Whichever form of solder you use (wire or paste solder), the material turns to liquid at a specific solder melting temperature. The primary factor that determines this melting point is the material's composition. We will look at these different solder compositions and the temperatures at which they melt to determine their most suitable applications. Read on to learn more!

Contents

Special Offer: Get $100 off your order!

Email [email protected] to get started!

What Is Solder?

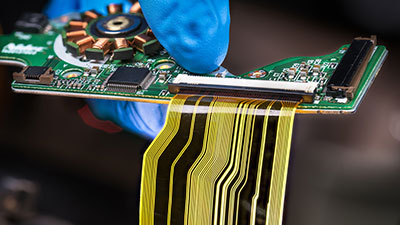

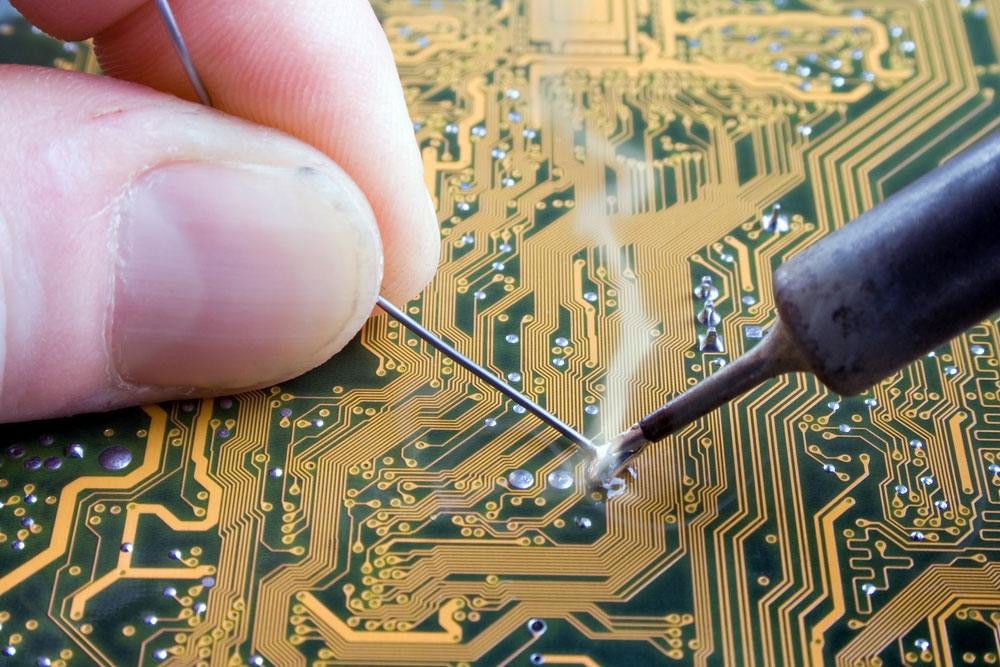

Solder is a metal alloy, primarily composed of lead and tin, used to join electronic components to circuit boards. Its melting temperature determines its suitability for different electronics applications.

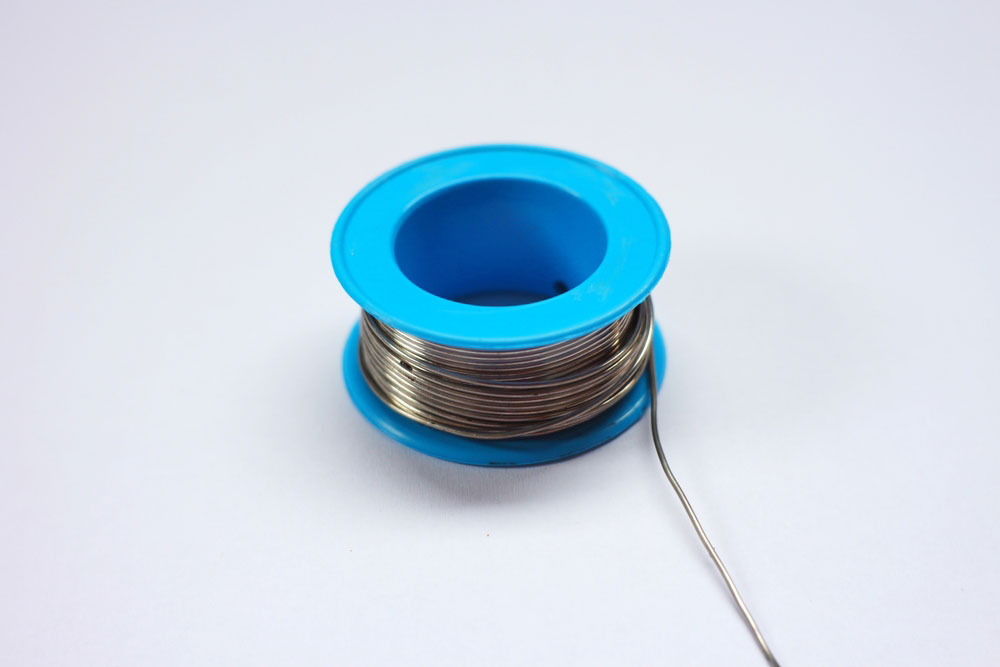

A solder wire coil

For example, sensitive components require low-temperature solder to prevent heat damage, while parts exposed to high temperatures need solder with a higher melting point to avoid melting during operation.

An automated high-precision solder-paste printer

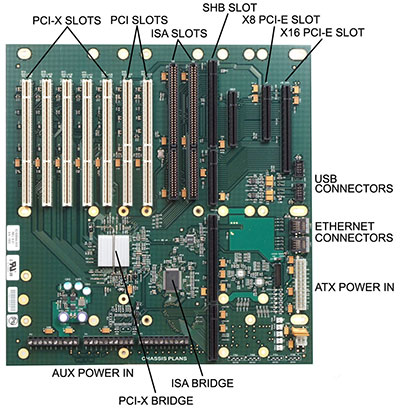

What Are the Different Categories of Solder?

Although there are different types of solder alloys, they fall into these two classifications.

Eutectic Solder

This solder type melts at a single temperature, and some manufacturing/ welding processes need this property because the material melts easily. Similarly, eutectic solder turns into a solid at a single temperature.

Non-Eutectic Solder

Non-eutectic solder does not melt at a single temperature; it has a melting range and begins turning into liquid at a specific temperature. The alloy continues melting and completely turns into a liquid when it reaches the higher end of the melting range.

A soldering iron scooping pickling paste

What Temperature does Solder Melt?

Here is a summary of the soldering temperature or melting point of typical solder alloys.

| Alloy | Melt Range | Peak Reflow |

| Tin (63%), Lead (37%) | 183°C | 210-220°C |

| Tin (48%), Indium (52%) | 118°C | 140-150°C |

| Tin (42%), Bismuth (58%) | 138°C | 160-170°C |

| Tin (42%), Bismuth (57%), Silver (1%) | 138-140°C | 160-170°C |

| Tin (89%), Silver (3%), Bismuth (0.5%), Indium (8%) | 200-205°C | 220-230°C |

| SAC305 - Tin (96.5%), Silver (3%), Copper (0.5%) | 217-221°C | 240-250°C |

| SN100C - Tin (99.3%), Copper (0.7%), Nickel (0.05%), Germanium (0.005%) | 227°C | 245-255°C |

| Tin (88%), Silver (3%), Bismuth (0.5%), Copper (0.4%), Indium (8%) | 197-202°C | 215-225°C |

Manufacturers usually use Bismuth and Indium to lower the solder melting point, so the common low melting temperature solders (150-170°C) include tin-indium, tin-bismuth, and tin-bismuth-silver.Also, Lead-free solders, such as tin-bismuth (58%) and tin-indium (52%), have lower melting points than Lead-based solders, like the tin-lead (37%) alloy. So consider using Lead-free solders, such as tin-bismuth-silver, to bond heat-sensitive components to PCBs due to their low peak-reflow temperatures.

Lead-free solder

High Temperature vs. Low-Temperature Solder

We'll leave Silver out of this comparison because it raises the wire solder temperatures to high levels that might be unsuitable for PCB assembly.

High-Temperature Solder

Pure Lead melts at 621°F/327°C, while pure Tin turns to liquid at 450°F/232°C. So increasing the Lead concentration raises the melting point. For instance, a Tin(10%)-Lead(88%)-Silver(2%) metal alloy turns into molten solder at 299°C (570°F).

A soldering iron with a Silver solder

Such solder alloys are ideal for welding components that operate in hot environments, like automotive, aviation, oil & gas extraction, etc.But you might have noticed that all soldiers contain some percentage of Tin. Although expensive, Tin has the advantage of having better wetting properties than Lead. So most manufacturers make Tin-based solders to give better bonding.

Low-Temperature Solder

Low-temperature solders contain higher tin concentrations mixed with other metals like Cadmium, Bismuth, and Indium. These materials have a melting temperature ranging from 47°C (117°F) to 160°C (320°F) and are suitable for the following soldering process applications.

- Mounting components on flexible PCBs

- Step or second-side PCB soldering to avoid disturbing standard lead-free solder joints or removing soldered components.

- Assembling heat-sensitive components

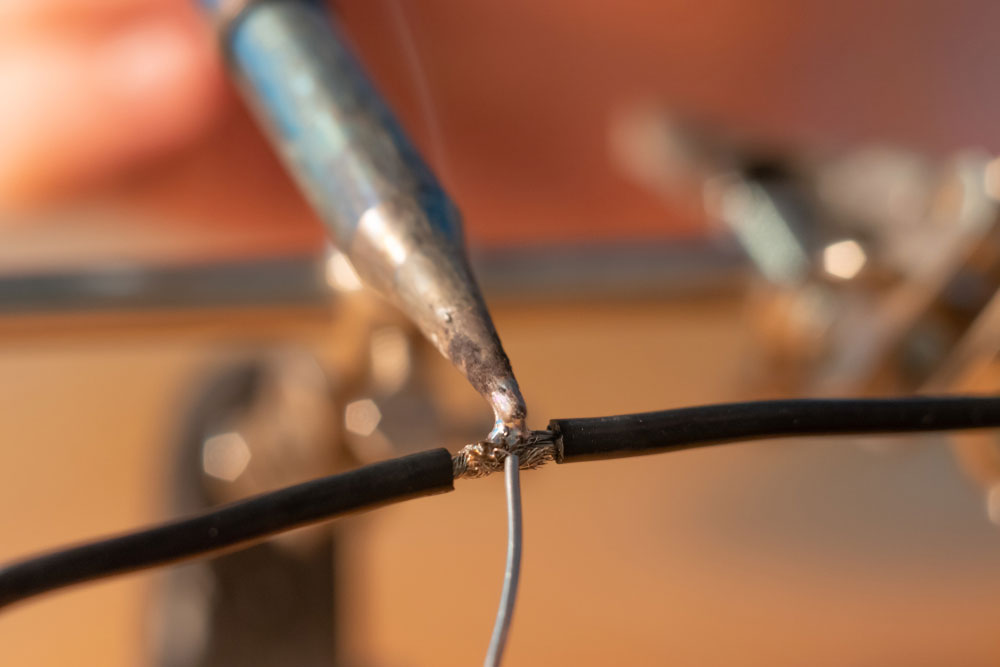

A technician soldering an electronic PCB

Low-temperature soldering also minimizes thermal energy requirements, which reduces power consumption and lengthens equipment lifespan.

Solder Blends

Solder consists of three primary materials: Tin, Lead, and flux. But from the table above, you will notice other additives or metals like Copper, Silver, and Nickel. These materials diversify the solder's properties in the following ways.

- Antimony: Enhances the solder's mechanical strength.

- Copper: Improves the solder-wetting characteristics while reducing the melting point

- Silver: Increases the alloy's mechanical strength but is not as pliable as Lead

- Nickel: Prevents the dissolution of the UBM (Under Bump Metalization layer)

Other Factors To Consider When Choosing Solder

Besides composition (which determines the melting temperature), consider these two factors before buying wire solder.

Solder Wire Diameter

Electronics wire solder usually has a diameter ranging from 0.5-1.5mm (some are even narrower than 0.5mm). Always match this diameter to the contact and connector size you want to solder.If the wire is too broad, you'll have a difficult time trying to maneuver around components on a dense PCB. This difficulty will increase the chances of thermal stressing or welding parts that don't require soldering.

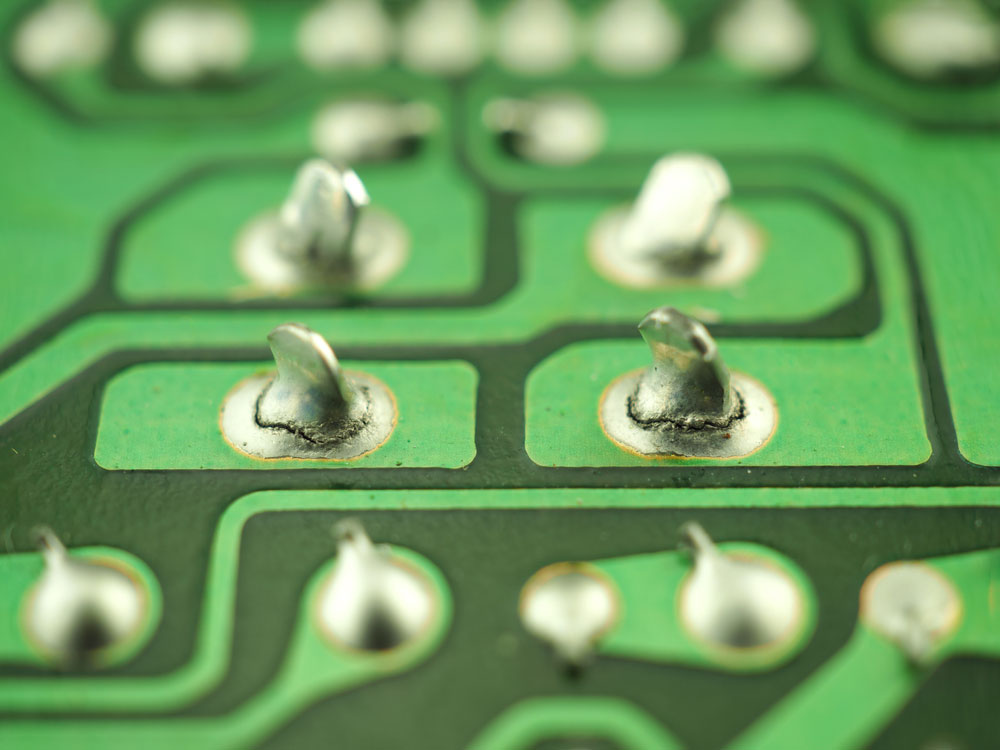

Cracked solder joints

On the other hand, if the wire is too thin, you'll burn through the solder quickly.

Solid Wire or Flux-Core Solder

Solder wire usually has an active flux core that activates automatically and flows over the soldering area when the solder melts. This type makes the soldering process easier because you don't have to clean the surface using solder flux before welding.

A flux-core solder wire

But with a solid wire solder, you must use solder flux to remove the oxide layer to give adequate wetting ability.

Wrap Up

As you can see, the solder metal composition affects its melting temperature, which determines its welding applications. Other metal blends affect the material's properties, but Tin and Lead are the most critical materials. Generally, Lead-free solder technology lowers the alloy's melting point, while Lead-based solder increases it. And remember to check the solder's diameter and core (flux or flux-free solder) if using a wire.

Special Offer: Get $100 off your order!

Email [email protected] to get started!