Most people require electronics to function under damp and humid conditions. Consequently, they must be secure against moisture and corrosion. As such, the first step is to ensure that the core of their circuitry is water-resistant. This situation is where waterproof PCBs come in. The following guide will examine what they are, their importance, their applications, and how PCB manufacturers produce them.

Contents

- What is a Waterproof PCB?

- Why Do You Need To Waterproof Electronics?

- Application Fields of Waterproof Circuit Boards

- Benefits of Waterproof PCBs

- The Limitations of Waterproof PCBs

- PCB Waterproof Methods

- Structural Waterproofing

- Potting

- Surface Coating (Applying Three-Proof Paint)

- Conformal Coating

- PCB Waterproofing Materials and Compounds

- Types of Potting Compounds

- Types of Conformal Coating Epoxyials

- Types of Surface Coating Materials

- How To Waterproof Your PCB

- Clean and Prepare the Surface

- Apply the Coating/Sealant

- Test for Waterproofing

- Do a Final Inspection

- DIY Waterproofing Methods at Home

- Use Clear Nail Varnish

- Use Special PCB Varnish

- Use Clear Silicone Adhesive (705)

- Use UV UV-curable Solder Mask

- How To Test a Waterproof PCB

- How to Remove the Conformal Coating of a Waterproof PCB

- How Temperature Changes Influence Waterproof PCBs

- Waterproofing Considerations

- Can You Customize Waterproof PCBs?

- FAQs

- Can you put a circuit board in water?

- What level of waterproofing do I need?

- Are waterproofing electronics expensive?

- Do waterproof coatings insulate against electricity?

- Conclusion

What is a Waterproof PCB?

Green printed circuit board.

Green printed circuit board.

A waterproof printed circuit board is a special PCB (or PCBA) whose functionality is not impeded by liquids. Essentially, they offer complete protection against water ingress.

These types of PCBs tend to have an IP rating of IP68+. Thus, they often provide further protection against dust and other impurities.

Truthfully, most commercial PCBs have a waterproof substrate. PCB components are often left vulnerable to liquid exposure.

Contrastingly, the entirety of a Waterproof PCB’s structure is liquid-resistant.

Why Do You Need To Waterproof Electronics?

The primary reason is to prevent breakdown caused by exposure to moisture.

Devices like smartphones and smartwatches have become part of us, meaning we have to be with them when doing our daily tasks like swimming or even running in the rain when going to our car, bus, or train.

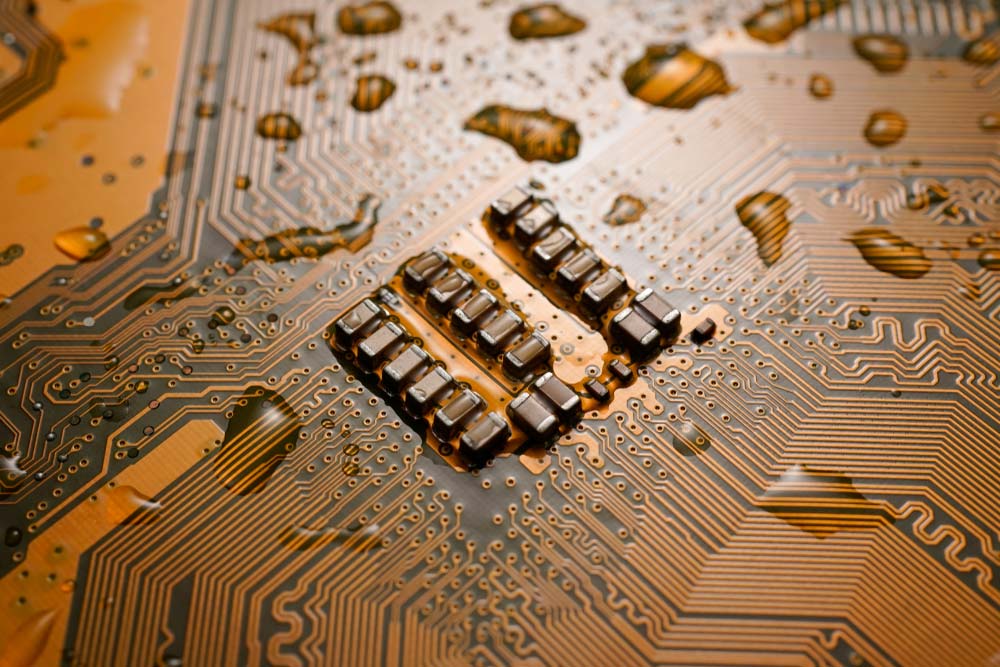

A waterproof PCB

Application Fields of Waterproof Circuit Boards

Circuit board waterproofing is most common in consumer electronics like smartphones, wearable devices, and other portable gadgets like tablets.

But you can also find this technology in medical devices like pacemakers and implantable cardioverter defibrillators because the PCBs are exposed to bodily fluids.

Aerospace, military, automotive, industrial, exterior lighting, security systems, and power supply systems require PCB waterproofing, as well, to resist the elements.

Benefits of Waterproof PCBs

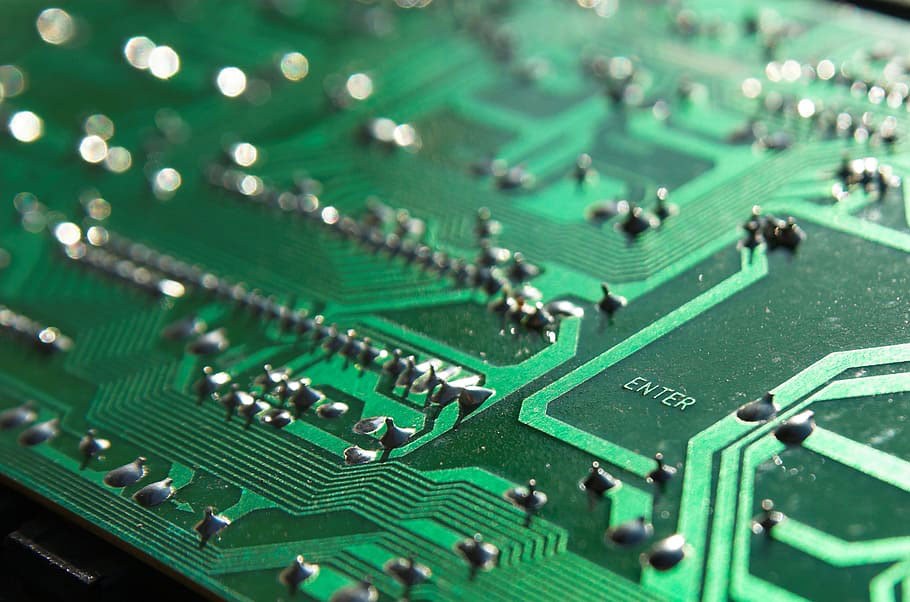

The back of a green PCB

The back of a green PCB

Source: Piqsels

Some of the critical benefits of Waterproof PCBAs include:

- High durability: Waterproof PCBs can tolerate excessive amounts of water and dust. They have protection against oxidation and corrosion.

- A more comprehensive range of use: Portable applications such as your cellphone or smartphone in harsher weather environments.

- Longer lifespan: Because of more stringent quality checks and waterproofing, these types of PCBs tend to last longer than standard PCBs

- Excellent functionality: Waterproof PCBs tend to be high-precision boards with high transfer rates. Thus, they must have consistent functionality regardless of the weather conditions. Again, they require additional testing to ensure their quality and functionality.

The Limitations of Waterproof PCBs

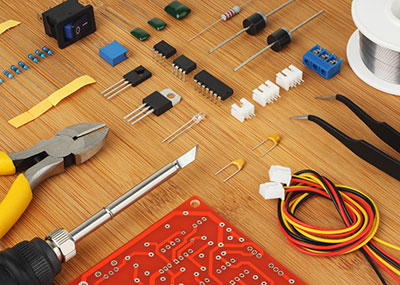

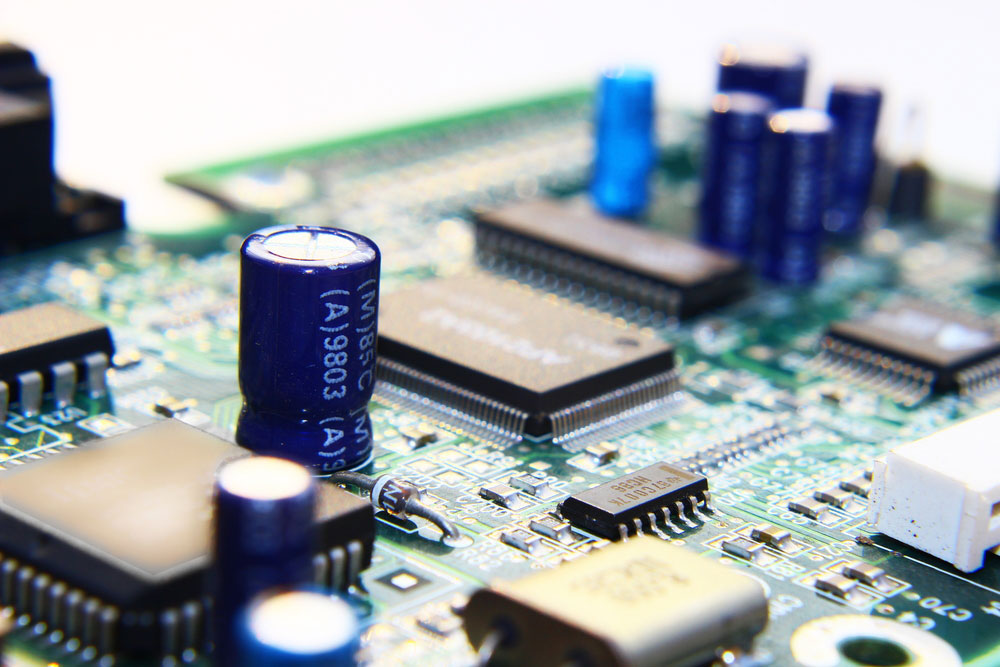

PCB with various electronic components

PCB with various electronic components

Some significant limitations of waterproof PCBs include:

- They are more expensive to manufacture and purchase.

- Waterproof PCBs require more time to produce. This factor is mainly due to the application of conformal and resin coatings. Additionally, they require stringent testing.

PCB Waterproof Methods

Electronics engineer designing a concept on a laptop with an image of a PCB behind him

Electronics engineer designing a concept on a laptop with an image of a PCB behind him

There are quite a few ways to waterproof PCBs. This section will explore some of the most popular and highlight their advantages and disadvantages.

Structural Waterproofing

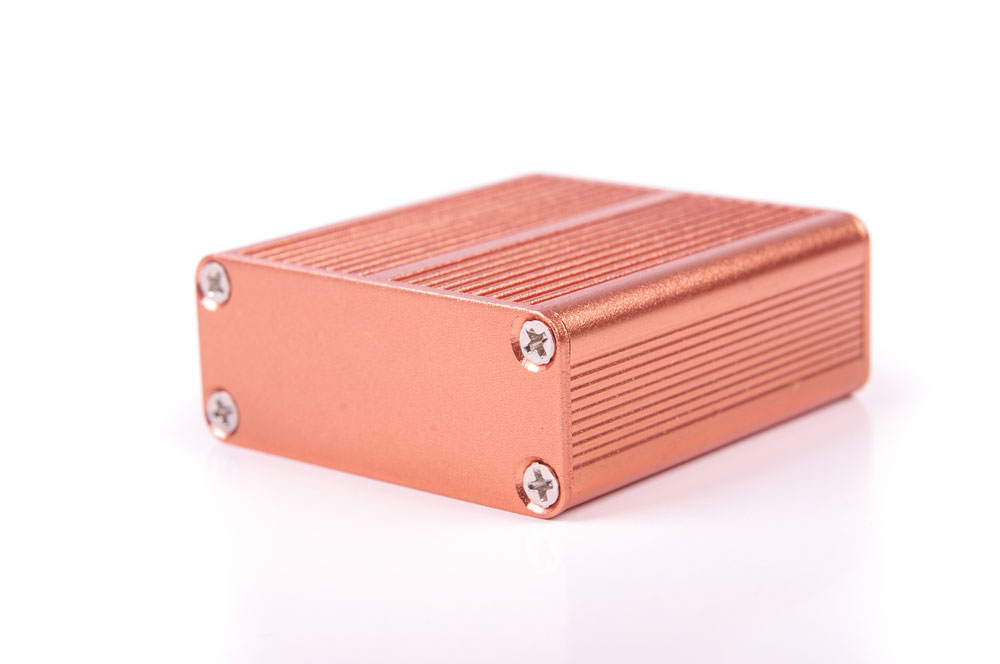

PCB Enclosure

PCB Enclosure

You should note that this method does not involve applying coating materials or chemicals to the PCB.

Instead, it would be best if you surrounded the circuit board with a waterproof casing.

You may also refer to this method as gasketing or shielding. This method may be preferable to most companies and engineers because it is a less invasive waterproofing method.

Additionally, most people consider it safer because there is little risk of damage to the PCB during the waterproofing process.

Pros

- Provide PCB with adequate waterproofing.

- Easy to implement

- Slight risk of damage to the PCB

Cons

- Expensive

- It may not always be effective under pressure or in situations heavy with moisture.

Potting

Generally, potting involves applying a protective layer to the PCB by drenching it in a water-resistant compound. However we use potting in waterproofing, but we also use it in high-voltage PCB design. Nevertheless, it involves surrounding the PCB’s body with an encapsulation resin (AKA potting compound). We can also limit potting to individual components. Unlike structural waterproofing, potting is more intrusive because you add a layer to the PCB. As such, it may interfere with the functionality of the PCB or disrupt its structural integrity.

Pros

- Strong protection against moisture

- Excellent protection against weather

- Offers above-average protection against dust, salt, and dirt

- Offers shock resistance

Cons

- Expensive

- Requires great skill and attention to detail to apply effectively

- It makes PCBs harder to repair

Surface Coating (Applying Three-Proof Paint)

This method is most suitable for people attempting to DIY waterproof their PCBs. It involves applying a protective oil called three-proof paint using a paintbrush. It is the least expensive method of PCB waterproofing.

While three-proof oil cannot protect your PCB against considerable amounts of wetness, it can effectively protect against spills, light dampness, and atmospheric moisture. However, it fails if we completely submerge the PCB in water for a considerable period.

Pros

- Cost-effective

- You can apply it at home

- Easy to apply

Cons

- Offers the least adequate water protection

- It is not environmentally friendly.

Conformal Coating

Airless spray gun that we may use in some forms of conformal coating

Airless spray gun that we may use in some forms of conformal coating

Conformal coating involves spraying the PCB with a waterproofing agent. We use some of the same compounds (Epoxy, silicone, urethane, etc.) in potting that we employ in conformal coating. While potting involves submerging the PCB in the potting mix, the conformal coating requires you to spray it on. You can perform spraying in one of three ways:

- Manually: This involves using a handheld spray gun or aerosol can to apply the coating. You cannot ensure an even layer when a human operator applies it. It may be preferable for DIY situations but unsuitable for large productions.

- Automated: This involves applying coating through a programmable machine. A machine or operator places the PCB on a conveyor belt, which runs the PCB through multiple spray heads. This process ensures more consistent spraying than manual sprEpoxy. Thus, it is more suitable for companies running large productions.

- Selective coating: This type of automated spraying where a machine will only spray conformal coating to specific parts of circuit boards. Additionally, the device may have a built-in UV lamp that dries and cures the layer as soon as the spray nozzle is applied.

Curing Methods for Conformal Coatings

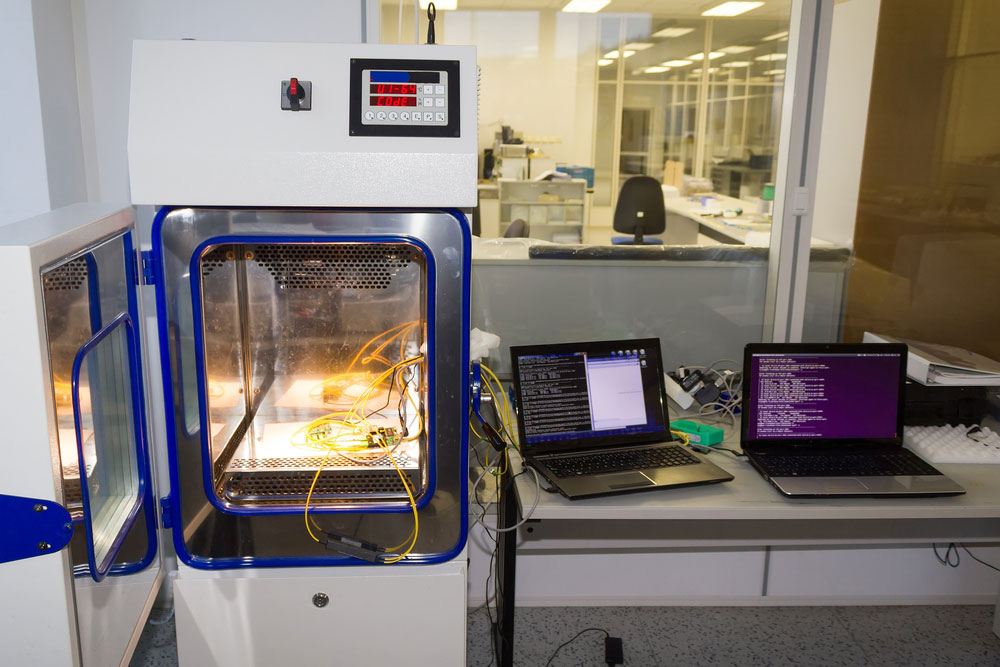

PCB-based devices being tested in an open temperature and climate test chamber

PCB-based devices being tested in an open temperature and climate test chamber

- Using solventless UV conformal coating involves applying a special conformal coating that quickly cures under UV light. Most companies prefer it because of its high production speed. However, you should note that UV coatings are harder to remove, repair, and rework. They are also difficult to apply manually. Nevertheless, they tend to offer excellent heat and cold resistance. Furthermore, they are environmentally friendly. However, UV conformal coatings often require a secondary curing process, such as heat.

- Heat: We can cure some conformal coatings by applying heat.

- Oxidative Cure: Some conformal coatings allow us to cure them using atmospheric oxygen. It means we can let the layer heal on its own or put it in an oxygen-rich chamber in most cases. Most oxidative cure coatings are solvent-based. As such, the drying process occurs before the curing process.

- Catalytic Cure: In this process, we add a chemical compound to the conformal coating. This process causes a chemical reaction in the initial mixture, causing it to harden and cure. Once we initiate this process, we cannot stop it.

- Dual-Cure System: A dual-cure system involves two (or more) curing methods. For instance, we can apply UV light and heating to a conformal coating.

- Condensation cure: Like oxidative curing, we can cure with conformal coatings by introducing moisture. How fast the compound cures is dependent on the amount of ambient humidity.

Pros:

- Multiple conformal compounds are available

- Easy to apply (depending on the method)

- Adequate protection against chemicals, dirt, and high temperatures

Cons:

- Ineffective against considerable amounts of moisture

PCB Waterproofing Materials and Compounds

Epoxy resin solution

Epoxy resin solution

Source: Wikimedia Commons

This guide section will explore common compounds and materials for waterproofing PCBAs.

Types of Potting Compounds

Epoxy

Two hands combining Epoxy to create an adhesive.

Two hands combining Epoxy to create an adhesive.

Even though we use Epoxy in potting, we can combine it with structural waterproofing. However, Epoxy can be expensive.

It is a saturated resin, which means its carbon chain consists of one bond. Nevertheless, it has excellent adhesion and renders priming unnecessary.

Additionally, it has high-temperature repulsion (maximum 205°c) and offers resistance to extreme weather conditions.

It’s also compatible with a wide variety of substrate types.

Urethane

Using urethane as a potting compound is advantageous because of its flexibility, abrasiveness resistance, and extensibility.

They can have a glass transition rating lower than -40°C and are highly suitable for SMT PCB potting.

You can increase their gelation period using an acceleratoEpoxyhout, affecting their quality.

Silicone

Epoxy one is one of the most popular potting alternatives because of its costEpoxyctiveness. Compared to Epoxy, it’s soft, pliable, and has better extensibility.

However, it may not perform well under high temperatures and compete against Epoxy’s adhesion rates.

Nevertheless, it has the broadest array of operating temperatures. Special silicone potting compounds can work under temperatures below -100 and just above 200°C.

Acrylic

Acrylic may be famous for being a compound that people use in paint. However, we also use acrylic resin in potting mixes. What makes acrylic unique is its fast drying and hardening.

You can use ultraviolet light (UV) or heat to dry and solidify it. Acrylic resin is transparent in appearance.

It can also provide you with moderate chemical resistance and adequate protection against moisture.

Types of Conformal Coating Epoxyials

Man applying urethane to a board through a spray nozzle.

Man applying urethane to a board through a spray nozzle.

We can use some potting materials in conformal coating. In addition to thEpoxy’serials, we may also use:

Para-xylylene

Para-xylylene provides a skinny coating. It can be a little challenging to apply and is often quite expensive. Additionally, its moisture protection is inadequate. However, you may use it for protection against erosion or dirt.

Fluoropolymer

Fluoropolymer is a compound that we use for nano-coating. It’s an excellent alternative to para-xylylene because it costs less while offering the same protection standard. Again, fluoropolymer provides minimal protection against moisture.

Types of Surface Coating Materials

Three-proof paint

Three-proof paint is a type of chemical agent-resistant coating. We may also refer to it as protective oil, waterproof glue, coating oil, insulating paint, or moisture-proof paint.

Water resistance isn't its only purpose as with the other materials in this guide. It can guard against low and high temperatures, erosion, shock, and dirt.

Three-proof paint is a thick liquid that takes considerable time to dry. Effectively, it may take up to 2 hours to dry completely.

Special Offer: Get $100 off your order!

Email [email protected] to get started!

How To Waterproof Your PCB

This process only requires four steps.

Clean and Prepare the Surface

Clean the PCB using isopropyl alcohol to remove contaminants like dirt and oil that might have accumulated on the surface. You can also use a general-purpose cleaner, but we recommend isopropyl alcohol, then dry the surface using a lint-free cloth.

A bottle of 91% isopropyl alcohol

Apply the Coating/Sealant

Apply the waterproof sealant on the clean and dry PCB surface, and you can use either a conformal coating, encapsulant, potting compound or any other sealant of your choice that is most suitable for the application.

Test for Waterproofing

Give the sealant some time to dry, then test its integrity by immersing the board in water.

The alternative is to use a pressure washer or rainfall simulation. If you detect any water retention or wetting on the PCB components, the seal requires reworking.

A waterproof circuit board with a black coating

Do a Final Inspection

Rework the seal (if necessary), then do a final visual check to determine if everything looks good before putting the PCB into use.

DIY Waterproofing Methods at Home

If you’re building a PCB at home and want to waterproof it or one you ordered from your fab house, you can use either of these four options to get the job done.

Use Clear Nail Varnish

This product is cheap and readily available in the market, and most DIYers use it to keep dust and moisture away from the PCB.

However, it hardens quickly and is extremely tough, which means there’s no going back once you apply it. So, you must test the circuit before applying the varnish because you won’t be able to access it.

Also, nail varnish doesn’t do well at high temperatures. The hardened layer can peel off if the PCB components get hot.

Use Special PCB Varnish

This varnish is a spray coat that hardens to form a flexible, transparent layer. This flexibility helps to prevent cracking. And since it is a PCB varnish, it is built for the task; it can withstand high temperatures, and you can solder through it. The material melts at the soldering point to give you access to the pad or component inside.

Use Clear Silicone Adhesive (705)

The 705 clear silicone adhesive is specifically suited for electronics applications because it can withstand high temperatures. It is non-conductive, solvent-free, and non-toxic.

A silicone glue gun dispensing clear silicone adhesive

Use UV UV-curable Solder Mask

Solder mask traditionally protects the copper traces from oxidation, which means it can withstand high temperatures and has high adhesion. UV curable solder mask requires a UV flashlight to harden, so apply the coat, then shine this light above it for about 30 seconds.

However, this material can only form a thin protection layer because it has a low viscosity. It also works best on flat surfaces because it needs a place to rest when hardening.

How To Test a Waterproof PCB

A hose drenching a set of PCBs in water

A hose drenching a set of PCBs in water

There are two methods you can use to test waterproof PCBs

- Using another compound: You can test the application of conformal coatings by applying a different mix to them. For instance, you can either use Epoxy on a non-epoxy conformal coating. If you have coated the PCB evenly, the mixture will not stick to it.

- Using an alcohol spray: We use this method to test for liquid conformal coatings. If droplets begin to form after applying the alcohol spray, your waterproof PCB uses a liquid-based conformal coating.

- Using Manual or Automatic Inspection: An inspector can manually verify the waterproof coating utilizing a lamp. Or we can use an automated scanner or optical device.

The only other way to test for effective waterproofing is to subject the PCB to moisture. This method can be risky. Thus, we suggest that you only try prototype PCBs this way.

Engineer testing a PCB

Engineer testing a PCB

How to Remove the Conformal Coating of a Waterproof PCB

You might want to remove the conformal coating from EpoxyPCB so you can fix or rework it. You can use the following methods to achieve this:

- Using Solvent: Solvents such as acetone compounds can remove waterproof coatings that are susceptible to them.

- Peeling: A complicated process where an operator will manually peel the coating off the PCB. Generally, peeling only works for hard silicone coatings.

- Applying concentrated heat: We can remove most conformal coatings by using heat. However, this method may cause damage to the PCB and its electronic components.

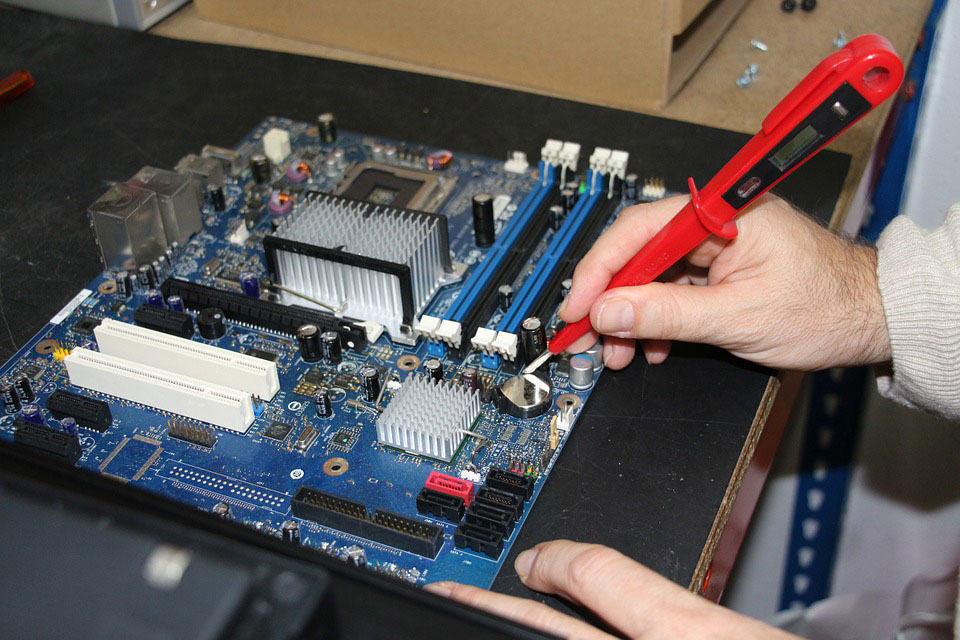

Oven machine applying heat to PCB

Oven machine applying heat to PCB

- Micro-blasting: Operators employ a spray containing a combination of compressed air and a soft abrasive to dislodge the coating from the PCB. This method is most effective against Epoxy and Parylene resins.

- Grinding (AKA Scraping): This method may risk damage to the PCB. It involves manually scraping coating from the PCB. It’s most effective against Epoxy, Parylene, and Polyurethane. However, grinding is risky because it may damage the PCB.

How Temperature Changes Influence Waterproof PCBs

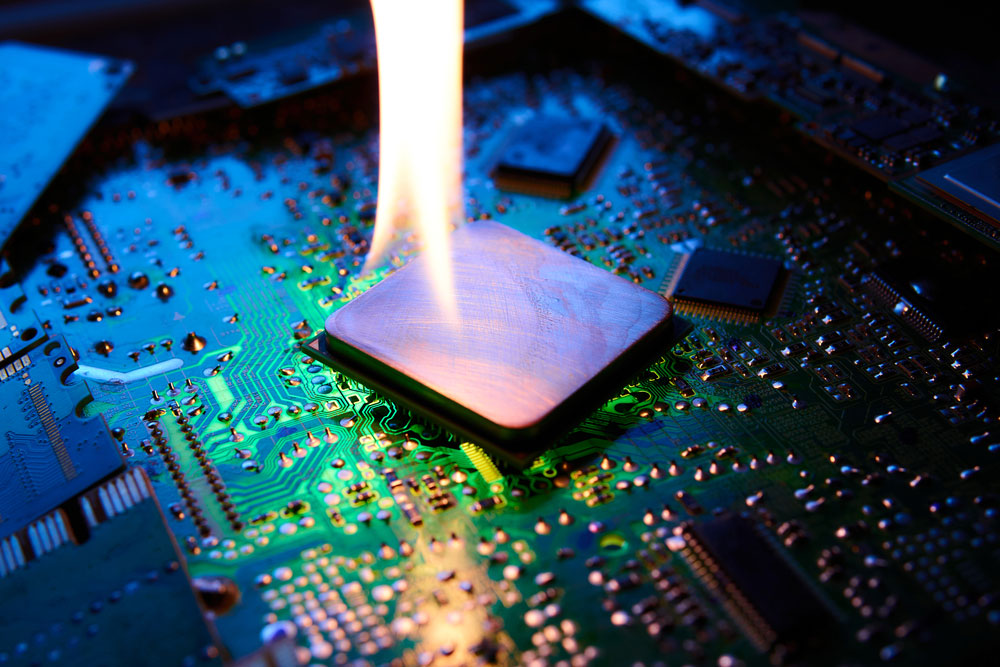

A PCB with a processor that is one fire

A PCB with a processor that is one fire

As evidenced in this guide, a suitable waterproofing compound can withstand extreme temperatures.

However, most of them have certain thresholds.

Effectively, if we subject waterproof PCBs to temperatures above (or far below) these thresholds, the PCB may suffer certain damages.

For instance, excessive heat or cold may damage the waterproof coating.

Additionally, the PCB’s core structure may lose some dielectric properties, causing it to malfunction.

Furthermore, it may incur damages to its solder joints. Thus, we must ensure that the PCB doesn’t get too hot or cold.

Waterproofing Considerations

- Waterproofing creates a seal that traps heat, so you have to reconfigure the board’s thermal design.

- Manual potting and coating control the application process better than automated spraying.

- High-density potting compounds weigh down the PCB; consider the lighter conformal coatings.

- Reworking waterproofed boards can be labor-intensive because you have to remove the coat and then reapply it.

- Leave access to programming ports or trace contacts when waterproofing.

- Apply an extra coating on tiny connector openings or test points after use.

- Check the component sheets to ensure the waterproofing is in their specified range.

An orange waterproofed circuit board

Can You Customize Waterproof PCBs?

Design Engineers designing a PCB using CAD software.

Design Engineers designing a PCB using CAD software.

.

We can customize most waterproof PCBs during the manufacturing phase.

However, once we apply the waterproof coating, it is nigh impossible to alter the PCB’s design unless you’re using structural waterproofing to remove the encasing without damaging it.

FAQs

Can you put a circuit board in water?

Yes, you can. But will it survive? If it is waterproofed, the answer is yes. But if not, the board will experience corrosion, especially on the metal surfaces.

Water also contains dissolved ions that can conduct electricity and short parts of the PCB.

What level of waterproofing do I need?

It depends on the application and the features you want on your device.

For instance, aerospace, military, and medical devices should have the highest waterproof rating because they must be highly reliable.

But you can have a higher waterproofing level on a smartphone to sell as a feature.

Are waterproofing electronics expensive?

Yes, they are. But it can pay for itself over time because you won’t have to worry about PCB repairs or parts replacements regularly due to exposure to moisture.

Do waterproof coatings insulate against electricity?

Yes. But potting, to be specific, is better at protecting the board against electrical arcs, which makes the method ideal for high-voltage electrical devices.

But PCBs usually handle low voltage circuits, so all waterproof coatings can insulate against the electricity flowing through them.

Conclusion

Waterproofing your PCB can be expensive. However, it’s necessary for situations where you’re building a device that will function under humid or moist conditions.

Furthermore, it’s essential to acknowledge that most waterproofing techniques have multiple purposes.

For instance, specific methods will protect your PCB from shock, weather conditions, dust, dirt, grime, etc.

So even if you’re not planning to use your PCB under damp conditions, potting or adding a conformal coating can be highly beneficial for you.

Nevertheless, we hope you’ve enjoyed reading this guide and found it helpful. As always, thank you for reading.

Special Offer: Get $100 off your order!

Email [email protected] to get started!