The nicked wire is a typical occurrence when dealing with wiring projects, and the issue is something you are likely to run into once or twice as a DIY electrician.

Luckily, the problem is easy to fix, but with the correct guidance. Remember, you are dealing with electricity and must repair the issue cautiously.

We will look at the causes of wire nicking and how to fix the problem below. Take a look!

Contents

What Is a Nicked Wire?

A nicked wire is a metal wire with the outer jacket torn due to stress on tight bends or excessive wear and tear.

These damaged wires need immediate repairs unless you are sure the electrical wire insulation is still intact.

A nicked wire for a phone charger

Special Offer: Get $100 off your order!

Email [email protected] to get started!

Causes of Nicked Electrical Wires

Nicked wires can occur due to the following issues.

Natural Causes

Most electrical wires have a plastic insulator and cable jacket. Although plastic is durable, it wears out over time.

Once it wears out, the exposed hot wires can short-circuit when they come into contact with neutral wires.

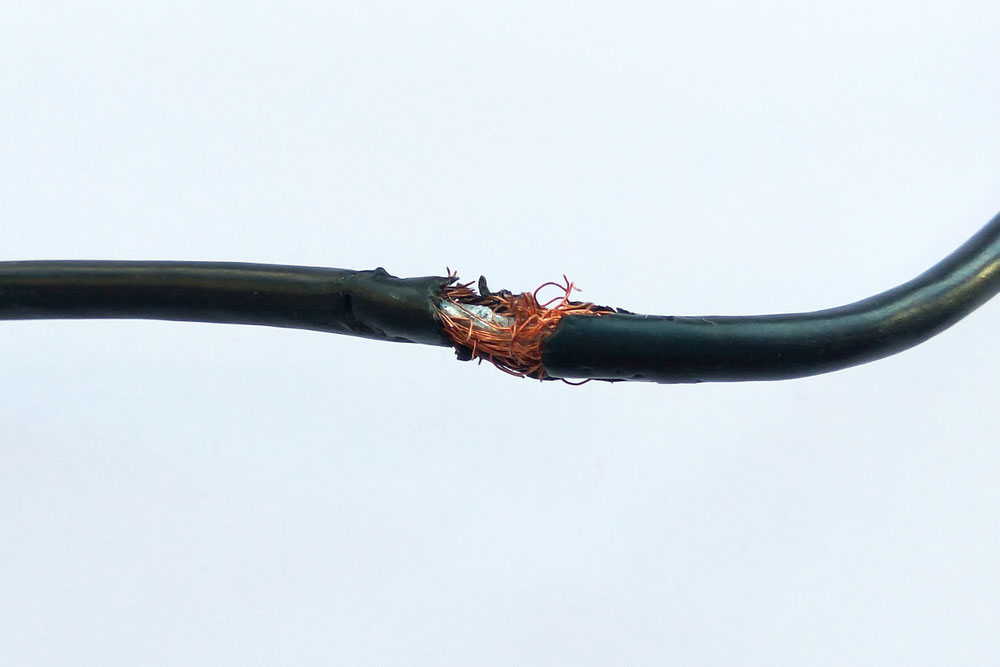

A nicked wire

Vibrations can also cause nicking after days or years.

These movements only need to create tiny spaces through the insulator, which can cause arcing as the current tries to flow out to ground wires or loads.

The arcing will continue accumulating heat that burns the insulation to expose more copper.

Impact Damage

An impact can damage the jacket and individual conductor insulation to reach the metal wire.

This impact could be due to dropping heavy or sharp objects on the wires, flexing extension cables repeatedly when moving, etc.

Improper Installation

An electrician can nick a wire in conduit when pulling it through during electric wiring projects.

It could be due to excessive stretching or flexing and can cause fire hazards in the walls and internal structures.

Rotting

Insulators wear out naturally over time, but they can rot and disintegrate faster when exposed to moisture and sunlight.

Besides damaging the cable, the rot can cause short-circuiting that can burn electrical appliances down the line.

A cable on fire due to short-circuiting

Accidental Nicking

If the wire is inside the walls, you can nick it accidentally when working on the surface.

It could be due to making cuts on the wood or punching nails in the wall.

So you need to know the wiring blueprint in the wall before making any modifications.

How To Fix a Nicked Wire

You need the following items.

- Wire stripper

- Screwdriver

- Electrical tape or wire kit

- Splice/junction box

- Safety glasses

Steps

Identify the Nicked Location

Begin by identifying the location of the electrical insulation wiring damage.

If you spot a nicked cable sheath, but the copper conductor strands are not showing, wrap electrical tape around the cable.

But if you can see the strands, replace or fix the wire.

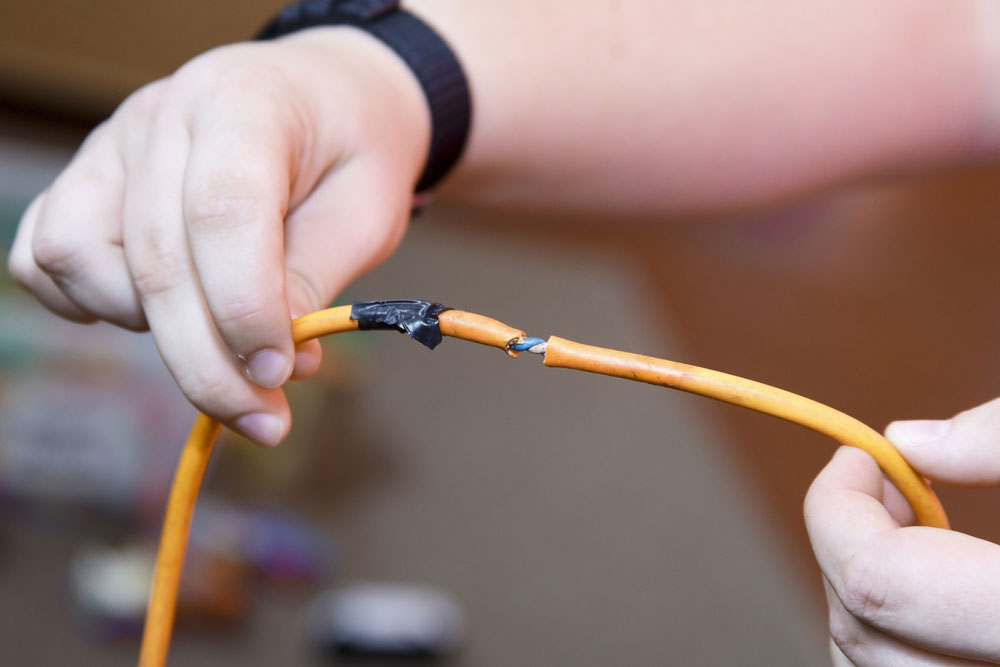

An electrician holding a section of a nicked wire

Fix the Damaged Wire

Disconnect the power supply before doing any fixing.

Cut the section with the exposed wire strands, then strip about 0.5 - 1 inch of the insulation to expose the wire ends.

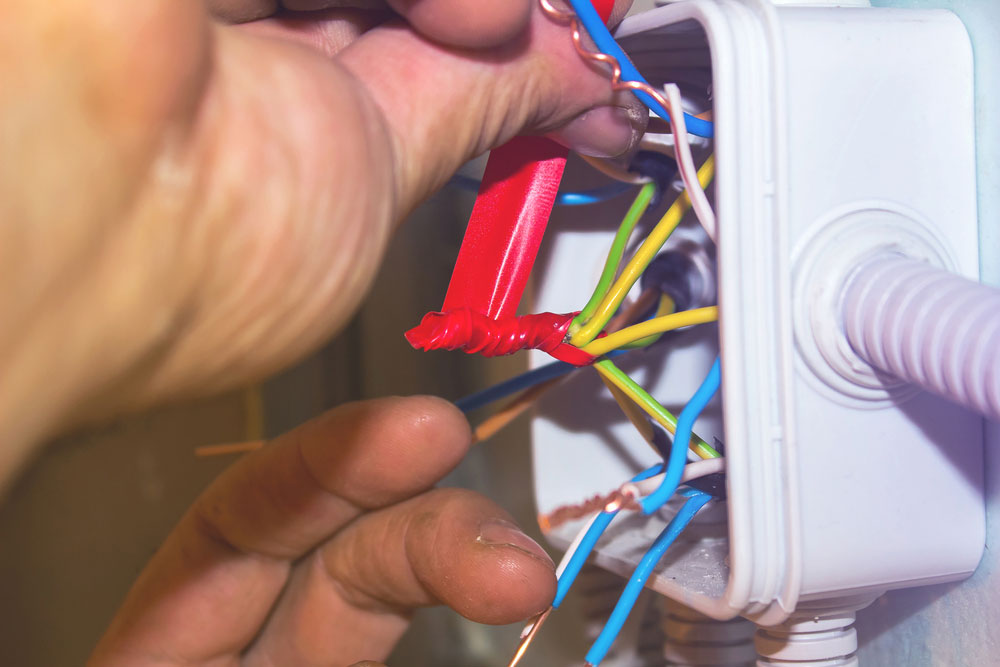

Next, pull the wires through the junction box clamps, and pull them far enough to allow the clamp to close over the wire casing.

Twist the wires together, then secure these twisted ends inside the screw slot using a screwdriver.

A junction box with welded wire ends

Junction boxes have different designs. So you might not have to twist the wires together.

Some require you to screw the wire ends separately with a metal plate joining them.

And if you know how to twist wires, you might not need a junction box. Electrical tape will be enough.

But the joint might not be as neat as when you use a junction box.

Reattach the Cord

After fixing the cable, screw the junction box into place to keep the cord from experiencing stress.

Also, it should be away from moisture and sunlight.

Final Inspection and Testing

Do the final checks to ensure the screws are tight.

Turn on the power supply and see if everything works.

Cover the splice box and screw the cover in place. That's it!

An electrician insulating wire ends using electrical tape in a junction box.

Safety Precautions

- Always turn off the power before doing the cable repair

- Avoid pulling the wire towards you to strip it; push the stripper instead

- Unplug all electrical devices before doing the cable repairs

How to Avoid Potential Wire Hazards from Damaged Electrical Wires

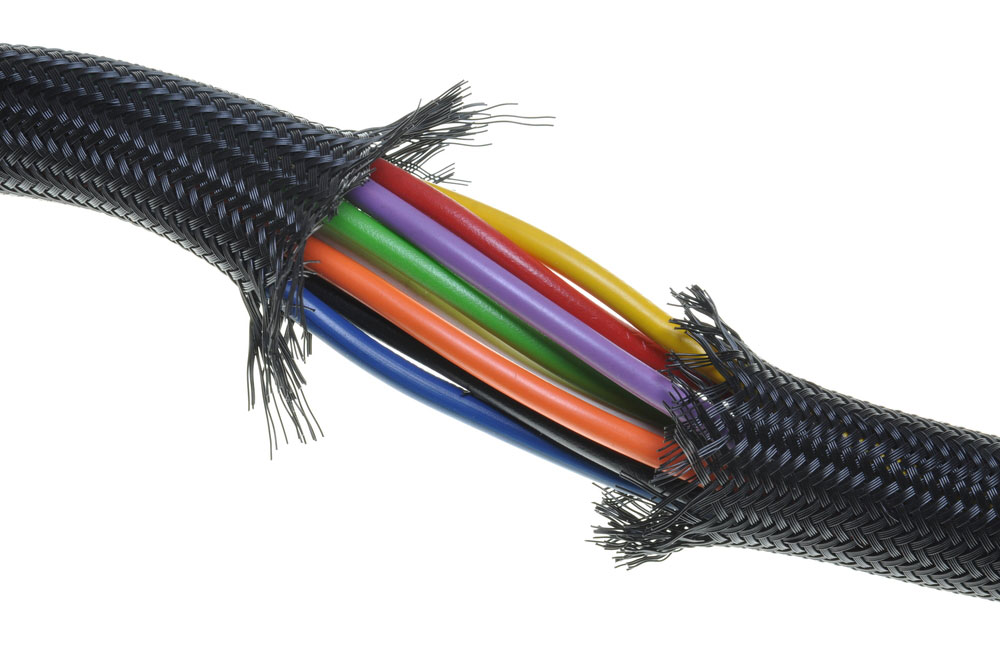

Multi-wire cables have individual wire insulators for the wires and an outer sheath to protect and secure all the pieces together.

A damaged outer sheath poses no risk, but you should wrap it with electrical tape to prevent damage to the individual wire insulators.

A cable with a damaged sheath, but the individual wire insulators are intact.

However, if there is damage to these inner insulations, you must splice the cables.

If you have enough slack in the wire, you can install an inline splice using a single accessible junction.

With considerable damage, you might have to follow the repair steps above or install a new wire from the junction box to replace the original cable length remaining to the destination or adjacent junction box.

And you might need another splice box, depending on access.

If replacing the remaining cable length is impossible, install a cable loop between the two junction boxes.

At OurPCB, we often see projects where multiple repairs and junction boxes create ongoing maintenance challenges. For applications requiring complex wire routing or frequent handling, we recommend considering professionally assembled solutions from a custom wiring harness manufacturer like our team. Pre-assembled harnesses with proper strain relief and protective jacketing can eliminate many common nicking issues from the start.

Contact a technician to handle this electrical work if you are not handy.

Wrap Up

In conclusion, a nicked wire might be a safety hazard, but it should not worry you because it needs an easy fix.

And the guide above should help you get the wire back to its normal state in a few minutes.

Contact us if you have any questions, and we'll respond ASAP.

Special Offer: Get $100 off your order!

Email [email protected] to get started!