Are you looking for the best way to get an accurate low-resistance measurement? If your answer is yes, then a Kelvin connection is what you need.

The Kelvin connection stands out because it simplifies your PCB design by merging all the connection terminals of a sensing circuit into one. Plus, it's necessary for accurate, current sensing.

However, you may meet many complex terms when reading up on Kevin's connections. But don't worry, we'll try to make the terms simple enough for you.

Here, in this article, you'll find out how Kelvin connections work, the different Kelvin connections, and their several applications.

Let's dive in!

Contents

What is Kelvin Connection?

The simplest way to define Kevin connections is to create contact between electrical potential and a current-carrying component. This contact reduces or removes the effects of contact resistance.

Why is this important? If you're dealing with low millivolt measurements like those found in a shunt resistor, the contact resistance is an unknown yet significant variable.

The best way to handle this is by using a four-terminal device. Two terminals conduct high currents in this device, while the other two run the voltage measurements.

Plus, if you're using devices with two terminals, you'll find clip leads connected close to the resistance element—allowing it to measure the potential. You can also refer to these clip leads as Kelvin clips.

Though the clip leads work for temporary measurements, you can easily convert a two-lead device to a four-lead device. Plus, you have to use soldered leads to replace the clips.

Additionally, the primary benefit of four-terminal sensing is how the separation of voltage and current helps remove impedance effects of the contact and wiring resistances.

Also, you can call four-terminal sensing the Kelvin sensing. Plus, you can reach every double-wire connection a Kelvin connection. Additionally, the set of contacts with designs that create a relationship between a force and detect pair and a single lead or terminal are Kelvin contacts.

How does a Kelvin Connection Work?

A Kelvin connection supplies current through a couple of current leads (force connections). Hence, these current leads create a voltage reduction through the impedance. And you can measure this using Ohm's law.

Now, a set of voltage leads (sense connections) work close to the impedance you're targeting. Also, the voltage leads won't involve the voltage reduction from the force connections. Thus, since the amount of current flowing to the gauging equipment is negligible, you can ignore the voltage decline in the current sensing resistor.

But that's not all.

You can also arrange the force cables of your Kelvin connection as an outside pair. Consequently, the sense cords will work as an internal pair. Interestingly, switching the positions of the sense and force connections could significantly affect your accuracy readings. Why? Because exchanging places would add more lead resistance to the current measurement.

For the Kelvin connection to work correctly, the force cables must carry large currents while measuring small resistances. On the other hand, the sense cables can have a small gauge.

Special Offer: Get $100 off your order!

Email [email protected] to get started!

Kelvin Connections and Test Measurements

There are four different types of Kelvin connections and test measurements, including two-wire connections, four-wire connections, degrees of Kelvin, and Semi Kelvin versus True Kelvin. Let's take a closer look at these connections.

Two-Wire Connections

You can measure the resistance of a component with a two-wire connection by forcing a test current through the element using a set of test leads. Next, the meter begins measuring the voltage across its terminals to show the resistance value of the component. This process is what we call the two-wire measurement.

Furthermore, the value of resistance for the two-wire method is dependent on the test lead's resistance. Also, the effect of the load resistance is a small volt drop that's not important.

However, there are problems with this method. When you're measuring small resistance values of 1Ω or less, the test lead's resistance will create a more significant volt drop, adding to the volt drop across the component. The result? The voltage measurement results won't show the actual value of the voltage across the element.

4-Wire Connections

With all the downsides of the two-wire connection, the four-wire Kelvin connection is more effective for low-resistance measurements. Additionally, you can make measurements using a different voltmeter and current source.

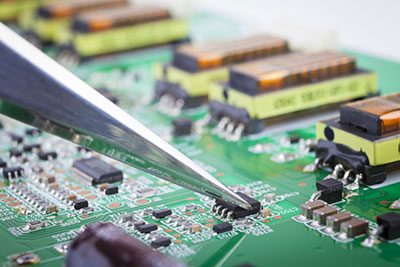

The configuration resistor of a Four-wire Kelvin connection forces the test current through the test resistance by using one set of power leads (test leads). Also, you can measure the voltage across the component you're testing by using your second set of sense leads.

Though the sensing pair receives a little bit of current, it's not enough for you to worry about because of the sense terminal's high impedance.

When the meter fully measures the volt drop, the values should be the same as the voltage across the test resistance—leading to a more accurate measurement.

Degrees of Kelvin

There are tons of test equipment that use semi Kelvin connections to devices under test. But they aren't true Kelvin connections. For instance, if you find spring probes in your circuit, it's a semi Kelvin connection. However, spring probes don't offer authentic Kelvin connections as each of the four wires ends at the probe receptacle.

Thus, your power and sense leads must directly link to have a genuine Kelvin connection. And it should be able to test the component lead.

Semi Kelvin Versus True Kelvin

There are ways to connect and disconnect a component you're testing while using a fixture and keeping a genuine four-wire Kelvin connection to the element. One of these ways includes using Kelvin blades. Kelvin blades are simply two spring blades placed in insulation.

Additionally, authentic Kelvin connections are ideal when you're measuring resistances greater than 1Ω. However, it would help to put the mechanical aspect of your relationship when building a test fixture.

For this reason, spring probes are solid alternatives to Kevin. Probes are easier to construct and maintain. Plus, they feature a life span longer than Kelvin blades. However, as we previously mentioned, spring probes can only offer semi Kelvin connections, and you should avoid using them to measure a resistance less than 1Ω.

Kelvin Connection Applications

Here are some applications that work with a Kelvin connection.

- Circuit boards

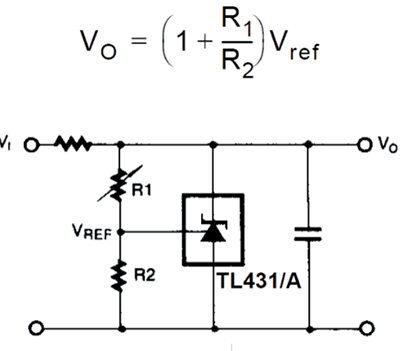

- Power supply voltage sense

- Battery power management

How A 4-wire Kelvin Test Identifies Concealed PCB Warriors

A 4-wire Kelvin test always locates the milliohm resistance variations from hole to hole. It also leads to a more complex separation of a pass from failure. Typically, you'd need to measure a few boards or panels to know the running average on the resistance measurements.

If the resistance values fall outside a set threshold, it will fail. Unfortunately, once a barrel has been branded as a failure, the only way to know if it's defective is through a destructive test on the hole by cross-section.

But that's not all.

The Kelvin sensing, 4-wire Kelvin connection, or 4-point probes method is an electrical impedance measuring method that uses separate electrodes for voltage sensing and current carrying. It uses these individual pairs to make measurements more accurate than the two-terminal sensing technique.

Additionally, separating the voltage and current in a Kelvin connection removes contact and lead resistance from the measurement. Plus, it makes it great for delivering precise measurements with acceptable accuracy when handling low resistance values.

Four-terminal detection works in some impedance analyzers and ohmmeters. It also helps in wiring for strain gauges and resistance thermometers. Plus, you can also use them to measure the sheet resistance of thin films.

Final Thoughts

In closing, we've seen that having a great understanding of the Kelvin connection is ideal if you want to get the perfect low-resistance readings.

Hence, we spoke extensively about the different testing equipment required to run the Kelvin connection readings.

However, we'd like to help if you're still unclear about a few things concerning this subject. So, feel free to contact us.

Special Offer: Get $100 off your order!

Email [email protected] to get started!