What is a 22-gauge wire used for? Let’s find out!

Whether using the American Wire Gauge (AWG) or Standard Wire Gauge (SWG) system, you should know that the wire diameter reduces as the gauge size increases.

Since these gauges can go up to 40, 22-gauge wire is in the lower range, making it among the thinnest cables for electrical applications.

So, read on to learn more about the uses of 22-gauge wires.

Contents

- What Is 22-Gauge Wire?

- What Is 22-Gauge Wire Used For?

- Can I Use 22-gauge Wires for Doorbells?

- What Is the Current-Carrying Capacity of 22-Gauge Wires?

- Is 22-gauge Wire Mechanically Sturdy?

- What Is the Difference Between 20-gauge and 22-gauge Wire?

- What Is the Difference Between 22-gauge and 24-gauge Wire?

- Is a Bigger Wire Better? How Do I Know What Gauge Wire to Use?

- Wrap Up

What Is 22-Gauge Wire?

Wire gauge refers to the electrical conductor’s size along its cross section or diameter. According to the AWG standard, 22-gauge wire has a diameter of 0.0253 inches or 0.6426mm.

This diameter is slightly broader than when using the SWG, which is 0.028 inches or 0.7112mm. Most people use the AWG standard, so we’ll ignore the SWG size.

Gauge or diameter sizes determine the wire’s electrical properties, such as the current carrying capacity, resistance, and signal frequency.

The material of the conductor also matters, so let’s consider the most typical one, which is copper.

A 22-gauge copper wire has the following electrical properties.

- Resistance per 1000 feet: 16.14 ohms

- Resistance per kilometer: 52.9392 ohms

- Maximum current carrying capacity: 0.92 amps

- Maximum frequency for 100% skin depth: 42 kHz

Since the cable is thin, it usually comes as a solid-core wire. It is uncommon to find small-diameter wires with stranded variations.

What Is 22-Gauge Wire Used For?

Thin electrical conductors have limited applications due to their high resistance.

But manufacturers produce them for a reason. Their typical applications include wiring in radio intercoms, walkie-talkies, tiny home security cameras, and alarm systems.

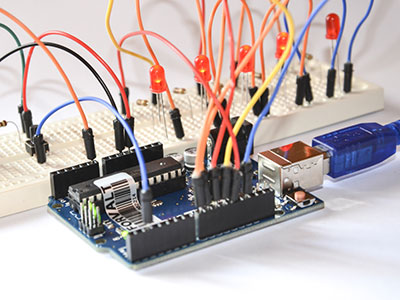

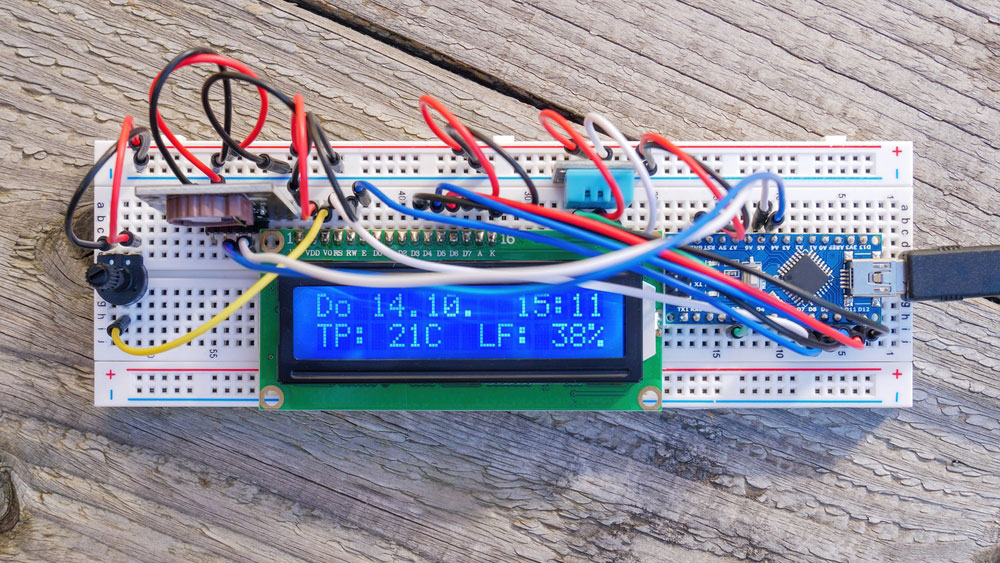

If you are into electronics and prototyping, you can use 22-gauge wires to connect components mounted in breadboards or PCBs (jumper wires).

A breadboard electronics project with jumper wires mounted in the socket holes

The most significant disadvantage of these tiny wires is the length factor.

If you use a long 22-gauge wire, its current carrying capacity will reduce drastically due to the high resistance. So you can’t use this cable in lengthy applications.

They are perfect for short connections in battery-powered devices.

Home alarm systems use AC, but the system doesn’t require a lot of power.

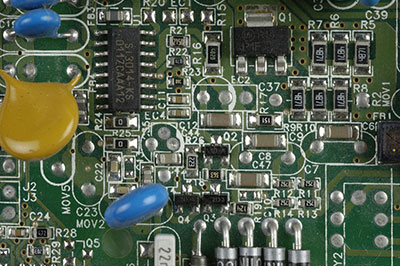

Plus, the 22-gauge wire only links devices for communication or sending signals between them.

For instance, if the sensor is on the door or window, it can send the signal to the control panel using a 22-gauge wire.

This panel then uses thicker wires to power the speakers to notify the entire neighborhood of the intrusion.

A home security system’s control panel

So, the keyword here is low-power or signal connections. You can use this wire to make electrical connections, so long as they don’t cover long distances.

You can use 22-gauge wire for traditional or sculpted wire jewelry if not for electrical wiring.

This jewelry-making wire is suitable for the following applications.

- Stringing glass beads

- Crafting ear wires

- Creating small stone frames and settings

- Larger coiling projects

- Interweaving intricate designs

Can I Use 22-gauge Wires for Doorbells?

Yes and no. It depends on the doorbell size. Most regular doorbells are low-voltage devices capable of running 22-gauge wires without overheating the conductor.

But high-end doorbells might have higher power requirements that can burn the wire.

So, check the doorbell’s electrical current rating before using the wire. But we recommend using an 18-gauge wire to be on the safe side.

These cable thicknesses can run power from the transformer to the button and the bell without issues.

And they will not require rewiring if you upgrade to a better doorbell.

Additionally, the wire is sturdy enough to handle stresses during and post-installation without breaking.

An advanced doorbell system with voice communication

What Is the Current-Carrying Capacity of 22-Gauge Wires?

As stated earlier, a 22-gauge wire can handle a maximum of 0.92 amps without overheating.

But it can transmit up to 7 amps, albeit with an overheating core.

When carrying this current, the copper conductor will hit 75°C.

However, this operation is impractical because these wires have PVC sheaths, and the insulation material temperature rating is 60°C.

So, the outer jacket will melt and disintegrate when you try to transmit such high current levels in the line.

Multiple solid-core wires with multicolored insulations

But the thin solid copper wire will not self-destruct because it has a melting point of over 1,000°C.

However, when exposed and hot, copper will oxidize quickly to become less conductive. Plus, it can be destructive by causing electrical shock or fires.

So, keep the temperatures low by using the wire only for transmitting low electrical current levels not exceeding 0.92 amps.

Special Offer: Get $100 off your order!

Email [email protected] to get started!

Is 22-gauge Wire Mechanically Sturdy?

Wire gauge primarily affects a cable’s electrical properties.

Since wires are not weight carriers, their mechanical strength is a secondary factor to consider.

As stated earlier, wire gauge refers to the conductor’s diameter. So, the thicker it is, the sturdier the wire.

The 22-gauge wire, being thin, is more likely to break or crush when under pressure.

Also, it is more brittle than the thicker copper wires, meaning it will get cut when bent several times.

22-gauge cables are not ideal for vehicle wiring applications because they are solid-core conductors.

The best conductors to use in car wire harnesses are the stranded types because they are flexible and can withstand movements as the car moves. When sourcing automotive wiring solutions, partnering with the best automotive wire harness manufacturers ensures you get stranded-core cables designed specifically for vehicular applications.

Solid core wires can break easily under these stresses.

Even the thin car speaker wires are an 18-gauge size with stranded cores. So, 22-gauge cables are not mechanically sturdy.

A car audio speaker with two wires

What Is the Difference Between 20-gauge and 22-gauge Wire?

Although the difference between 20-gauge and 22-gauge wires is tiny, it plays a significant role in defining the conductor’s capabilities.

The former has a diameter of 0.0319 inches or 0.8128mm, making it a medium wire.

But the latter measures 0.0253 inches or 0.6426mm in diameter, classifying it as a medium-fine wire.

An ounce of 20-gauge wire will be 19 feet long, while an ounce of 22-gauge wire will stretch for 31 feet.

For jewelry applications, the medium wire is ideal for wire sculpting and making wire jewelry using jigs.

You can also use the wire to make lightweight clasps and heavy-duty ear wires.

And using the wire gauge when dead soft is better because it is harder to bend when half-hard.

A handmade jig for making ear wires

On the other hand, the medium-fine wire is versatile enough to fit most beads, such as stone and crystal.

So you can use it to make rosary-style wrapped links, headpins, and ear wires.

And you can make these items using 22-gauge dead-soft or half-hard wire.

What Is the Difference Between 22-gauge and 24-gauge Wire?

We’ve already looked at the properties of the 22-gauge wire above, and the 24-gauge type is a thinner wire (0.0201 inches/0.5105mm).

A 24-gauge cable falls in the fine wire category, and it is better to use it when half-hard.

This state makes the wire sturdier to use in jewelry making without snapping.

You can use it to make rosary-style beaded links, provided the beads have tiny holes, like pearls.

A cross rosary

An ounce of 24-gauge wire can stretch to 48 feet, more than 10 feet longer than its 22-gauge counterpart.

Is a Bigger Wire Better? How Do I Know What Gauge Wire to Use?

Bigger wires are always better because they have a higher current-carrying capacity.

Therefore, your circuit will not have voltage drops or overheating wires if the load is higher than what the conductor can carry.

But there are some downsides. First, bigger wires are more expensive, meaning the project cost will be higher.

Second, they are heavier, making them burdens for weight-sensitive applications.

So you should determine the maximum current the circuit requires for transmission, then get a matching wire gauge by checking their ampacity charts or ratings.

Wrap Up

22-gauge wire has limited electrical applications due to its thin structure and high resistance, but it is ideal for making the joining structure in jewelry.

So consider it for traditional wire jewelry designs.

You can also use it for specific electrical applications, but be cautious about the electrical ratings of the devices because the wire has high resistance.

Contact us if you need help determining if a 22-gauge wire is ideal for your project. We’ll be happy to help.

Special Offer: Get $100 off your order!

Email [email protected] to get started!