaround ✓ ISO Certified ✓ Professional Engineering Support

2 Layers PCB Manufacturer: OurPCB Advantage

| Feature | OurPCB Specification | Industry Benefit |

|---|---|---|

| Manufacturing Precision | ±0.1mm tolerance | Ensures component fit and reliability |

| Material Quality | FR4, High TG FR4, Metal Core, Halogen Free, CEM-3, Rogers, etc. | Enhanced durability and performance |

| Copper Thickness | ≤20oz options | Flexible current-carrying capacity |

| Minimum Trace/Space | 2.5/2.5mil | Supports complex routing requirements |

| Standard Thickness | 0.1-10mm | Options for various applications |

| Surface Finish Options | HASL, ENIG, OSP, Immersion Silver | Application-specific finishing |

| Manufacturing Time | As fast as 3 days | Rapid prototyping capability |

| QC Process | 100% E-test & AOI inspection | Guaranteed functionality |

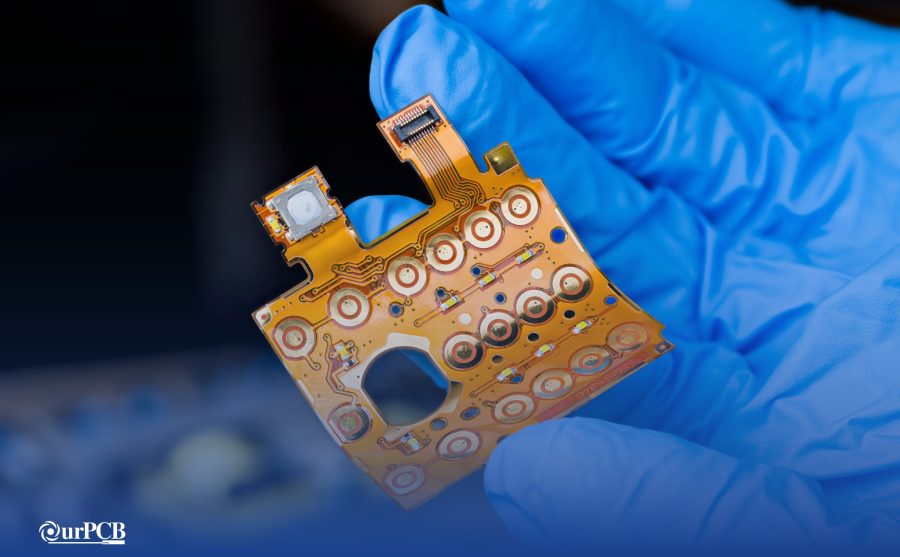

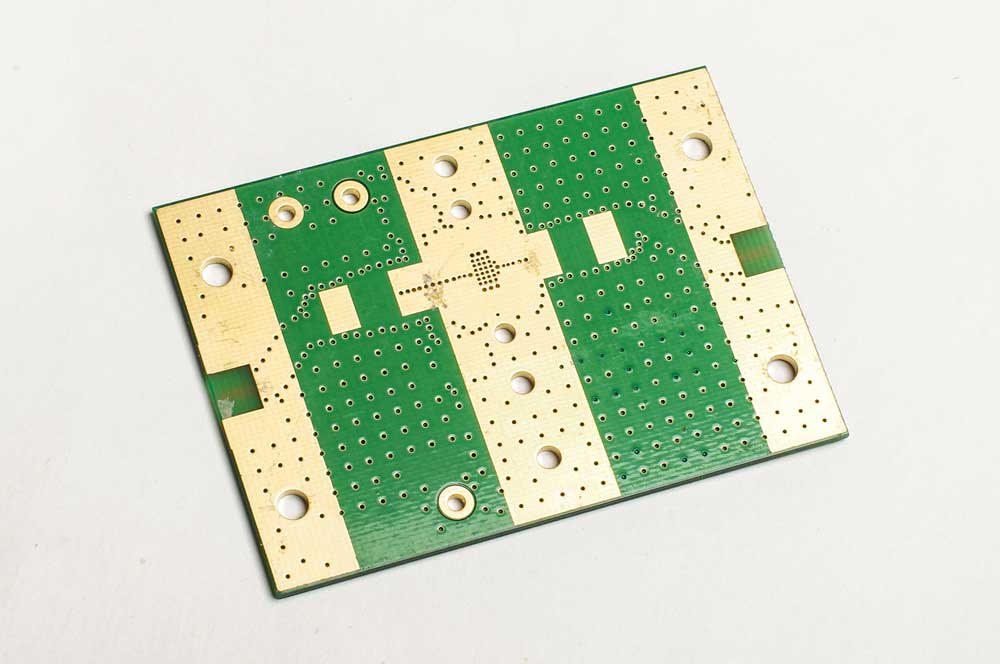

2 Layers PCB Case Study

Layers: 2L+Copper substrate

Thickness: 3.2mm

Surface finish: Immersion gold

Outler layer copper thickness: 6oz

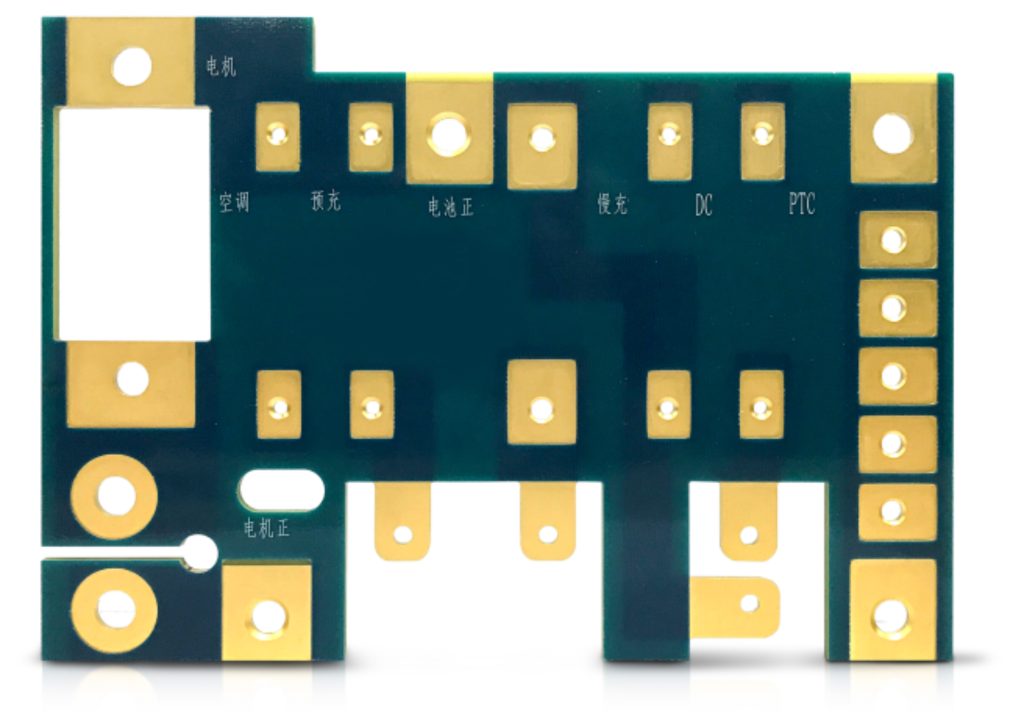

Layers: 2L

Thickness: 6.0mm

Min. hole size: 0.6mm

Outler layer copper thickness: 2oz

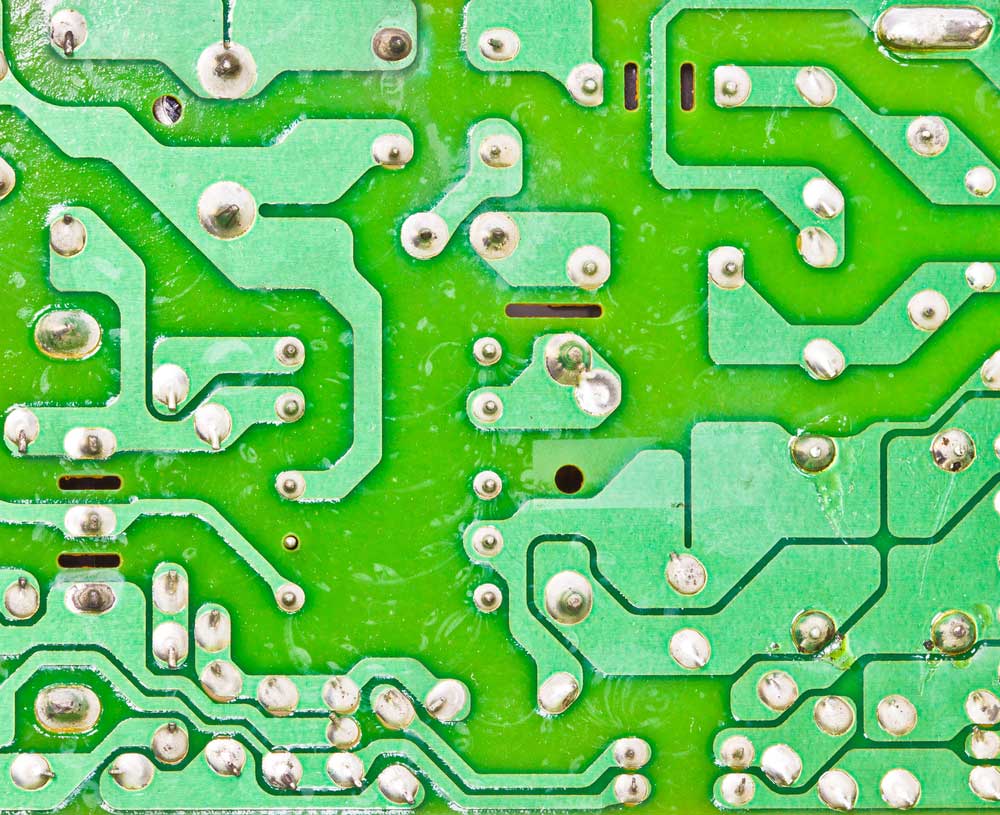

2 Layers PCB Structure

Our 2 layers PCB design features a complete stack-up that includes:

- Top Copper Layer – Primary signal routing and component placement

- Dielectric Core – FR-4 substrate providing insulation and mechanical support

- Bottom Copper Layer – Additional routing and ground plane

- Solder Mask – Protective coating on both sides

- Silkscreen – Component identification and markings

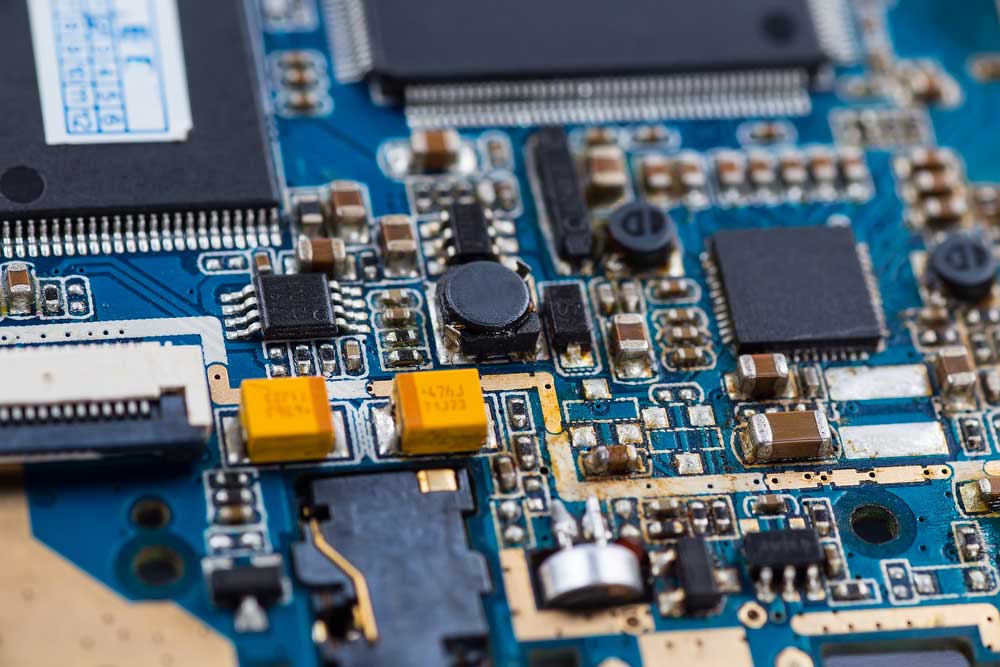

Integrated Circuit Board of a Hard Disk

2 Layers PCB Stack-Up and Design

As an experienced 2 layers PCB manufacturer, OurPCB provides optimized stack-up configurations for maximum performance:

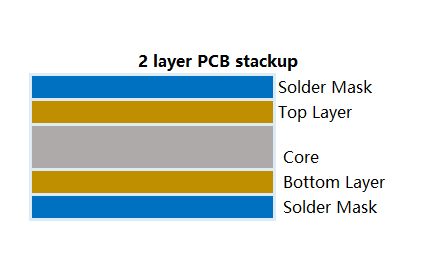

Standard 2 Layers PCB Stack-Up

- Layer 1 (Top): Signal layer with component mounting

- FR-4 Core: Dielectric material with controlled thickness

- Layer 2 (Bottom): Ground/power plane or additional signal routing

2 layer PCB stack-up

Critical Design Elements for 2 Layers PCB

- Signal Integrity: Our 2 layers PCB design minimizes crosstalk through proper trace spacing

- Ground Plane: We implement solid ground planes to reduce noise and improve signal return paths

- Power Distribution: Strategic power routing ensures stable voltage delivery

- Component Placement: Optimized for thermal performance and assembly efficiency

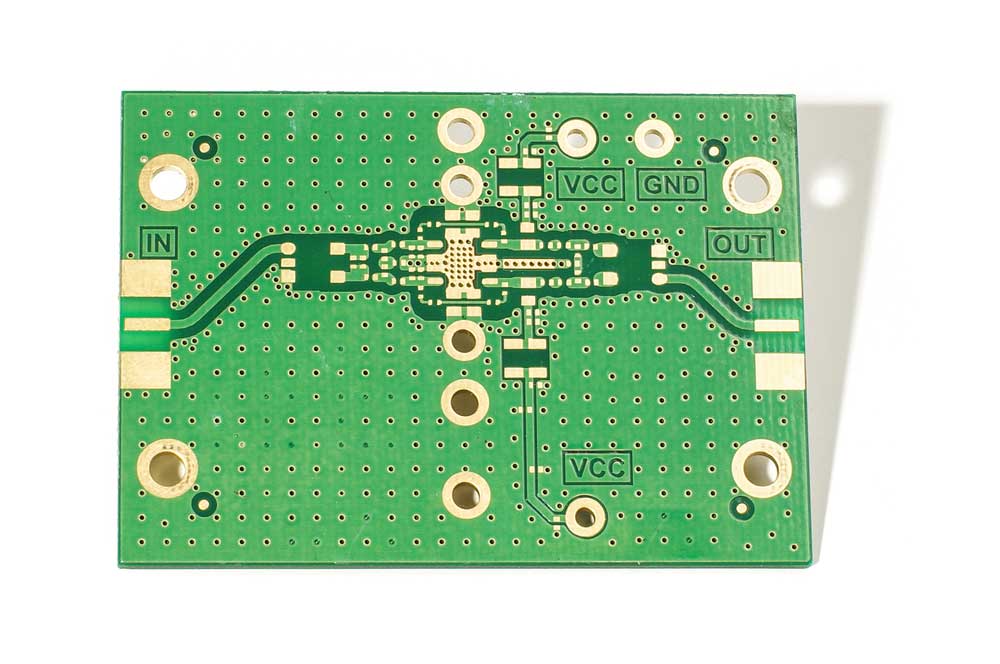

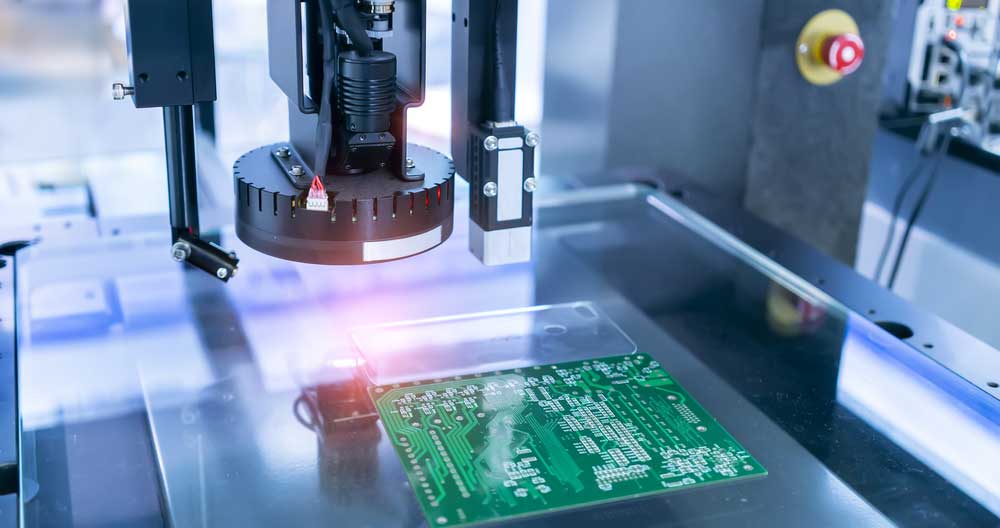

pcb prototyping

2 Layers PCB Thickness

As a professional 2 layers PCB manufacturer, OurPCB offers various thickness options to meet your specific requirements:

- Standard Thickness: 1.6mm (0.063″)

- Thin Profile Options: 0.8mm, 1.0mm, 1.2mm

- Thicker Options: 2.0mm, 2.4mm

The thickness of your 2 layers PCB impacts several performance factors:

- Mechanical Stability: Thicker boards provide better mechanical support

- Electrical Performance: Controlled impedance for high-frequency applications

- Thermal Management: Heat dissipation characteristics

- Weight Considerations: Critical for mobile and aerospace applications

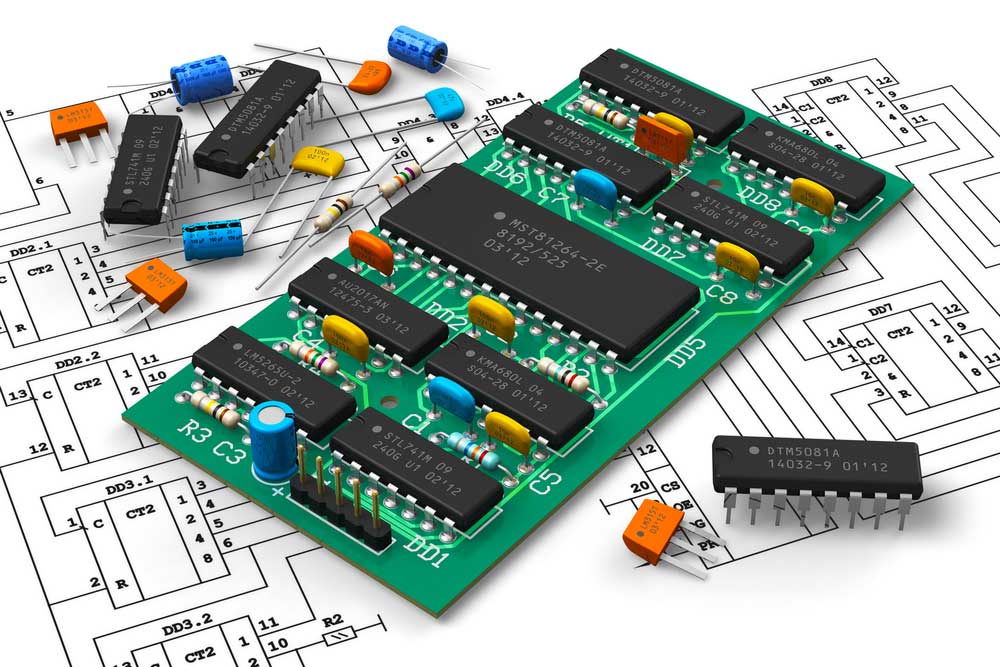

Electronic printed circuit boards

2 Layers PCB Manufacturing Process

At OurPCB, our 2 layers PCB manufacturing process follows these precise steps:

- Material Preparation: Selection of premium copper-clad laminates

- Imaging: Precision photolithography to define circuit patterns

- Etching: Controlled copper removal to create circuit traces

- Drilling: CNC precision drilling for component holes and vias

- Metallization: Copper plating of holes for layer interconnection

- Solder Mask Application: Protection of conductive traces

- Surface Finish: Application of chosen final finish (HASL, ENIG, etc.)

- Silkscreen Printing: Component identification markings

- Electrical Testing: 100% E-test to verify circuit integrity

- Final Inspection: Dimensional and visual quality checks

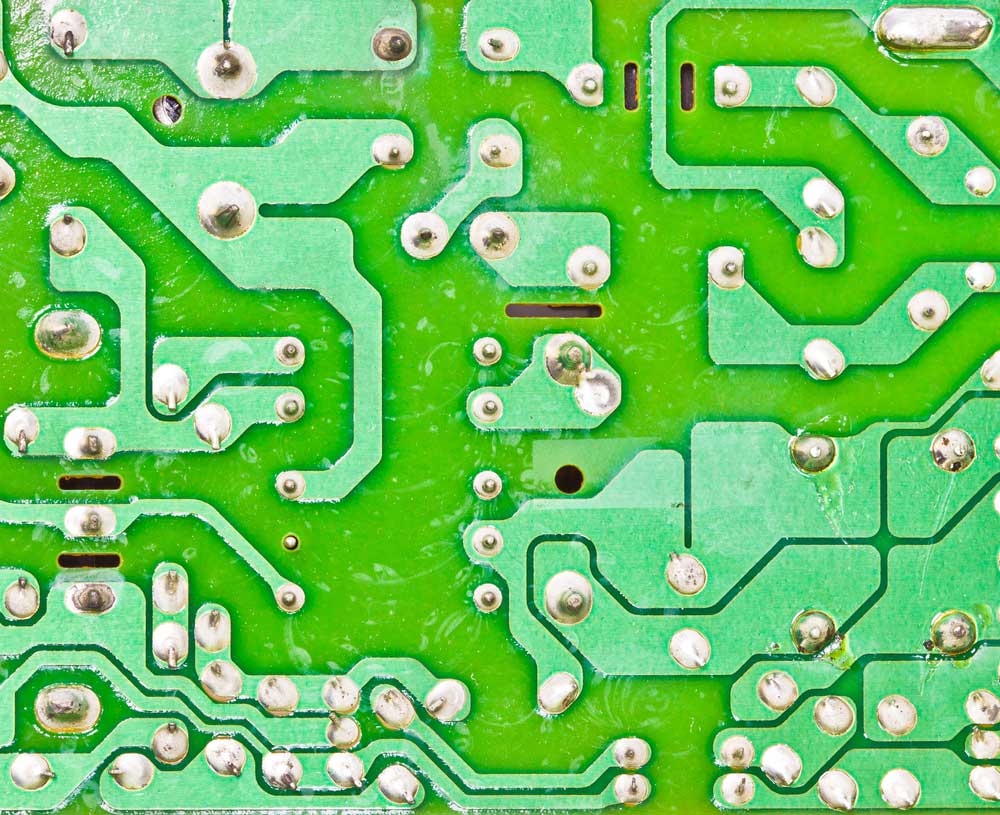

Electronic printed circuit board bottom layer

2 Layers PCB Cost Factors

As a competitive 2 layers PCB manufacturer, OurPCB optimizes costs while maintaining quality:

- Board Size: Price typically ranges from $1-$5 per square inch for standard orders

- Quantity: Significant discounts available for higher volume orders

- Design Complexity: Features like controlled impedance affect pricing

- Material Selection: Standard FR-4 vs. specialized materials

- Surface Finish: HASL is most economical; ENIG offers superior performance

- Turnaround Time: Expedited services available at premium rates

Vision measuring instrument inspecting PCB circuit board

Special Offer: Get $100 off your order!

Email [email protected] to get started!

2 Layers PCB vs. 4 Layers PCB: Making the Right Choice

As both a 2 layers PCB manufacturer and multi-layer specialist, OurPCB provides guidance on selecting the optimal board type:

2 Layers PCB Advantages:

- Cost-Effective: 30-50% lower production costs

- Simpler Manufacturing: Faster turnaround times

- Sufficient for Many Applications: Ideal for less complex circuits

- Easier Prototyping: Quicker design iterations

- Thinner Profile Options: When space constraints are critical

When to Consider 4 Layers PCB:

- Complex routing requirements

- High-speed digital circuits

- Improved EMI/RFI performance needs

- Dense component placement

- Dedicated power and ground planes required

Digital circuit board with microchips

Applications of 2 Layers PCB

Our 2 layers PCB manufacturing services support diverse applications:

Consumer Electronics

- Computer peripherals

- Tablets and smartphones

- Home appliances

- Audio equipment

Industrial Applications

- Control systems

- Power supplies

- Instrumentation

- Monitoring equipment

Automotive Electronics

- Dashboard controls

- Lighting systems

- Sensor interfaces

- Entertainment systems

Medical Devices

- Patient monitoring

- Diagnostic equipment

- Non-critical medical devices

- Laboratory instruments

Electronic circuit board

2 Layers PCB Design Methods

As an experienced 2 layers PCB manufacturer, OurPCB supports both major assembly techniques:

Through-Hole Technology

- Components with leads inserted through holes

- Stronger mechanical connections

- Ideal for high-reliability applications

- Better for components subject to mechanical stress

Surface Mount Technology (SMT)

- Components mounted directly on the surface

- Higher component density

- Better for high-speed applications

- More efficient manufacturing process

- Reduced size and weight

Using the computer

Single-Sided vs. 2 Layers PCB

Understanding the differences helps select the right board for your application:

Single-Sided PCB

- Components and traces on one side only

- Limited routing capabilities

- Lower manufacturing cost

- Simpler design requirements

- Suitable for very basic circuits

2 Layers PCB (Double-Sided PCB)

- Components and traces on both sides

- Significantly more routing space

- Greater design flexibility

- Better signal integrity

- Higher component density

- More challenging thermal management

Benefits of 2 Layers PCB

As a premier 2 layers PCB manufacturer, OurPCB’s double-sided boards offer significant advantages:

- Increased Routing Capacity: Components and traces on both sides maximize available space

- Design Flexibility: More options for component placement and trace routing

- Compact Size: Smaller footprint compared to single-sided designs

- Improved Signal Integrity: Better control of impedance and crosstalk

- Cost-Effective Complexity: More capable than single-sided without the cost of multi-layer boards

- Reliability: Proper ground planes improve electrical performance and stability

- Versatility: Suitable for a wide range of applications from simple to moderately complex

Blue prototyping PCB in a hand

How to Choose Between 2 Layers PCB and Multi-Layer Options

When working with OurPCB as your 2 layers PCB manufacturer, consider these factors:

Project Factors to Consider:

- Budget Constraints: 2 layers PCBs are more economical

- Circuit Complexity: Component count and routing density

- Signal Integrity Requirements: High-speed signals may need additional layers

- Size Limitations: Smaller boards may require additional layers for routing

- Thermal Considerations: Heat dissipation needs

- Electromagnetic Interference: Shielding requirements

- Production Timeline: 2 layers PCBs typically have faster turnaround

- Expected Product Lifespan: Reliability requirements

Why Choose OurPCB as Your 2 Layers PCB Manufacturer

OurPCB delivers exceptional value through:

- Engineering Expertise: Design review and optimization support

- Quality Materials: Premium substrates and copper foils

- Advanced Equipment: State-of-the-art manufacturing technology

- Rigorous Testing: 100% electrical testing and visual inspection

- Flexible Options: Customized solutions for your specific requirements

- Competitive Pricing: Excellent value without compromising quality

- Fast Turnaround: Expedited services when you need them most

- Dedicated Support: Professional assistance throughout your project

Request Your 2 Layers PCB Quote Today

Partner with OurPCB, your trusted 2 layers PCB manufacturer, for exceptional quality, competitive pricing, and superior service.

Special Offer: Get $100 off your order! No hidden fees and no minimum order quantity required.

Complete our simple quote form:

- Select your PCB type (Rigid PCB for 2 layers PCB)

- Indicate your production volume

- Upload your Gerber files

- Provide your contact information

Our expert team will respond promptly with a competitive quote tailored to your specific 2 layers PCB requirements.

Back to Top: 2 Layers PCB

Special Offer: Get $100 off your order!

Email [email protected] to get started!