Printed circuit boards come in different shapes and sizes. We have rectangular, round, octagonal, and many more. Even so, the most popular PCB shapes are either rectangular or square. Round PCBs aren't as common as the other PCBs, but demand for them has been rising with the continuous technological advancements.

In this post, we will introduce round PCB and teach you how to make one in Eagle CAD. In addition, you will get tips on how to choose a round PCB manufacturer.

Contents

- What is Round PCB?

- Circular Circuit Board Design Rules

- Types of Round PCB

- Single-sided round PCB

- Double-sided round PCB

- Multilayer round PCB

- Applications of Round PCB Board

- Medical Industry

- Consumer electronics

- Wearable devices

- Telecommunication industry

- LEDs

- Round LED PCB

- Benefits

- How to Make a Round Circuit Board in Eagle CAD?

- Step 1

- Step 2

- Step 3

- Step 4

- How to Choose the Best Round PCB Manufacturer

- Quality

- Experience

- Customer service

- Turnaround time

- Summary

What is Round PCB?

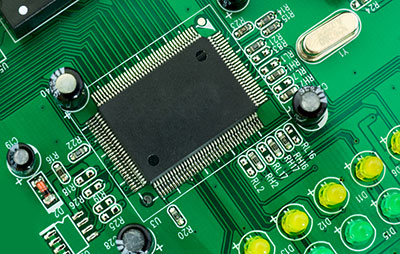

Round PCB

As the name implies, round PCBs are circular-shaped PCBs. These PCBs have grown in popularity since they work efficiently in commercial and domestic devices.

The fabrication process of circular PCBs is highly complex; therefore, manufacturers take more time. As a result, these PCBs tend to cost more.

Likewise to all other PCBs, circular PCBs have electronic components, widths, and traces.

Electronic components

Most people like circular custom PCB because they have extra board space. Thus they are better to work with compared to rectangular PCBs. The only downside is that circular PCBs are challenging to use.

You can find round PCBs in rigid-flex circuits and miniature wearable devices.

Circular Circuit Board Design Rules

To make a circular PCB, you must follow certain rules and procedures.

Firstly, you must draw the board shape on your CAD tool since here is where your board's foundation lies. For instance, if you use the PCB on a high-speed device, you will need to draw a multilayer board.

Secondly, you must define the ground planes and power in different layers. Moreover, you will also require a polygon to outline the power plane and ground shapes.

Some software has layout tools that can help you customize your ground planes and power to suit your circular board. For instance, the Altium designer software has a polygon editor, enabling the inclusion of complex board shapes.

Thirdly, you will need panelization schemes to design the PCB properly.

Circular Circuit Board Design

Types of Round PCB

Single-sided round PCB

Single-sided round PCBs have a single copper conductive layer and are arguably the most common round PCB type.

Manufacturers call them single-sided because they have electrical components on one side and a conductor pattern on the opposite side.

Single-sided circular PCBs are mainly made of one substrate and work well on low-density designs.

In addition, single-sided round designs are easy to fabricate PCB. Therefore, they are cheaper to produce compared to other circular PCBs.

Manufacturers use surface mount technology or through-hole technology to make single-sided circular PCBs.

Double-sided round PCB

Double-sided round PCBs have conductive layers on both sides. Because of this feature, designers prefer these PCBs to single-sided circular circuit boards.

Double-sided circular PCBs are in many consumer electronics, wearable devices, and lighting systems.

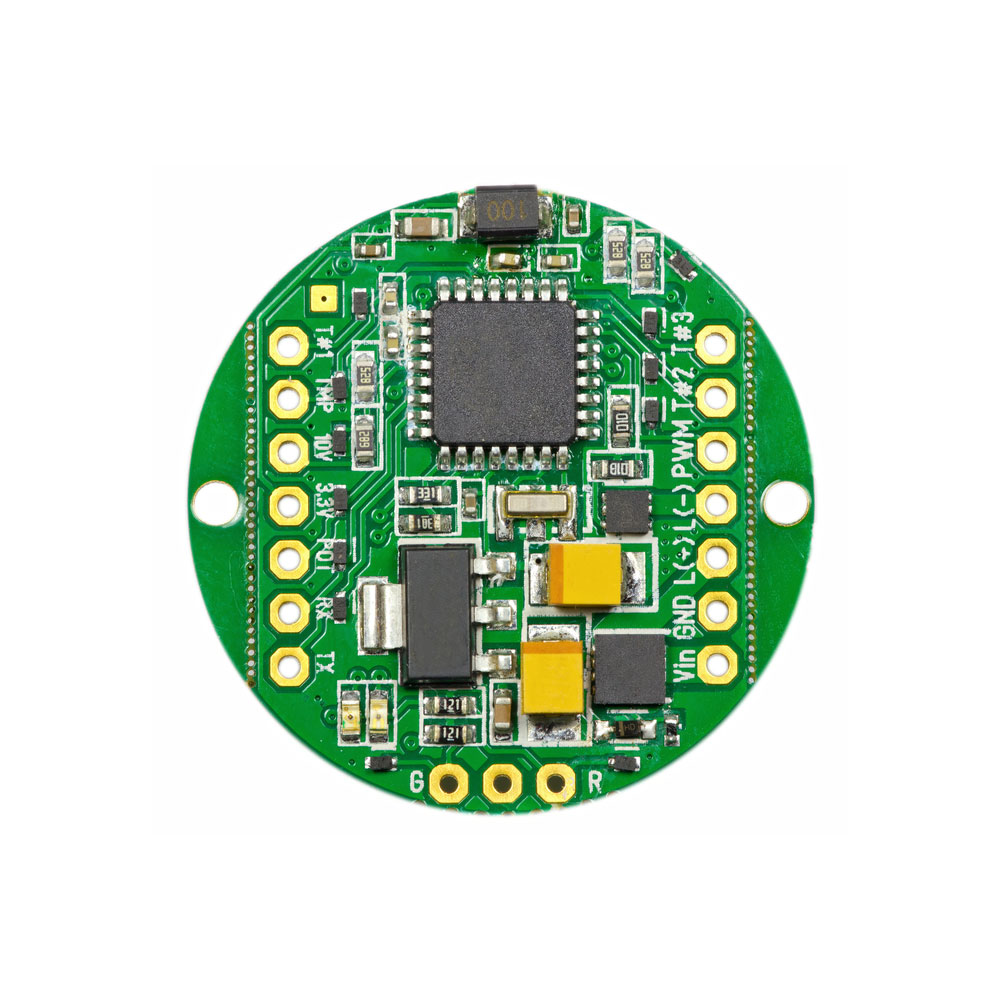

Multilayer round PCB

Multilayer circular PCBs have more than two conductive layers, making them ideal for high-speed applications.

Compared to the other PCBs, multilayer circular circuit boards offer more benefits. For instance,

- They provide high assembly density

- Provide additional board space

- Can handle high-capacity applications

Even though multilayer PCBs have numerous advantages, they are challenging to fabricate and costlier.

Special Offer: Get $100 off your order!

Email [email protected] to get started!

Applications of Round PCB Board

Medical Industry

Since circular PCBs are lighter and long-lasting, manufacturers use them to make hearing aids and monitoring devices.

A hearing aid

Consumer electronics

Round PCBs have found their way to items we use daily, such as smartwatches.

Smartwatches

Wearable devices

Wearable devices like virtual reality headsets and fitness trackers are made using round PCBs.

Children wearing virtual reality headsets

Telecommunication industry

Round PCBs provide adequate routing space, making them ideal for telecommunication devices.

LEDs

Light-emitting diodes also use circular PCBs since they provide substantial electrical and thermal properties.

LEDs

Round LED PCB

Round LED PCBs are circuit boards made from aluminum with soldered LEDs. As a result of round PCB's ability to enhance heat dissipation, manufacturers mostly use them for applications that require plenty of LEDs.

Round LED PCBs are primarily used in lighting fixtures, for example, desk lamps and LED circuits.

Benefits

- Saves energy

- Small size

- Vibration and thermal shock resistant

- Enhances heat dissipation

- Friendly to the environment

How to Make a Round Circuit Board in Eagle CAD?

Step 1

Begin by clicking on the CAD software icon on your desktop or click on the "Start" menu and navigate to the "all programs" section.

Step 2

To open the layout file, click on "File," then tap "open," scroll down, and double click on "OK."

If a layout file hasn't been created, you can create a new one by heading to "file" and selecting "New."

Afterward, enter your preferred layout file name in the "file name" section and select "OK."

Step 3

Now that you have created and named your file, start by adjusting your board's outline depending on the PCB size.

The default board shape is usually a square. Hence to modify the size, you will have to left-click on either side of the outline and move it right or left.

While modifying the size, ensure you maintain a square shape so that when you try to change it into a circle, it doesn't have an oval shape.

In addition, all square sides need to be symmetrical to the circle's diameter.

Step 4

Firstly, In the command bar at the beginning of the layout, type "MITER 2" and click enter; your mouse icon will change to a + sign.

Secondly, left-click on one of the corners of the square; doing so converts the rectangular layout to a circular one.

However, if your rounded corner seems relatively small, you can repeat the procedure by typing "MITER 3" or a high number.

Similarly, if the corner seems larger, you can reduce the number. Follow the same process for the remaining corners.

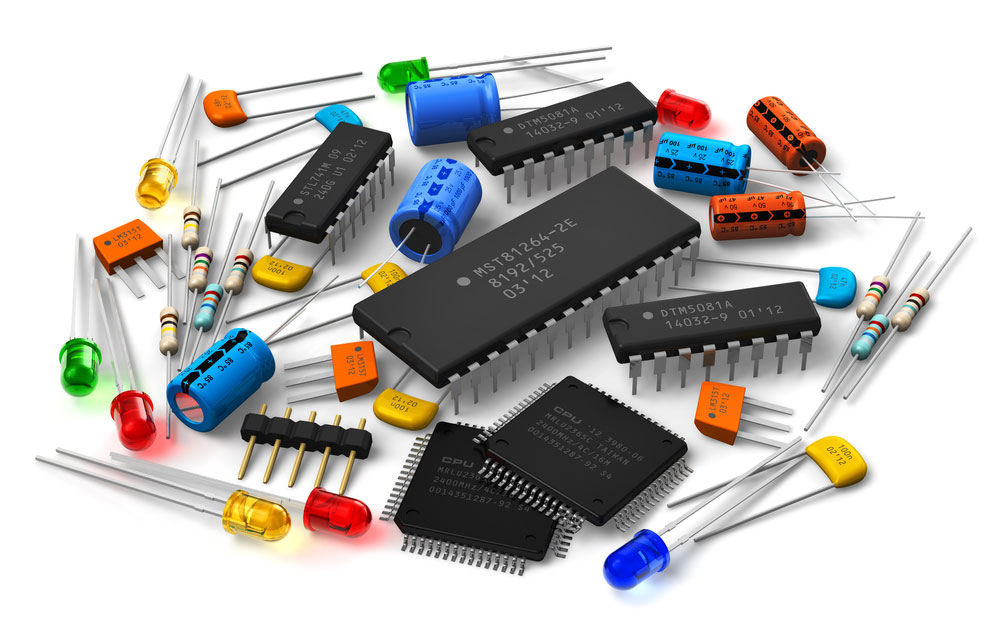

How to Choose the Best Round PCB Manufacturer

Quality

You must pick a manufacturer that uses high-quality materials and carries out several tests before delivering the product.

Some tests include micro section testing, E-tests, thermal stress tests, and others.

The tests are critical as they help identify any circuit board defects, ensuring the product's quality.

PCB Manufacturing

Experience

The more experience a manufacturer has, the more refined his processes are, which means high-quality products. Therefore, ensure you ask how long a manufacturer has been in the field before committing.

Customer service

An ideal manufacturer offers customized service, tech support, and fast quotation responses. You can find this information by reading manufacturer's reviews and talking to previous clients.

Turnaround time

Refers to how long a manufacturer takes to deliver your product. Select a manufacturer who will deliver on the agreed time.

Summary

Even though square and rectangular-shaped PCBs are popular, some applications can only use round PCBs. Especially devices with a curved design.

Yes, circular-shaped PCBs are time-consuming to fabricate and costlier, but they make up for it by being long-lasting.

To make a proper functioning round PCB, ensure you follow all the design rules and work with a competent manufacturer.

Special Offer: Get $100 off your order!

Email [email protected] to get started!